Method for sectional processing for life garbage

A domestic garbage and garbage technology, applied in the direction of biofuel, solid waste removal, solid fuel, etc., can solve the problems of poor collection and transportation economy, low scale benefit, unstable calorific value of garbage, etc., to reduce operating costs and improve Effect of incineration ability, incineration ability improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

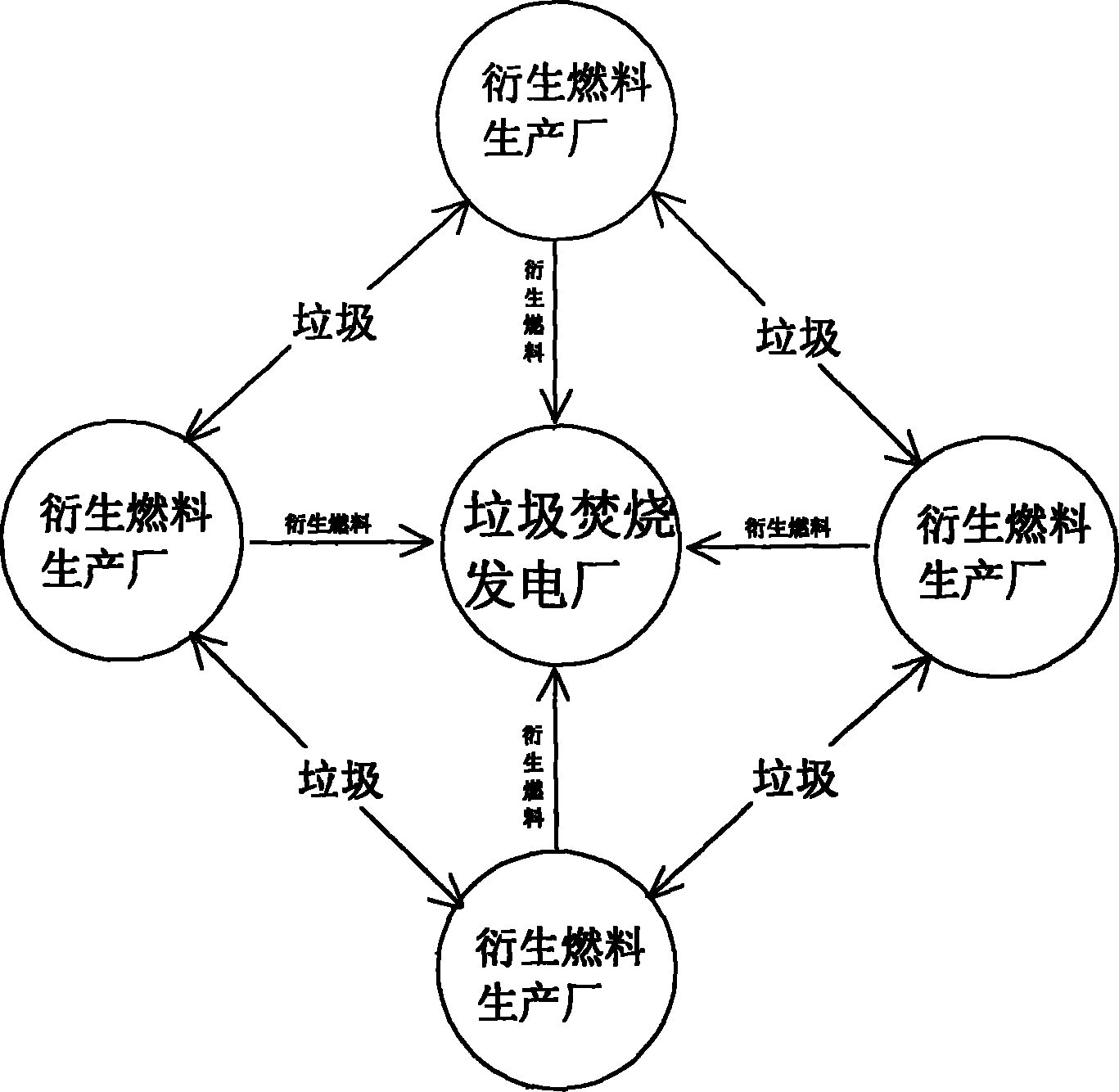

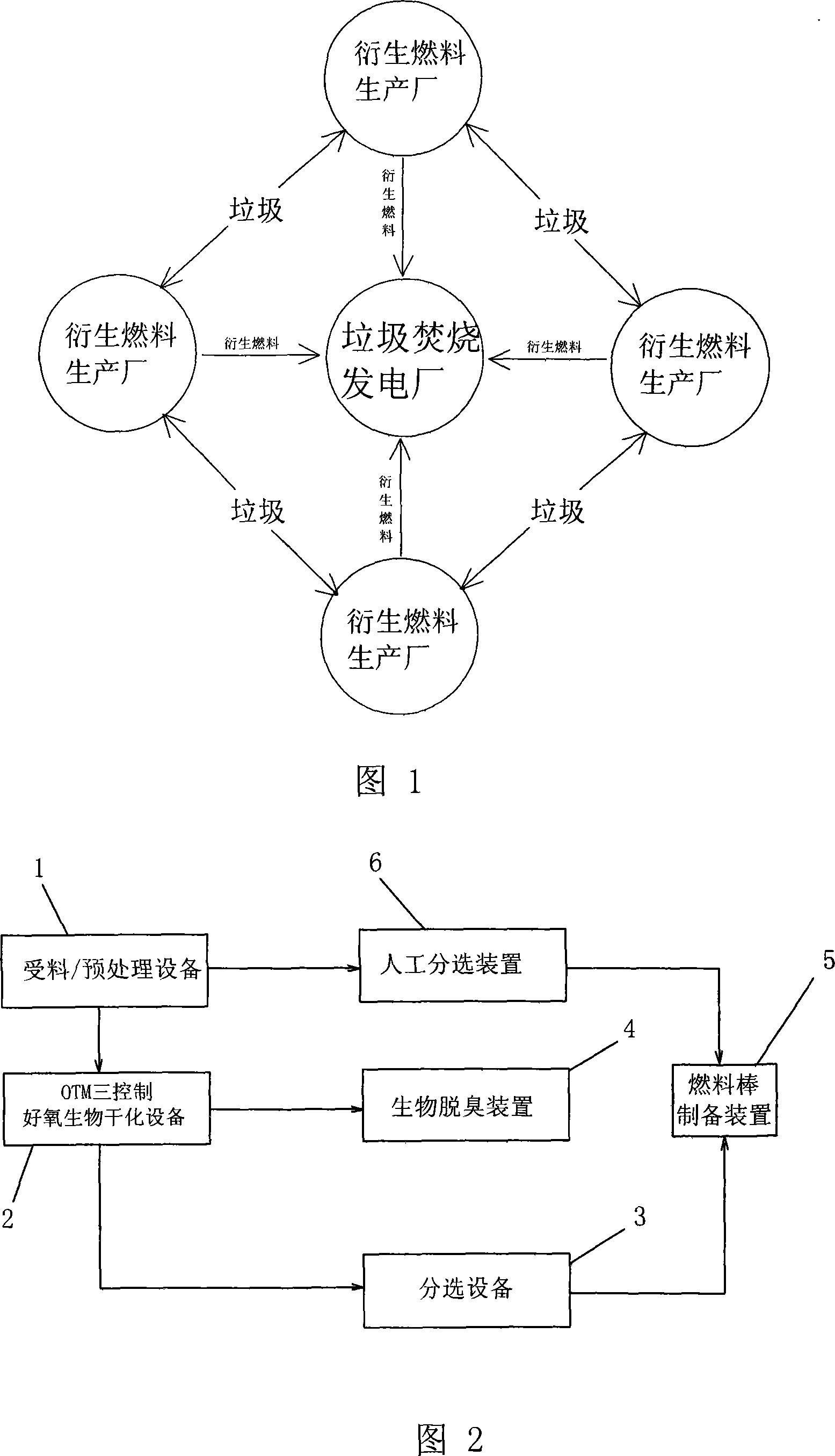

[0052]Fig. 1 shows the schematic flow chart of the present invention's method for disposing domestic waste in sections. In the county (city) area served by the incineration plant, according to traffic and administrative division conditions, several biological stems are set around the incineration plant (garbage incineration power plant) Derived fuel production facility (derivative fuel production plant); within the service area of the facility, domestic waste is first collected and transported to a biological drying treatment facility for biological drying and partial sorting, and converted into low-moisture combustible waste (derivative fuel production plant). fuels), inert inorganics, recyclable metals, glass, etc. The combustible waste is then transferred to the incineration plant for centralized incineration, the inert inorganic matter is transferred to the landfill for disposal, and recyclable metal, glass and other objects are included in the waste recycling system for ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com