Tail end curing system applied to zero discharge of wastewater

A zero-emission and wastewater technology, applied in water/sewage treatment, chemical instruments and methods, water/sludge/sewage treatment, etc., can solve the problems of expensive equipment and large footprint of drying and evaporation towers, and achieve less equipment, The effect of small footprint and low operating cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

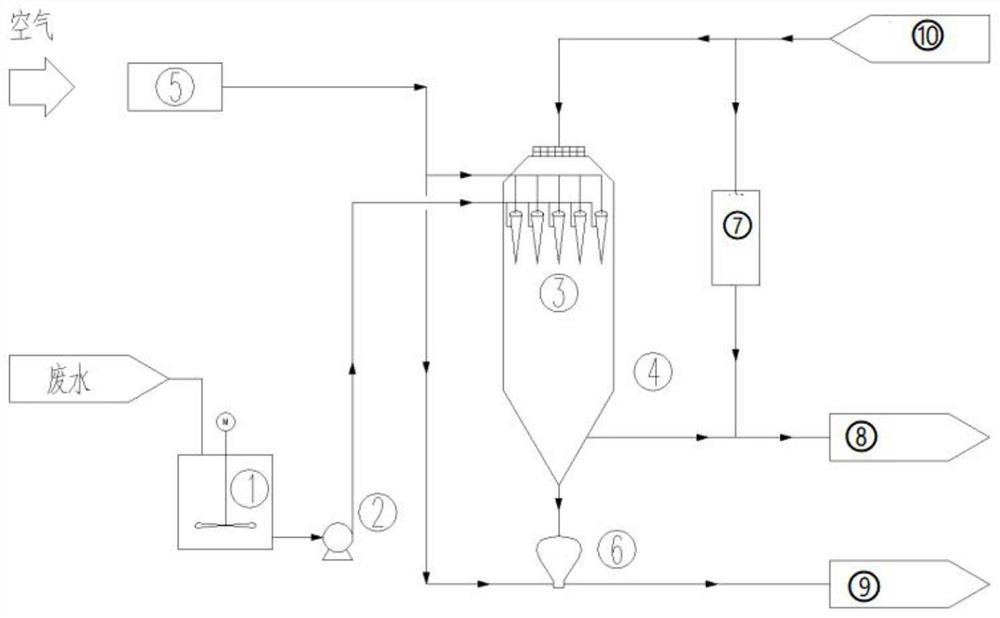

[0019] like figure 1 As shown, a terminal solidification system applied to zero discharge of wastewater includes a wastewater buffer tank 1, a wastewater delivery pump 2, a wastewater atomization device 3, a drying evaporation tower 4, an air compressor 5, and a pneumatic ash conveying device 6. The waste water buffer tank 1 is connected to the waste water atomization device 3 through the waste water delivery pump 2, and the waste water is transported from the waste water buffer tank to the waste water atomization device under pressure through the waste water delivery pump, and the compressed air is used to assist the atomization, and the atomized waste water is directly sprayed into the In the drying evaporation tower 4, the waste water after atomization is evaporated by utilizing the waste heat of the flue gas. The top of the drying evaporation tower is provided with a flue gas inlet, and the flue gas inlet is connected with the high-temperature flue 10 in front of the air pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com