Spinning machine having yarn slack elimination device

A spinning machine and relaxation technology, which is applied in the field of spinning machines, can solve the problems of time-consuming, difficult mechanism, and inability to fine-tune the rotation torque change in spinning, and achieve the effect of stabilizing the rotation resistance and forming stable quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

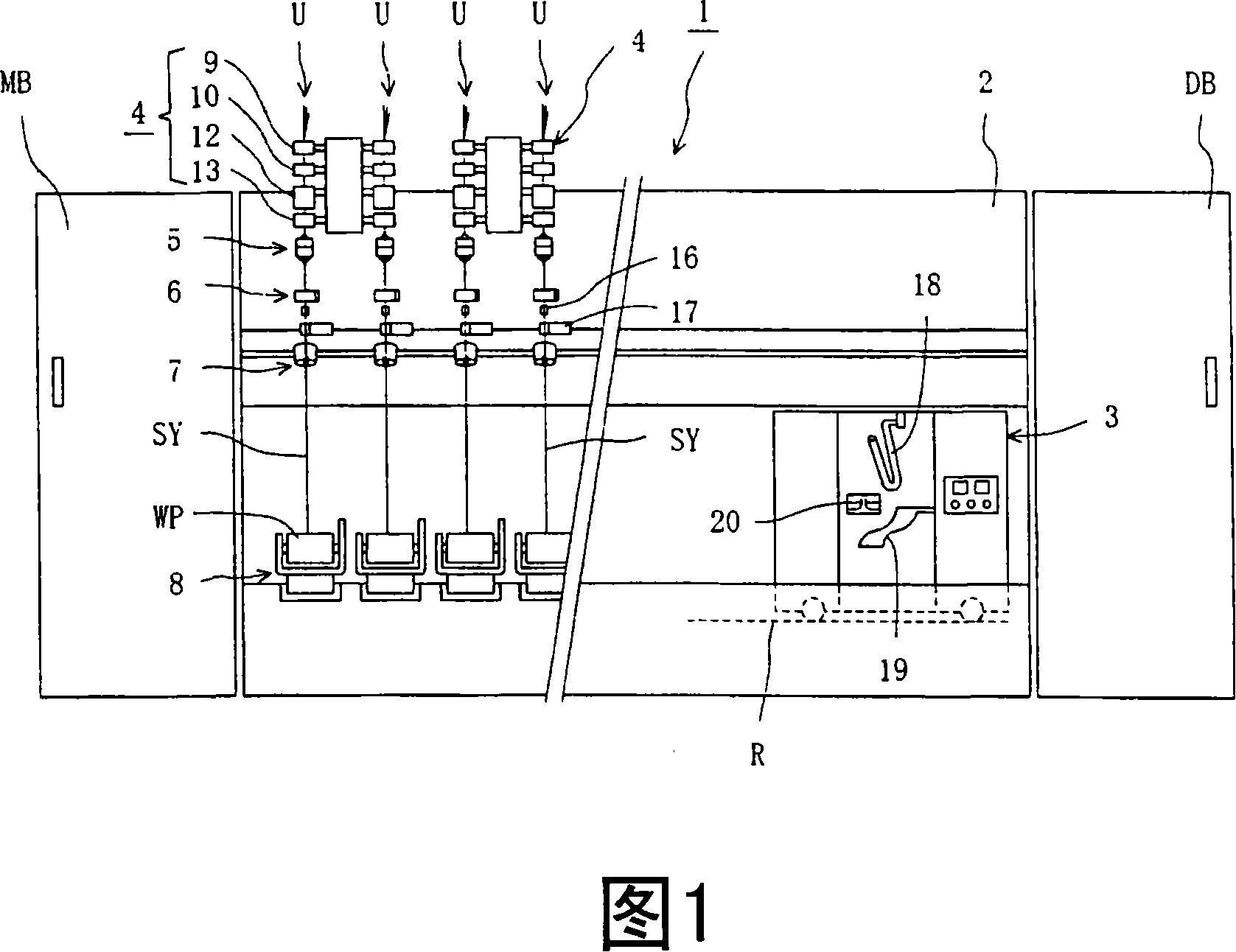

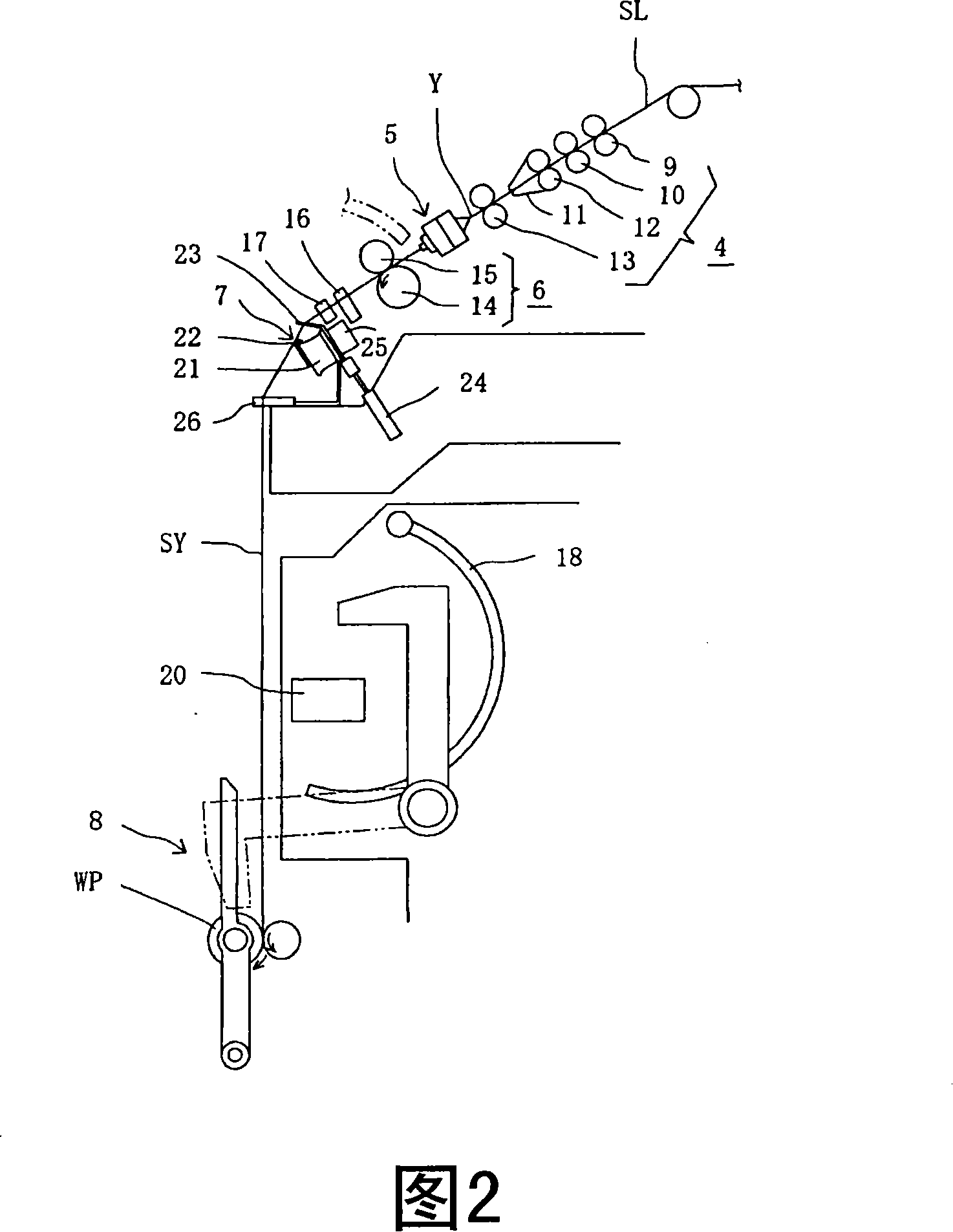

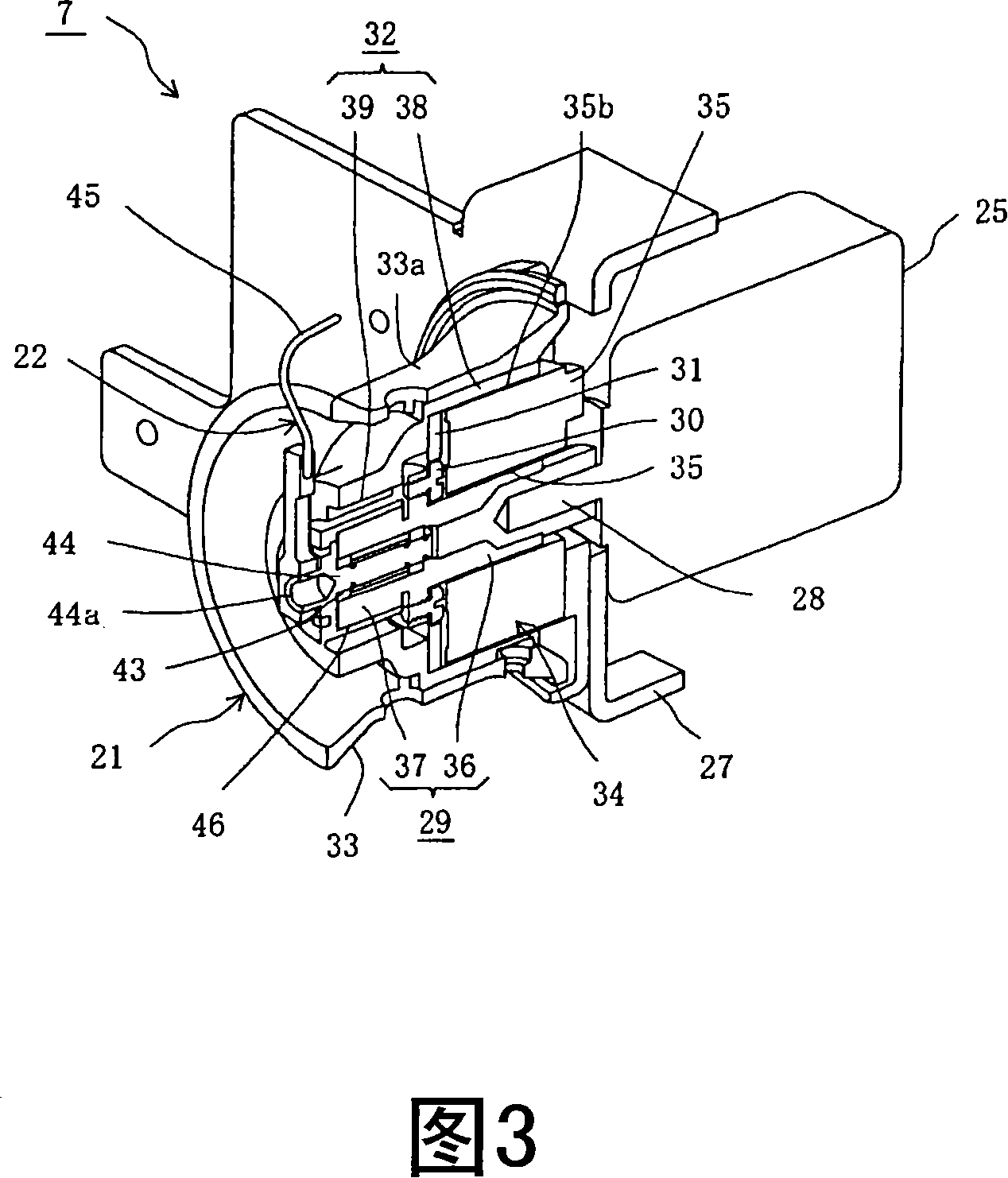

[0024] Hereinafter, the yarn slack removal device incorporating the electromagnetic tensioner of the present invention will be described in detail based on specific examples shown in the drawings. Fig. 1 is a schematic overall front view showing an example of a spinning machine to which the present invention is applied, and Fig. 2 is a schematic side view showing a partial section of the spinning machine in Fig. 1 .

[0025] First, the spinning machine 1 to which the present invention is applied will be described. As shown in FIG. 1, this spinning machine 1 is configured by arranging a plurality of spinning units U in a machine-length direction between a prime mover box MB and a dust box DB. The spinning machine 1 is provided with a rail R along the direction in which the above-mentioned spinning units U are arranged, and is configured so that the yarn joining cart 3 can reciprocate on the rail R in the left-right direction. The piecing trolley 3 travels toward the spinning u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com