Piston cylinder power machine by using laser to directly evaporate water

A piston-cylinder, laser-directed technology for power machines. field, can solve the problem of air pollution and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

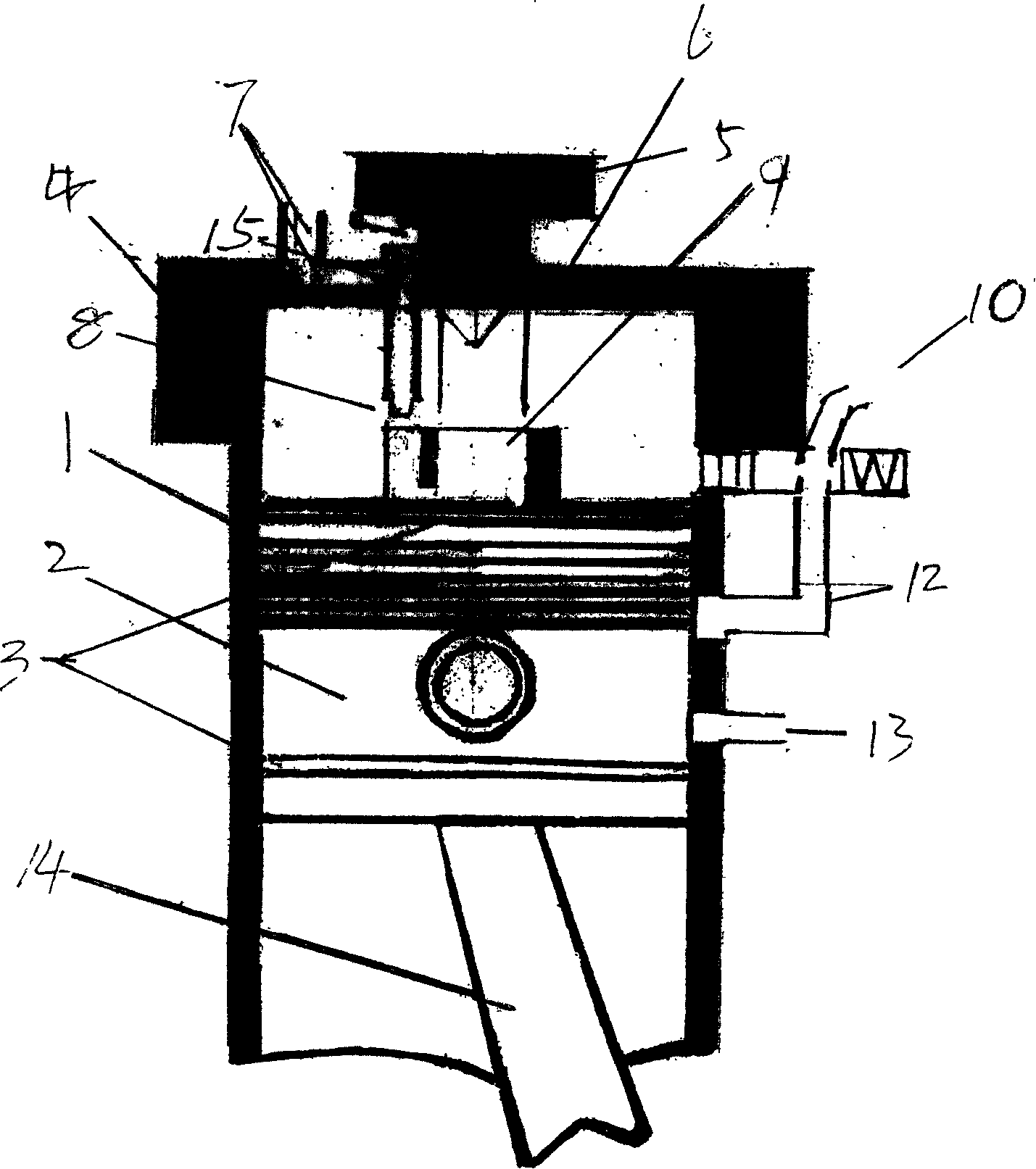

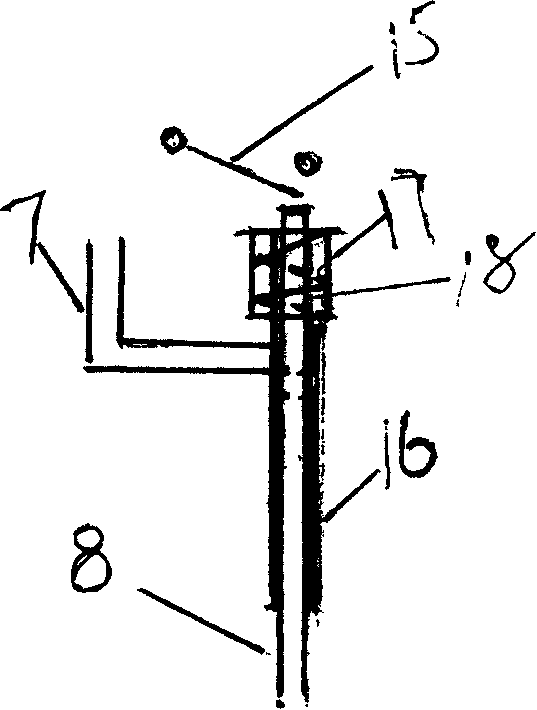

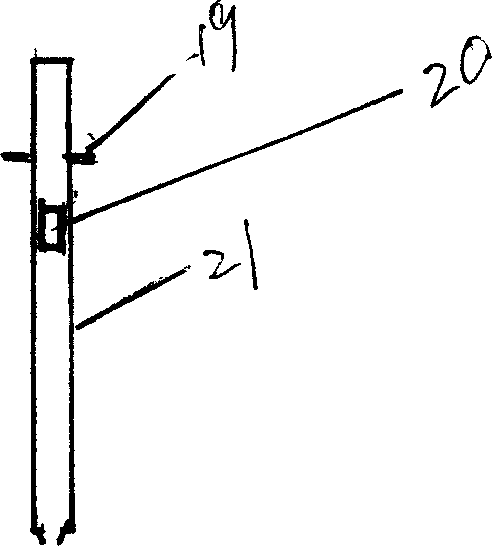

[0028] figure 1 As shown, there is a sealed piston ring 3 on the cylinder block 1, piston 2, and piston 2; a cylinder head 4 is set on the cylinder block; a laser 5 is set in the center of the cylinder head 4; a laser head 6 is set in the cylinder head 4; Water supply pipe 7, laser contact switch 15, piston center device receiving water cup 9, cylinder body 1 outer device have also been provided with water supply pipe 7, laser contact switch 15, cylinder body 1 outside device and vent system (see Fig. 5) upper vent total port 10, stage clip 11, piston plug valve 24, Piston plug valve cylinder body 25, upper vent through port 10, and lower vent port 13. When piston 2 is on the top of the cylinder, piston 2 is blocked at the upper vent port 12, blocking the upper vent port of the cylinder. When piston 2 Continue upward to withstand the pressure-free water nozzle 6 and simultaneously ascend until the water injection pipe 21 communicates with the through opening 20 of the water su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com