Axial flow compressor stator blade arrangement style

An axial flow compressor and stator vane technology, which is applied to the components of the pumping device for elastic fluid, mechanical equipment, non-variable-capacity pumps, etc. It is not easy to meet the requirements, the realization is difficult, etc., to achieve the effect that is easy to achieve

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

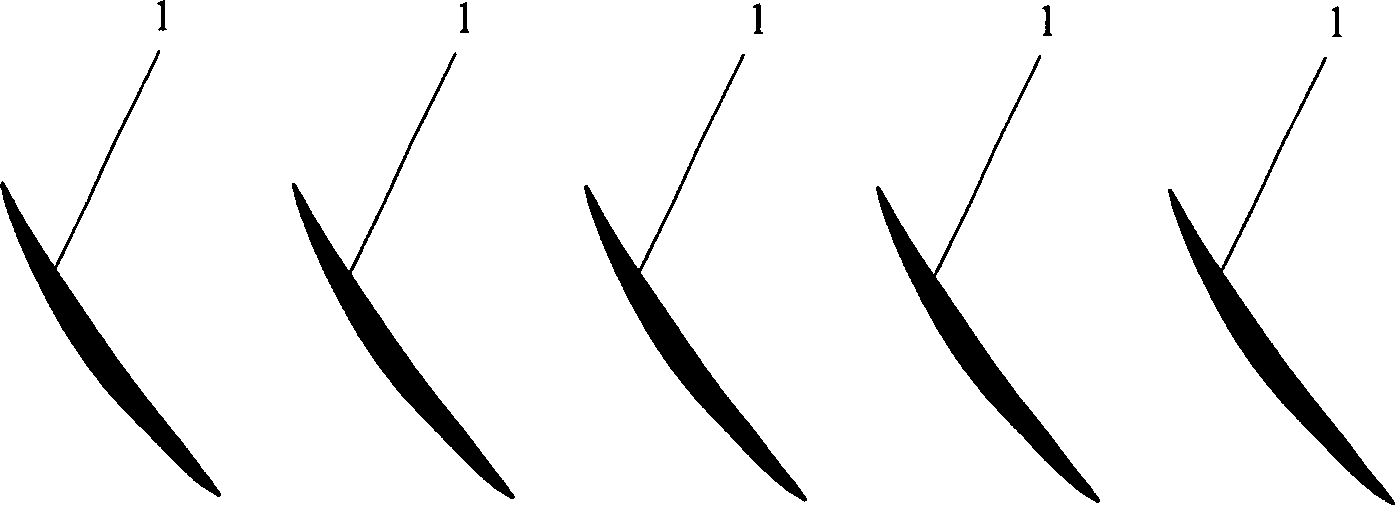

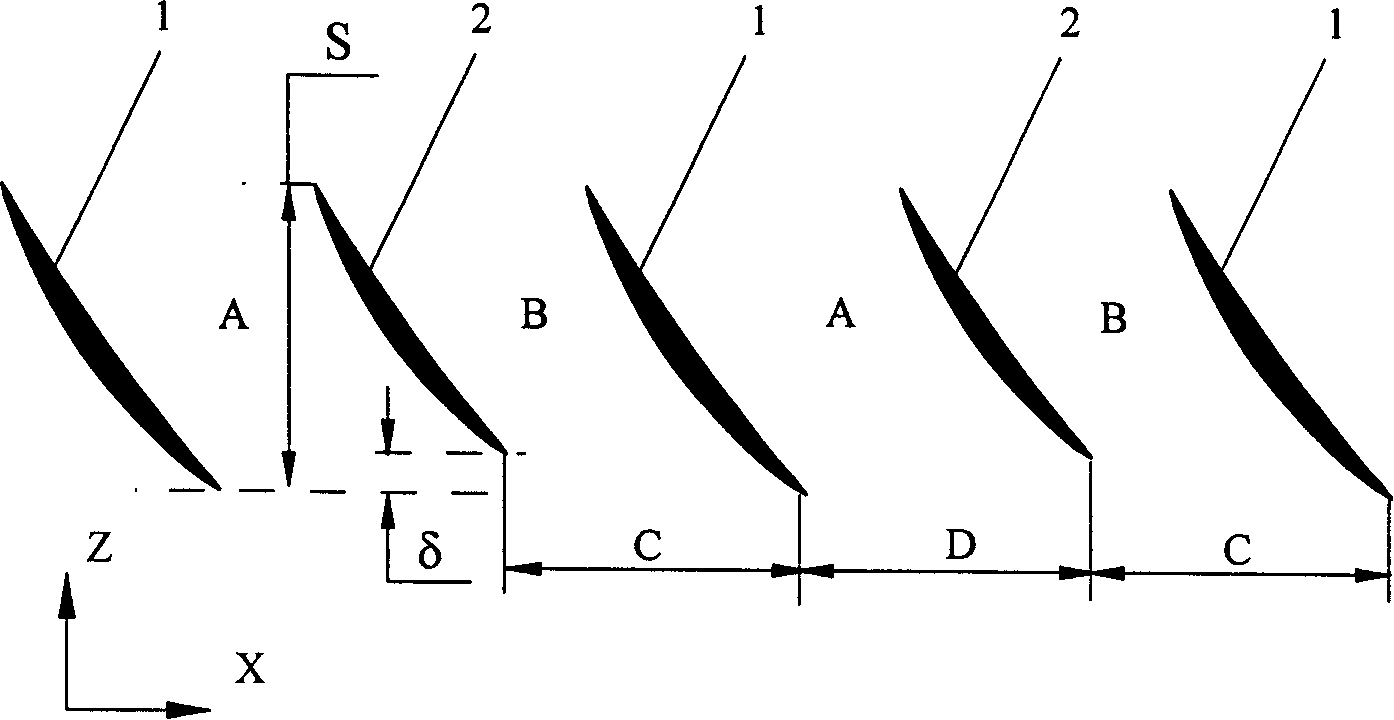

Embodiment 1

[0023] This embodiment is a single-stage axial flow compressor with 60 stator blades. In practice, the stator blades of the compressor are made into 30 wide blades 1 and 30 narrow blades 2, the number of blades in the blade row remains unchanged, the size of the wide blades 1 is the same as the conventionally designed size when they are evenly arranged, and the narrow blades The geometric size of 2 is 6% smaller than that of wide blade 1, and the wide blade 1 and narrow blade 2 are alternately arranged along the circumferential direction, that is, the X direction, to form a row of stator blades. When arranging, the axial position of the leading edge of each adjacent wide and narrow blade has a δ misalignment, so that the trailing edge of the blade in the same row of stator blades is at the same axial position, but the leading edge is not at the same axial position The distance δ that the axial position of the narrow blade 2 leading edge is staggered backward than the axial pos...

Embodiment 2

[0026] This embodiment is a two-stage axial flow compressor, with 57 stator blades in the first stage and 74 stator blades in the second stage.

[0027] In practice, the first-stage stator blades of the compressor are made into 29 wide blades 1 and 28 narrow blades 2, the axial chord length of the wide blades 1 is the same as the conventionally designed size when they are uniformly arranged, and the geometric dimensions of the narrow blades 2 Compared with the wide blade 1, it is reduced by 10%; when arranging, one side of the two wide blades 1 is arranged adjacent to each other along the circumferential direction, that is, the X direction, and the other side is respectively adjacent to the narrow blade; The blades are arranged in such a way that wide blades 1 and narrow blades 2 are alternately arranged to form a row of stator blades. When arranged, the axial positions of the leading edges of all wide blades 1 are the same, and the axial positions of the leading edges of all ...

Embodiment 3

[0031] This embodiment is a single-stage axial flow compressor with 67 stator blades. In practice, the stator blades of the compressor are made into 34 wide blades and 33 narrow blades, the number of blades in the blade row remains unchanged, and the geometric dimensions of the narrow blades 2 are reduced by 12% compared with the wide blades 1; , along the circumferential direction, that is, the X direction, first arrange one side of the two wide blades 1 adjacent to each other, and the other side is adjacent to the narrow blade respectively; then arrange the remaining blades alternately according to the wide blade 1 and the narrow blade 2 Arranged in a manner to form a row of stator blades. When arranged, the axial positions of the leading edges of all wide blades 1 and wide blades 1 are the same, and the axial positions of the leading edges of all narrow blades 2 are also the same, while the axial positions of the leading edges of adjacent wide blades and narrow blades Ther...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com