Glass plate silica gel solar condenser lens production method and solar condensing device

A technology of condensing lens and glass plate, applied in solar thermal devices, condensing mirrors, heating devices, etc., can solve problems such as low efficiency, and achieve the effects of high solar transmittance, light weight and low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

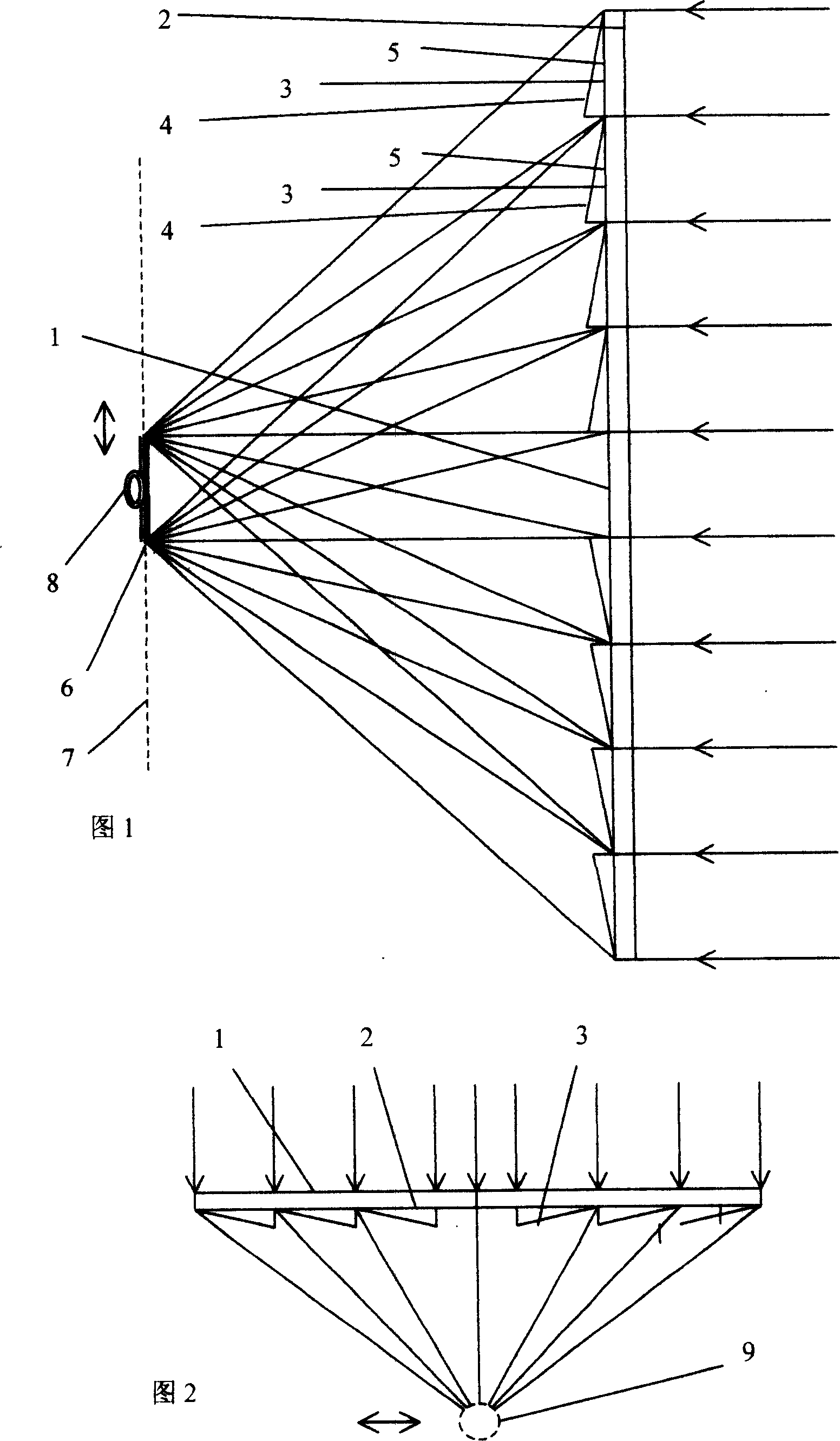

[0012] Fig. 1 shows an embodiment of the present invention, a solar concentrator equipped with a one-dimensional refractive lens manufactured according to the method of the present invention. In the figure, the refractive lens 1 is made of silica gel directly on the glass plate 2 through a mold to form many silica gel lenses 3 . The silicone lens 3 has two mutually non-parallel planes, that is, the oblique refraction plane 4 and the flat refraction plane 5 . Because it has two plane refraction surfaces, it is different from the situation that the common focusing convex lens has a focus. In the figure, the light emitted from the refraction lens 1 has refraction but no focus, and its projection area on the photocell 6 is still a light band. . The included angles between the two refraction surfaces of the adjacent silicone lenses 3 are different, so that the projection areas of the refracted light of all the silicone lenses 3 on the converging plane 7 are accurately overlapped t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com