Hydraulic pressure automatic leveling method and leveling system for ladle car

An automatic leveling and water bag car technology, applied in the field of leveling system, can solve the problems of no real-time adjustment, etc., achieve the effect of small vibration, small deformation damage, and avoid oscillation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

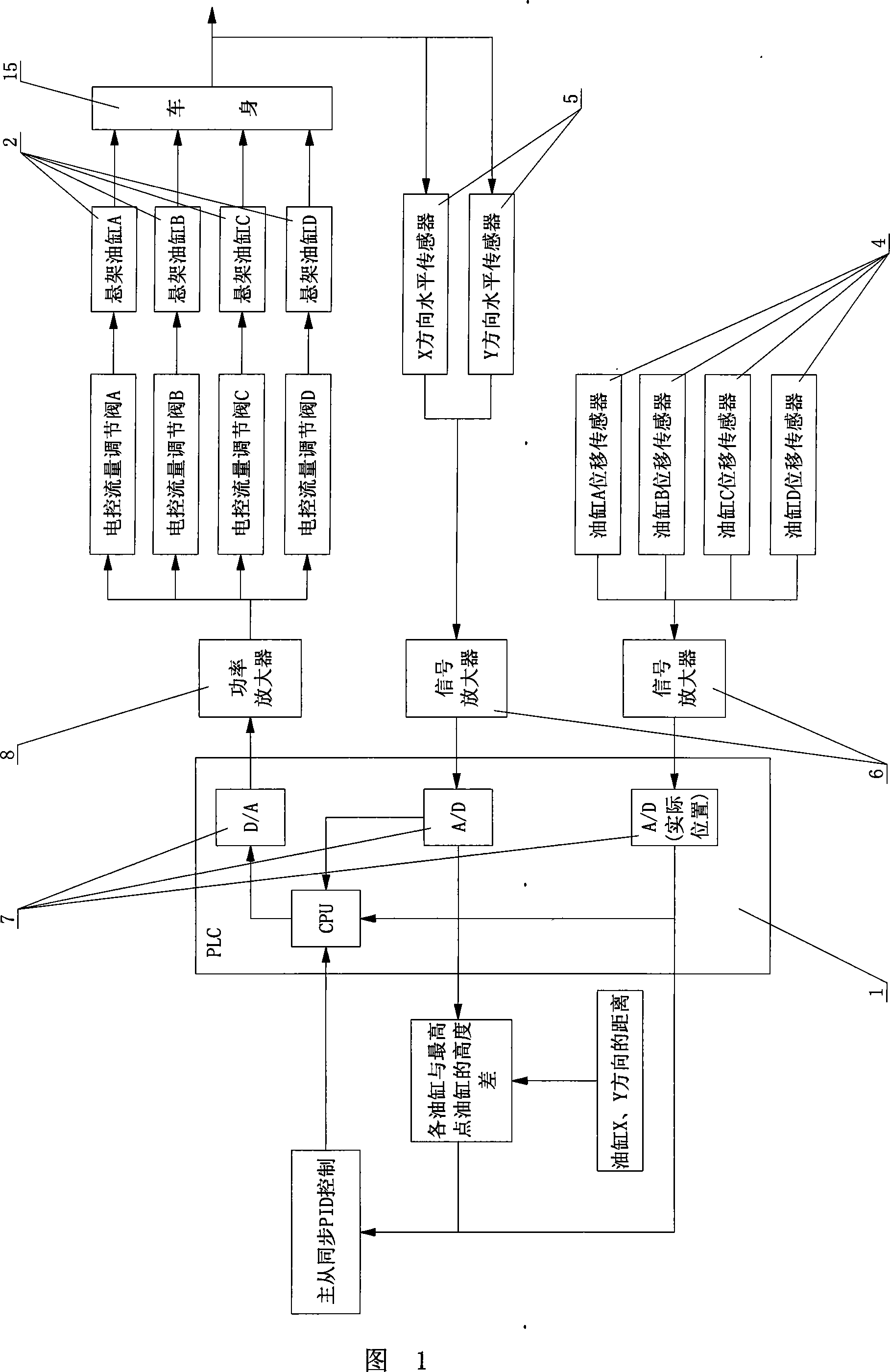

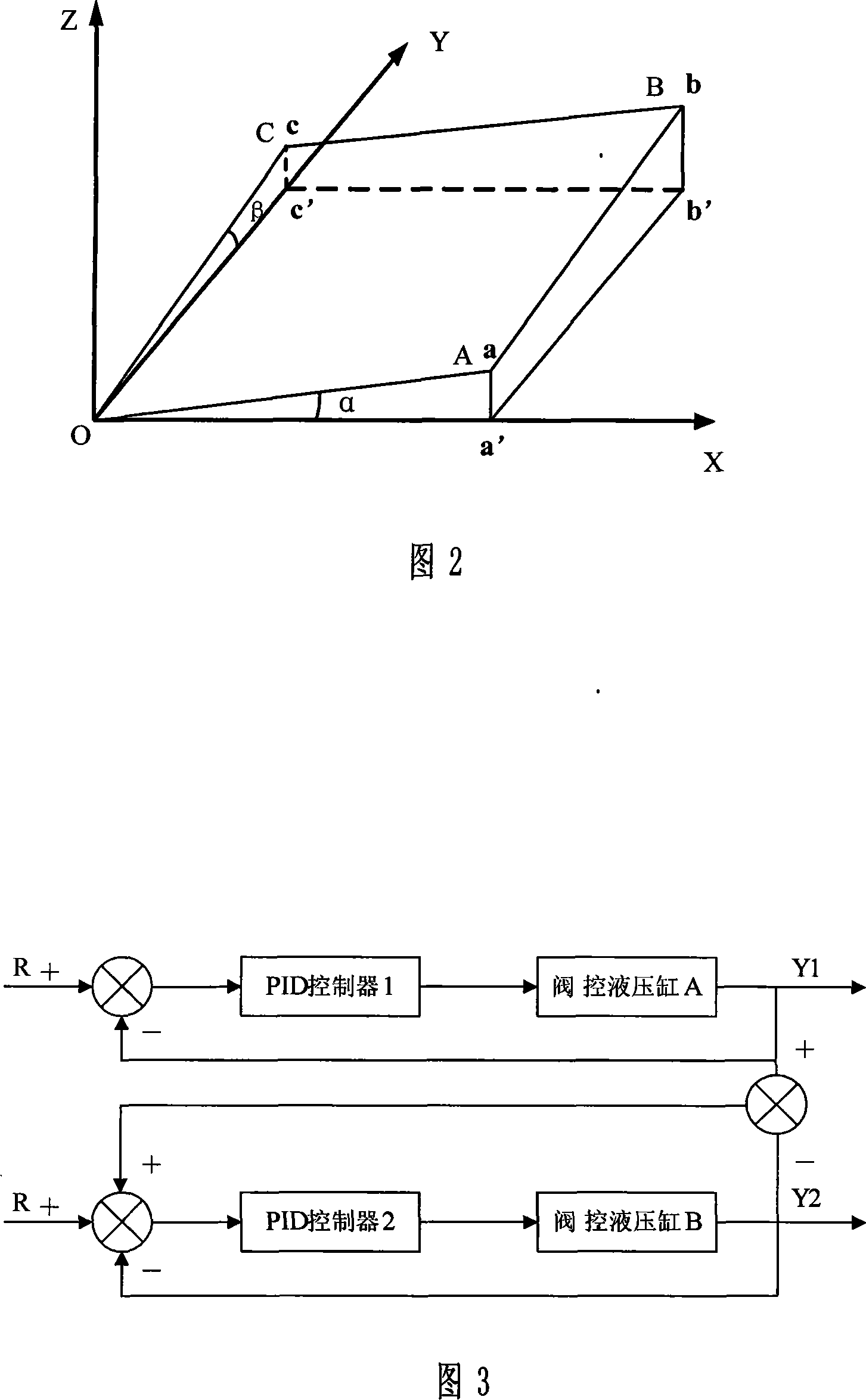

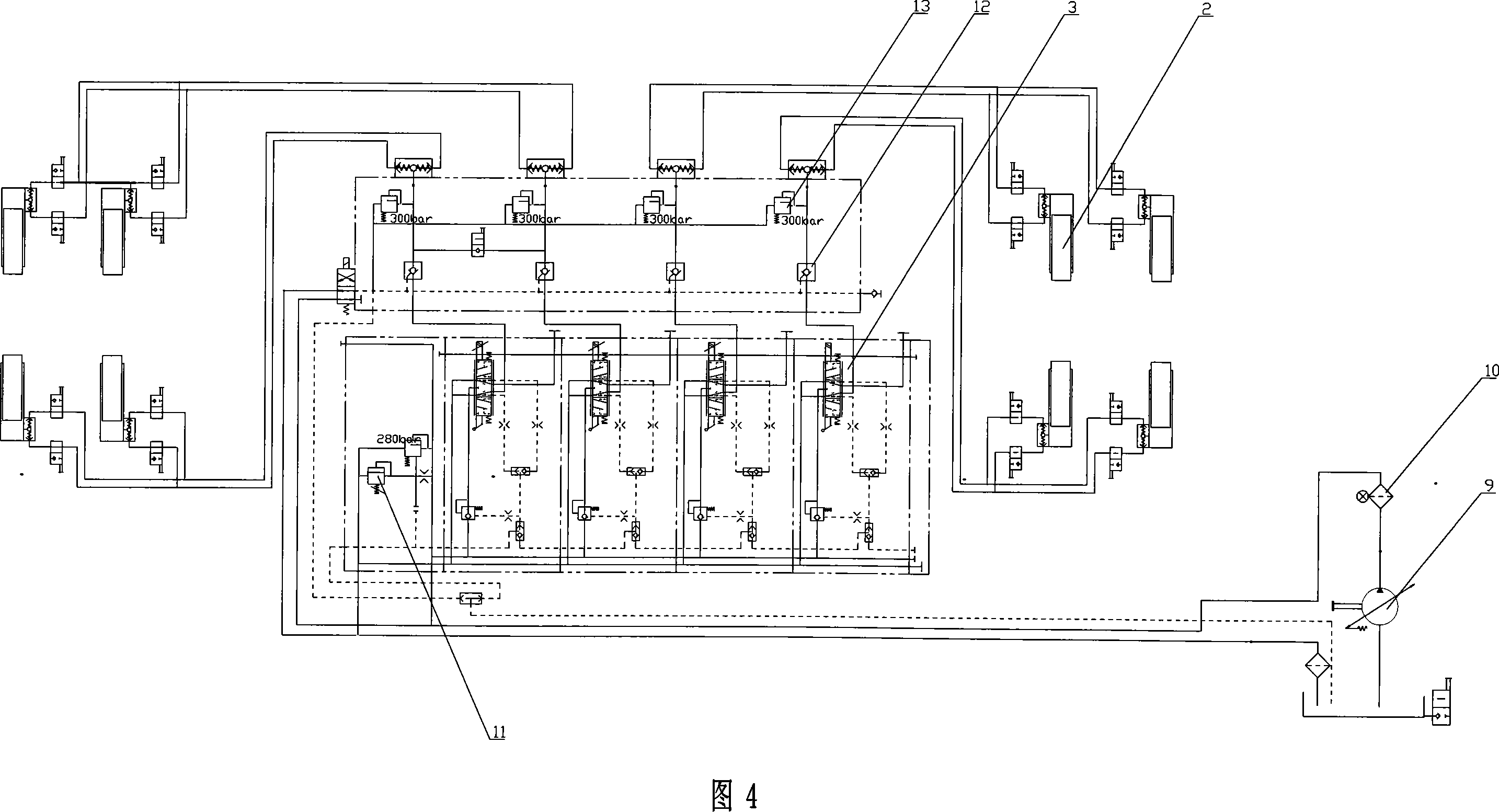

[0037] The invention discloses a hydraulic automatic leveling method for a molten iron chartered car, the steps of which are: (1), firstly, divide it into an X direction and a Y direction according to the plane of the vehicle body 15 and set two corresponding inclination sensors 5 , Four sets of suspension oil cylinders 2 and corresponding position sensors 4 are arranged between the tires on the ladle car and the car body; (2), the main control unit 1 circulates through the inclination sensor 5 and the position sensor 4 to collect in real time the horizontal position signal and The position signal of the suspension oil cylinder 2 judges the highest support point of the lower body 15 at a certain moment by the positive and negative values of the inclination angles in the X and Y directions, and the actual position of the four suspensi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com