Method for smelting host board and waste hardware, and device thereof

A motherboard and hardware technology, applied in the field of smelting of motherboards and waste metal and its devices, can solve problems such as changing combustion temperature and time, incomplete combustion, difficult recycling, destruction and decomposition, etc., to avoid high temperature tempering, Rapid cooling and exhaust, the effect of improving gas processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

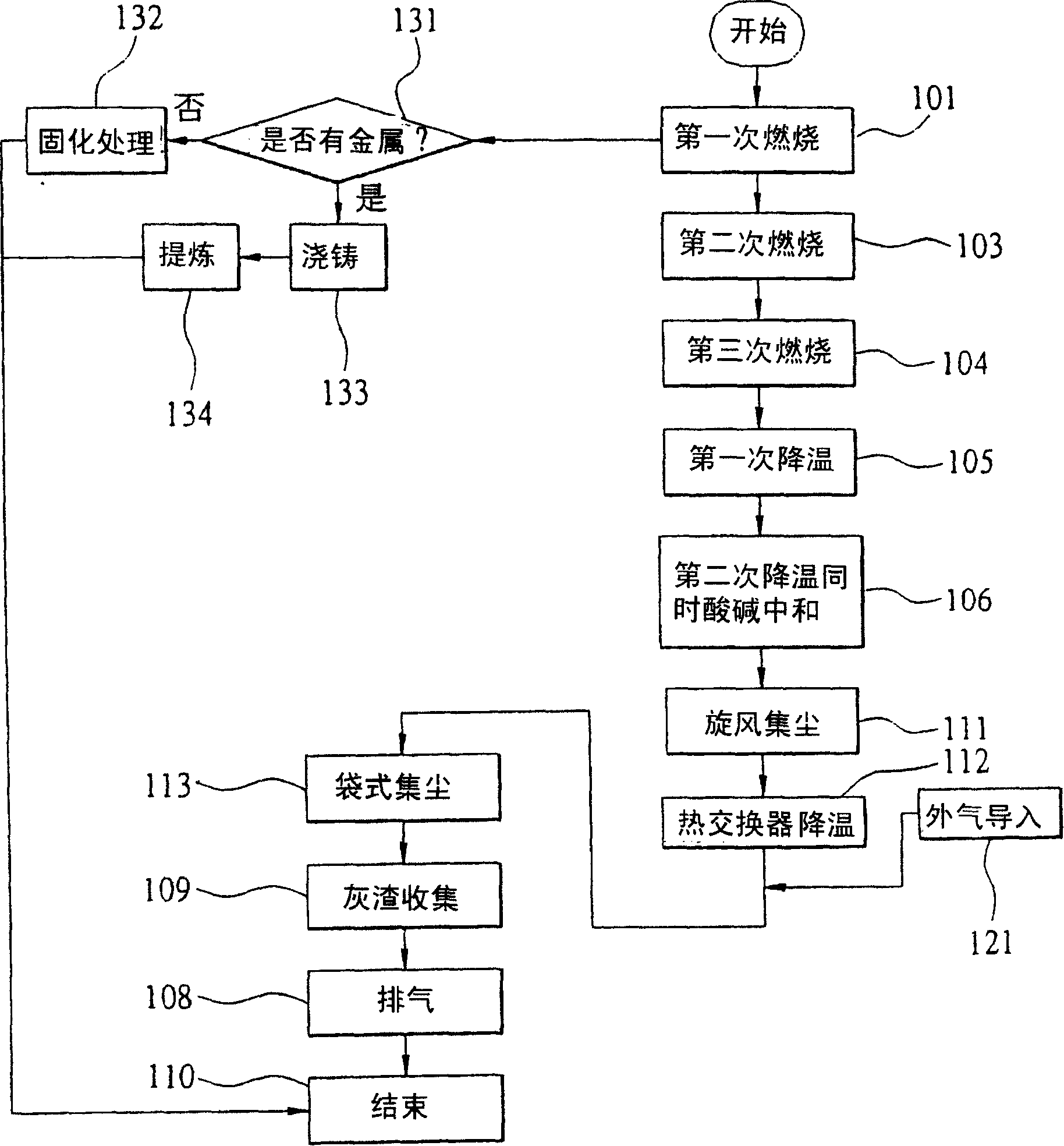

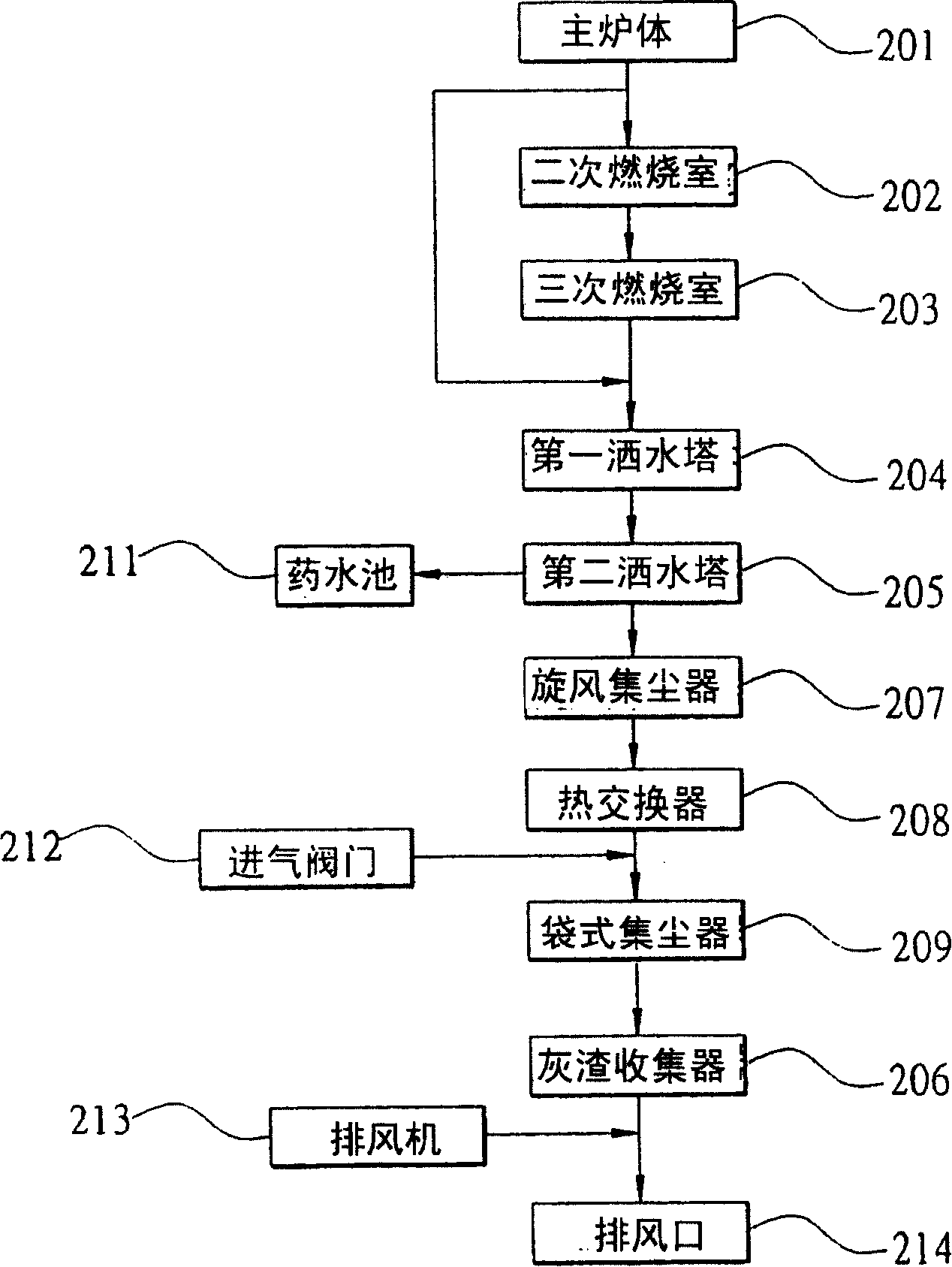

[0041] figure 1 It is the overall flow chart of the main board and scrap metal smelting method of the present invention, which is referred to figure 2 The structural block diagram of the embodiment of the smelting device of the main board and scrap metal, it can be clearly seen that the present invention mainly implements a "first combustion" step 101 in a main furnace body 201, and utilizes a lower combustion temperature (about 1200℃~1300℃) to carry out preliminary and main combustion, burn the combustible parts such as the main board and waste hardware into residues, and separate them into solid and gas parts; and the solids go through the "whether there is metal" step The judgment of 131, and then heating at high temperature to separate the solid into metal and non-combustible (such as: glass) parts, the above non-metallic residue can be "solidified" step 132, and add an appropriate amount of lime material (white stone powder) , to increase the fluidity and separation of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com