Air outlet structure of air conditioner of heat pump laundry dryer

A technology of a washer-dryer and a tuyere structure, which is applied to other washing machines, household dryers, washing devices, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

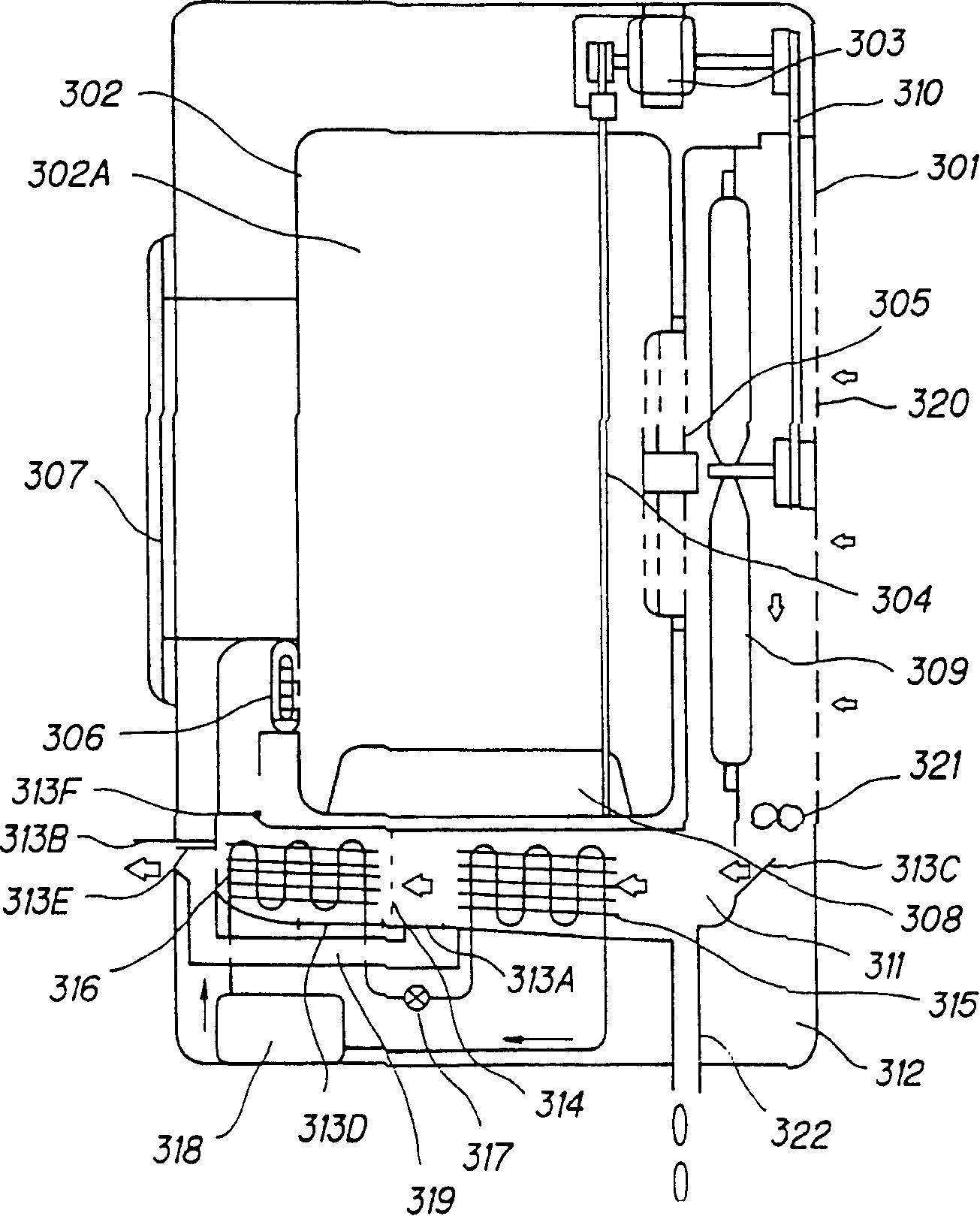

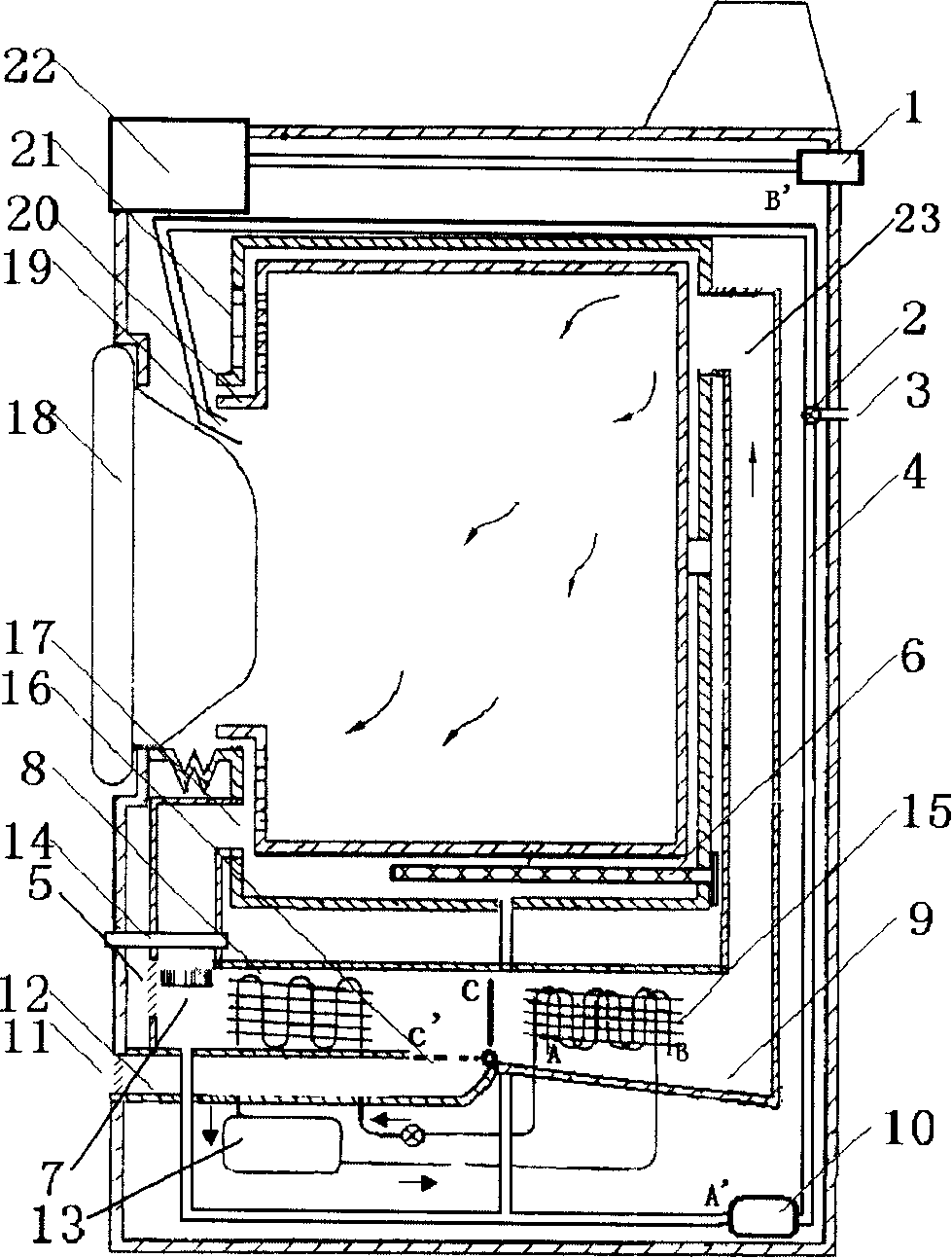

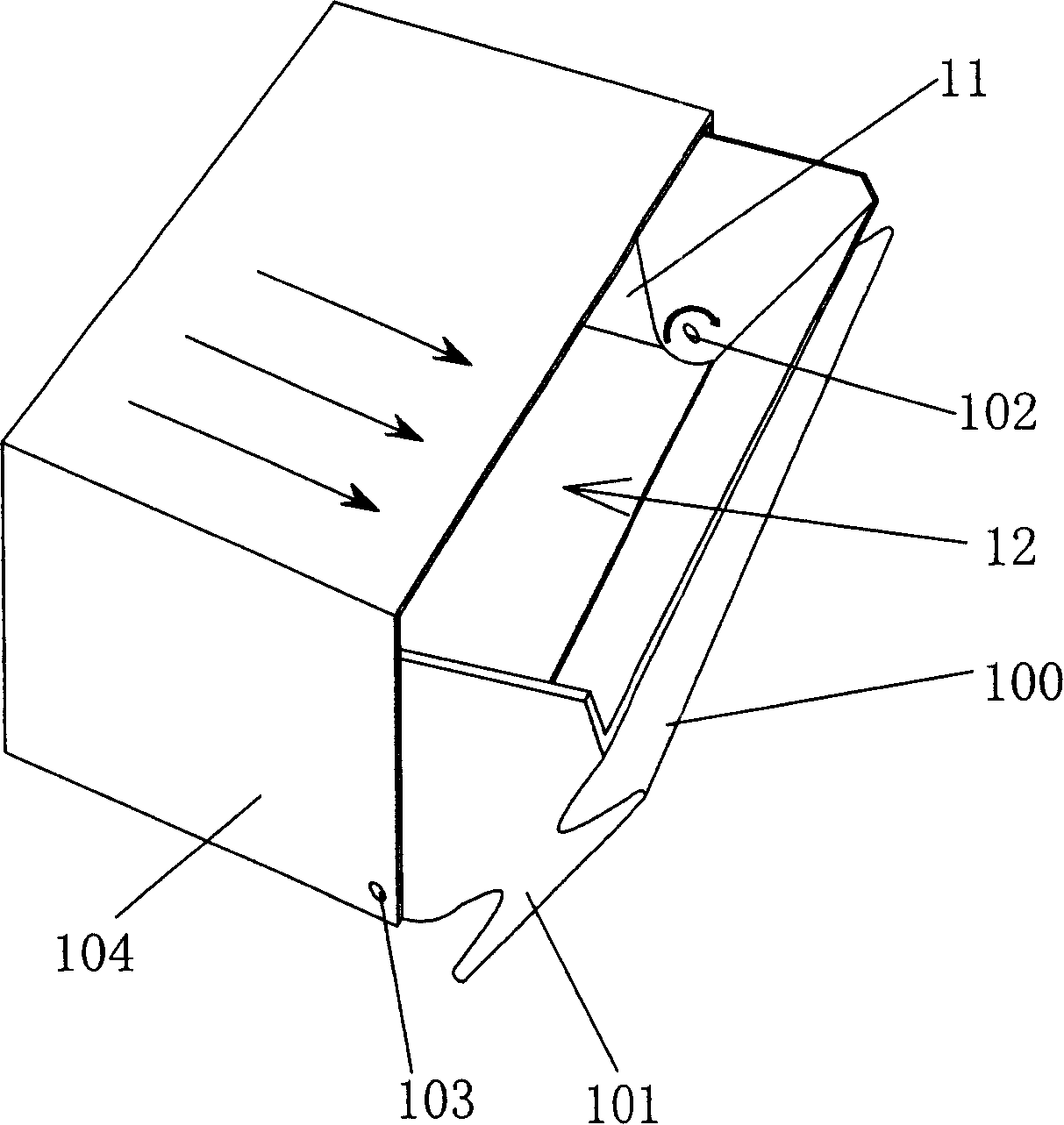

[0033] figure 2 It is a schematic diagram of the heat pump washing and drying machine used in the preferred embodiment of the present invention. The drum washing machine according to the present invention includes a shell, in which an outer tub 21 is arranged, and a rotatable inner tub 20 is arranged inside the outer tub 21. The inner tub The side of 20 is provided with some holes, to facilitate washing liquid and air circulation, in the upper rear side of the outer tub 21 of the drum, that is, the rear end relative to the washing machine door 18, and the lower side of the outer tub 21 front end of the drum, hot air is provided. outlet 17 and hot air inlet 23,

[0034] They are connected by an air duct, and a fan 7 is set in the hot air channel on the front side under the hot air outlet 17, and an openable and closable vent 5 is provided on the side wall of the hot air channel on the upper side of the fan 7. .

[0035]In the gap between the bottom of the inner tub 20 and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com