Electric ink display equipment and mending method thereof

An electronic ink and display device technology, which is applied to circuits, electrical components, electric solid devices, etc., can solve problems such as affecting the display quality of electronic ink display devices, and achieve the effects of improving display quality, improving production yield, and avoiding disconnection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In order to make the above-mentioned and other purposes, features and advantages of the present invention more obvious and understandable, the detailed description is as follows in conjunction with the accompanying drawings and embodiments:

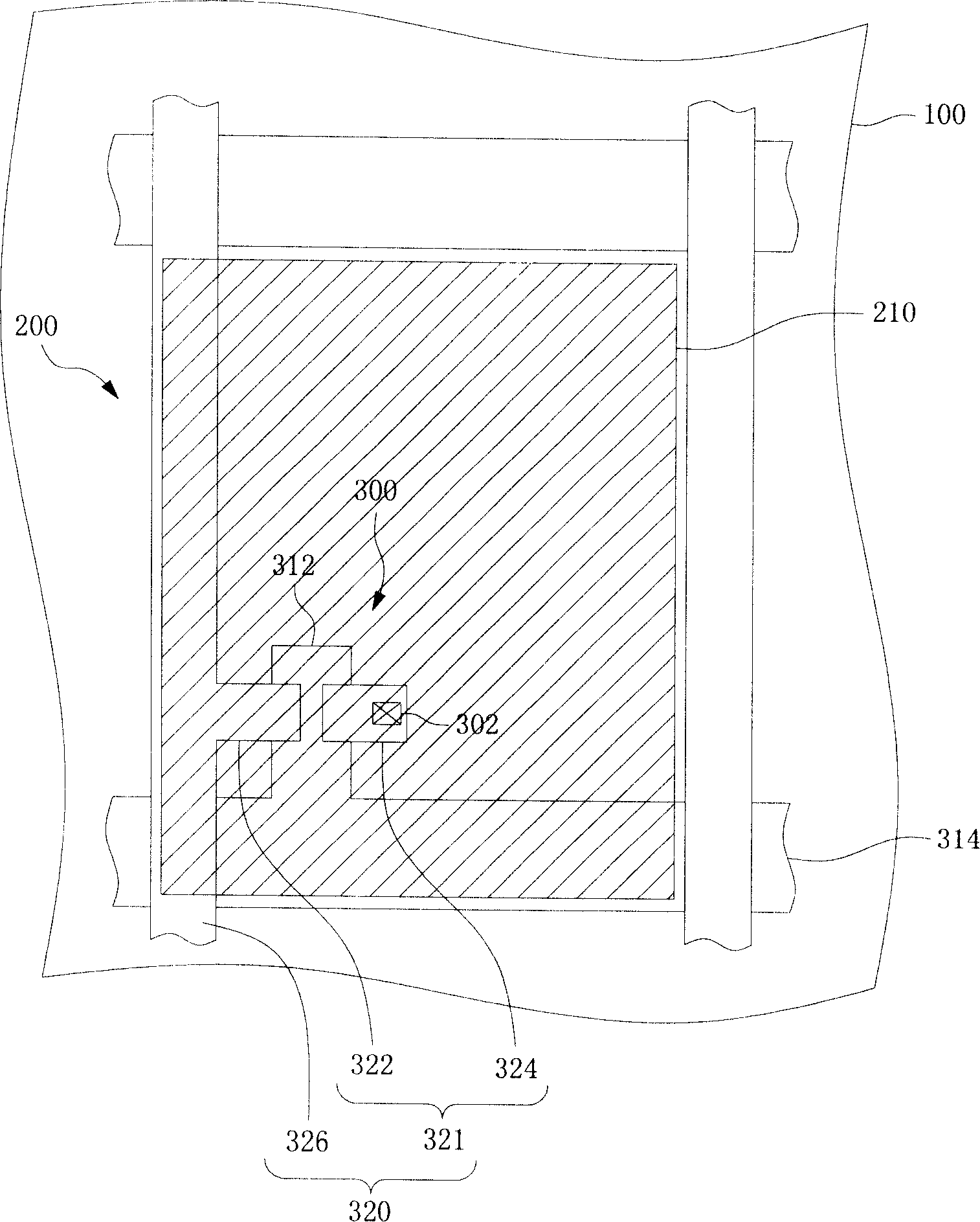

[0033] figure 1 It is a schematic diagram of a pixel unit of a thin film transistor array substrate according to a preferred embodiment of the present invention. No. figure 1 , the pixel unit 200 is disposed on a first substrate 100, the pixel unit 200 includes a thin film transistor 300 and a pixel electrode 210, and is driven by a scan wiring 314 and a data wiring 326, wherein the thin film transistor 300 has a Gate 312 and a source / drain 321, the gate 312 is electrically connected to the scanning wiring 314, one end 322 of the source / drain is electrically connected to the data wiring 326, and the other end 324 uses a contact window 302 and The pixel electrodes 210 are electrically connected. It is worth mentioning that the pi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com