Method for preparing alpha-tetralin ketone by catalyzed oxidation tetrahydronaphthalene

A technology of tetralin and tetralone, which is applied in the preparation of carbon-based compounds, chemical instruments and methods, preparation of organic compounds, etc., can solve problems such as low efficiency, and achieve good selectivity, mild reaction conditions, and reaction conversion. high rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Embodiment 1: tetralin air oxidation

[0024] In a 250 ml three-necked flask, put 100 ml of tetralin, 1.6 g of N-hydroxyphthalimide and 15.7 g of 1-fluoro-9,10-anthraquinone; heat up to 80°C while stirring, and use Insert the air guide tube in the reaction solution, feed air continuously, the air flow rate is 50 ml / min, and the excess air is discharged from the serpentine condenser tube, react for 15 hours, and analyze the product composition with a gas chromatograph. As a result, the conversion of tetralone was 90%, and the selectivity of α-tetralone was 93%.

Embodiment 2

[0025] Embodiment 2: tetralin oxygen oxidation

[0026] In a 250 ml autoclave, put 50 ml of tetralin, 2.0 gram of N-hydroxyphthalimide and 1.0 gram of 2-ethyl-9,10-anthraquinone; seal the autoclave and heat up to When the temperature in the kettle was 80°C, feed oxygen until the oxygen pressure in the kettle reached 0.5 MPa, react for 5 hours, and analyze the composition of the product with a gas chromatograph. As a result, the conversion rate of α-tetralin was 93%, and the selectivity of α-tetralone was 96%.

Embodiment 3

[0027] Embodiment 3: tetralin oxygen oxidation

[0028] Tetralin was catalyzed and oxidized in the same manner as in Example 2, except for the quinone compound used. The reaction results are shown in Table 1.

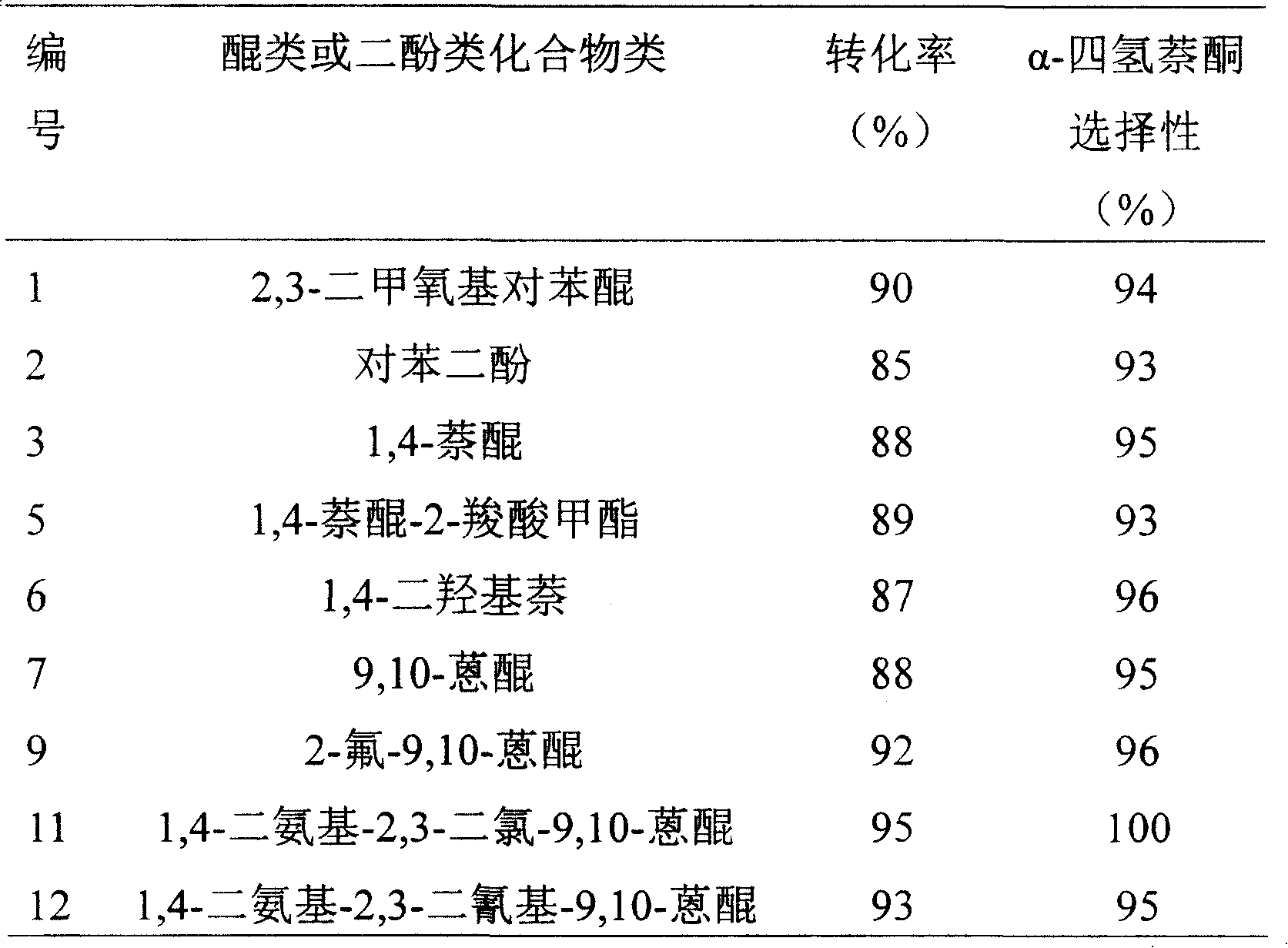

[0029] Table 1: Reaction results of various quinones or diphenols for tetralin oxidation

[0030]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com