Online management method and system for multiple steam turbines important durable member calendar service-life

A management system and steam turbine technology, which is applied in the field of online management of the calendar life of important durable parts of multiple steam turbines, and can solve the problems of inconvenient use and maintenance and high investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

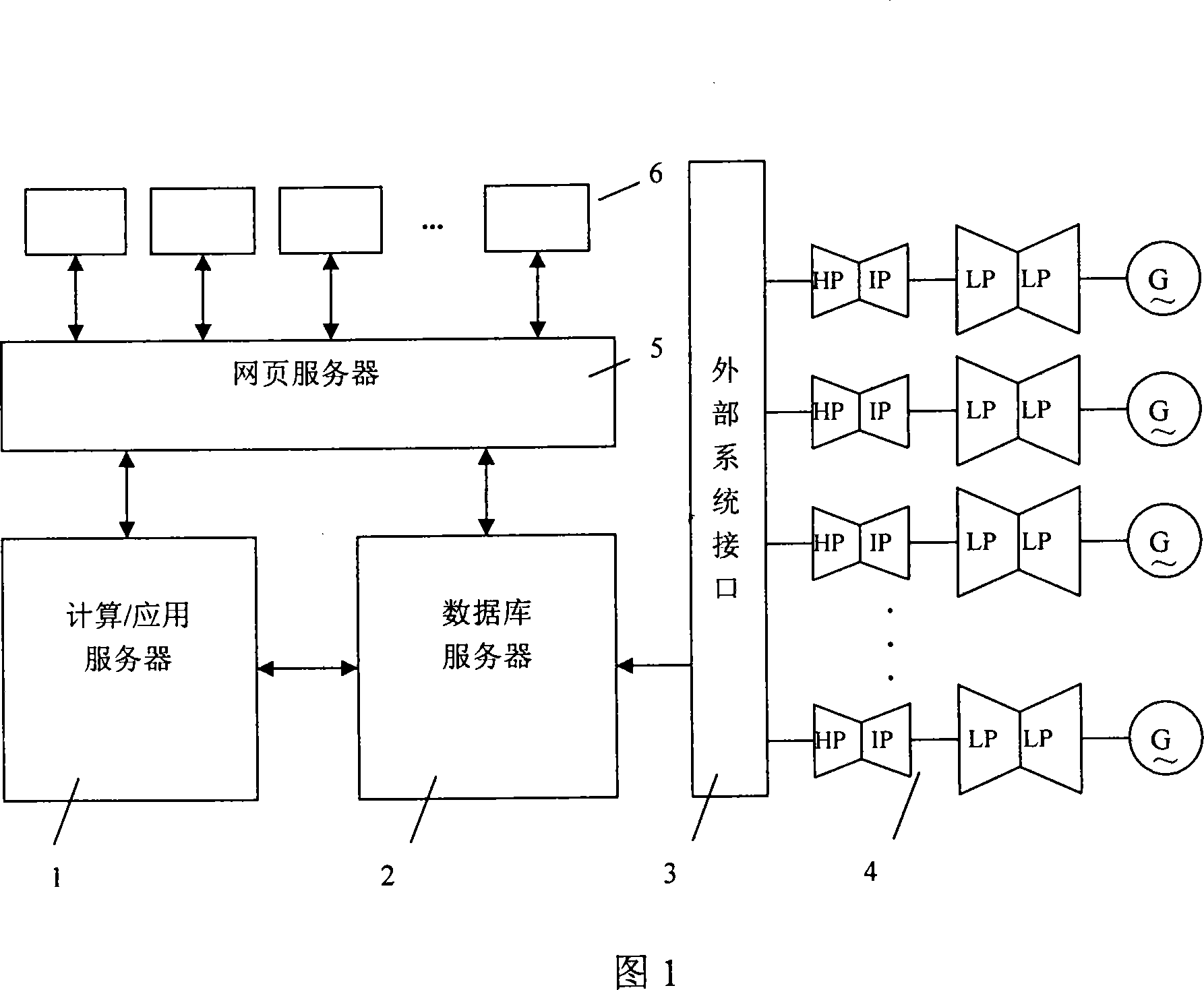

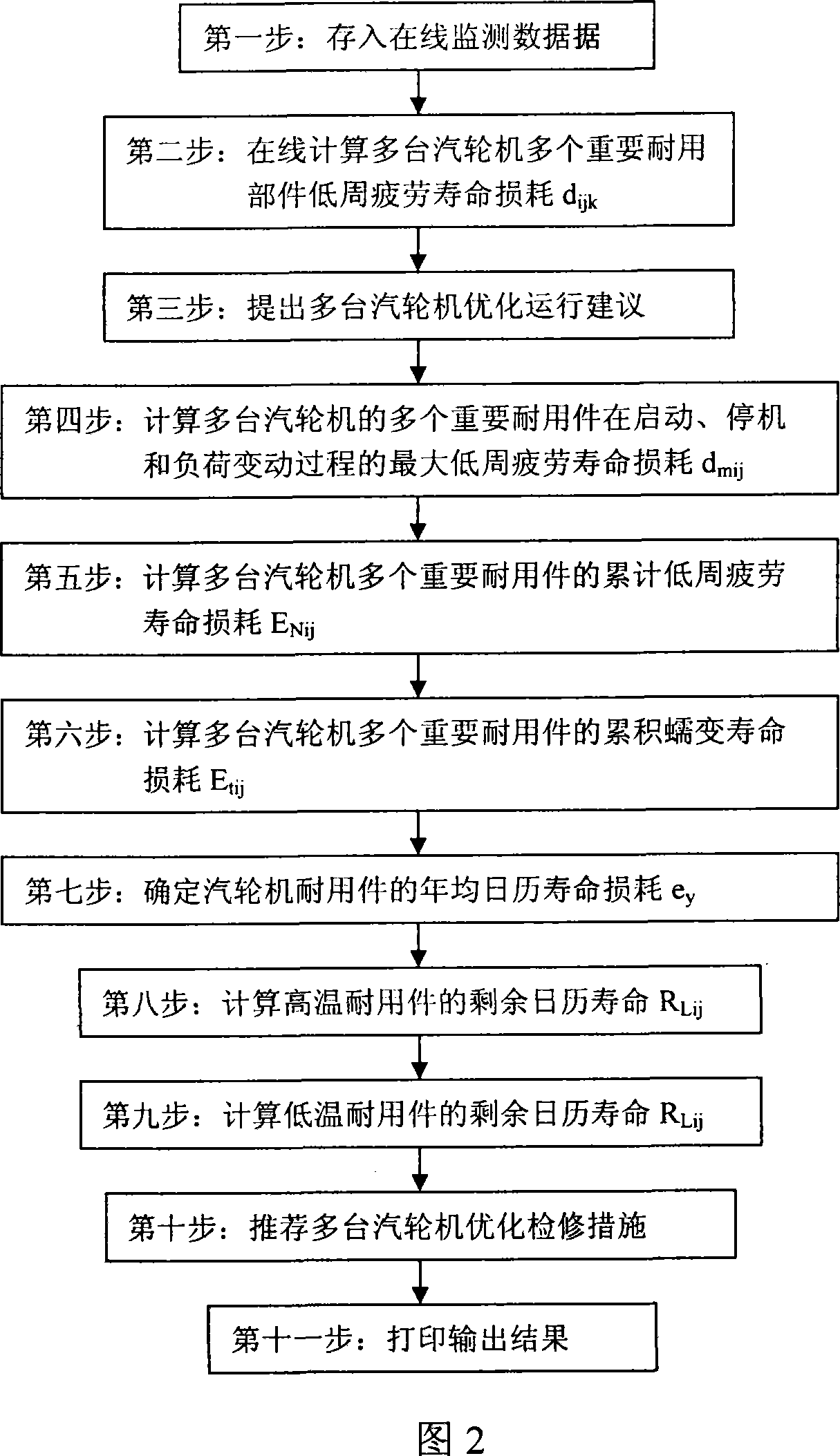

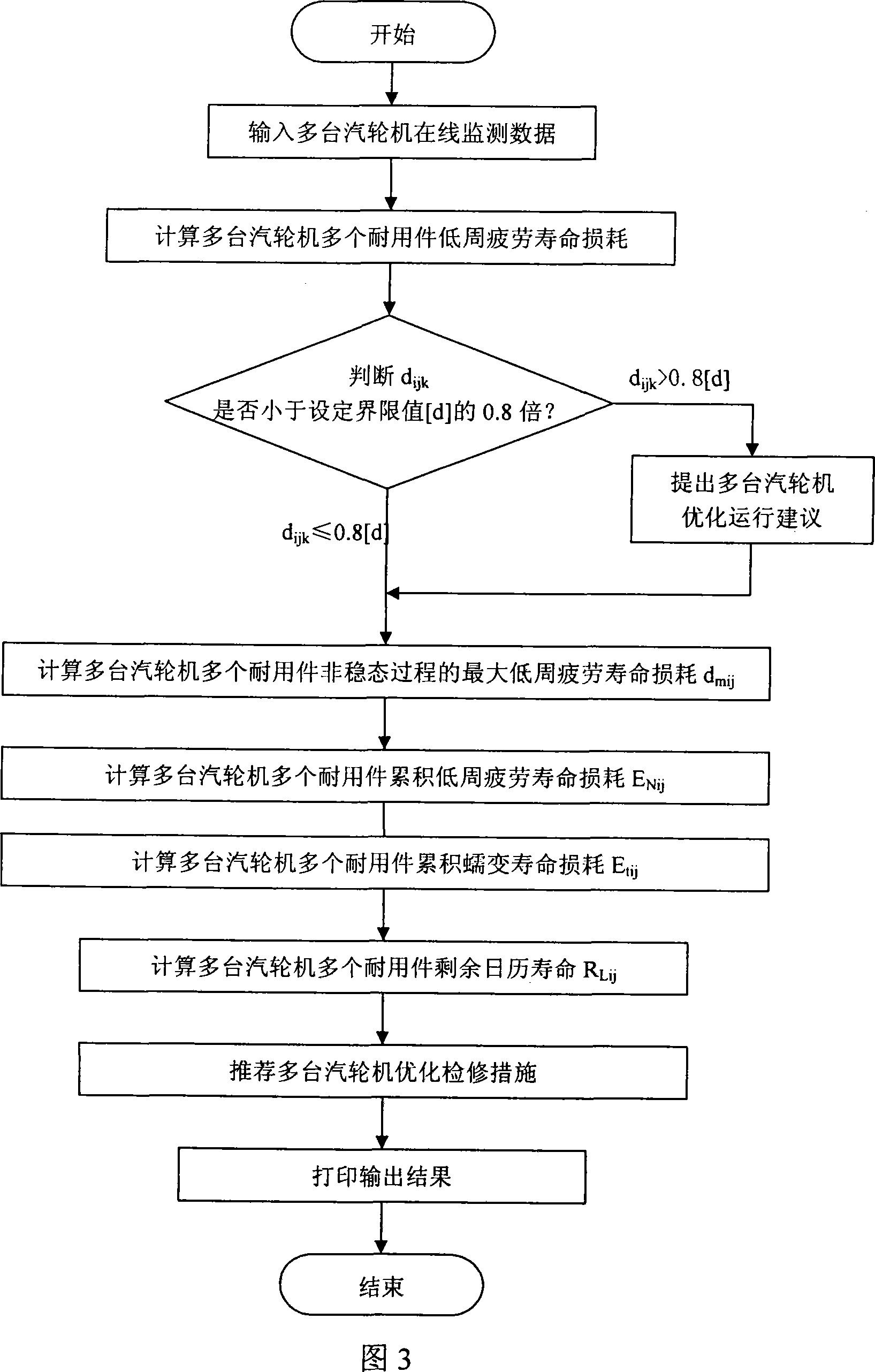

[0078] For the high and medium pressure rotors, main steam valve housings and low pressure rotors of two subcritical 300MW steam turbines of a certain type with an inlet steam temperature of 538°C and the high and medium pressure rotors of a supercritical 600MW steam turbine with a certain type of steam inlet temperature of 566°C, the The calendar life management system shown in Fig. 1, the flow chart of the method provided by the present invention as shown in Fig. 2 and the computer software for the calendar life management of a plurality of important durable parts of steam turbines shown in Fig. 3 are used to calculate the calculated life. The prediction results of the remaining low-cycle fatigue life of seven important durable parts of the three steam turbines are listed in Fig. 4.

[0079] The first step: every Δτ=3 minutes, store the measuring point data of the data acquisition system (DAS) of these two subcritical 300MW steam turbines and a supercritical 600MW steam turbi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com