Automatic debugging method and system of optical module

A technology of optical module testing and optical module, applied in transmission system, transmission monitoring/testing/fault measurement system, electromagnetic wave transmission system, etc. Dependence on skilled workers, reducing the participation of human factors, and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

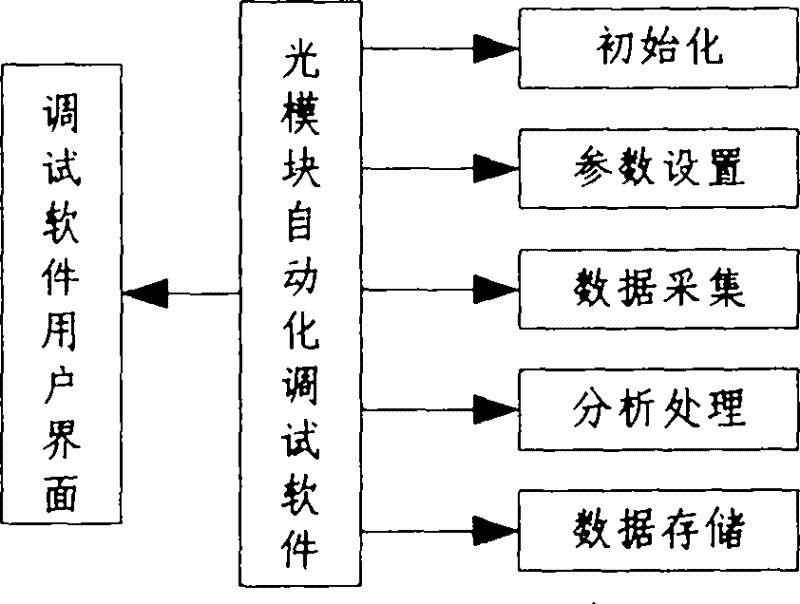

[0059] The content and functions of the present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

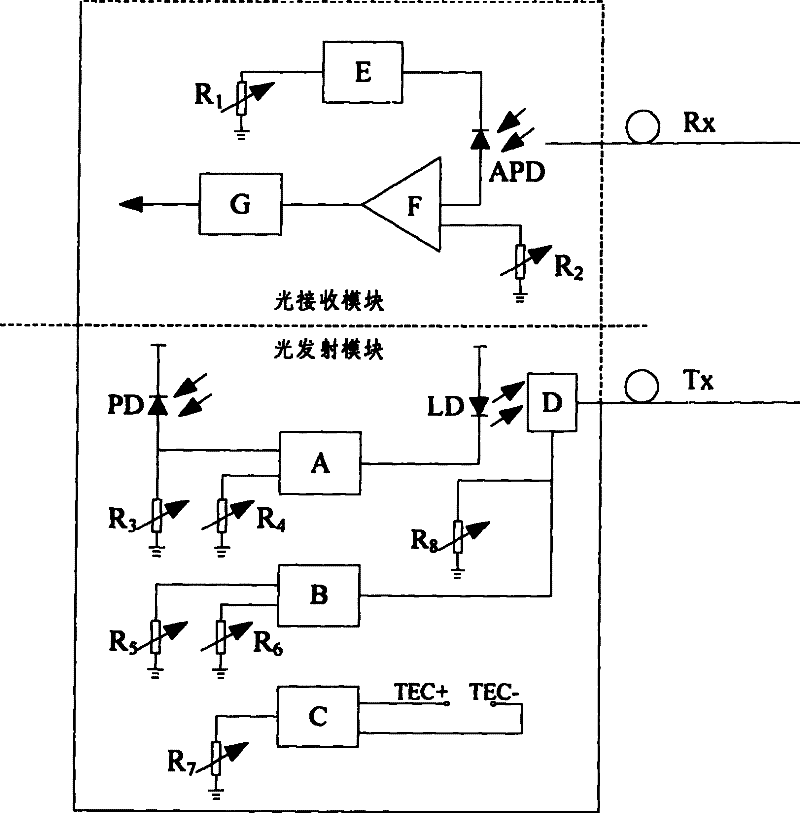

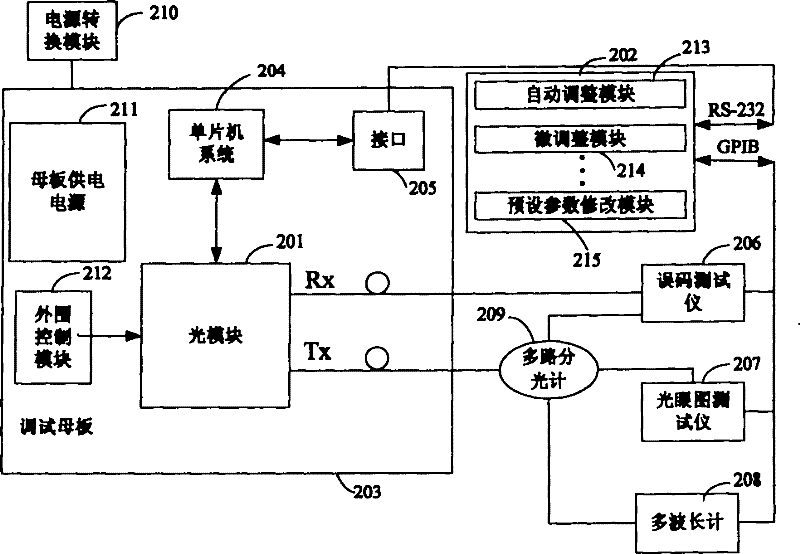

[0060] figure 2 It is a hardware system for automatic debugging of optical modules, mainly composed of optical module 201, main control computer 202, debugging motherboard 203, single-chip microcomputer system 204, interface 205, bit error tester 206, optical eye diagram tester 207, multi-wavelength meter 208, It consists of a multi-channel spectrometer 209 , a power conversion module 210 , a motherboard power supply 211 and a peripheral control module 212 .

[0061] The optical module 201 to be debugged has a digital adjustment function; the main control computer 202, the optical module automatic debugging software specifically includes: an automatic adjustment module 213, a micro-adjustment module 214 and a preset parameter modification module 215, etc.; a debugging motherboard 203 Carrying the optical module 201 and o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com