Bamboo composite art plate and method for producing same

A composite process and production method technology, applied in the field of building decoration materials, can solve the problems of poor aesthetics, single bamboo board texture, easy deformation, etc., and achieve the effect of beautiful board texture, different patterns, and increased stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

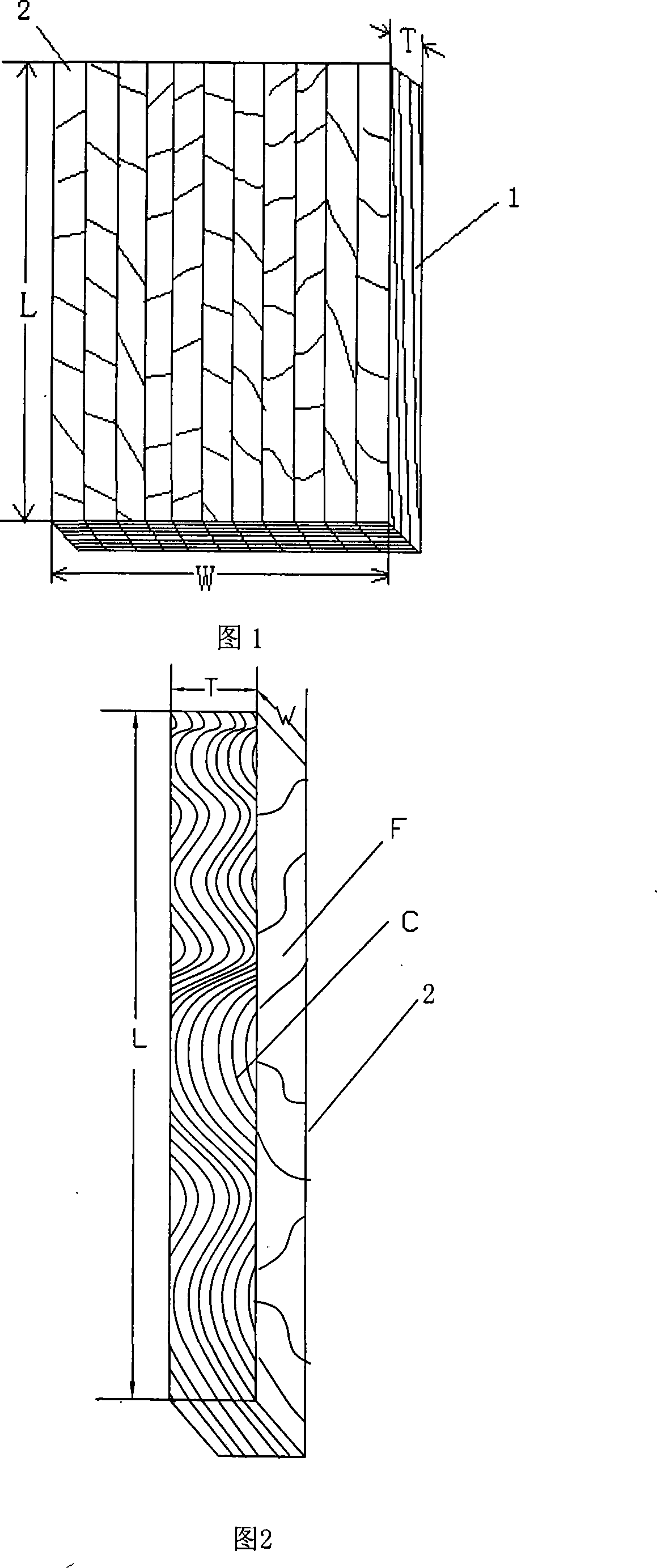

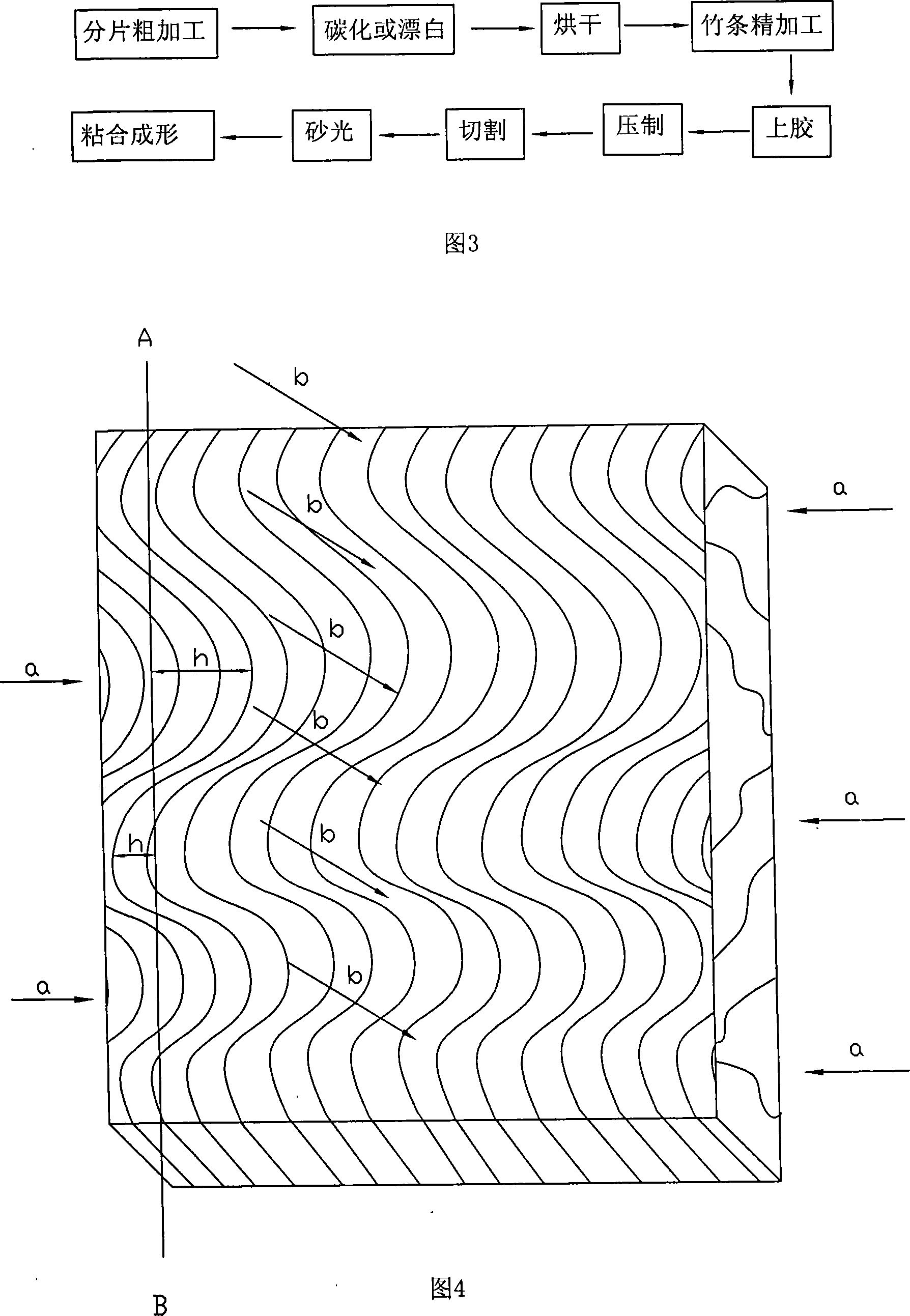

[0017] Referring to Fig. 1, Fig. 2, bamboo composite process plate 1 of the present invention is formed by mutual bonding of plate strips 2, and described plate strip 2 is obtained by twisting and pressing cutting of multilayer bamboo strips, and plate strip 2 length L is 4mm ~2770mm, the width W is 1mm~30mm, and the thickness T is 1mm~50mm. The length L of the bamboo composite process plate 1 is 4mm-2770mm, the width W is 4mm-1220mm, and the thickness T is 2mm-50mm. The surface of the bamboo composite craft board 1 has irregular textures. The irregular texture may be a combination of irregular squares, irregular rectangles, irregular rhombuses and other irregular shapes. The reason for the irregular texture is that when the multi-layer bamboo strips are twisted and pressed, the bamboo nodes on each bamboo strip are arranged in dislocation, and various irregular textures are formed as the twisted curvature is different during pressing.

[0018] Referring to Fig. 3, the produ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com