Patents

Literature

64results about How to "Different styles" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Stone-emulating roads plate fabrication process

InactiveCN101307588AElegant textureElegant effectMixing operation control apparatusSidewalk pavingsSurface layerOrganic dye

The invention relates to a process for preparing a stone-like road slab, belonging to the cement and cement compositions field. The process is characterized in that the preparation process is as follows: river sands, cements, organic dyes and the cement solution or dye additives are mixed; or colorful sand grains in different colors, which are made in advance, cements and the cement solution are mixed to prepare groups of colorful sand pulps similar to the imitating stone in pattern and color, and the groups of colorful sand pulps are orderly ejected on bottom plates of molds respectively by a throwing jet, and after the multiple ejections or shakes, stone-like patterns are made to form a pattern surface layer, and a concrete reinforcing bottom layer is cast on the pattern surface layer and undergoes tamping, natural maintenance and demoulding; use levels of materials of the groups of colorful sand pulps, the pattern surface layer and the concrete reinforcing bottom layer are prepared according to marked quality requirements of concretes needed. The process of the invention has the advantages of wide material source, low manufacturing cost, simple and convenient process and environmental protection and no radioactivity, and can overcome defects in color and texture of cement colorful ground tiles and show the texture and the effect of natural stones.

Owner:胡雪辉

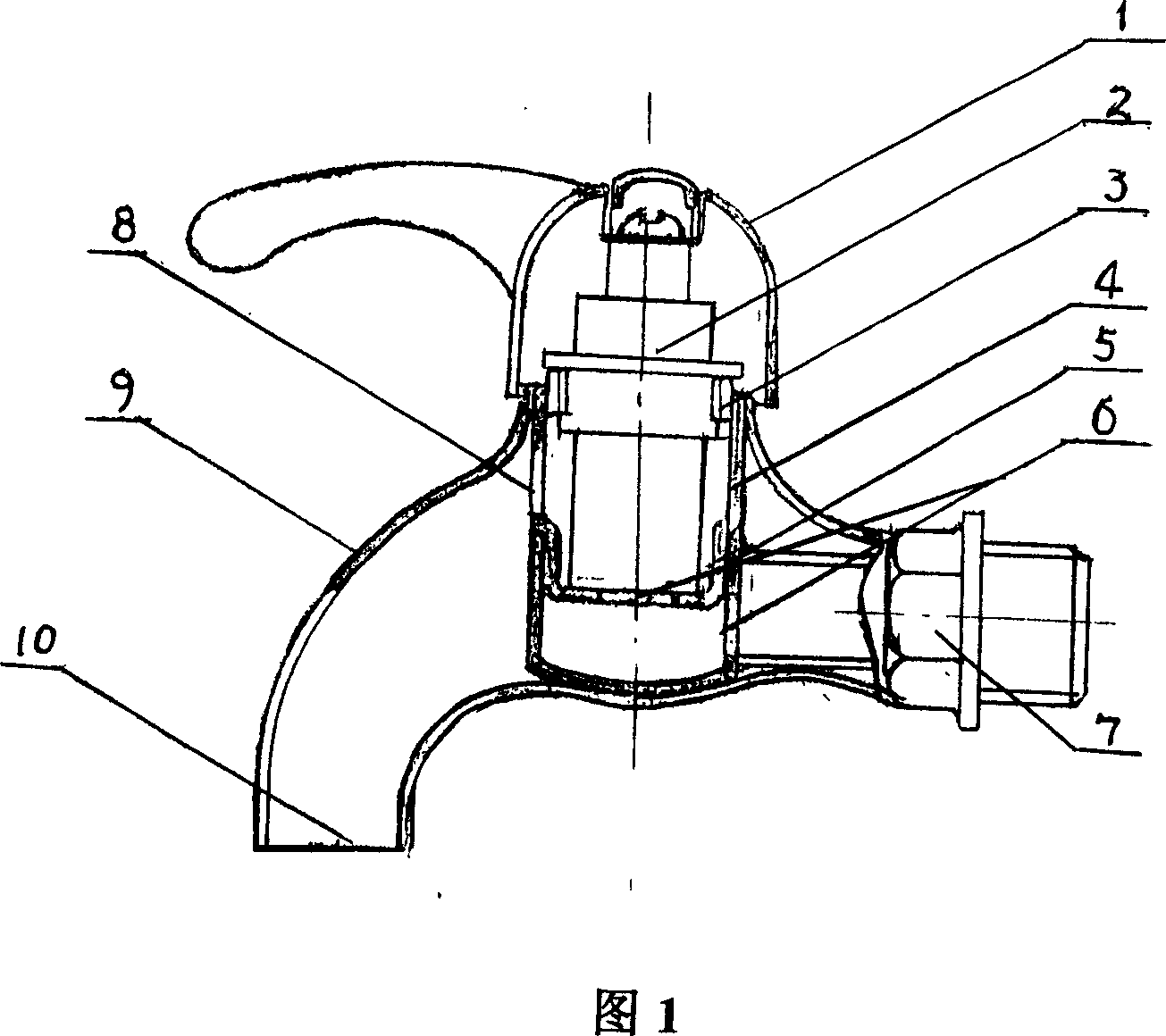

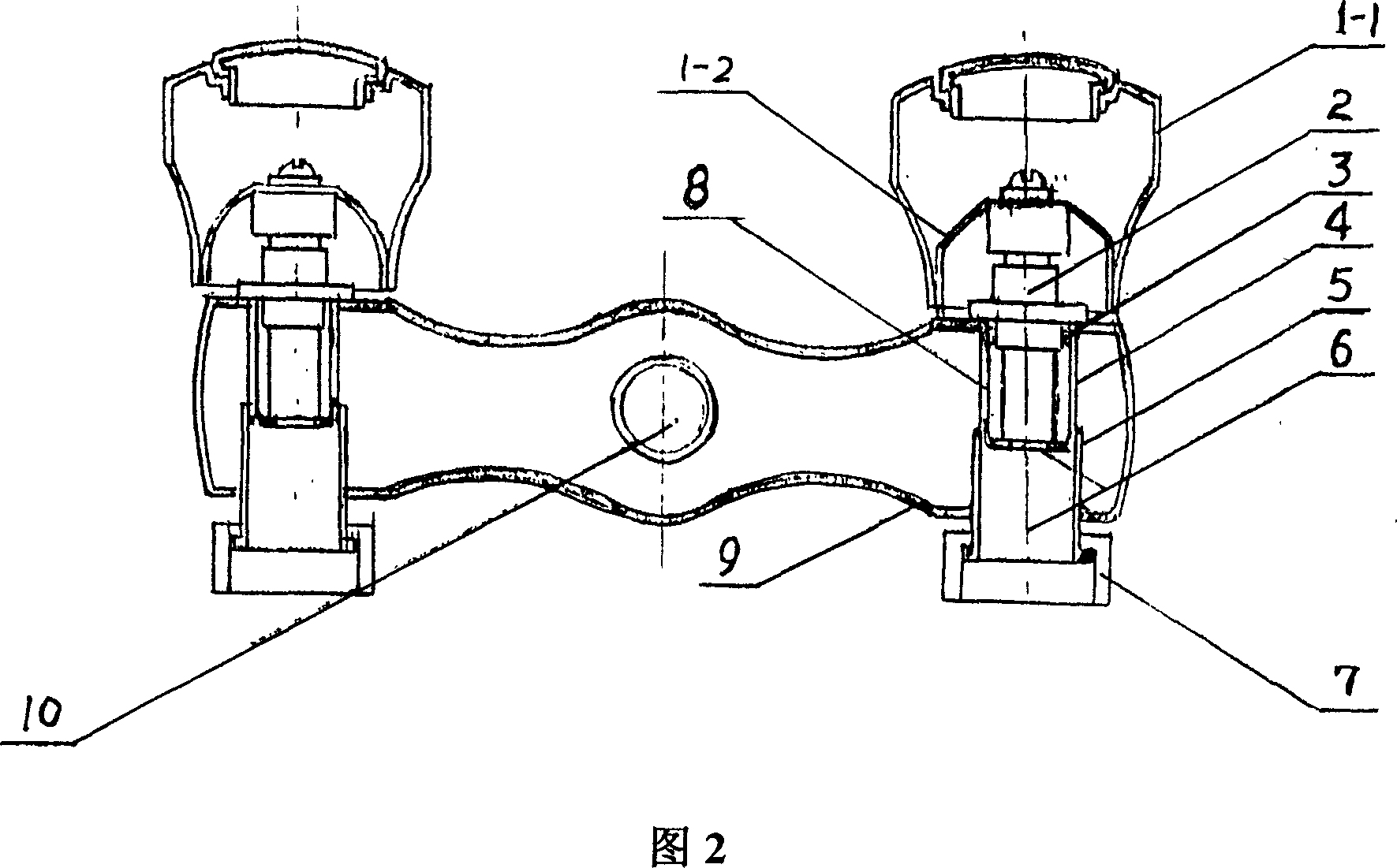

Combined water tap

InactiveCN1945076AReduce consumptionAvoid pollutionOperating means/releasing devices for valvesValve housingsPunchingMaterial consumption

The combined water tap is made with stainless steel or other metal plate, and through punching into handle, water tap casing and valve seat, welding, adhering or screw connecting these three parts into one integral, and installing the valve core into the valve seat. The present invention has the advantages of less material consumption, simple making process, low power consumption, less pollution and capacity of obtaining various appearances.

Owner:文刚

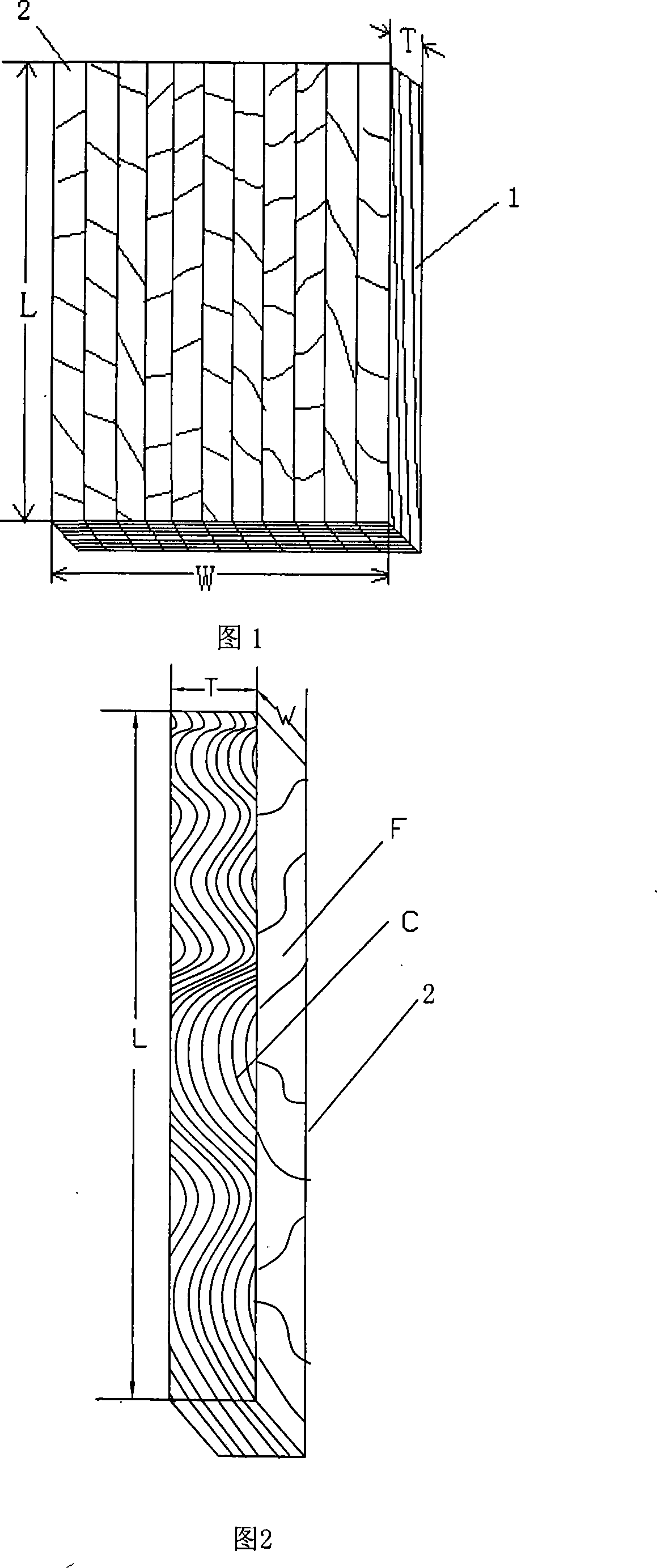

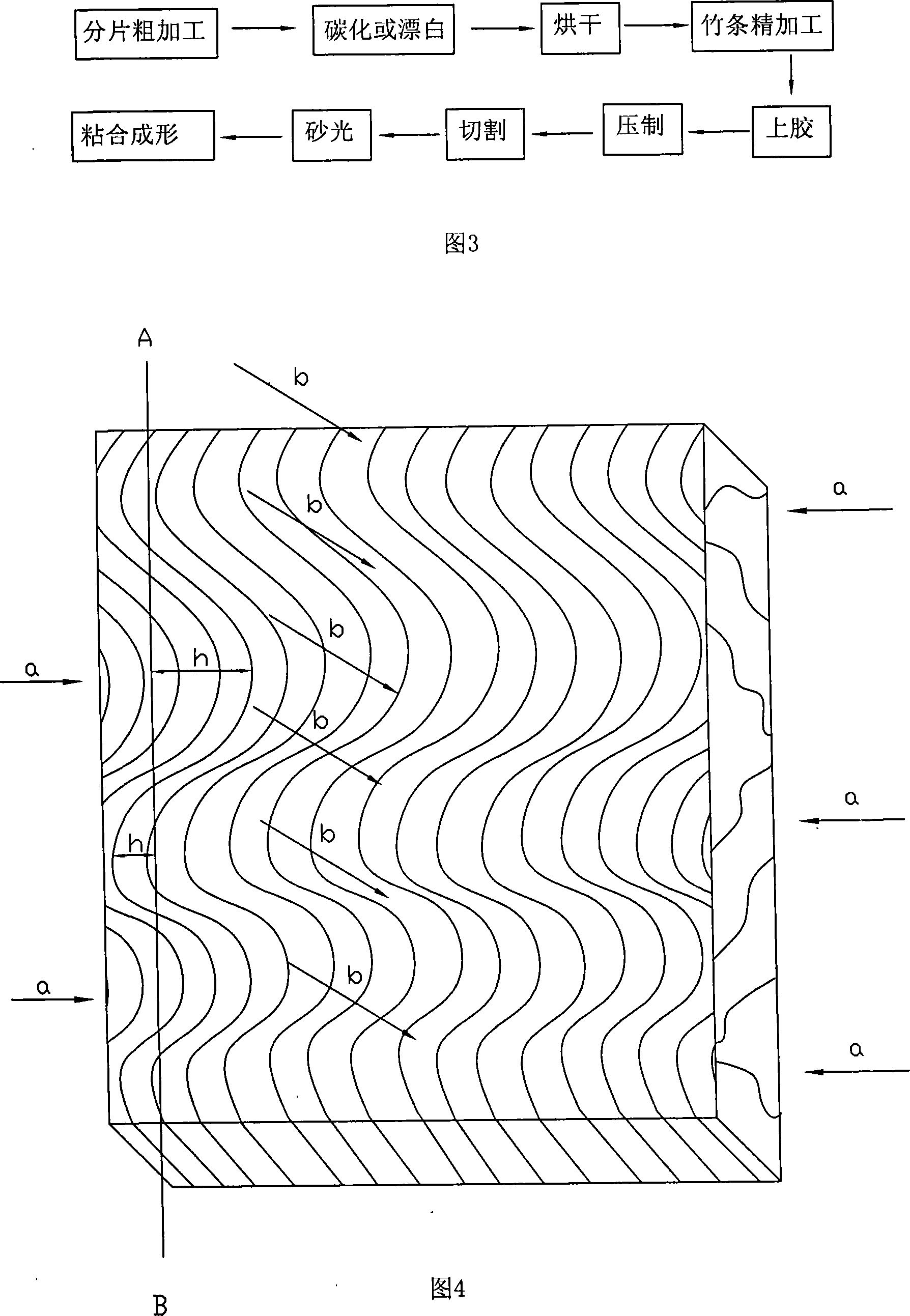

Bamboo composite art plate and method for producing same

InactiveCN101181794AEliminate or weaken deformation factorsImprove stabilityWood working apparatusFlat articlesCarbonizationComposite material

The invention discloses a board made of bamboo composite technology and a production method thereof. The bamboo composite craft board has the following structural features: multi-layer bamboo strips are twisted, pressed and cut into board strips, and the board strips are bonded to each other to form a bamboo composite craft board, and the surface of the bamboo composite craft board has irregular textures. Its production method includes rough processing of slices, carbonization or bleaching, drying, fine processing of bamboo strips, gluing, pressing, cutting, sanding, and bonding. Its characteristics are: the bamboo strips are extruded and twisted into wavy. Advantages of the present invention: 1. The multi-layered bamboo strips are twisted, pressed and cut into plank strips, and the plank strips are bonded to each other to form, completely release the internal stress of the planks, and can eliminate or weaken the deformation of the bamboo. 2. The surface of the board after cutting and bonding is composed of various irregular small pieces, and the texture is beautiful and generous. 3. The special pressing method is used to make the product have rich natural texture and increase the stability of the board.

Owner:潘可安

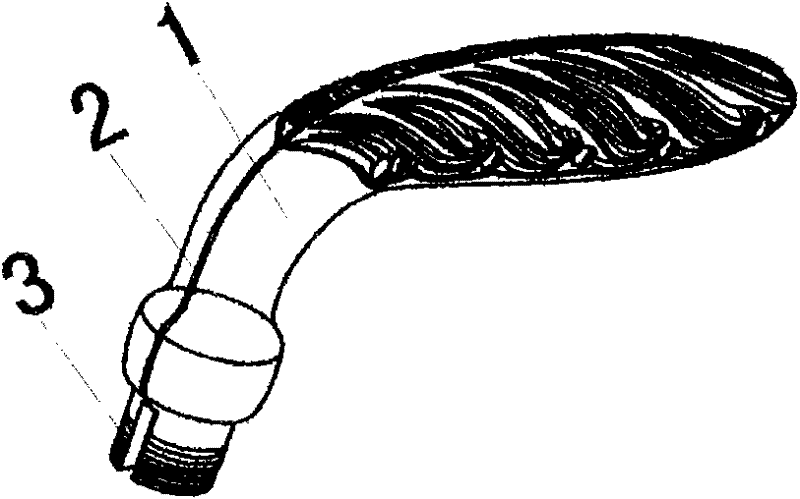

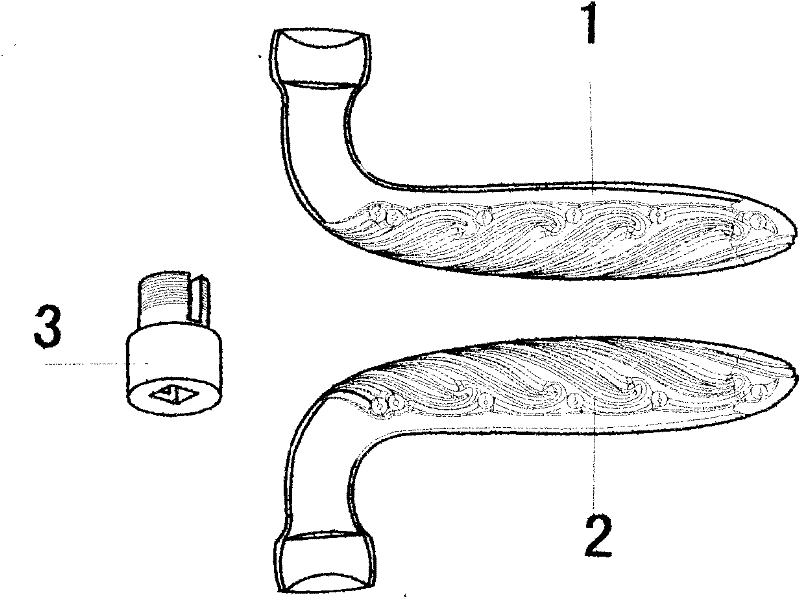

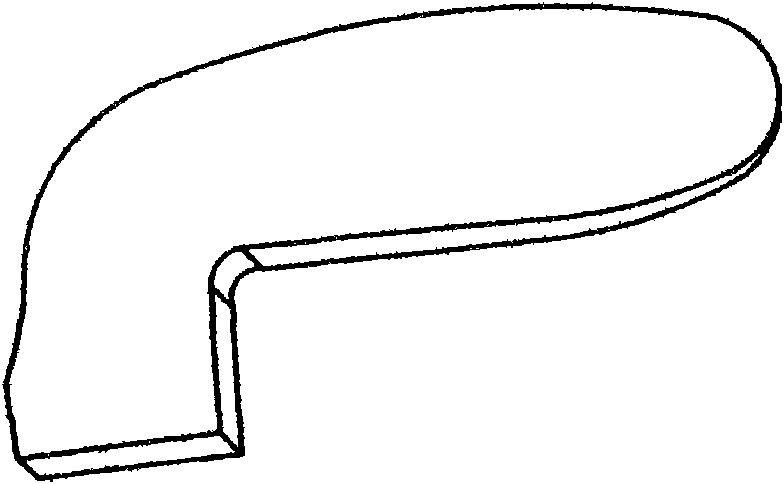

Production process of pressure formed hollow handle of metal plate

InactiveCN102161066AEasy to processShorten the production cycleWing handlesMetal-working apparatusEngineeringMetal

The invention discloses a production process of a pressure formed hollow handle of a metal plate. The production process is characterized in that the handle consists of a handle lower shell, a handle upper shell and a handle head. The process comprises the following steps that: the hollow handle lower shell and the hollow handle upper shell are formed into a handle with a required shape by applying a pressure to the metal plate through a hardware die; the handle lower shell and the handle upper shell are welded to form a hollow lock handle shell; and the handle head is fixed on a head of the hollow lock handle shell and is fixedly connected in a way of welding or pin riveting. In order to make the product more attractive, the welded product is polished, and then whether the product is to be electroplated and sealed with paint is determined according to needs. The production process has the advantages of easiness in processing, short production period, low cost, attractive appearance, durability, various shapes and styles, good handfeel, light weight, environment friendliness, resource conservation and the like, particularly, the advantages in saving materials and resources are obvious; and the material ratio of a hollow lock to a solid lock with the same style is about 1 to 2, and the material ratio of the hollow lock to solid lock with some style is 1 to 3 or more.

Owner:陈坚

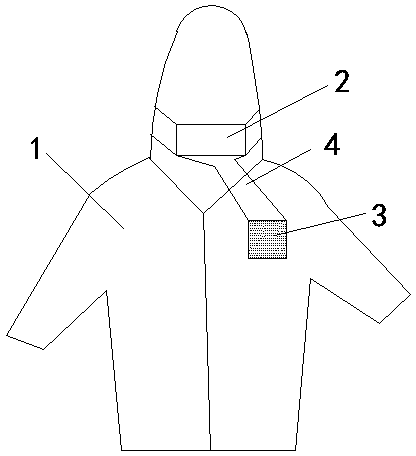

Composite fabric warmth retention garment

InactiveCN104351996AImprove cooling effectEnhance downproof performanceProtective garmentSpecial outerwear garmentsAdhesiveEngineering

The invention relates to a composite fabric warmth retention garment. The composite fabric warmth retention garment comprises a back fabric (3) and a front fabric (1), wherein the back fabric (3) is arranged on an outer layer and is strongly reflective; the front fabric (1) is arranged on an inner layer and is weakly reflective; a warmth retention layer (2) is arranged between the back fabric and the front fabric and comprises an inner-layer fabric and an outer-layer fabric; adhesion sections which are arranged at intervals and are parallel to each other are arranged between the inner-layer fabric and the outer-layer fabric; a filling space is formed between the adjacent adhesion sections between the inner-layer fabric and the outer-layer fabric; the front fabric comprises a woven fabric and a knitted fabric; the woven fabric and the knitted fabric are adhered together through an adhesive in an alignment mode. The warmth retention of the garment is improved. One surface of the fabric is the woven fabric, and the other surface of the fabric is the knitted fabric, so that the manufactured garment can be worn with both surfaces, has different styles and is novel and unique.

Owner:JIANGYIN YINGXIN WEAVING

Composite fabric of wool fabric and velvet pile

InactiveCN102363382ASimple manufacturing processReduce use costLayered productsWoolCivil engineering

The invention discloses a composite fabric of a wool fabric and a velvet pile. The composite fabric, one side of which is provided with the wool fabric and the other side of which is provided with the velvet pile, is simple in making process. The composite fabric comprises the wool fabric. The composite fabric is characterized in that: the velvet pile is bonded to the opposite side of the wool fabric through a bonding agent, and the opposite side of the wool fabric is mutually bonded with the base fabric of the velvet pile. After the wool fabric is compounded with the velvet pile, the loose and big grid-like base fabric of the velvet pile is covered; and when clothes are made, a lining does not need to be made, so that the making process of the clothes is simplified and the using cost of the fabric is reduced. The clothes can be worn on two sides with different styles. When the wool fabric is at the outside, the whole clothes are flat, stiff, smooth and warm; and when the velvet pile is at the outside, the clothes have strong hair feeling and are dignified and graceful. The composite fabric which is a two-side clothes fabric is an organic combination of a natural fabric and an artificial fabric, and has relatively low price and attractive appearance.

Owner:ZHEJIANG LINGLONG TEXTILE

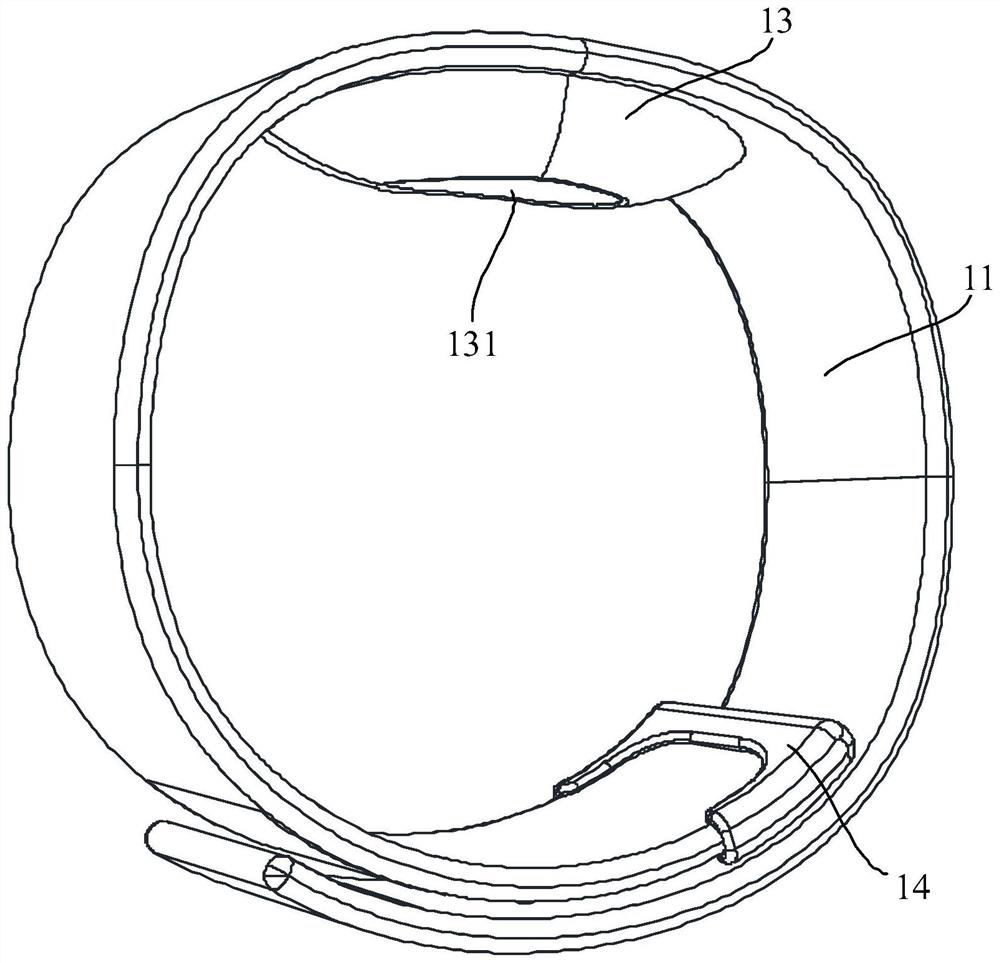

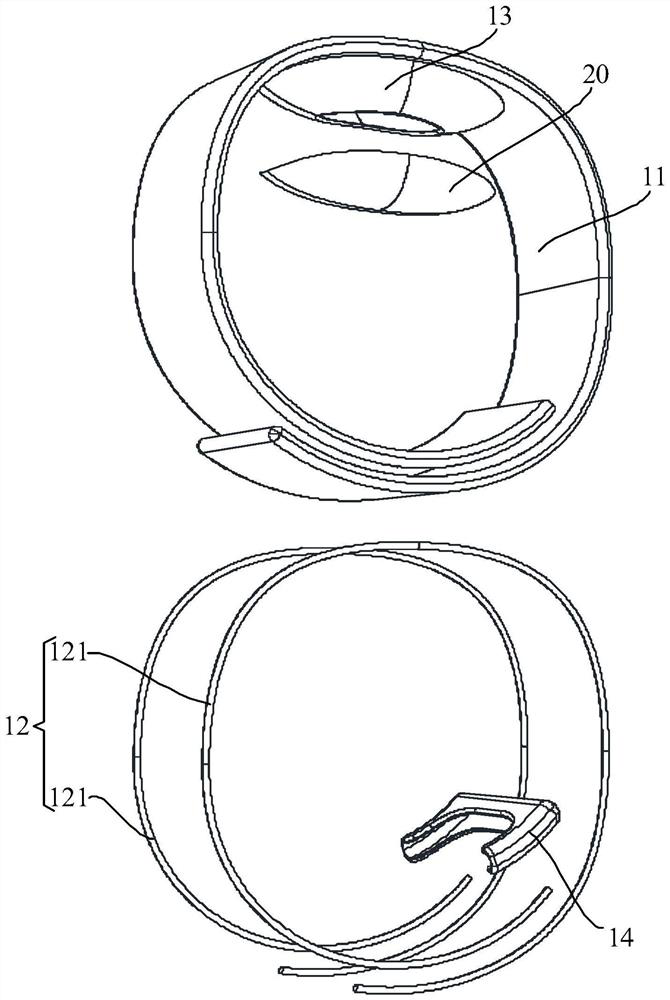

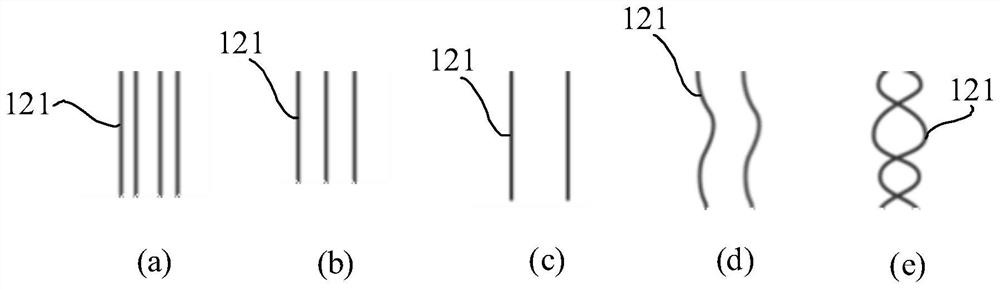

Wrist strap and wrist-worn equipment

ActiveCN113475828AEasy to removeImprove user experienceBraceletsWrist-watch strapsPhysical medicine and rehabilitationPhysical therapy

The invention discloses a wrist strap and wrist-worn equipment, and the wrist strap comprises a strap body part which is provided with two separable end parts; a memory metal wire in a strip shape extending in the length direction of the belt body part and arranged on the strap body part; wherein the memory metal wire has an annular memory state in a natural state, so that the strap body part is naturally kept in an annular shape, and the wrist strap is naturally kept in a wearing state; and a first installation cavity formed in the strap body part, wherein the memory metal wire is contained and installed in the first installation cavity. According to the technical scheme, a user can conveniently and quickly wear or remove the wrist-worn device on the wrist, so that the use experience of the user is improved.

Owner:GEER TECH CO LTD

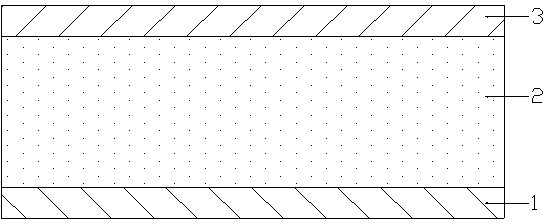

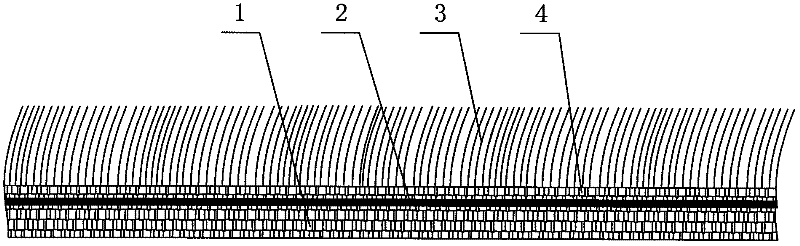

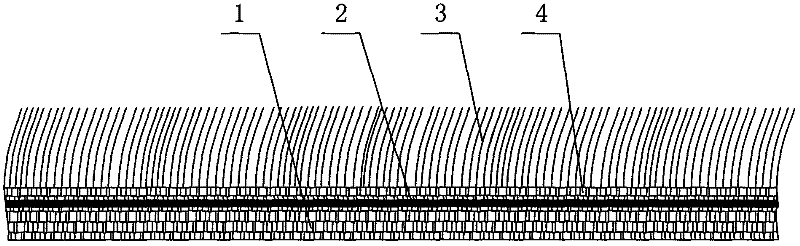

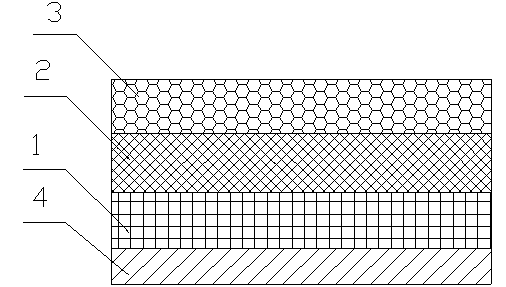

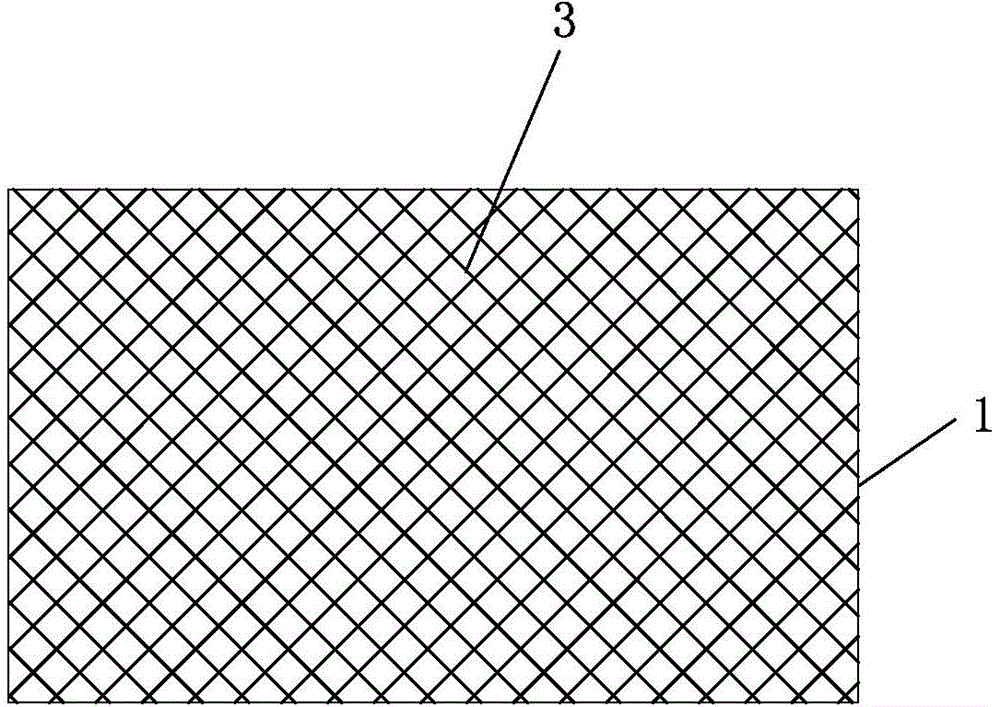

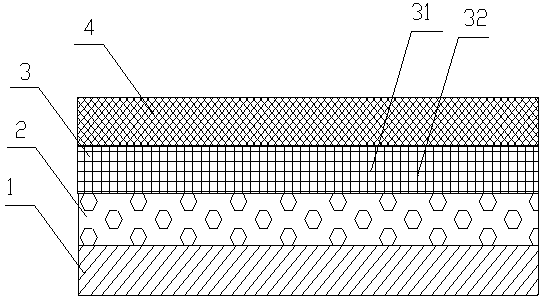

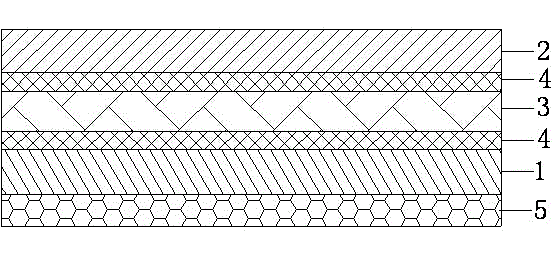

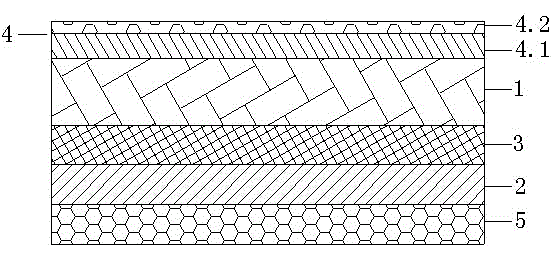

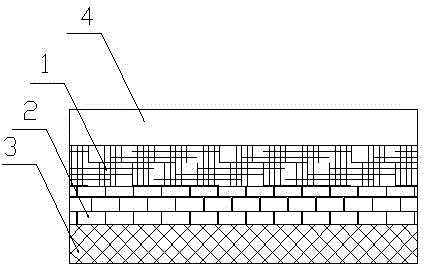

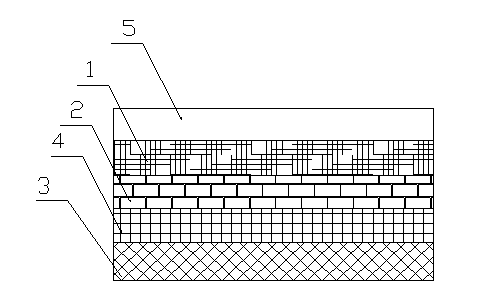

Waterproof fireproof antibacterial composite fabric

InactiveCN104354372AImprove fire and flame retardant performanceImprove fire performanceSynthetic resin layered productsMetal layered productsFiberAdhesive

The invention relates to a waterproof fireproof antibacterial composite fabric which comprises a bottom layer (4), wherein the surface of the bottom layer is compounded with a base layer (1); the base layer (1) is formed by connecting warp yarns (11) with weft yarns (12); the warp yarns (11) and the weft yarns (12) are formed by weaving nano-silver fibers; a fireproof layer (2) is arranged on the outer side of the base layer (1); a waterproof layer (3) is arranged on the upper surface of the fireproof layer (2); the bottom layer is made of a textile; the textile comprises a woven textile and a knit textile; the woven textile and the knit textile are adhered together through an adhesive. The waterproof fireproof antibacterial composite fabric is higher in waterproof property and fireproof property, and the antibacterial efficiency can be improved. One surface of the fabric disclosed by the invention is the woven textile, and the other surface of the fabric is the knit textile, so that the two surfaces of a made costume can be used; the styles of the two surfaces of the costume are different, so that the costume is novel and unique.

Owner:JIANGYIN YUEDA DYEING & PRINTING

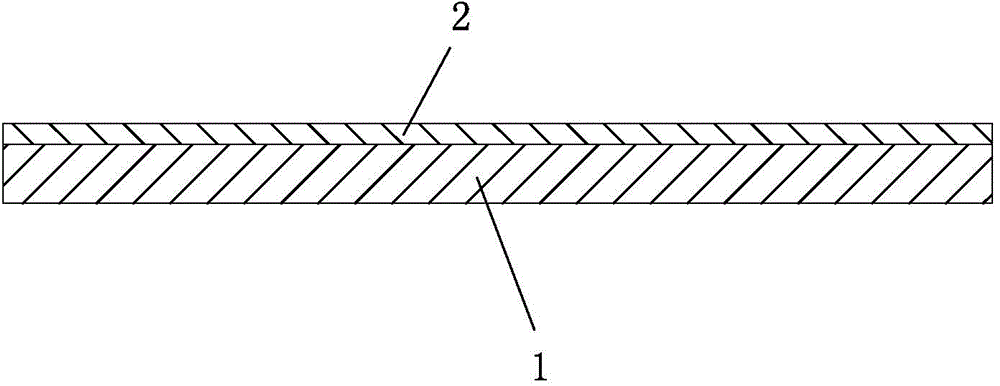

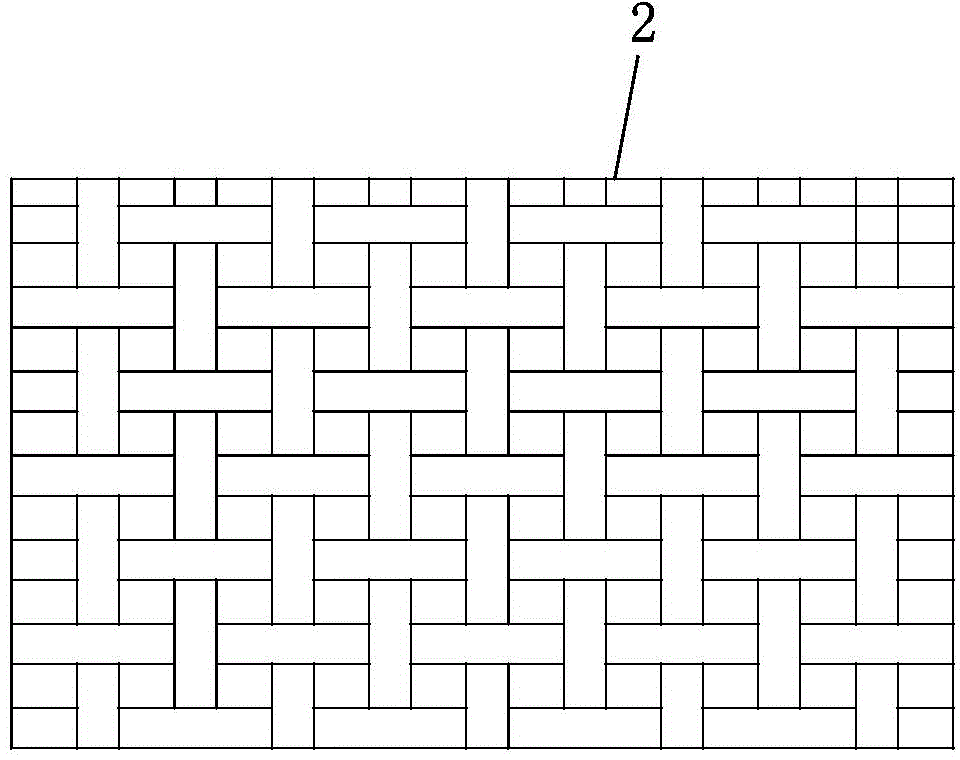

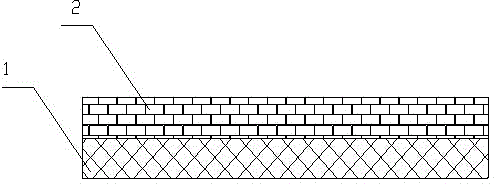

Glass fiber based asphalt shingle

InactiveCN106592875AImprove flexibilityLight weightRoof covering using tiles/slatesSynthetic resin layered productsGlass fiberAsphalt shingle

The invention provides a glass fiber based asphalt shingle which comprises a base layer, a modified petroleum asphalt layer, a coating layer, a waterproof layer, a fireproof layer and a reinforcing layer, wherein the modified petroleum asphalt layer wraps the outer side of the base layer so as to form a modified petroleum asphalt wrapped part; the coating layer and the fireproof layer are both arranged at the outer side of the modified petroleum asphalt wrapped part; the coating layer is arranged above the modified petroleum asphalt wrapped part; the fireproof layer is arranged under the modified petroleum asphalt wrapped part; the waterproof layer is arranged under the fireproof layer; the reinforcing layer is arranged between the coating layer and the modified petroleum asphalt wrapped part. The glass fiber based asphalt shingle has the advantages of different styles, heat insulation, low heat conductivity coefficient of products, sound absorption and sound insulation, colorful effect, corrosion resistance, excellent waterproof effect, dust prevention and self-cleaning effect as well as simple and convenient paving.

Owner:TIANJIN YUSHEN BUILDING WATERPROOF MATERIAL

High-strength high-sound-insulation thermoplasticity sound insulation plate and production technology thereof

The invention belongs to the technical field of sound insulation boards, and particularly relates to a high-strength high-sound-insulation thermoplasticity sound insulation plate and a production technology of the sound insulation plate. The technology comprises the following steps: (1), raw materials are taken according to the formula and are mixed at a high speed to form a composite material; (2), the prepared composite material is distributed to a spiral feeding machine to be fed; (3), the composite material is fed to a screw extrusion machine through the spiral feeding machine, and through molding of a large-opening mould of the screw extrusion machine, a sound insulation plastic plate is manufactured; (4), a twin-roller machine carries out embossing treatment on the surface of the sound insulation plastic plate manufactured in the step (3); (5), an outer layer is compounded on the outer surface of the sound insulation plastic plate; (6), rolling press polish shaping is carried out on the sound insulation plastic plate compounded with the outer layer; (7), cooling treatment is carried out; (8), the cooled sound insulation plastic plate is split and cut; (9) traction is carried out; and (10) cutting packaging is carried out. The plastic plate is manufactured through mixing machining of various high polymer materials and a performance additive, and the plastic plate has the beneficial effects of being uniform and solid in material, fireproof, flame-resistant, ageing-resistant, green and environment-friendly.

Owner:浙江富华新材料科技有限公司

Preparing method for roller-transition-slurry imitation natural stone texture tile

ActiveCN105884397AIncrease diversityThe decorative effect is clear and realisticCeramic shaping apparatusBrickSlurry

The invention discloses a preparing method for roller-transition-slurry imitation natural stone texture tile. The preparing method includes the following steps that 1, well-known raw materials for a ceramic blank are selected, ceramic pigment is added, and slurry with at least two kinds of color is prepared through wet-method ball-milling; 2, the color slurry is transited with a roller which is capable of 360-degree uninterruptedly rolling, and has the pattern hollowed-out effect and / or the transition effect; 3, the color slurry in the step 2 is unevenly mixed to obtain uneven slurry; 4, the uneven slurry is distributed on a brick blank; 5, the brick blank obtained in the step 4 is put into a kiln and sintered, and the imitation-natural-stone-texture tile is obtained. According to the preparing method, the color slurry is transited through the roller and distributed in the straight line trend or the oblique line trend according to the pattern of the roller accordingly, and the mixing degree of the color slurry can be increased; a pattern layer formed in the brick blank can be shown a plurality of different pattern textures such as strip shaped, flocculent and pinnate with the uneven mixing method accordingly, and the diversity of the decorative effect is improved.

Owner:FOSHAN DONGPENG CERAMIC +3

Hot pepper cake and preparation method

InactiveCN1915085AEasy to carryAvoid harmClimate change adaptationFood preparationMentha spicataPreservative

Owner:欧阳英华

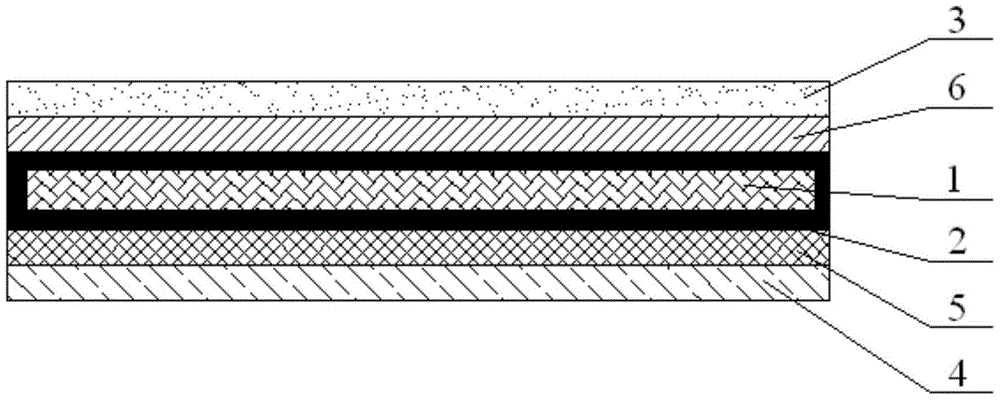

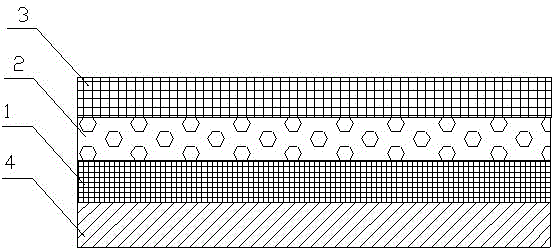

Anti-static anti-radiation fireproof composite fabric

The invention relates to an anti-static anti-radiation fireproof composite fabric which comprises a base layer (1), wherein the upper surface of the base layer is adhered with a layer of aluminum alloy thin film (2); an anti-static layer (3) is arranged on the aluminum alloy thin film and is formed by weaving warp yarns and weft yarns; the warp yarns are cotton yarns, and the weft yarns are conductive fibers; a fireproof layer (4) is arranged on the outer surface of the anti-static layer; the base layer is made of textiles; the textiles comprise a woven textile and a knit textile which are adhered together through an adhesive. The anti-static anti-radiation fireproof composite fabric is extremely high in anti-static property, radiation resistance and fire resistance. The fabric is novel and unique.

Owner:JIANGYIN BETTER TEXTILE

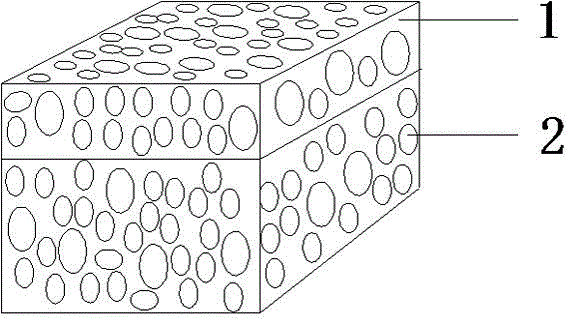

Moisture-absorbing bamboo charcoal fiber composite fabric

InactiveCN105644018AImprove breathabilityDifferent stylesSynthetic resin layered productsAdhesiveEngineering

The present invention relates to a moisture-absorbing bamboo charcoal fiber composite fabric, which comprises bamboo charcoal fibers (1), wherein a base layer (5) is compounded under the bamboo charcoal fibers, a layer of a nonwoven fabric (2) covers on the bamboo charcoal fibers, a moisture-absorbing layer (3) is arranged between the nonwoven fabric and the bamboo charcoal fibers, the base layer is made from a fabric, the fabric comprises a woven fabric and a knitting fabric, and the woven fabric and the knitting fabric are adhered through an adhesive. According to the present invention, the moisture-absorbing bamboo charcoal fiber composite fabric has good gas permeation; with the moisture-absorbing bamboo charcoal fiber composite fabric, the sweat can be timely sucked away and can be timely evaporated; and one surface of the fabric is the woven fabric, and the other surface is the knitting fabric, such that both surfaces of the prepared clothing can be used, the styles are different, and the clothing is novel and unique.

Owner:JIANGYIN SHENGDA BUILDING MATERIALS

Anti-static anti-bacterial radiation-resistant combined fabric

The invention relates to an anti-static anti-bacterial radiation-resistant combined fabric. The anti-static anti-bacterial radiation-resistant combined fabric comprises a bottom layer (4), wherein a base layer (1) is compounded on the surface of the bottom layer, the base layer is formed by warp yarns and weft yarns through connection, the warp yarns and the weft yarns are formed by nano-silver fibers through spinning, an aluminum alloy film (2) is bonded on the upper surface of the base layer through adhesive, an anti-static layer (3) is arranged on the aluminum alloy film and is formed by the warp yarns and the weft yarns through weaving, the warp yarns are formed by cotton yarns, the weft yarns are formed by conductive fibers, the bottom layer is formed by a fabric, the fabric comprises a woven fabric and a knitted fabric, the woven fabric and the knitted fabric are bonded together by the adhesive in a folded mode; one side of the fabric is the woven fabric and the other side of the fabric is the knitted fabric, both sides of the manufactured garment can be used, the styles are different, and the fabric is novel and unique.

Owner:JIANGYIN NEW QUANSHENG TEXTILE PRINTING & DYEING

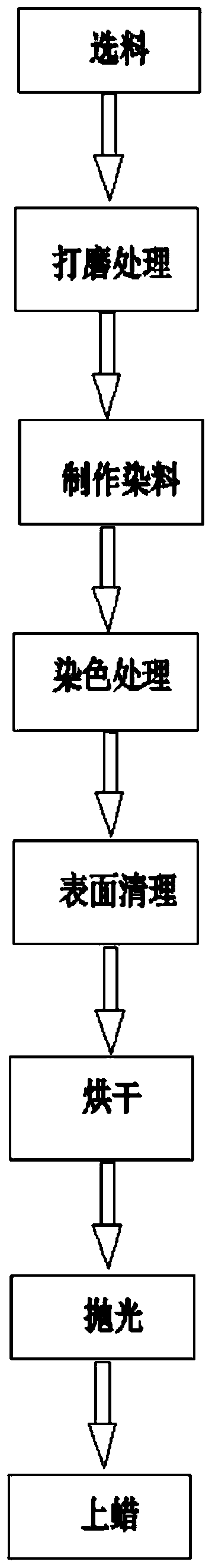

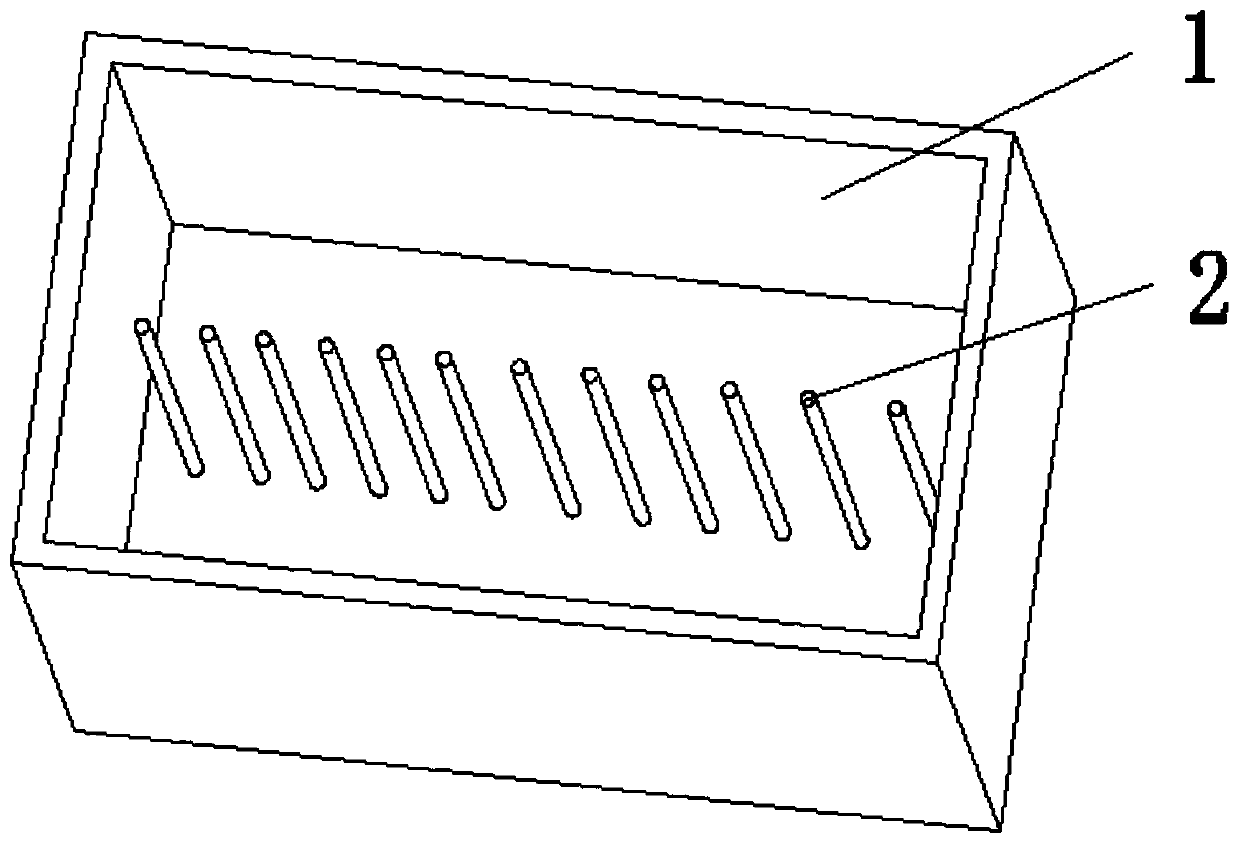

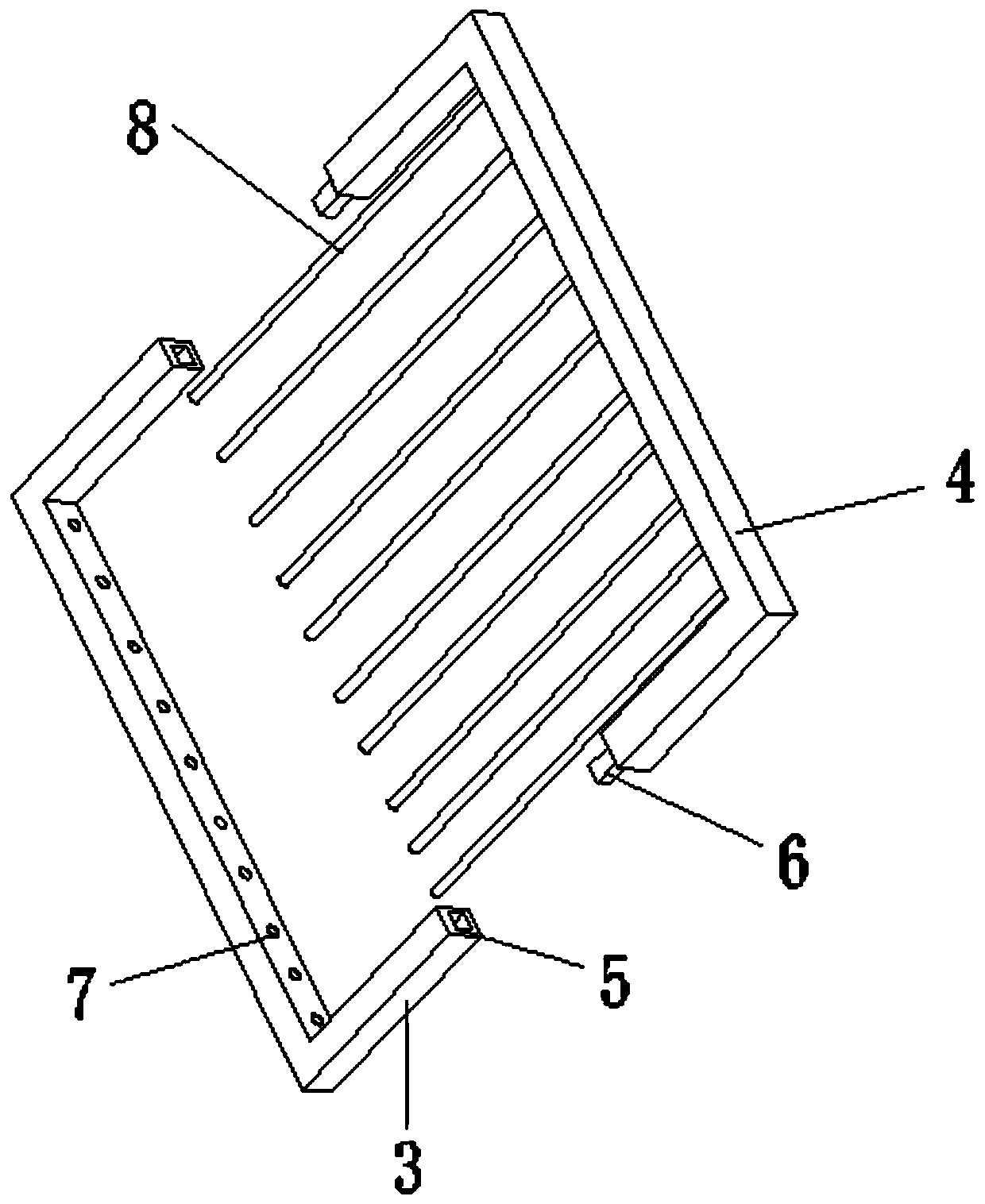

Process for treating brush pen holder

ActiveCN110394868AUniform colorNo pollution in the processWood treatment detailsCane mechanical workingSurface cleaningEngineering

The invention discloses a method for treating a defective brush pen holder. The method comprises the steps of material selection, sanding, dye preparation, dying, surface cleaning, drying, polishing and waxing; pattern polishing is carried out on rough blanks of bamboo brush pen holders; natural plant dyes made of plants capable of naturally dying are used for dyeing the rough blanks of the bamboobrush pen holders; the manufactured brush pen holders are uniform in color and luster, and have speckle patterns, so that the brush pen holders are diversified; the natural plant dyes are environment-friendly and pollution-free, and the dyed colors of the brush pen holders can be diversified according to different selected natural plants; meanwhile, the speckle patterns can be diversified according to different polished patterns; flaw parts of the rough blanks of the defective bamboo brush pen holders can be polished to remove surface flaws and then dyed, so that the rough blanks of the defective bamboo brush pen holders can be reused, the production cost is saved, and the waste is reduced; and the process is a great breakthrough in the field of brush pen holder manufacturing.

Owner:NANXUN SHANLIAN SONGBAI LAKE PEN FACTORY

Raisin agate lacquer jewel case

InactiveCN104522969AUnique color textureDifferent stylesSpecial ornamental structuresOther accessoriesLacquerEngineering

The invention relates to a raisin agate lacquer jewel case. The raisin agate lacquer jewel case comprises a case body and raisin agate, the case body is made in a shape by wood, the outer surface of the case body is engraved with grooves different in size, the raisin agate machined through cutting are bonded in the grooves respectively, and the grooves are identical with the machined raisin agate in shape and size. The grooves can be spliced into a pattern and can also be bestrewn on the outer surface of the case body, and therefore the raisin agate of various sorts is sufficiently bonded to the box in an inlaid mode, and the jewel case inlaid with stone of various colors and materials is formed.

Owner:王旭东

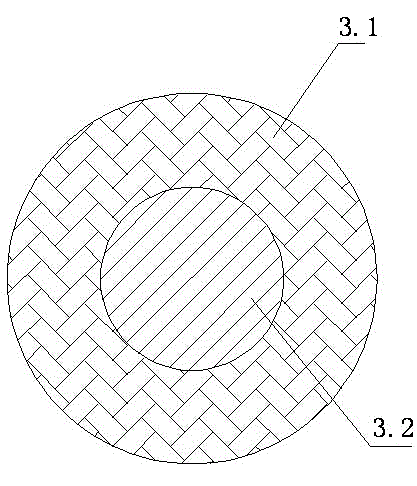

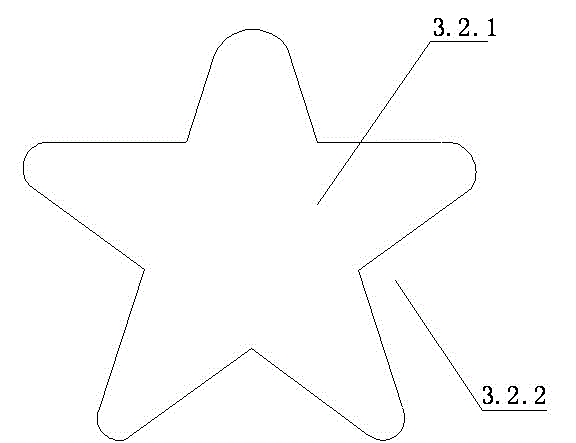

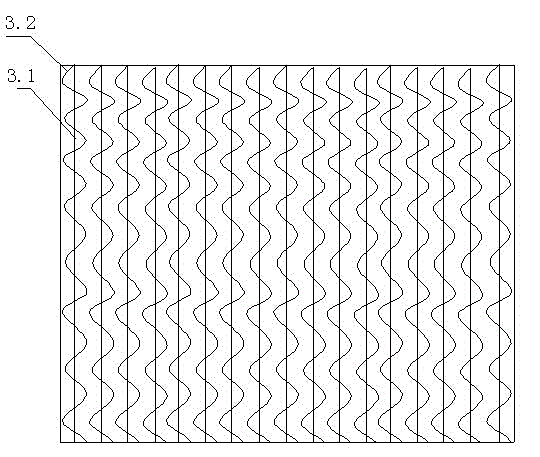

Flame retardant composite textile fabric

InactiveCN105644046AAnti-static hasSpecial rigiditySynthetic resin layered productsMetal layered productsFiberYarn

The present invention relates to a flame retardant composite textile fabric including an upper cotton cloth layer (1) and a lower cotton cloth layer (2), a base layer (5) is compounded under the lower cotton cloth layer, an anti-static layer(3) is arranged between the upper cotton cloth layer (1) and the lower cotton cloth layer (2), the anti-static layer(3) is made from core-spun yarn fiber, the core-spun yarn fiber includes a yarn (3.1) and a metal wire (3.2), the metal wire winds the yarn, the surface of the upper cotton cloth layer (1) is covered with a layer of fire-retardant coating (4), and the fire-retardant coating (4) comprises a bottom fire-retardant polyurethane layer (4.1) and a top silicone oil layer (4.2). The base layer is made of a fabric, the fabric comprises a machine-woven fabric and a knitted fabric, the machine-woven fabric and the knitted fabric are bonded together by an adhesive. The flame retardant composite textile fabric is low in cost and bending-variable. One side of the flame retardant composite textile fabric is the machine-woven fabric, and the other side of the flame retardant composite textile fabric is the knitted fabric, so that garments prepared from the flame retardant composite textile fabric can be used in both sides, and are different in styles, novel and unique.

Owner:吴建平

A kind of preparation method of imitation natural stone texture ceramic tile of screen transition slurry

ActiveCN105729626BPromote formationThe effect is clear and vividAuxillary shaping apparatusSurface layering apparatusScreen printingSlurry

The invention discloses a method for preparing a natural-like stone texture ceramic tile by utilizing screen printing transitioned slurries. The method comprises the following steps: (1) selecting a known ceramic body raw material, adding ceramic pigments, and preparing slurries of at least two colors through wet ball-milling; (2) transitioning the prepared colored slurries by utilizing a screen printing plate which has a hollowed-out pattern and / or a transition effect; (3) non-uniformly mixing the transition colored slurries obtained in step (2), so as to obtain a non-uniform slurry; (4) applying the non-uniform slurry to a ceramic body; and (5) feeding the slurry-applied ceramic body obtained in step (4) into a kiln for ceramic tile firing. As the colored slurries are transitioned by utilizing the screen printing plate, the method provided by the invention is simple and effective, and the pattern of the prepared ceramic tile can be formed conveniently; and by means of non-uniform mixing, strip crosses can be formed between or among the colored slurries or the colored slurries can be mixed in a staggered manner, so that strip, flocculence, pinniform and several other different pattern textures can be displayed on a pattern layer formed on the ceramic tile body, and the decorative effect diversity can be improved.

Owner:FOSHAN DONGPENG CERAMIC +3

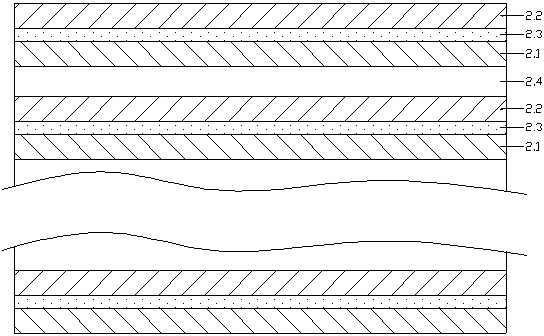

A kind of preparation method of imitation natural stone texture tile of uneven mixing

A preparing method of a nonuniformly mixed tile with imitated natural stone textures is disclosed. The method includes (1) selecting raw materials well known in the art for a ceramic blank, adding a ceramic color material, and preparing slurry with at least two colors through wet method ball milling, (2) nonuniformly mixing the slurry at a pre-mixing platform to obtain nonuniform slurry, (3) stirring the nonuniform slurry with a spiral roller and / or a mace which are disposed at the tail end of the pre-mixing platform, (4) applying a tile blank with the stirred nonuniform slurry obtained in the step (3) to form a pattern layer, and (5) putting the tile brick obtained in the step (4) into a kiln and firing to obtain the tile with the imitated natural stone textures. Through nonuniformly mixing the nonuniform slurry, the mixing degree of the nonuniform slurry is increased, the pattern layer formed through applying the tile blank with the nonuniform slurry can show striped pattern textures, flocculent pattern textures, penniform pattern textures, and other different pattern textures, and diversity of decoration effects is increased.

Owner:FOSHAN DONGPENG CERAMIC +3

A kind of preparation method of imitation natural stone texture tile

ActiveCN105819904BGood blendingThe decorative effect is clear and realisticNatural stoneMaterials science

The invention provides a preparation method of tiles with imitated natural stone grains.The preparation method comprises the following steps that 1, color pastes are prepared, wherein the pastes of at least two colors are prepared by selecting common raw materials for ceramic bodies and adding ceramic pigments through wet ball milling; 2 premixing is conducted, wherein the color pastes are unevenly mixed to obtain an uneven paste; 3, the uneven paste is applied to tile green bodies to form pattern layers; 4, the tile green bodies obtained in the step 3 are placed in a kiln for sintering, and then the tiles with the imitated natural stone grains are obtained.According to the preparation method, strip-shaped intersection or staggered mixing is formed between the color pastes through an uneven mixing method, the paste is applied to the pattern layers formed on the tile green bodies, multiple different pattern grains such as a strip shape, a flocculent shape and a pinnate shape can be presented, the prepared tiles with the imitated natural stone grains have the decorative effects of different patterns and lines, the grains are rich and diverse, different in style and clear and vivid in effect, and therefore the diversity of the decorative effect is improved.

Owner:FOSHAN DONGPENG CERAMIC +3

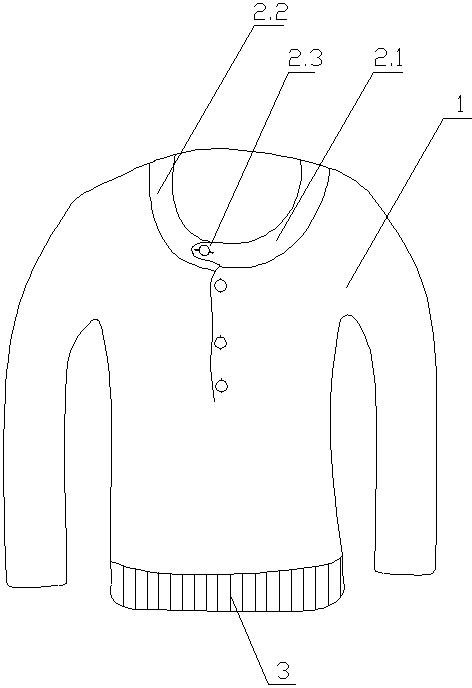

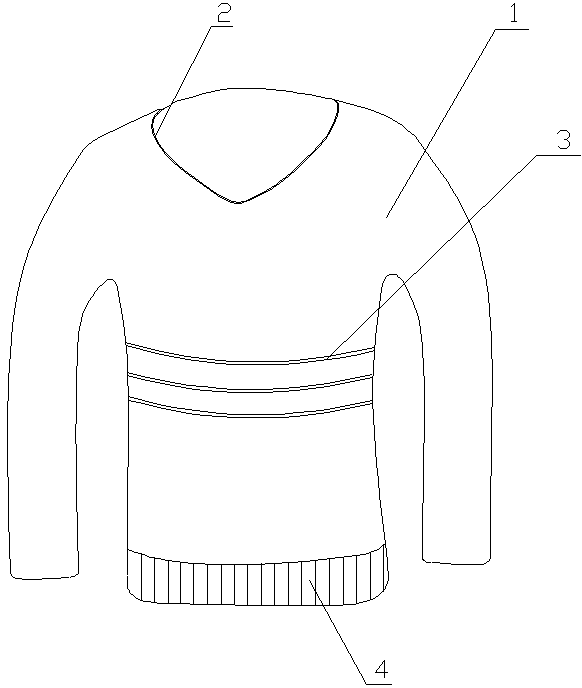

Warm-keeping and attractive men's cashmere sweater made of composite fabric

InactiveCN104336943AAdd dimensionAesthetically pleasingGarment special featuresProtective garmentEngineeringWoven fabric

The invention relates to a warm-keeping and attractive men's cashmere sweater made of composite fabric. The warm-keeping and attractive men's cashmere sweater comprises a sweater body (1) which is made of cashmere, sleeves are made of fabric, a collar of the sweater body (1) comprises a left collar opening (2.1) and a right collar opening (2.2), one end, close to the right collar opening (2.2), of the left collar opening (2.1) extends to form a warm-keeping piece (2.3) which is located above the right collar opening (2.2), a button hole is formed in the warm-keeping piece (2.3), and a button matched with the button hole is arranged on the right collar opening (2.2); the fabric includes woven fabric and knitted fabric, and the woven fabric and the knitted fabric are bonded together through bonding agents. The warm-keeping and attractive men's cashmere sweater have good warm-keeping performance on the throat after worn, and the fabric adopted is novel and unique.

Owner:JIANGYIN SHENGDA BUILDING MATERIALS

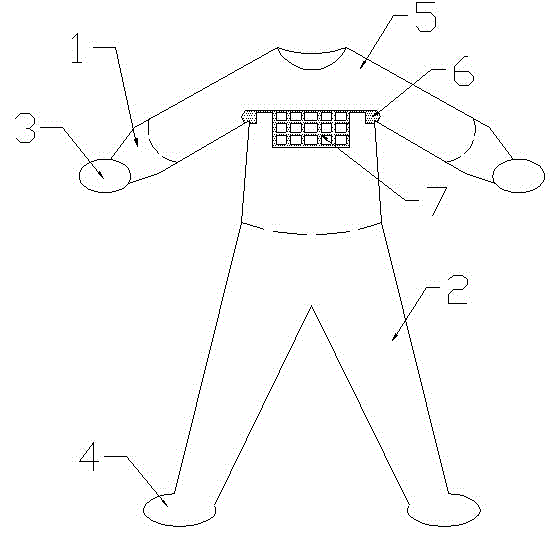

Composite fabric oil rub resistant garment

InactiveCN104305607AAvoid contaminationEasy to scrubProtective garmentSpecial outerwear garmentsEngineeringActive carbon

The invention relates to a composite fabric oil rub resistant garment which comprises a garment body and a garment lining (5), wherein the oxter parts of the garment lining (5) are respectively provided with a layer of active carbon fabric (6); the active carbon fabrics (6) form a grid type net (7) at the chest part of the garment lining (5). The garment body is made of fabrics which comprise an organic woven fabric and a knitted fabric; the organic woven fabric and the knitted fabric are bonded together by a binding agent. The composite fabric oil rub resistant garment provided by the invention can prevent sweat from depositing at oxter parts, and can effectively prevent bacteria and peculiar smell from generating. One side of the fabric is the organic woven fabric and the other side of the fabric is the knitted fabric, both sides of manufactured garment can be used, so that the styles are different, and the garment is novel and unique.

Owner:JIANGYIN YUEDA DYEING & PRINTING

Fine-ductility combined fabric women's cashmere sweater

InactiveCN104336884AImprove toughnessImprove tensile propertiesGarment special featuresLayered productsAdhesiveEngineering

The invention relates to a fine-ductility combined fabric women's cashmere sweater which comprises a sweater body (1). A body of the sweater body is made of cashmere, sleeves of the sweater body are made of fabrics, a first reinforcing strip (2) is arranged at a neckline of the sweater body (1), a plurality of second reinforcing strips (3) are arranged at the waist of the sweater body (1) in wearing, strip projections are vertically arranged at a lower hem (4) of the sweater body (1), the fabrics include woven fabrics and knitted fabrics, and the woven fabrics and the knitted fabrics are folded and adhered together through adhesives. The cashmere sweater is long in service life, the woven fabrics are arranged on one surface of each fabric, the knitted fabrics are arranged on the other surface of each fabric, two surfaces of the made garment can be used, and the cashmere sweater has different styles and is novel and unique.

Owner:JIANGYIN CHUNLAN TEXTILE

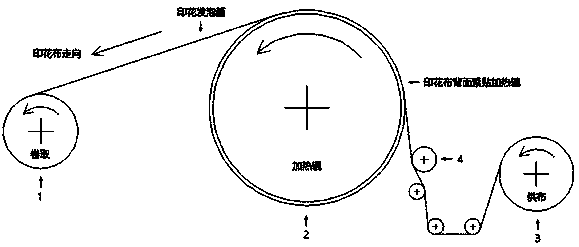

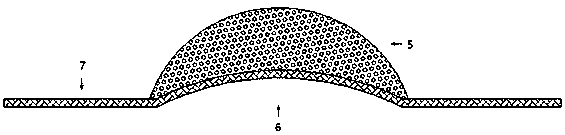

Three-dimensional foaming printing process

The invention discloses a three-dimensional foaming printing process. The three-dimensional foaming printing process is characterized in that a to-be-printed fabric is transported under a continuously moving screen, foaming printing pulp is modulated according to the three-dimensional effect of a flower pattern, and the foaming printing pulp is prepared from an adhesive, a filler, a plasticizer, a stabilizer, a foaming agent and a regulator; the adhesive is a copolymer emulsion of ethyl acrylate and styrene, or a copolymer emulsion with poly(butyl acrylate) as the main body; printed cloth is subjected to cloth baking process with the drying temperature of 70-80DEG C; the hot ironing process is performed finally, a heating roller of a press-polishing machine is used, the printed face of the printed cloth is taken as the front face, the reverse side of the printed cloth is attached to the heating roller, the wrapping angle of the printed cloth to the heating roller is adjusted to be 100-150 degrees, the baked printed cloth passes through an opening roller to be attached to the heating roller to be ironed in constant temperature, the temperature of the heating roller is adjusted to be 160-180DEG C, the operation speed is 10-20m / min, natural cooling is performed, and the printed cloth is then coiled to a coiling roller. By means of the special foaming color paste for printing, the reverse side of the printed cloth is closely attached to the heating roller, the wrapping angle is adjusted, the temperature of the heating roller is controlled, the three-dimensional foaming effect of printing is realized, and the printed cloth is coiled to the coiling roller after natural cooling.

Owner:WUJIANG FUHUA WEAVING

Composite fabric waterproof warm-keeping fabric

InactiveCN105619978AGood warmth retentionGuaranteed warmthSynthetic resin layered productsAdhesiveEngineering

The invention relates to a composite fabric waterproof warm-keeping fabric. The composite fabric waterproof warm-keeping fabric sequentially comprises an outer layer (1), a fabric layer (2) and an inner layer (3); the outer layer (1) and the fabric layer (2) are stitched; the outer layer (1) is a windproof waterproof breathable film; the fabric layer (2) is a fabric; the inner layer (3) is a warm-keeping layer; the fabric comprises a woven fabric and a knitted fabric which are paired and bonded together through an adhesive. The composite fabric waterproof warm-keeping fabric has a water-proof effect, and the warm-keeping effect of clothing is good. The woven fabric is arranged on one side of the fabric, and the knitted fabric is arranged on the other side of the fabric, clothes made by the waterproof warm-keeping fabric can be used on two sides to show different styles, and accordingly, good novelty is realized.

Owner:周忠平

Composite fabric garment capable of filtering air

InactiveCN104287220ATo achieve the effect of purifying the airDifferent stylesLayered productsFire rescueRespiratorAir filter

The invention relates to a composite fabric garment capable of filtering air. The composite fabric garment comprises a garment body (1). A mask (2) is arranged on the neckline of the garment body (1). A filter box (3) is arranged on a pocket and filled with active carbon granules. The mask (2) and the filter box (3) are connected through a hose (4). The garment body (1) is made of a fabric. The fabric is formed by first yarns and second yarns. The first yarns and the second yarns sequentially form loops in the weft yarn direction of the fabric body, are alternately and longitudinally crossed and sleeved in sequence to form the fabric body of a weft knitted structure, protruding strips are arranged on the front face of the fabric body, and the protruding strips are formed by knitting the first yarns and the second yarns. The composite fabric garment can achieve the long-term air filtering effect.

Owner:JIANGYIN SHENYING KNITWEAR & TEXTILE

Anti-static waterproof thermal composite material

InactiveCN104385737AGood warmth retentionGuaranteed warmthSynthetic resin layered productsInsulation layerAdhesive

The invention relates to an anti-static waterproof thermal composite material. The anti-static waterproof thermal composite material sequentially comprises an outer layer (1), a fabric layer (2) and an inner layer (3), wherein the outer layer (1) and the fabric layer (2) are stitched; the outer layer (1) is a windproof water-resistant breathable film; the fabric layer (2) is a fabric; the inner layer (3) is an insulation layer; an anti-static layer (4) is arranged between the inner layer (3) and the fabric layer (2) and formed by weaving warp yarns and weft yarns; the fabric comprises a woven fabric and a knitted fabric which are paired and bonded through an adhesive. The anti-static waterproof thermal composite material has a water-proof thermal effect. As one side of the fabric is the woven fabric, and the other side of the fabric is the knitted fabric, clothes made by the anti-static waterproof thermal composite material can be used on two sides to show different styles, and accordingly, good novelty is realized.

Owner:JIANGYIN CHENGXIN SPECIAL PRINTING

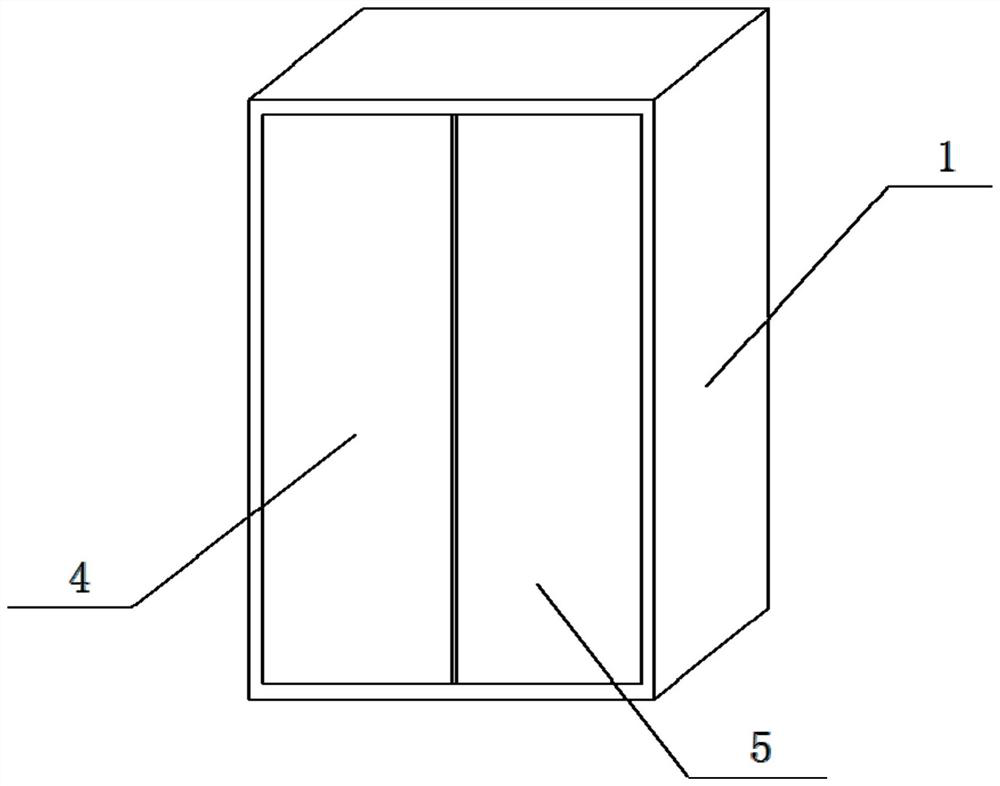

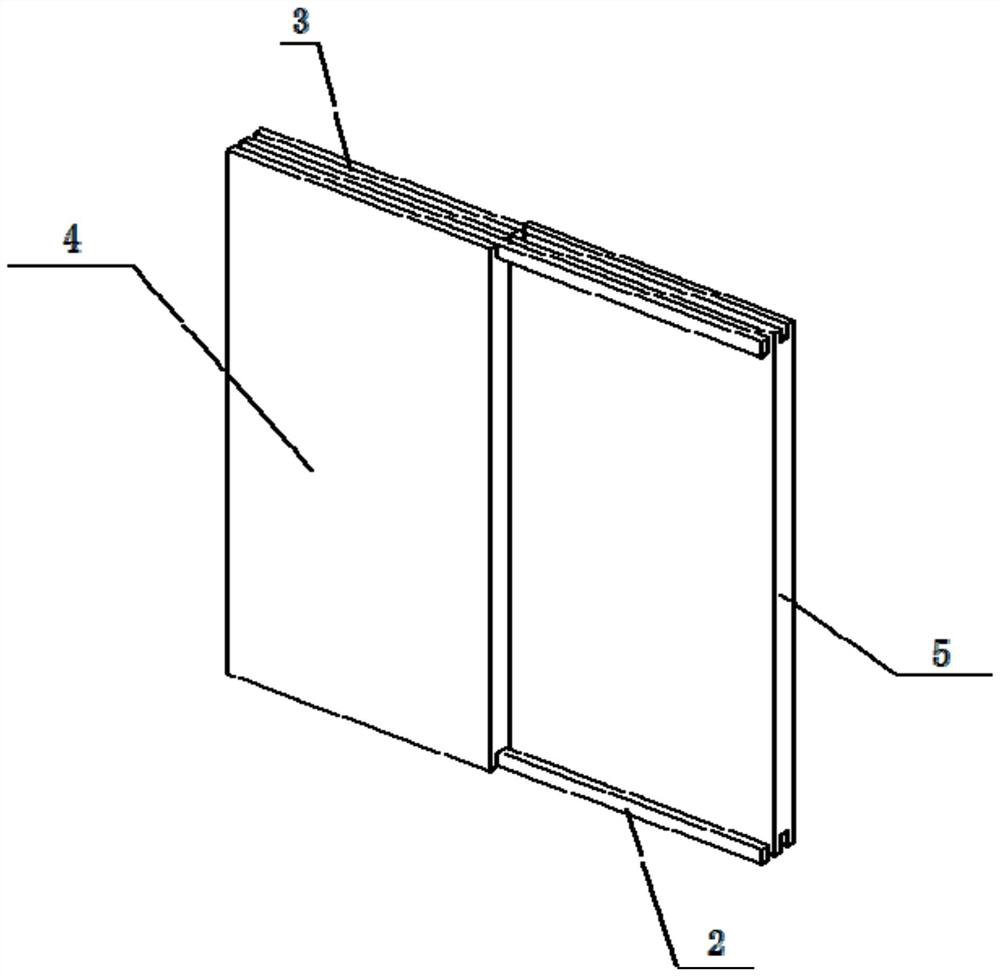

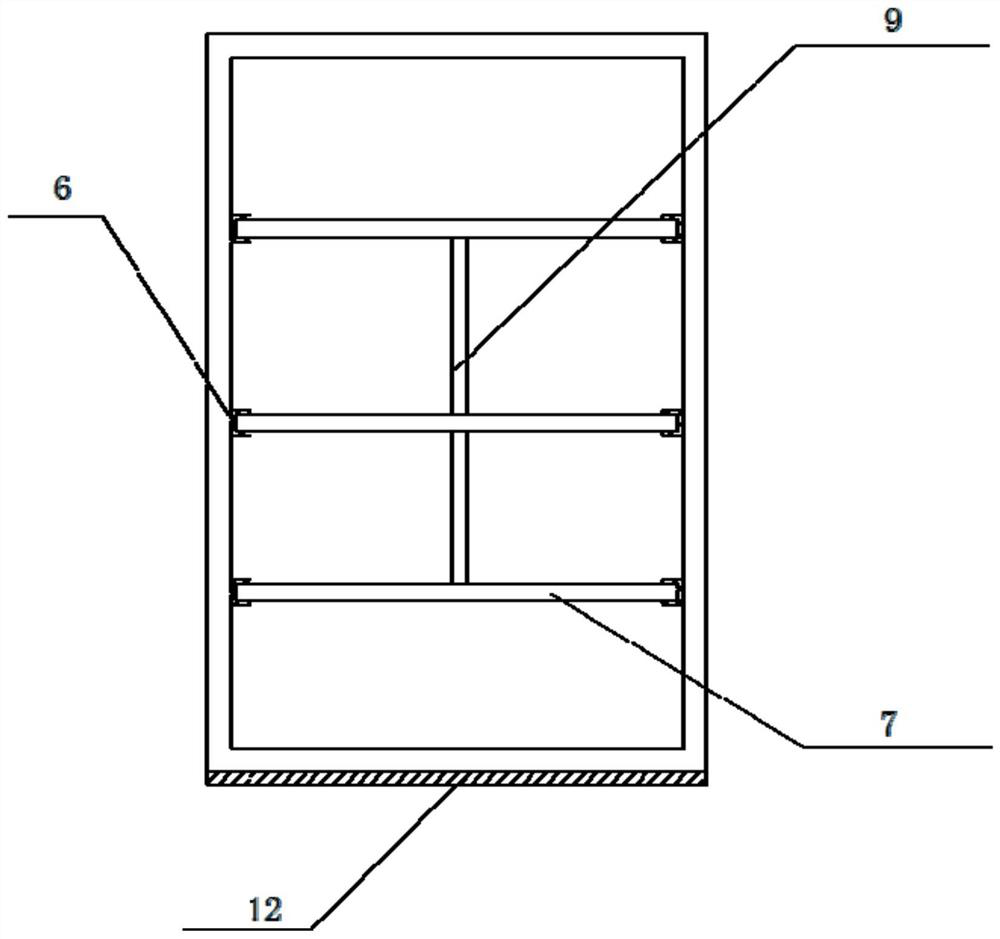

All-wood storage cabinet with sliding door

InactiveCN111839025AEasy to fixEasy to disassembleCabinetsWork tools storageHazardous substanceDust control

The invention discloses an all-wood storage cabinet with a sliding door. The cabinet comprises a cabinet body, and first rails are arranged at the positions, close to the front face, of the bottom andthe top of an inner cavity of the cabinet body. The back surfaces of the first rails are fixedly connected with second rails; a first sliding door is movably clamped in the inner cavities of the clamping grooves of the first rails; a second sliding door is movably clamped in the inner cavities of the clamping grooves of the second rails; the side surface of the inner cavity of the cabinet body isfixedly connected with an aluminum alloy clamping groove; a transverse plate is fixedly connected to the inner cavity of the aluminum alloy clamping groove; a first bayonet is formed in the inner cavity of the transverse plate; a vertical plate is clamped in the inner cavity of the first bayonet; and a second bayonet is formed in the inner cavity of the vertical plate. As is well known, dust in the cabinet body is difficult to clean up, and a dust removal gap is reserved between the transverse plate and the back plate, so the dust on the upper portion can be easily cleaned up to the lowest layer and then swept away; and ecological plates are adopted as base materials of the whole storage cabinet, so paint is avoided, emission of toxic and harmful substances caused by paint is reduced, andthe storage cabinet is more environmentally friendly.

Owner:宜兴市柏霖家居有限公司

Antistatic composite fabrics

InactiveCN105624879AImprove securityImprove performanceWeft knittingLayered productsYarnAntistatic agent

The invention relates to antistatic composite fabrics, which comprises a base layer (1); an antistatic layer (2) is arranged on the surface of the base layer (1); the antistatic layer (2) is made by weaving a warp yarn and a filling yarn, wherein the warp yarn is cotton yarn and the filling yarn is conductive fiber; the conductive fiber is striped in a spacing of 5-10mm; the base layer is made of fabrics; the fabrics comprises woven fabrics and knitted fabrics; and the woven fabrics and the knitted fabrics are bonded together by an adhesive. A good antistatic performance is provided. The clothes made by the fabrics can be worn in two sides with different styles. The clothes is novel and distinguished.

Owner:吴孟涛

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com