Production process of pressure formed hollow handle of metal plate

A technology of sheet metal and production technology, which is applied to metal processing equipment, spherical handles of wing fans, handles of wing fans, etc., and can solve problems such as excessive material consumption, difficult processing, and long production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

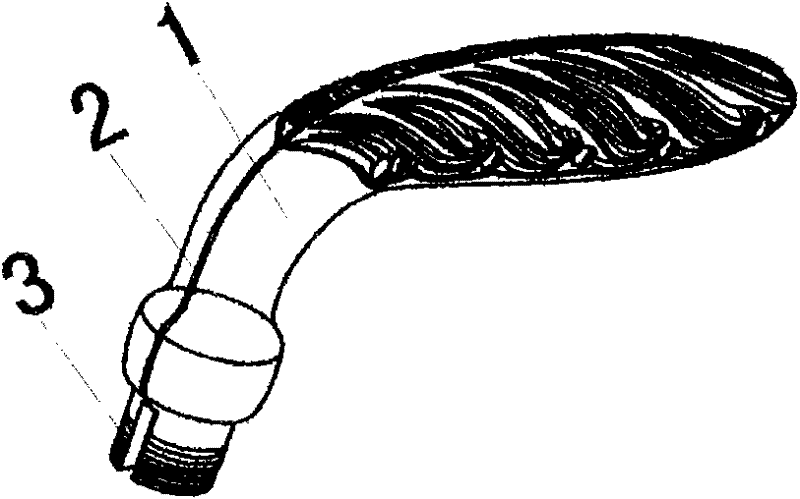

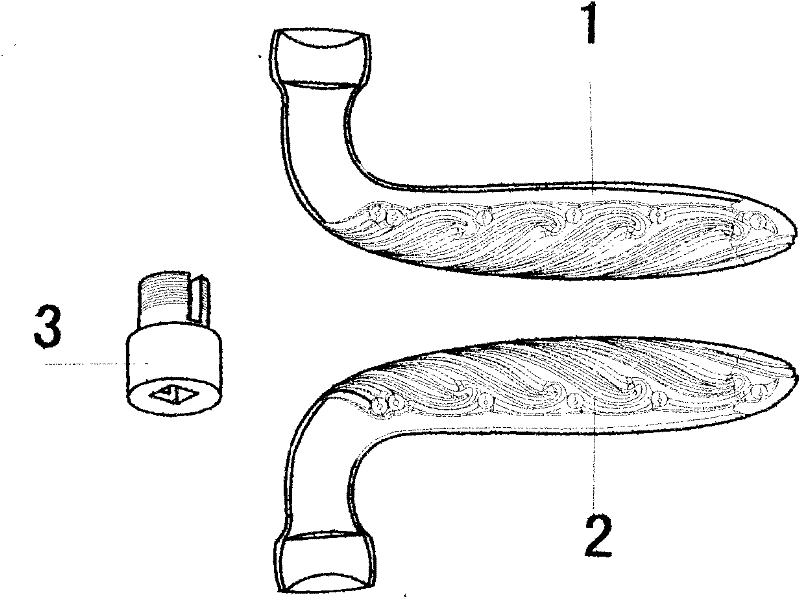

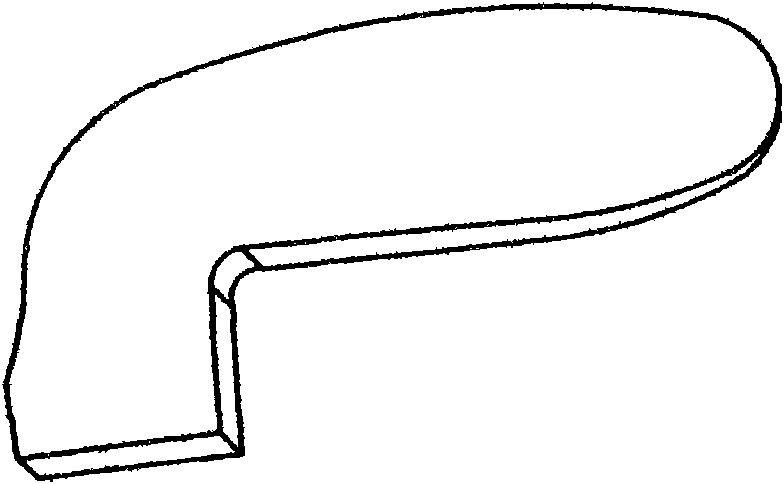

[0014] 1. An example: a hollow lock handle formed by pressure forming of a brass plate, the thickness of the plate: 1.20mm, refer to the "Instructions Attached Figure 1 " figure 1 , figure 2 , image 3 , which comprises a handle lower shell (1), a handle upper shell (2), and a handle head (3), the steps are as follows:

[0015] A. According to the shape of the hollow lock handle formed by the pressure forming of the metal sheet, disassemble and design the composite structure of the hollow lock handle: handle lower shell (1), handle upper shell (2), handle head (3), and calculate the lower handle The blank size of the shell and the upper shell of the handle (4);

[0016] B. Make corresponding stretching molds and cutting molds respectively according to the shape of the handle lower shell and the handle upper shell;

[0017] C. Use the cutting die to apply pressure to the metal sheet and cut it into a lower handle shell sheet blank and a handle upper shell sheet blank. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com