High-strength high-sound-insulation thermoplasticity sound insulation plate and production technology thereof

A production process and high-strength technology, applied in the field of sound-proof panels, can solve the problems of high strength, inconvenient construction, and high cost, and achieve the effect of uniform and solid materials and improved aesthetics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

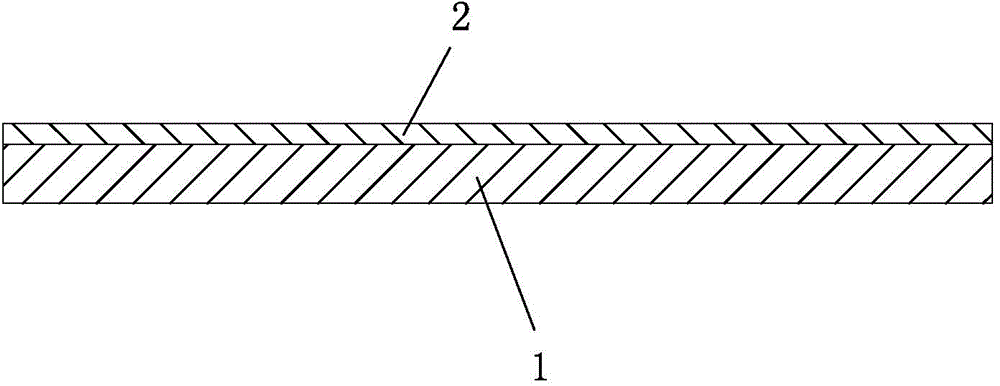

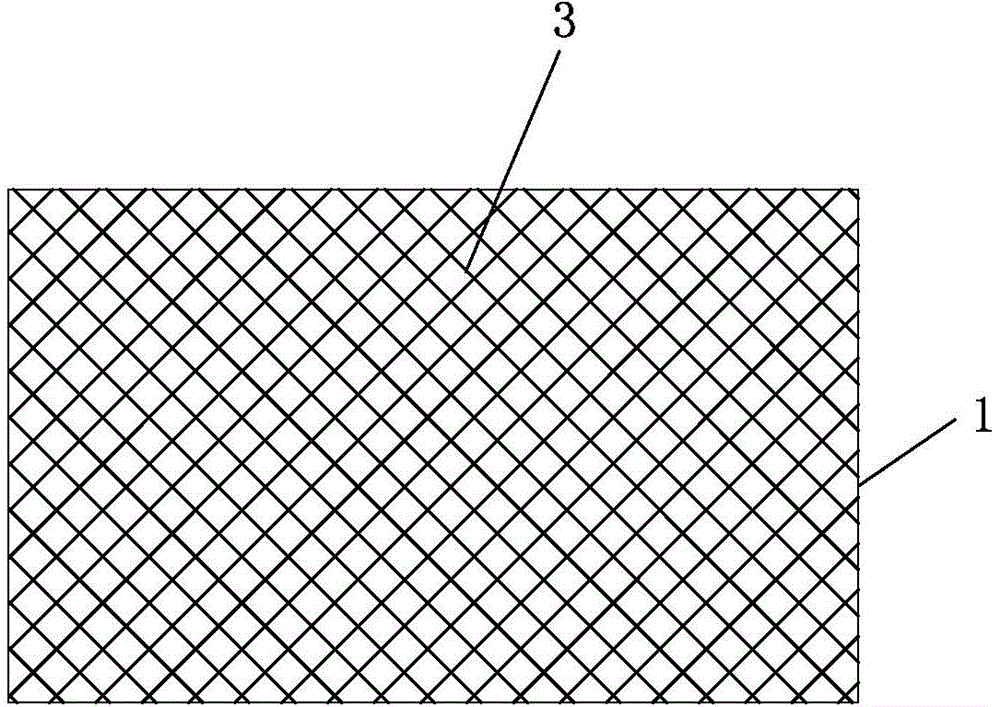

[0035] The present invention will be further described below with specific embodiment, see figure 1 —3:

[0036] A production process of a high-strength and high-sound-insulation thermoplastic sound-insulating board, comprising the following steps:

[0037] (1) Take raw material PVC resin, plasticizer, stabilizer, sound insulation function body, processing aid, flame retardant according to the formula and carry out high-speed mixing to form synthetic material;

[0038] (2) distributing the synthetic material prepared in step (1) to the screw feeder;

[0039] (3) The screw feeder sends the synthetic material to the screw extruder, and forms the sound-insulating plastic board 1 through the large die of the screw extruder;

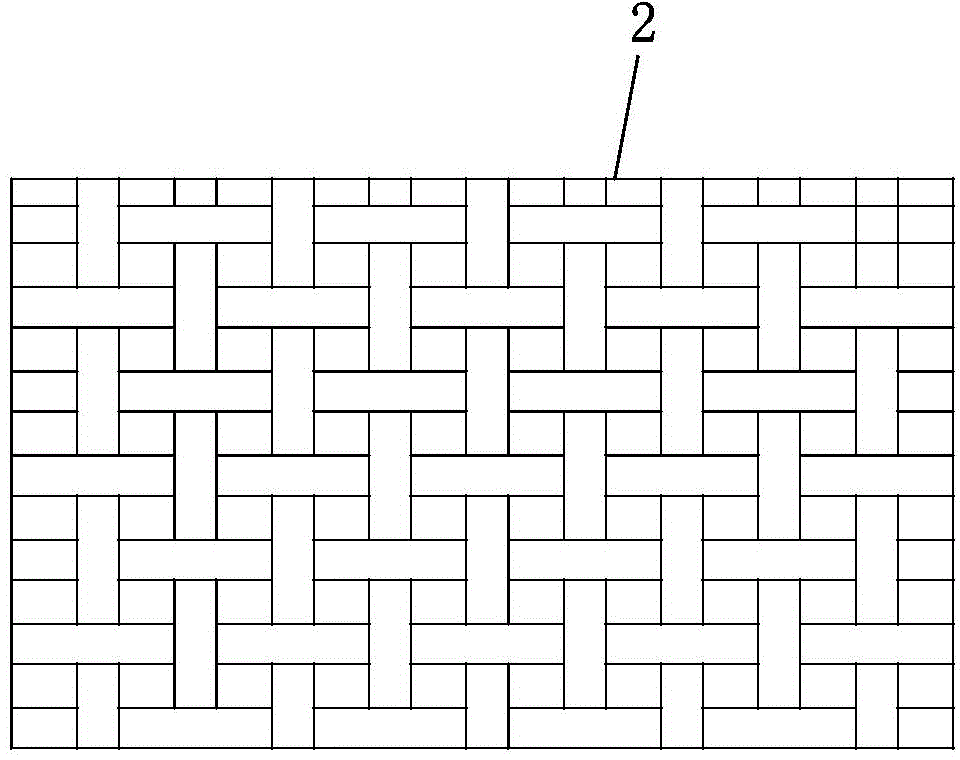

[0040] (4) embossing the surface of the sound-insulating plastic plate prepared in step (3) by a roller machine;

[0041] (5) an outer layer 2 is compounded on the outer surface of the sound-insulating plastic plate after step (4);

[0042] (6) rolling th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com