Three-dimensional foaming printing process

A printing process and three-dimensional technology, applied in the field of three-dimensional foam printing process, can solve the problem of insufficient three-dimensional printing, and achieve the effect of different styles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] A three-dimensional foaming printing process of the present invention adopts flat screen printing or rotary screen printing process according to the pattern plate making, the printed fabric is transported under the constantly moving screen, and the foaming printing paste is prepared according to the three-dimensional effect required by the pattern , the proportion of foaming color paste for printing according to the mass percentage:

[0033] Adhesive 40%;

[0034] Filling material 15%;

[0035] Plasticizer 35%;

[0036] Stabilizer 2%;

[0037] Foaming agent 2%;

[0038] Regulator 0.5%;

[0039] The mesh number of the printing screen is 80 mesh (the specific value depends on the pattern and fineness), and the printing speed is 20m / min;

[0040] Then carry out the drying process on the printed cloth: the drying temperature is 70°C;

[0041] Finally, perform the blanching process:

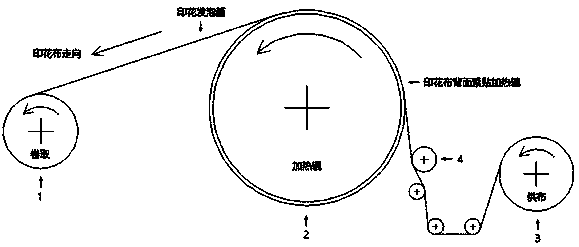

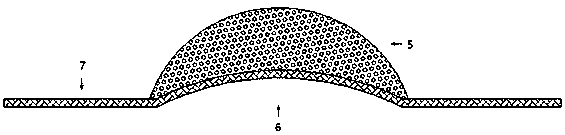

[0042] The fabric calender is used as the hot-foaming equipment, and only the heatin...

Embodiment 2

[0045] A three-dimensional foaming printing process of the present invention adopts flat screen printing or rotary screen printing process according to the pattern plate making, the printed fabric is transported under the constantly moving screen, and the foaming printing paste is prepared according to the three-dimensional effect required by the pattern , the proportion of foaming color paste for printing according to the mass percentage:

[0046] Adhesive 42%;

[0047] Filling material 18%;

[0048] Plasticizer 36%;

[0049] Stabilizer 2.1%;

[0050] Foaming agent 2.2%;

[0051] Regulator 1%;

[0052] The mesh number of the printing screen is 100 mesh (the specific value depends on the pattern and fineness), and the printing speed is 30m / min;

[0053] Then dry the printed cloth: the drying temperature is 70-80°C;

[0054] Finally, perform the blanching process:

[0055] The fabric calender is used as the hot-foaming equipment, and only the heating roller of the calend...

Embodiment 3

[0058] A three-dimensional foaming printing process of the present invention adopts flat screen printing or rotary screen printing process according to the pattern plate making, the printed fabric is transported under the constantly moving screen, and the foaming printing paste is prepared according to the three-dimensional effect required by the pattern , the proportion of foaming color paste for printing according to the mass percentage:

[0059] Adhesive 45%;

[0060] Filling material 20%;

[0061] Plasticizer 38%;

[0062] Stabilizer 2.2%;

[0063] Foaming agent 2.5%;

[0064] Regulator 2%;

[0065] The mesh number of the printing screen is 120 mesh (the specific value depends on the pattern and fineness), and the printing speed is 40m / min;

[0066] Then carry out the drying process on the printed cloth: the drying temperature is 80°C;

[0067] Finally, perform the blanching process:

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com