Combined water tap

A combined type and faucet technology, applied in valve details, engine components, valve housing structure, etc., can solve the problems of not conforming to the development and construction of a conservation-oriented society, complex casting process of blank production, high energy consumption, etc., and achieve easy appearance modeling , easy assembly and low material consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

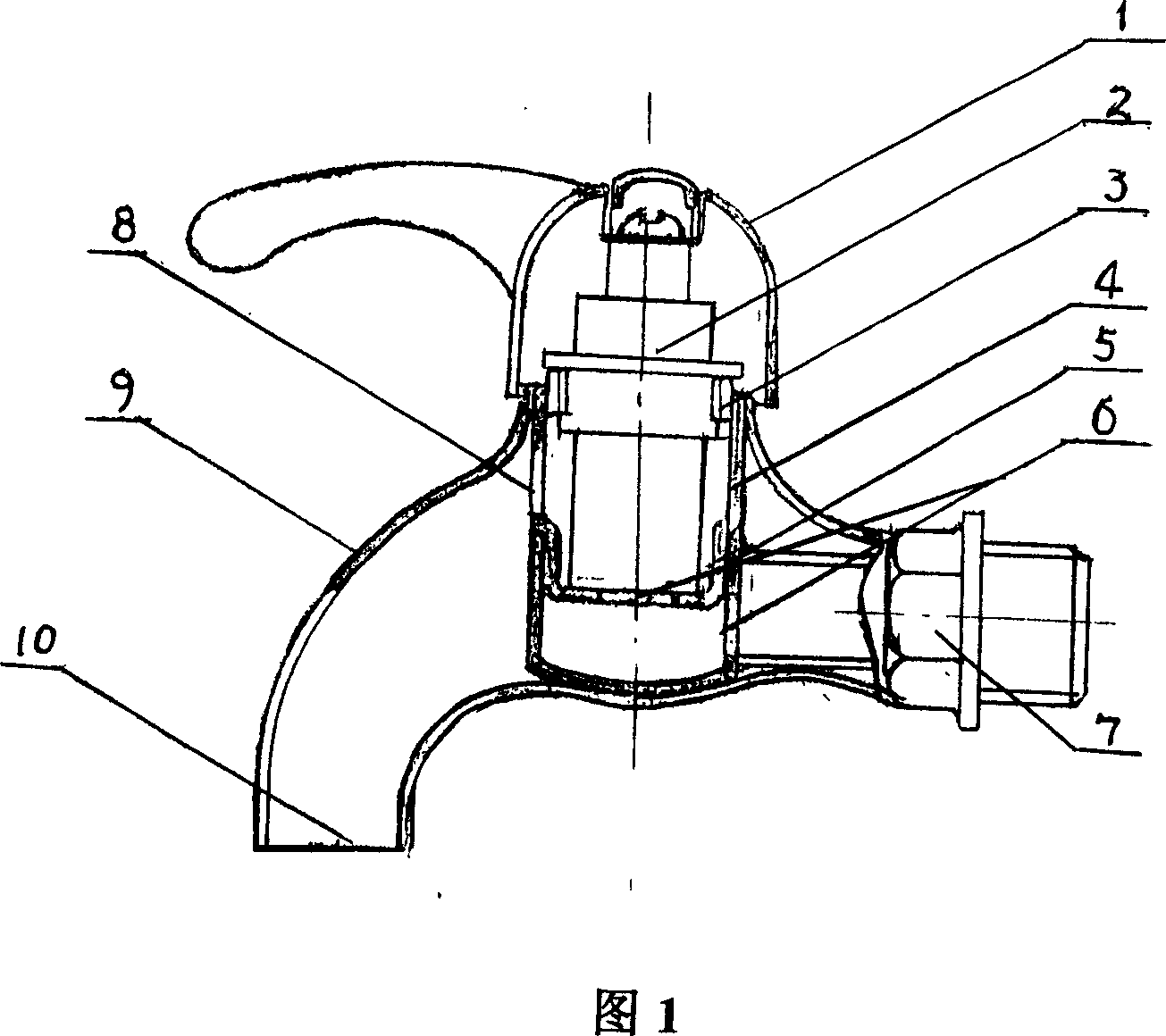

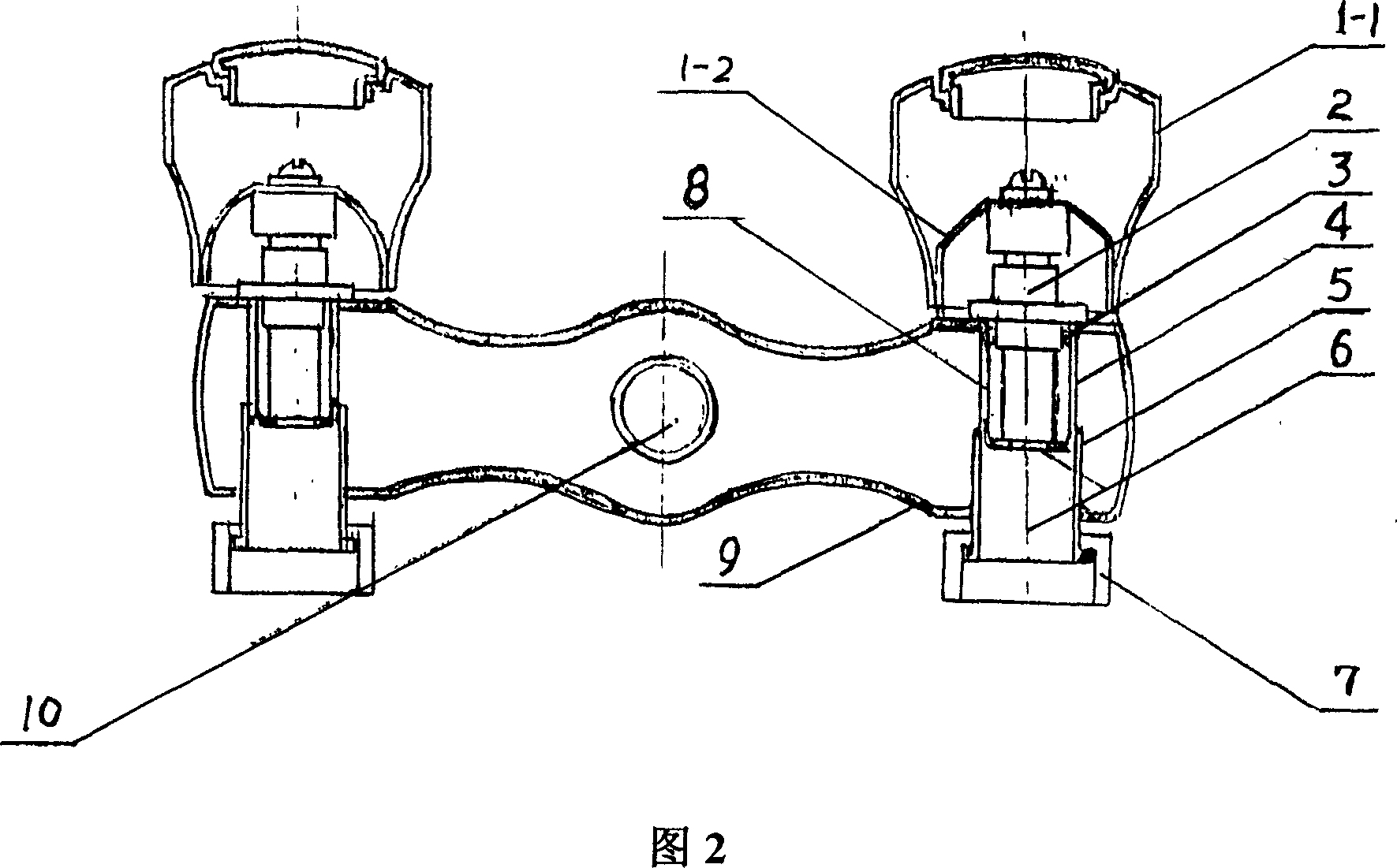

[0012] The content of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0013] Figure 1 shows a combined faucet structure with an appearance, which consists of handle 1, faucet housing 9, valve core seat and ceramic valve core 2. The handle 1, faucet housing 9 and valve core Seats are stamped and formed from stainless steel sheets. The handle 1 is an integral part formed by stamping and forming of stainless steel, and is directly connected with the valve core 2 through screws and inner tooth sleeves. The valve core seat is composed of a valve core fixed sleeve 4 and a water inlet sleeve 5 stamped and formed by stainless steel. The upper end of the valve core fixed sleeve 4 is threadedly connected with the outer shell of the valve core 2 through a welded connection nut 3, and the lower part is welded with the water inlet sleeve 5. The side wall of water jacket 5 has the water inlet hole 6 that communicates with water inlet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com