Cashew nut oil modified alkyd resin moulding material and preparation method thereof

A technology of phenolic resin and cashew nut shell oil, which is applied in the field of cashew nut shell oil modified phenolic resin molding compound and its preparation, can solve the problems of poor strength, use and development, high brittleness, etc., and achieve short molding time and good impact resistance , economic and social benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

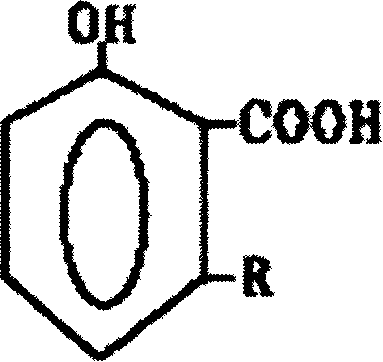

Method used

Image

Examples

Embodiment Construction

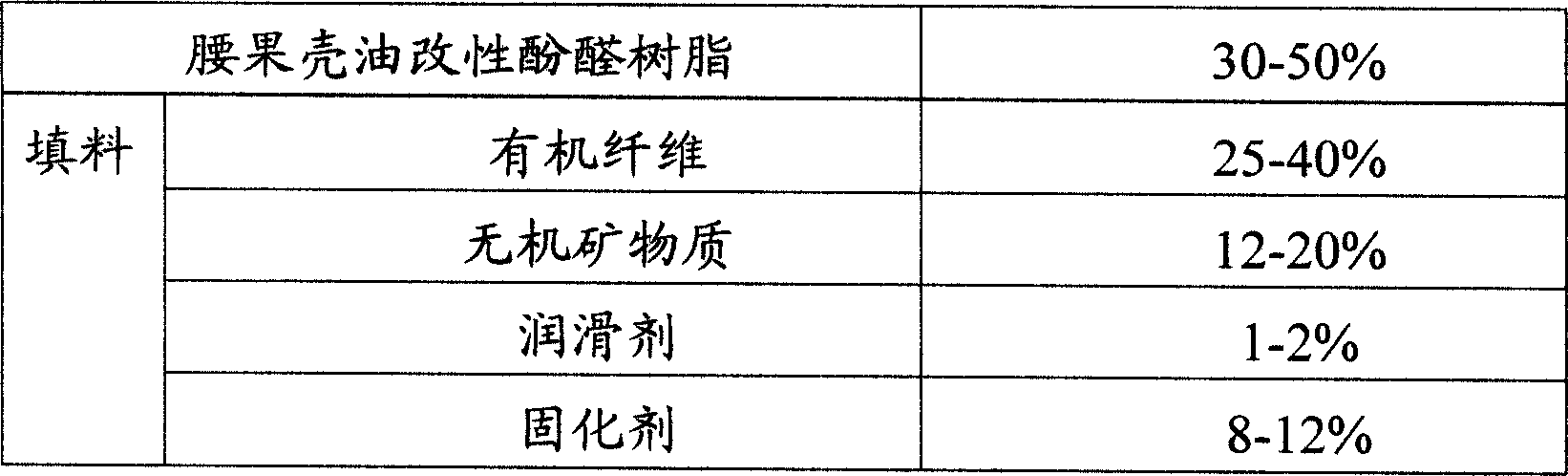

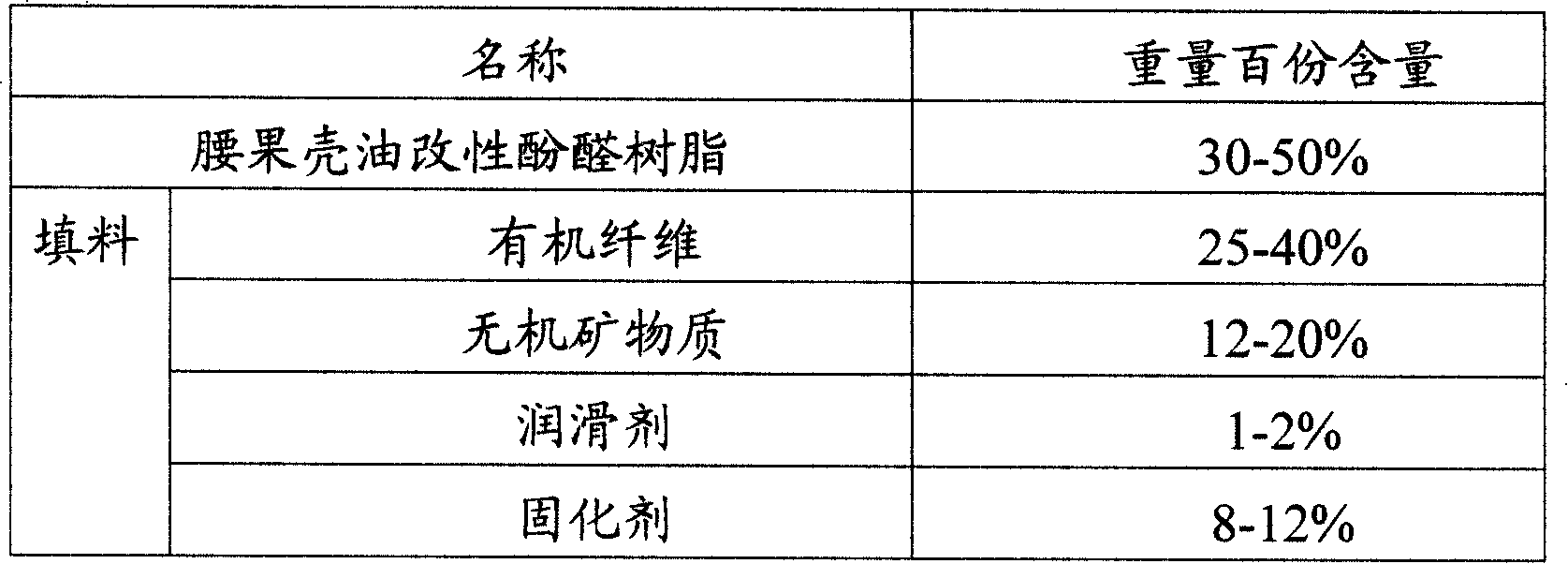

[0018] The cashew nut shell oil modified phenolic resin is crushed and mixed with other materials according to the above formula 1 and 2, masticated in the range of 100-120°C, reacted for 3-5 minutes, cooled, crushed, mixed and packaged, which is the finished product.

[0019] The result of the test according to GB1404-1995 after the above-mentioned formula is sampled is as follows, wherein embodiments 1 and 2 are respectively according to the finished products of the above-mentioned formula 1 and 2:

[0020]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com