Inorganic silver-impregnated antibiotic zeolite microparticles retention agent, method of producing the same and applications

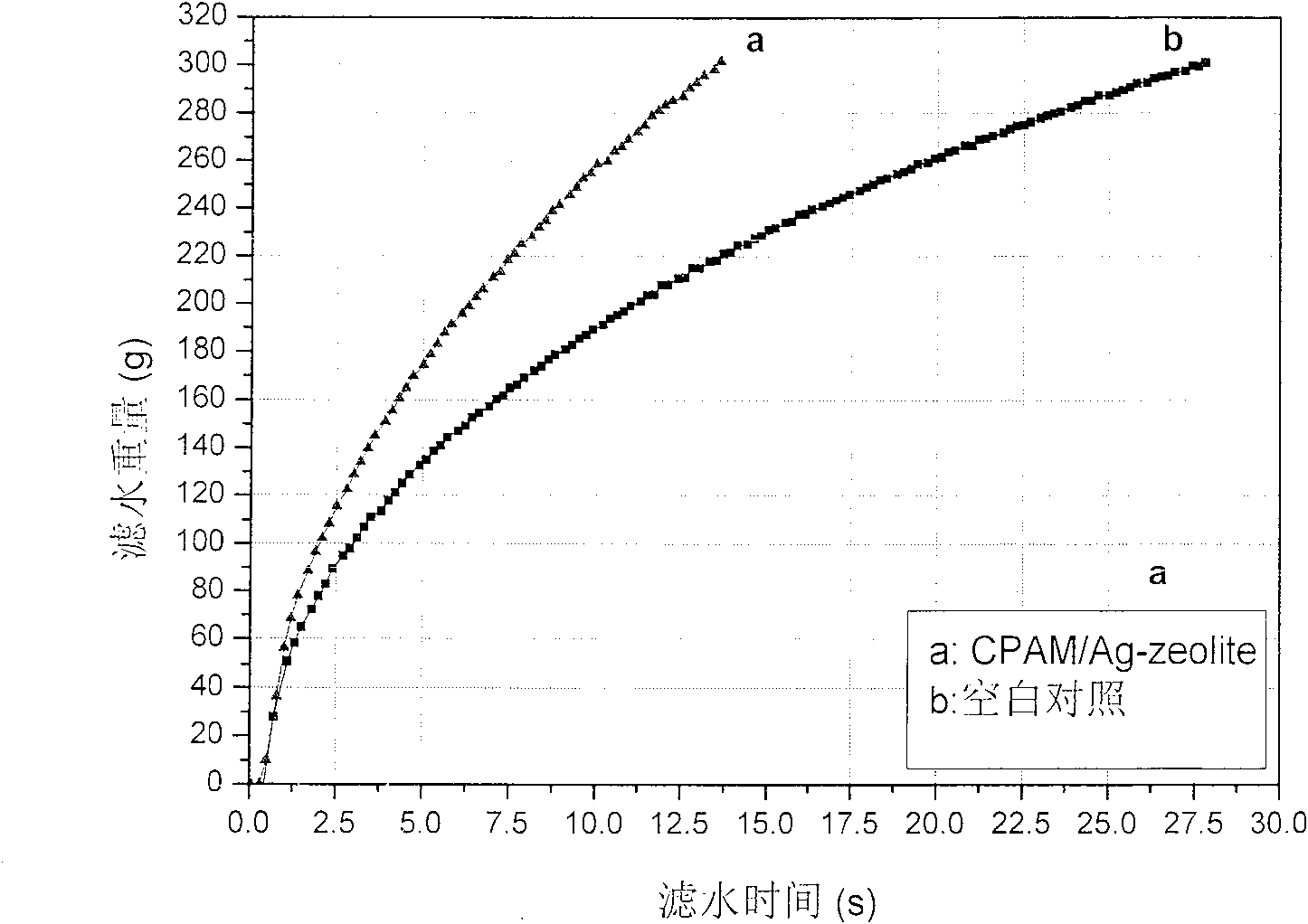

A silver-loaded antibacterial and particle retention technology, applied in inorganic compound addition, textile and papermaking, fiber raw material processing, etc., can solve the problems of poor antibacterial effect, uneven distribution, and low retention efficiency of antibacterial agents. Simple preparation process, good uniformity, good retention and drainage performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Embodiment 1: be the AgNO of 0.20mol / l with hematilite and concentration 3 Reaction, the reaction solid-liquid ratio is 0.8g / 10ml, the reaction temperature is 60°C, the reaction pH value is 6.5, and the reaction time is 2.5 hours. The chemical composition of the stilbene used is mainly SiO 2 and Al 2 o 3 , followed by CaO. SiO in single crystal 2 +Al 2 o 3 Content is 72.89wt%, SiO 2 and Al 2 o 3 The molar ratio is 7.1, the CaO is 8.80wt%, and there is also a very small amount of K 2 O, Na 2 O. The crystal chemical formula is (K 0.017 Na 0.042 Ca 1.13 ) 1.189 [Al 1.997 Si 7.05 o 18 ]·6.75H 2 O. Then wash with deionized water, use a centrifuge to centrifuge at 3000r / min for 20 minutes, pour off the supernatant, and repeat the washing until the supernatant is tested by sodium chloride solution without white precipitation, and then the resulting modified The zeolite was dried at 105°C for 4 hours, and then ground to a particle size of 500 mesh. When in...

Embodiment 2

[0023] Embodiment 2: be the AgNO of 0.15mol / l with hematilite and concentration 3 Reaction, the reaction solid-liquid ratio is 1g / 10ml, the reaction temperature is 70°C, the reaction pH value is 6.5, and the reaction time is 1.5 hours. Then wash with deionized water, use a centrifuge to centrifuge at 3000r / min for 20 minutes, pour off the supernatant, and repeat the washing until the supernatant is tested by sodium chloride solution without white precipitation, and then the resulting modified The zeolite was dried at 105°C for 5 hours, and then ground to 500 mesh. When in use, add cationic polyacrylamide with a molecular weight of about 7.5 million before the pressure screen, the dosage is 0.40kg / t, and then add inorganic silver-loaded antibacterial zeolite particulate retention agent to the head box, the dosage is 0.8kg / t, the dosage is 0.8kg / t. The silver-loaded content of the antibacterial particulate retention aid reaches 3.6%, the retention rate when used reaches 96.8% (...

Embodiment 3

[0024] Embodiment 3: be the AgNO of 0.30mol / l with hematilite and concentration 3 Reaction, the reaction solid-liquid ratio is 1.2g / 10ml, the reaction temperature is 60°C, the reaction pH value is 7.0, and the reaction time is 3.0 hours. Then wash with deionized water, use a centrifuge at 3500r / min, centrifuge for 15 minutes, pour off the supernatant, and repeat the washing until the supernatant is tested by sodium chloride solution without white precipitation, and then the resulting modified The zeolite was dried at 110°C for 5 hours, and then ground to 400 mesh. When in use, add cationic polyacrylamide with a molecular weight of about 7 million before the pressure screen, the dosage is 0.20kg / t, and then add inorganic silver-loaded antibacterial zeolite particle retention agent in the headbox, the dosage is 1.2kg / t, the The silver-loaded content of the antibacterial particle retention aid reaches 4.0%, the retention rate reaches 97.2% (200 mesh) when used, and the antibacte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com