Modified guar gum, preparing method thereof, and application of the same in preparing tobacco thin sheet

A guar gum and modified technology, applied in the application, tobacco, tobacco processing and other directions, can solve the problems of fast swelling and hydration, high water-insoluble content and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

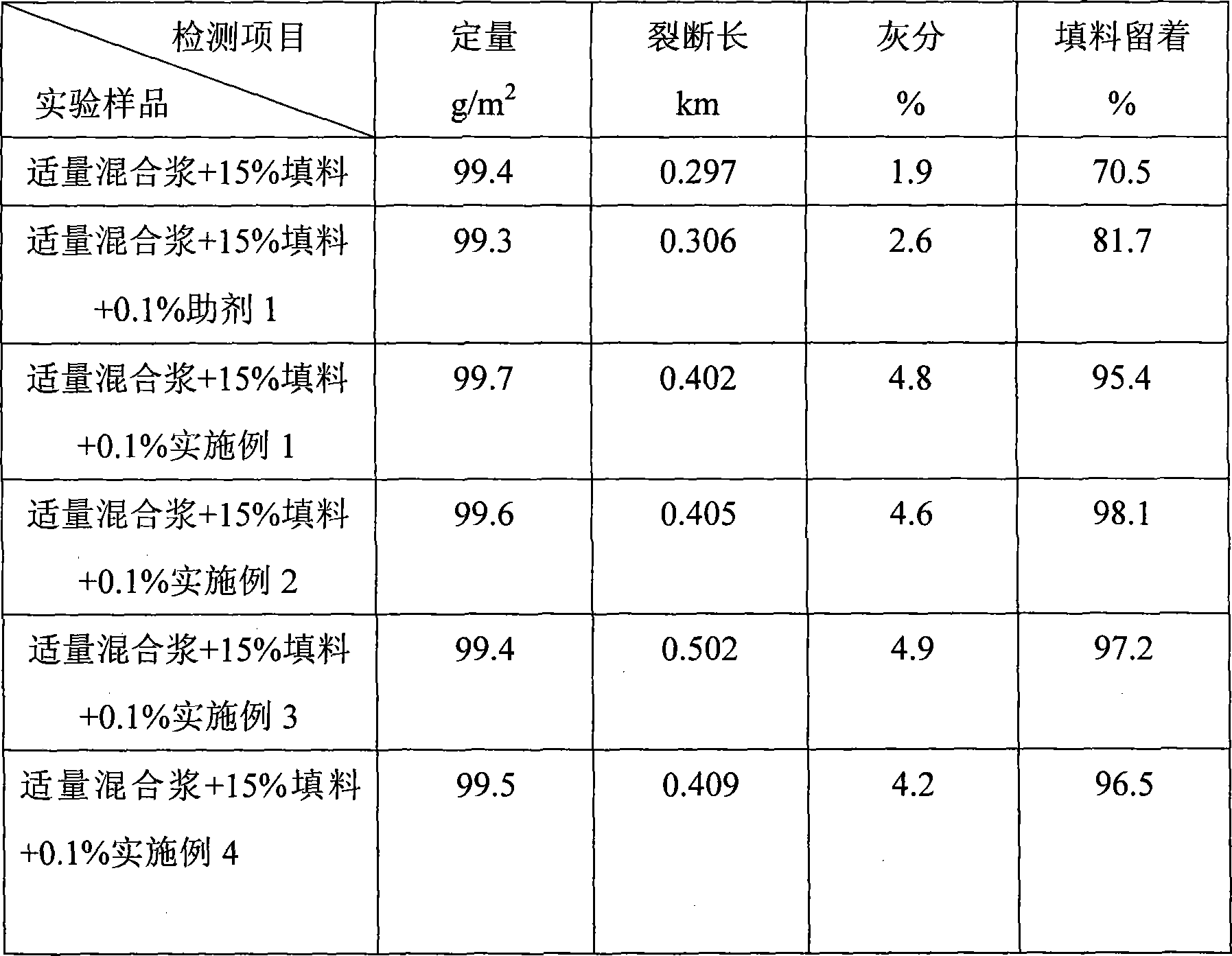

Examples

Embodiment 1

[0026] Add 100 grams of methanol to the reaction kettle at normal temperature, after dispersing 60 grams of guar collagen powder evenly, add 10 grams of sodium hydroxide solution with a weight concentration of 50%, raise the temperature to 20 ° C, and then slowly add 3 grams of epichlorohydrin, Continue the heat preservation reaction for 5 hours, add hydrochloric acid, adjust the pH value of the system to 8, then slowly add 5 grams of cationization auxiliary agent 3-chloro-2 hydroxypropyl-trimethyl ammonium chloride, heat up to 70 ° C, heat preservation reaction for 1 hour , cool down and discharge, use 12 grams of hydrochloric acid to neutralize the pH of the system to 8, filter with suction, dry and pulverize, seal and pack for later use.

Embodiment 2

[0028] Add 150 grams of sherwood oil in the reaction kettle under normal temperature, after dispersing 70 grams of guar collagen powder evenly, add weight concentration and be 15 grams of 50% triethanolamine solution, be warming up to 50 ℃, then slowly add 5 grams of phosphorous trichloride, Insulate and react for 2 hours, add sulfuric acid, adjust the pH value of the system to 10, then slowly add 7 grams of cationization aid 2,3-epoxypropyltrimethylammonium chloride, then heat up to 35 ° C, and insulate for 3 hours. Cool down and discharge, use 16 grams of acetic acid to neutralize the pH to 7.5, filter with suction, dry and pulverize, seal and pack for use.

Embodiment 3

[0030] Add 200 grams of acetone to the reaction kettle at room temperature, disperse 80 grams of guar collagen powder evenly, add 20 grams of diethylenetriamine solution with a weight concentration of 50%, raise the temperature to 80 ° C, and then slowly add 8 grams of sodium tripolyphosphate , heat preservation reaction for 7 hours, add glacial acetic acid, adjust the pH of the system to be 9, then slowly add 10 grams of cationization aid dimethylaminoethyl methacrylate benzyl quaternary ammonium chloride, then heat up to 45 ° C, heat preservation reaction 5 hours, cooled and discharged, neutralized the pH to 8 with 10 grams of sulfuric acid, filtered with suction, dried and pulverized, sealed and packaged for later use.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com