Application of Carboxymethyl Chitin as Retention and Drainage Aid

A technology of carboxymethyl chitin and retention and drainage aid, applied in the field of papermaking aids, can solve the problems of short shelf life, no carboxymethyl chitin, poor retention and drainage effect, etc., and achieves low cost , Excellent retention and drainage performance, good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

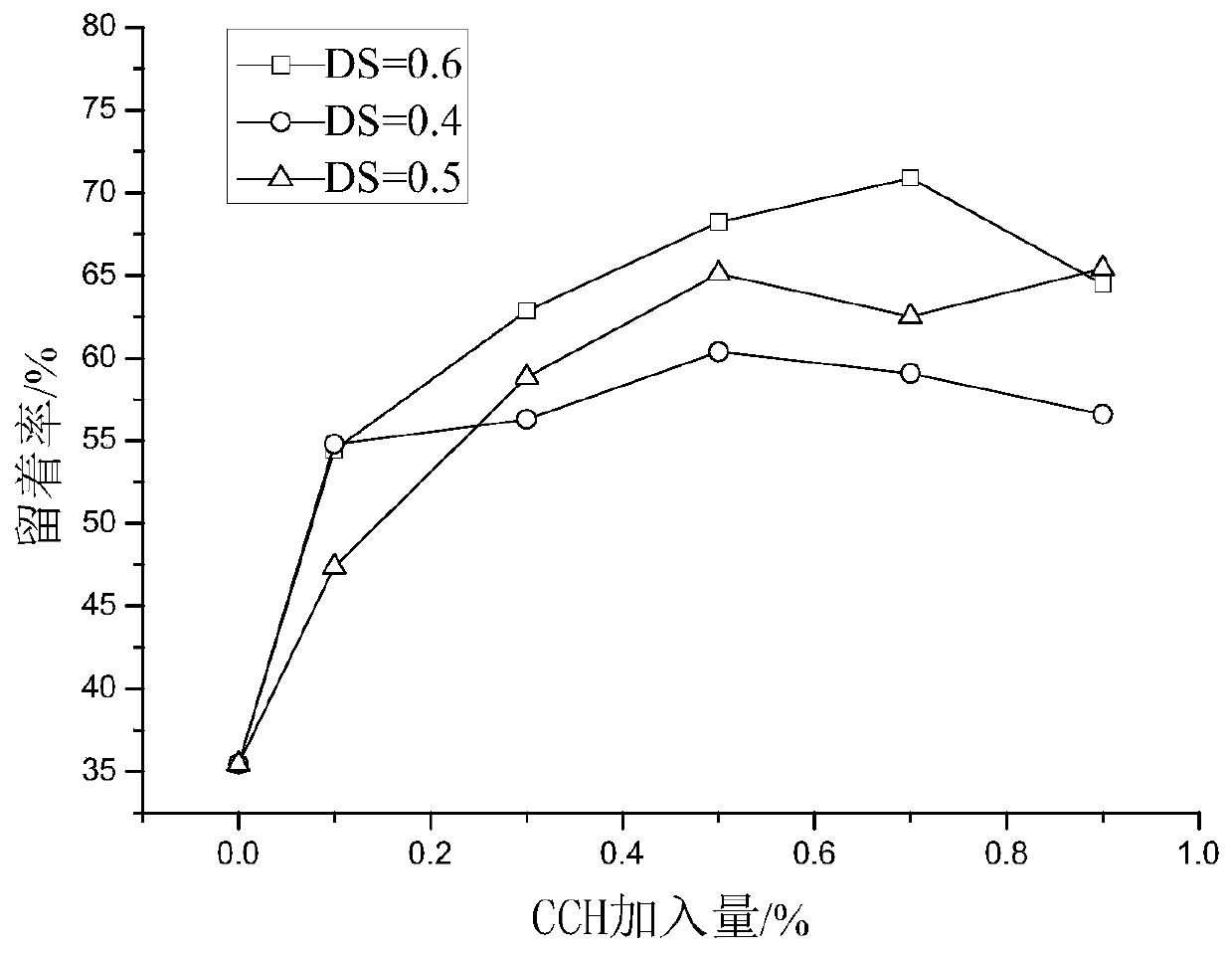

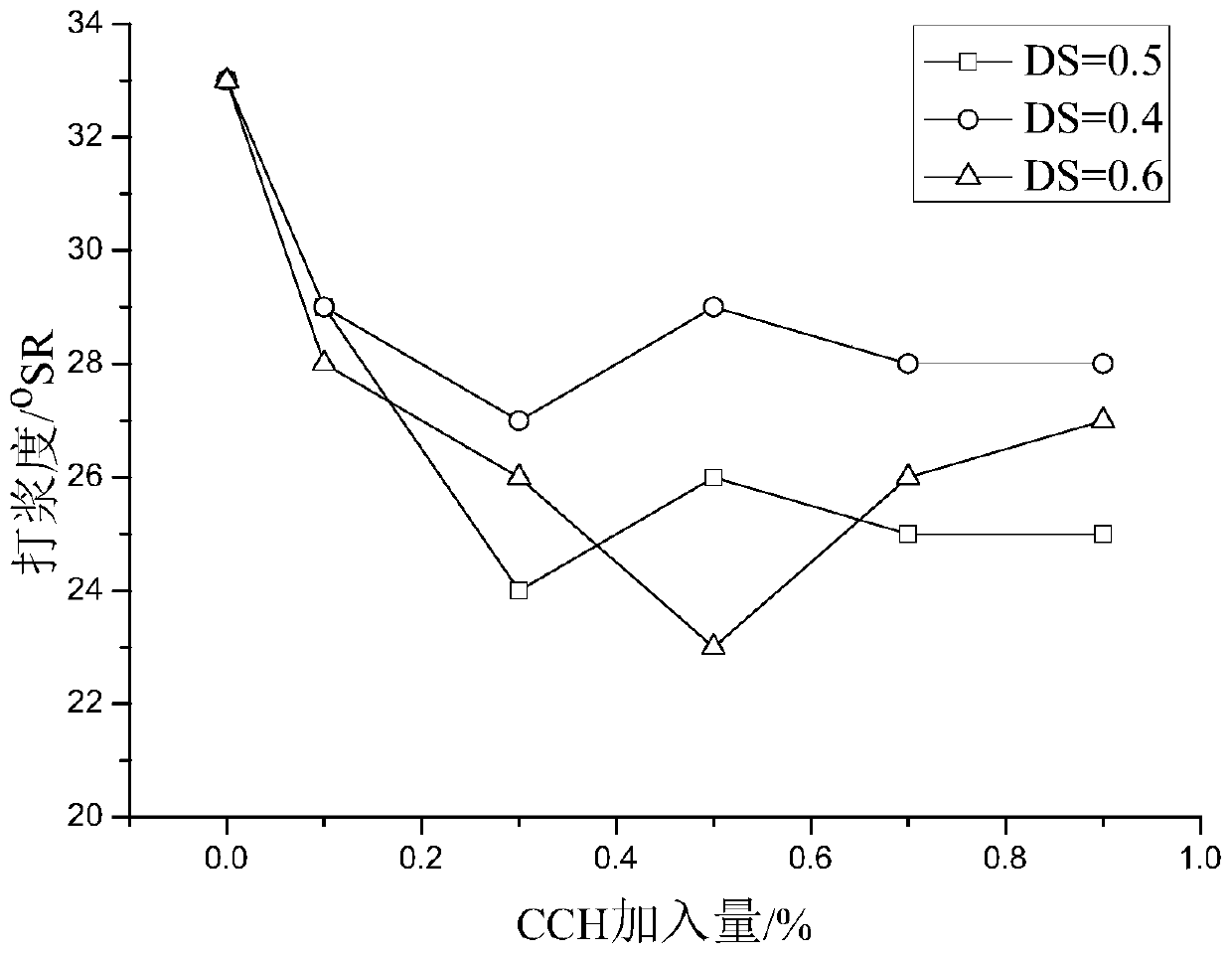

[0030] Weigh an appropriate amount of pulp with a pulp concentration of 1.2% and dilute it with tap water to 0.2% pulp in a dynamic water filter, add 30% kaolin (relative to the dry weight of the pulp), stir at 300rpm for 30s, and add different predetermined amounts of substitution degrees 0.4 carboxymethyl chitin (relative to the dry weight of the pulp), stirred at 300rpm for 30s, and after the water was filtered, the filtrate was mixed evenly.

Embodiment 2

[0032] Weigh an appropriate amount of pulp with a pulp concentration of 1.2% and dilute it with tap water to 0.2% pulp in a dynamic water filter, add 30% kaolin (relative to the dry weight of the pulp), stir at 300rpm for 30s, and add different predetermined amounts of substitution degrees 0.5 carboxymethyl chitin (relative to the dry weight of the pulp), stirred at 300rpm for 30s, and after filtering, the filtrate was mixed evenly.

Embodiment 3

[0034] Weigh an appropriate amount of pulp with a pulp concentration of 1.2% and dilute it with tap water to 0.2% pulp in a dynamic water filter, add 30% kaolin (relative to the dry weight of the pulp), stir at 300rpm for 30s, and add different predetermined amounts of substitution degrees 0.6 carboxymethyl chitin (relative to the dry weight of the pulp), stirred at 300rpm for 30s, and after filtering, the filtrate was mixed evenly.

[0035] Determination of retention performance:

[0036] The retention performance is characterized by the retention rate of kaolin. The determination method is as follows: take about 10 mL of the filtrate, and measure its absorbance at 550 nm. Weigh different amounts of kaolin to prepare a suspension, measure its absorbance at 550nm, and obtain a standard curve y=1.552x+0.0079. The calculation method of filler retention rate is as follows:

[0037]

[0038] Among them: y—absorbance;

[0039] x—the mass of kaolin in the filtrate, g;

[004...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of substitution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com