Anilox roller printing device

A technology of printing device and anilox roller, which is applied in printing, printing machine, rotary printing machine, etc., and can solve problems such as manufacturing tolerances

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

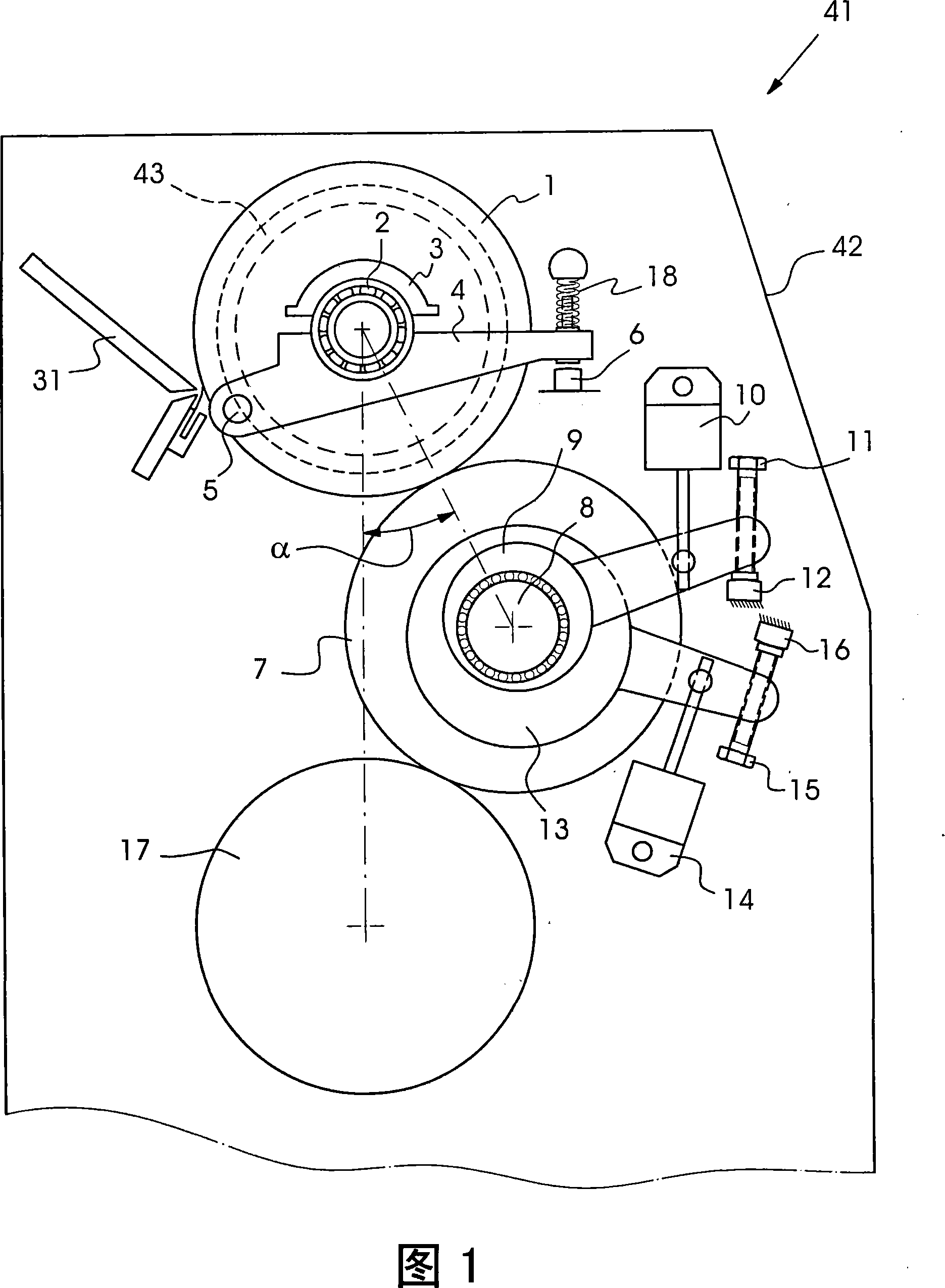

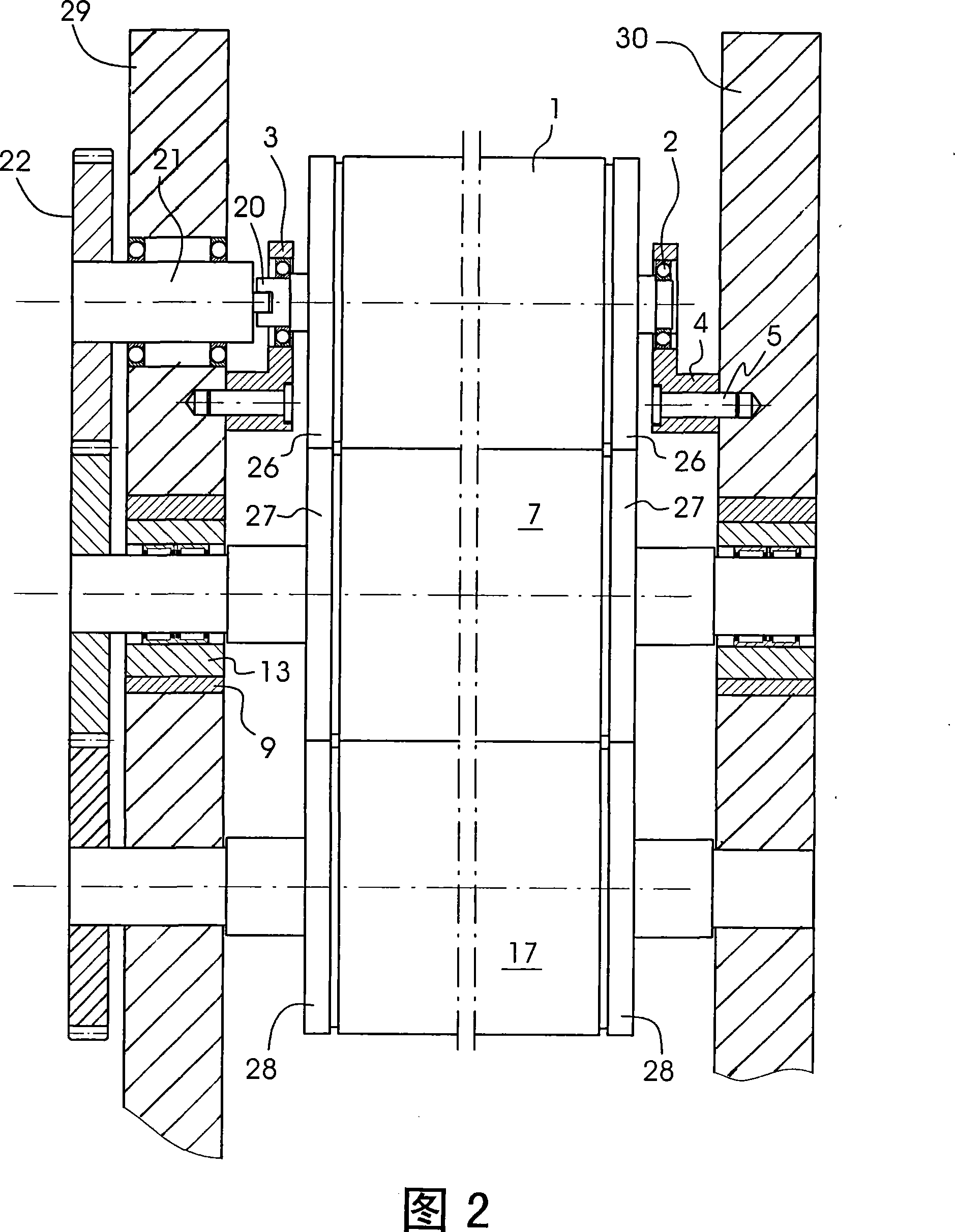

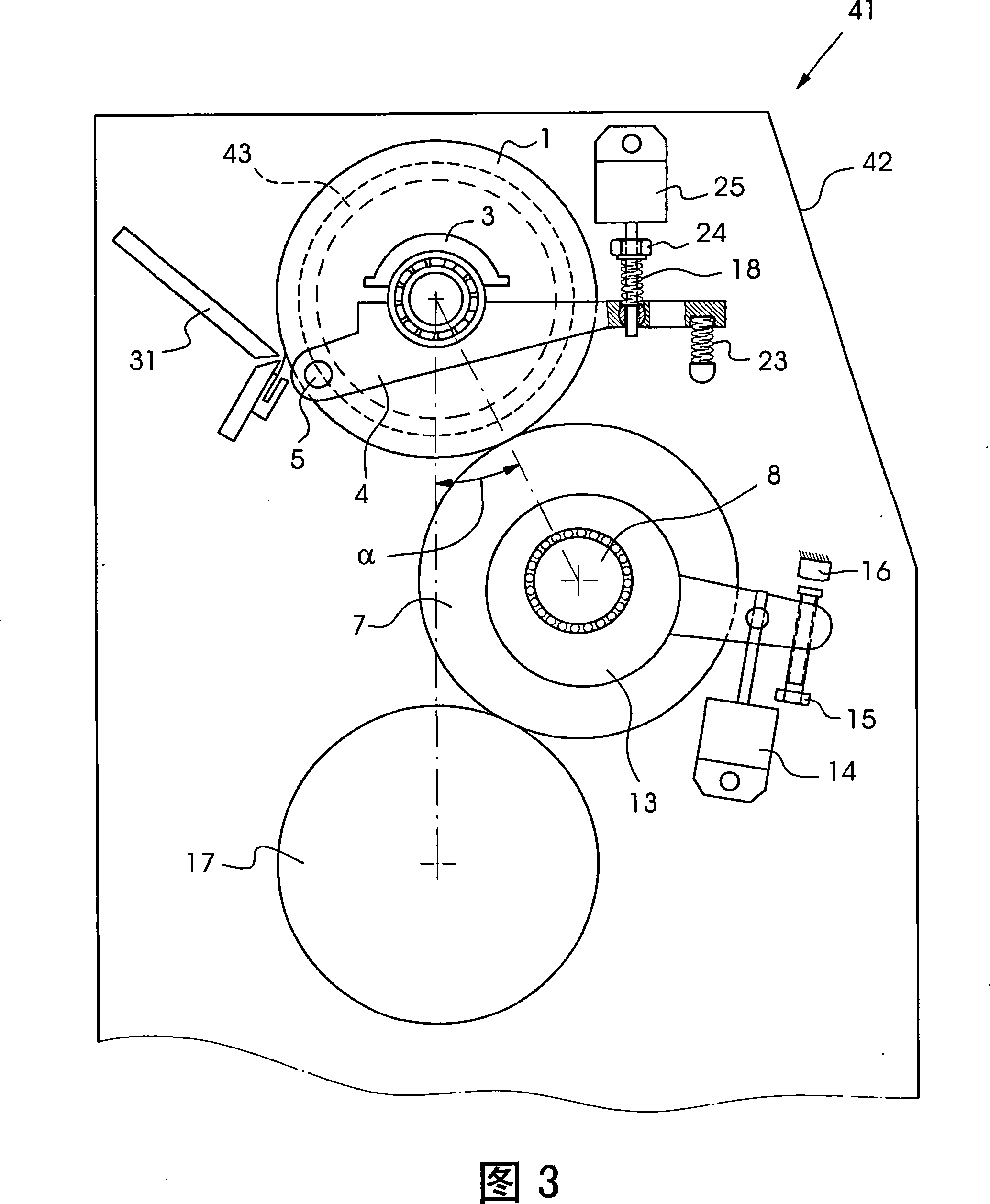

[0029] In FIGS. 1 to 5 , components and elements corresponding to each other are marked with the same reference numerals.

[0030] A printing press 41 is partially shown in FIGS. 1 and 2 . This detail shows an anilox printing unit 42 of a printing press 41 . The anilox printing unit 42 includes an anilox roller 1 , an ink form roller 7 and a printing plate cylinder 17 . Furthermore, the anilox printing unit 42 includes a blanket cylinder and an impression cylinder, which are not shown in the drawing. A doctor blade type ink fountain 31 rests on the screen roll 1 in order to supply the screen roll 1 with printing ink.

[0031] Mounted on the journals of the engraved roller 1 are pivot bearings 2 , which are mounted detachably by the operator in roller locks 3 . The rolling bearing 2 is a rolling bearing. The roller locks 3 are each arranged on a pivot lever 4 pivotable about a hinge 5 . Each pivot lever 4 is loaded by a spring 18 , which is supported with one end on the pi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com