DC converter valve restoration period transient forward voltage test method

A DC converter valve and forward voltage technology, which is applied in the field of power electronics and power systems, can solve problems such as inapplicability of test methods, unsatisfactory test valves, poor equivalence, etc., and achieve wide range of test products and equivalence Good, the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

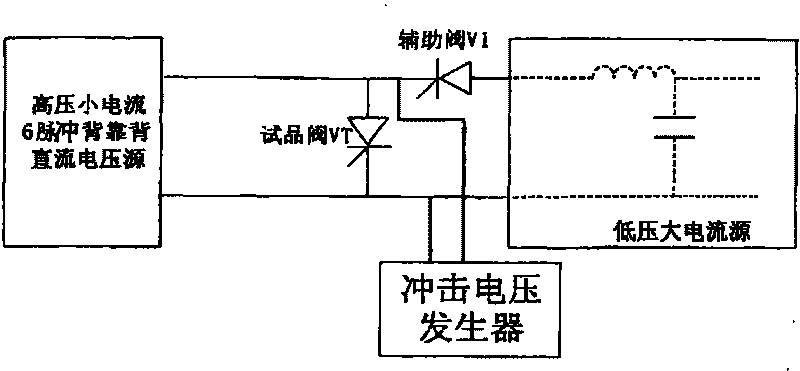

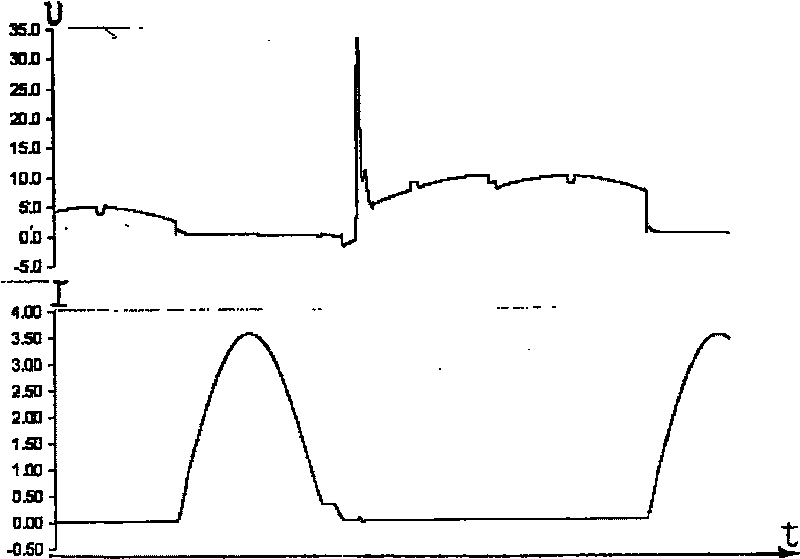

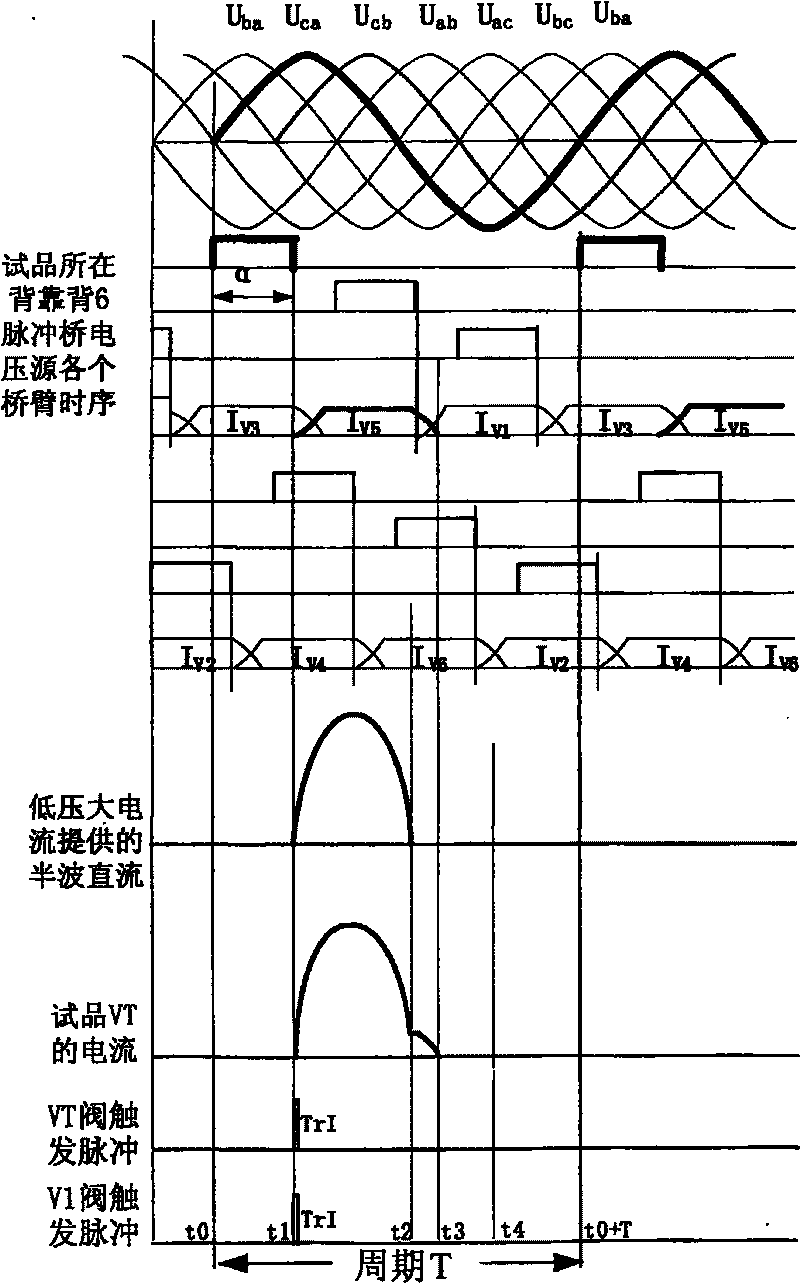

[0014] refer to figure 1 , represents the principle block diagram of the instantaneous forward voltage test during the recovery period of the DC converter valve. In the figure, the high-voltage small current source is a back-to-back 6-pulse bridge DC power supply, and VT is the test valve, which is connected in parallel with the impulse voltage generator, and then connected with the auxiliary valve V1 and The circuits connected in series with low-voltage and high-current sources are connected in parallel, and the instantaneous forward voltage test during the recovery of the DC converter valve is referenced in the connected circuits. figure 2 Shown are voltage and current waveforms obtained in the above test. refer to image 3 , represents the trigger timing diagram of pulses added in the instantaneous forward voltage test during the recovery period. The abscissa in the figure represents different periods within a test cycle, and the ordinate represents the state of each trig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com