A reset type sma piezoelectric friction hybrid damper

A hybrid damping and damper technology, applied in building components, anti-vibration and other directions, can solve the problems that the control force of the damper cannot be adjusted in real time, cannot achieve shock absorption, and is insufficient in energy consumption, and achieves a significant energy consumption effect and strengthens reset. Effects, effects with short response time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings and examples.

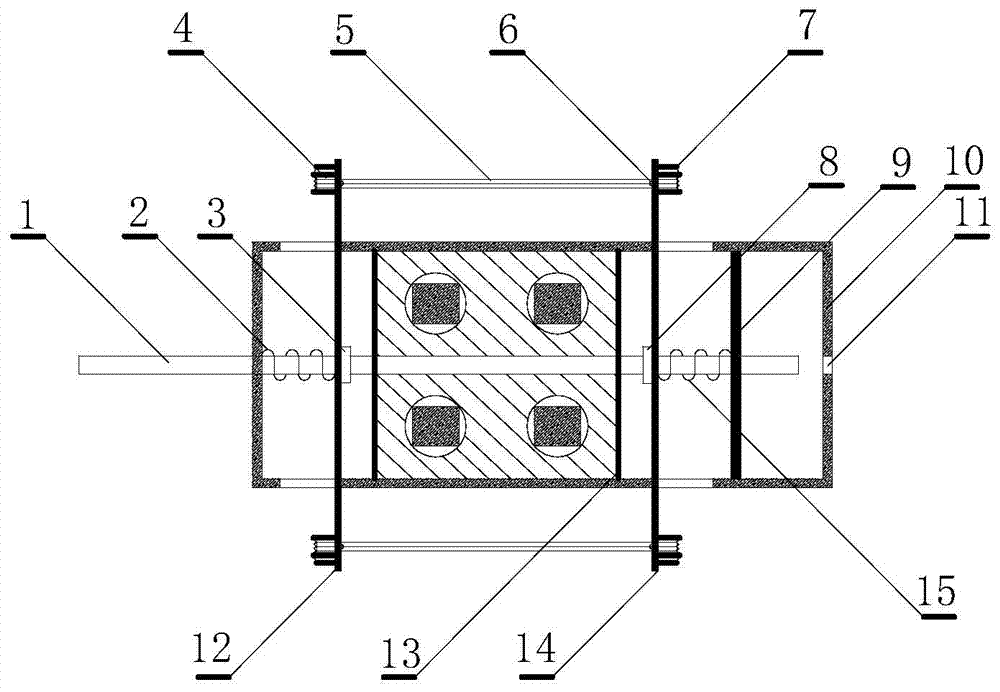

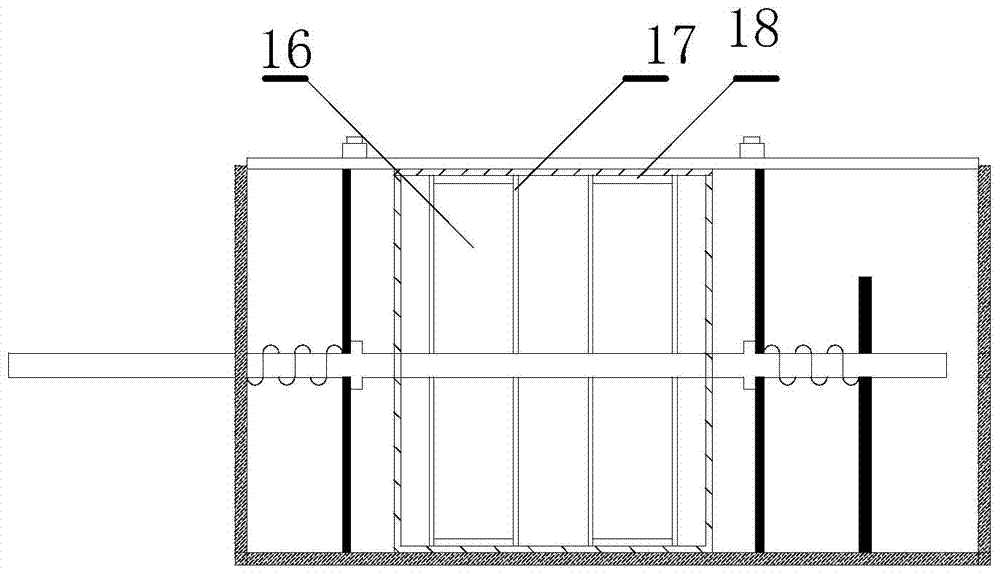

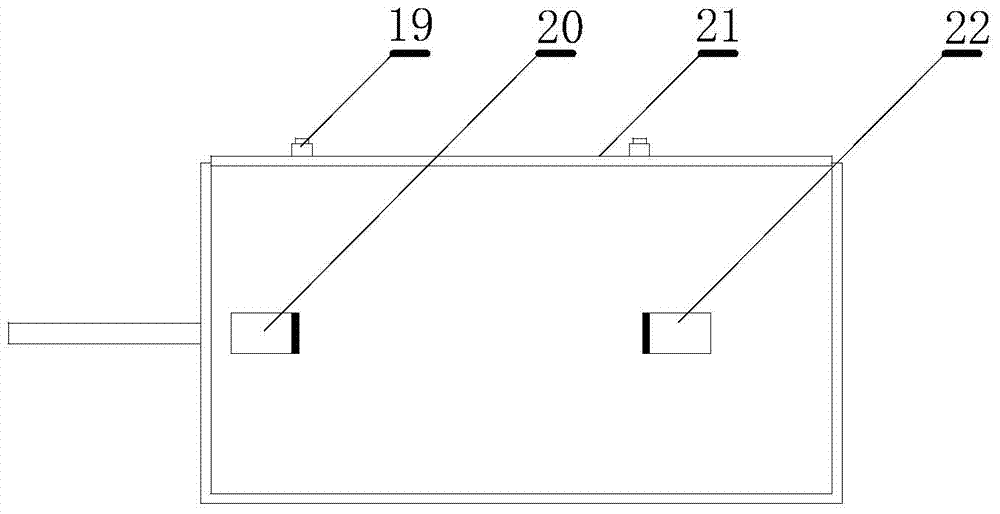

[0018] like figure 1 , figure 2 and image 3 As shown, the present invention is a reset type SMA piezoelectric friction hybrid damper, the housing is composed of a top cover 21 and a damper box 10 ; The top cover 21 and the inner surface of the damper box 10 are pasted with wear-resistant carbon fiber friction material; the sleeve 17 is fixed in the piezoelectric ceramic driver box 13, and the piezoelectric ceramic driver 16 is placed in the sleeve 17, and the piezoelectric ceramic driver Spacers 18 are provided at both ends of 16 ; the vertical fixed baffle 9 is welded in the damper box 10 near its right side wall. The left side of the piezoelectric ceramic driver box 13 is provided with a vertical left sliding plate 12, and the right side is provided with a vertical right sliding plate 14, such as Figure 4 As shown, the upper and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com