Producing method of solar energy collecting plate

A technology of solar energy collection and manufacturing method, which is applied in the direction of solar collectors, solar thermal energy, solar thermal power generation, etc., can solve the problems of limited solar energy utilization, insufficient focal length, and inability to use solar energy, etc., to achieve short focal length and large energy collection, The effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

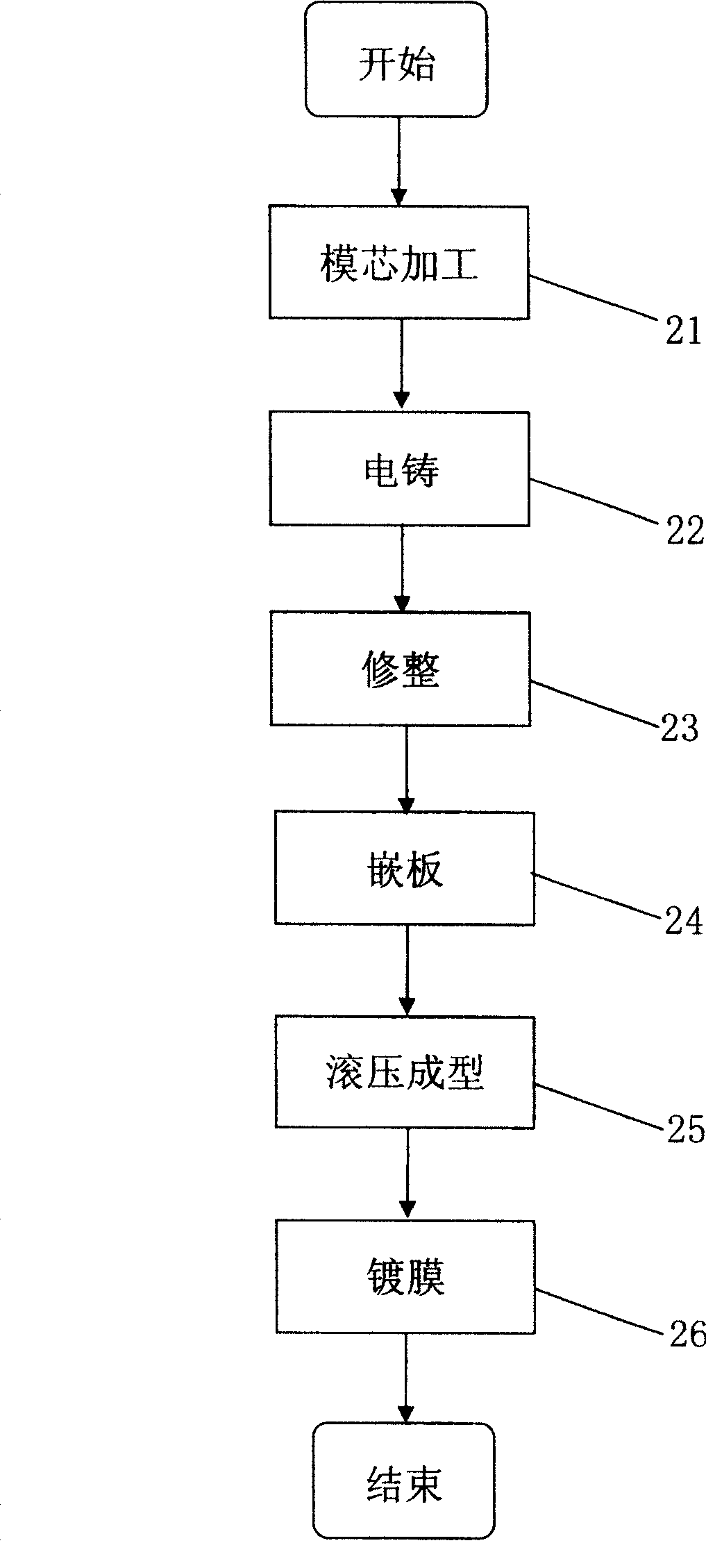

[0019] like figure 2 Shown is the process flow chart of the manufacturing method of the solar collection panel of the present invention; It includes the following steps: the mold core processing step 21: select a positive focal length mold core with a suitable focal length, cut it into the required size, and assemble it into an array plate; the electroforming step 22: Perform electroforming on the assembled array plate, and electroform a negative focal length template; trimming step 23 trims and processes the template after electroforming; paneling step 24: select a suitable anti-aging plate and cut it to be equivalent to the template The size of the plate is embedded between the template and the optical plate; rolling forming step 25: sending it to a rolling lens forming machine for rolling forming; coating step 26: coating the outside of the lens with an anti-ultraviolet film.

[0020] In the mold core processing step 21, the mold core is selected and cut and then assembled...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com