Distribution module

A wiring module and cable slot technology, applied in the field of wiring modules, can solve the problems of low potting efficiency, easy corrosion of connection points, inconvenient assembly, etc., so as to improve potting efficiency, easy wiring operation and simple structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

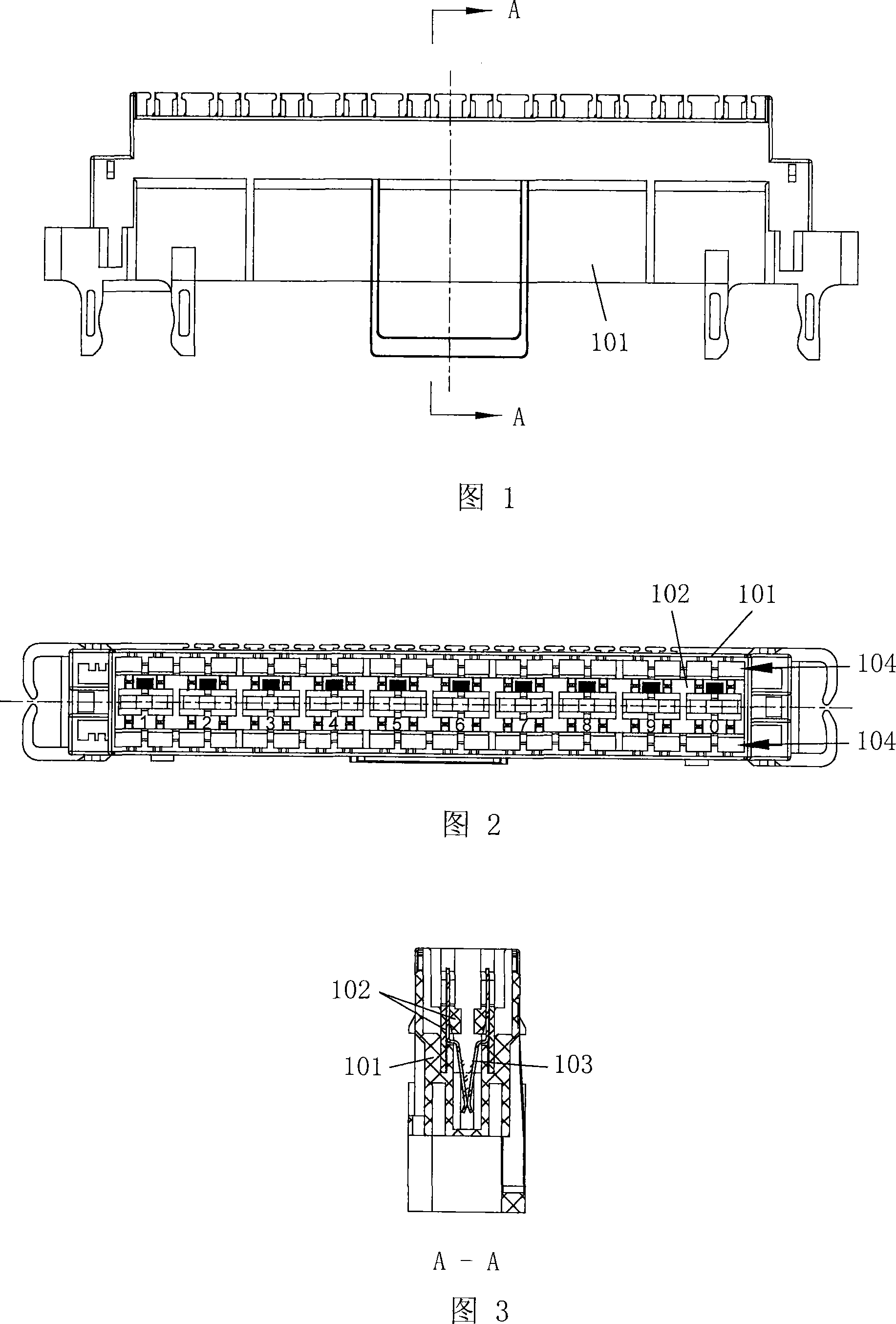

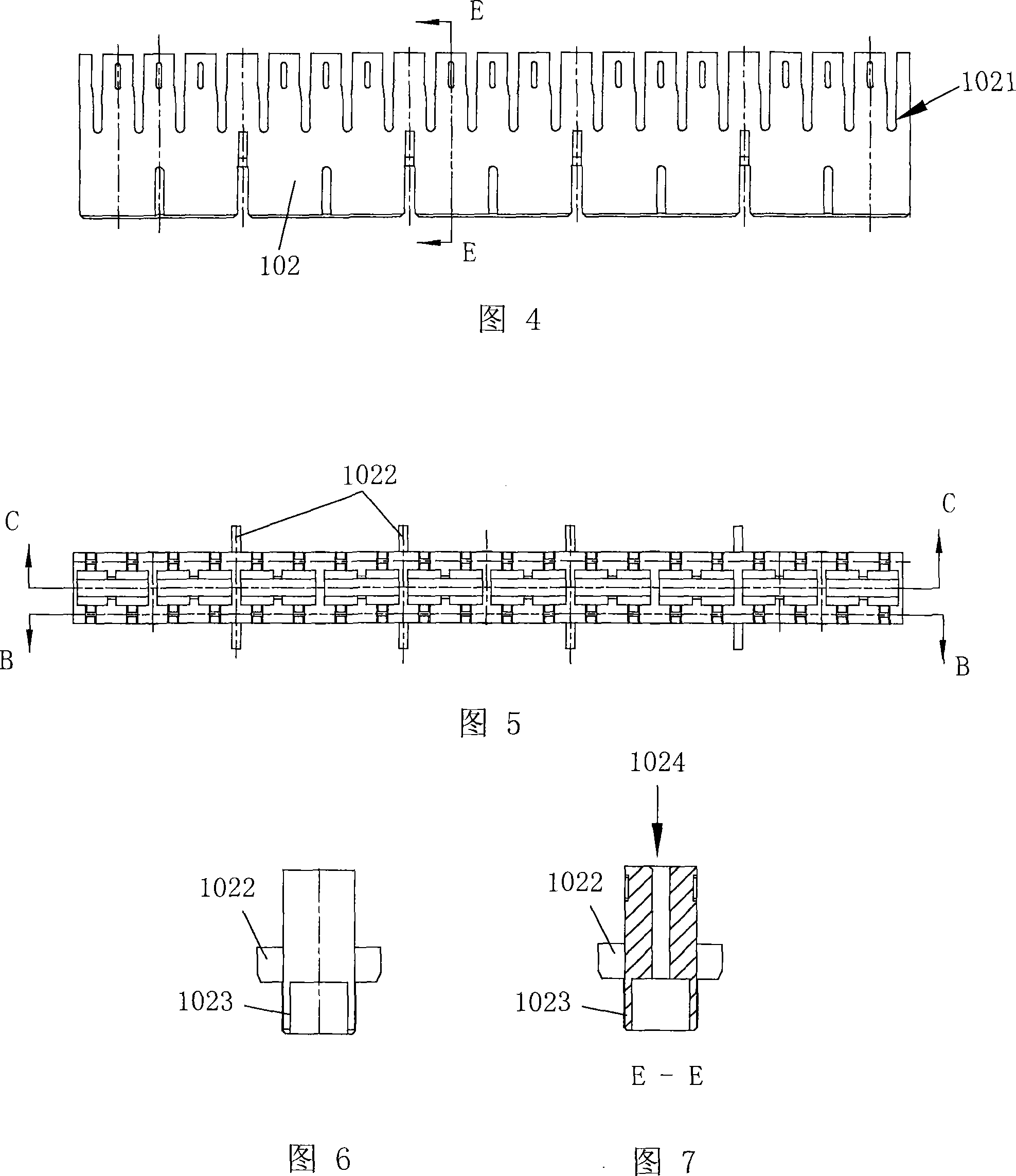

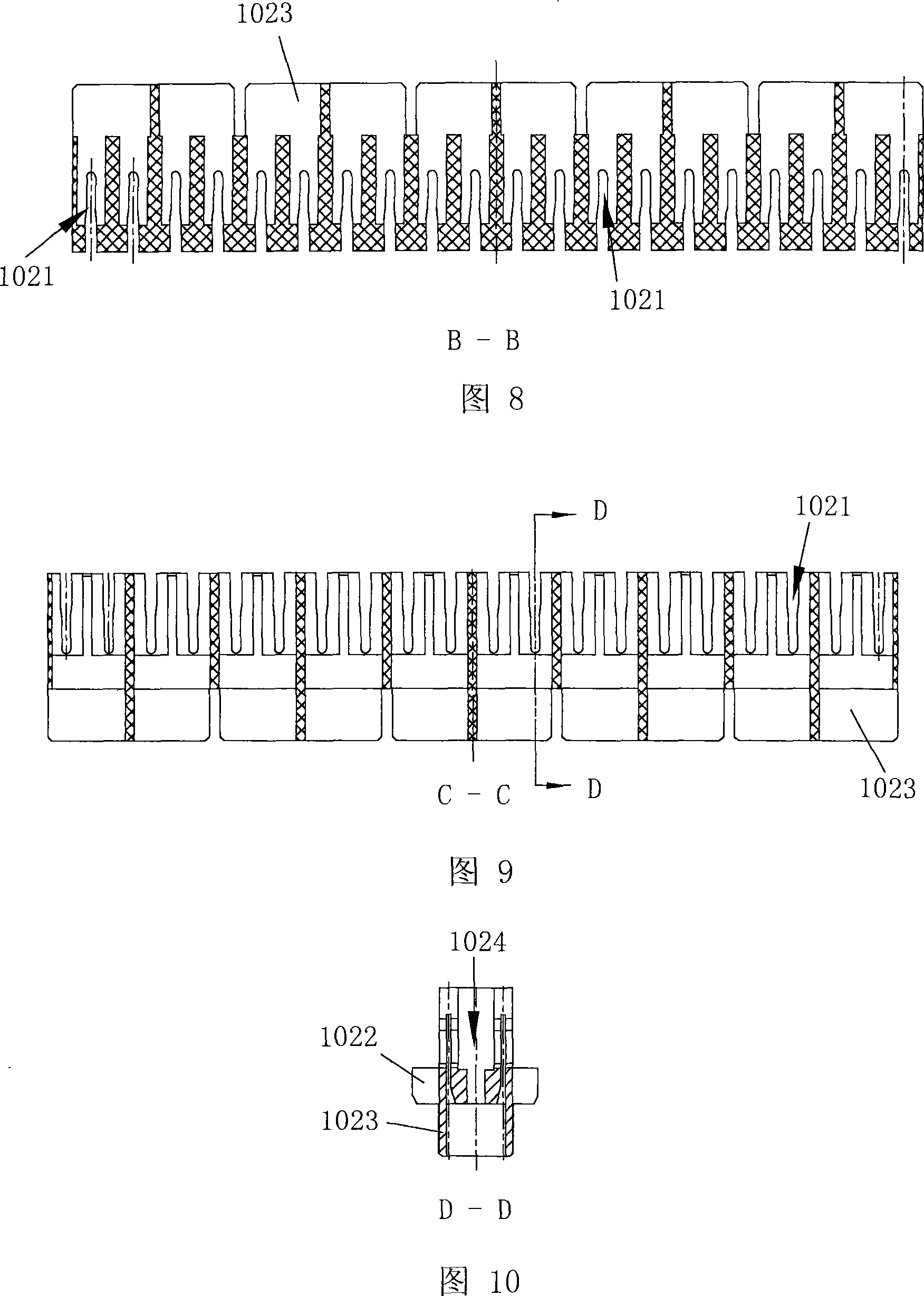

[0035] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings. The first embodiment of the present invention is a 10-loop moisture-proof wiring module. Referring to FIGS. Groove 1011, the groove 1011 has an opening, a bottom surface and a side wall, the bottom surface and the side wall of the groove 1011 jointly define an accommodating cavity that can accommodate a liquid moisture-proof agent; the terminal base 102 is arranged in the groove 1011 of the bracket 101, The bracket 101 is an integrally formed plastic part, and the terminal base 102 is also an integrally formed plastic part; the top of the side wall of the bracket 101 is provided with a cable management port 101, and the top of the terminal base 102 is provided with a clamping port 1021, and at least the bottom of the clamping port 1021 is located at the cable management port. The area below the mouth 1014 that can accommodate the liquid moisture-proof agen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com