Device for delivery of TRPV1 agonists

A delivery device, agonist technology, applied in the direction of anti-inflammatory agent, capsule delivery, sheet delivery, etc., can solve problems such as undescribed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

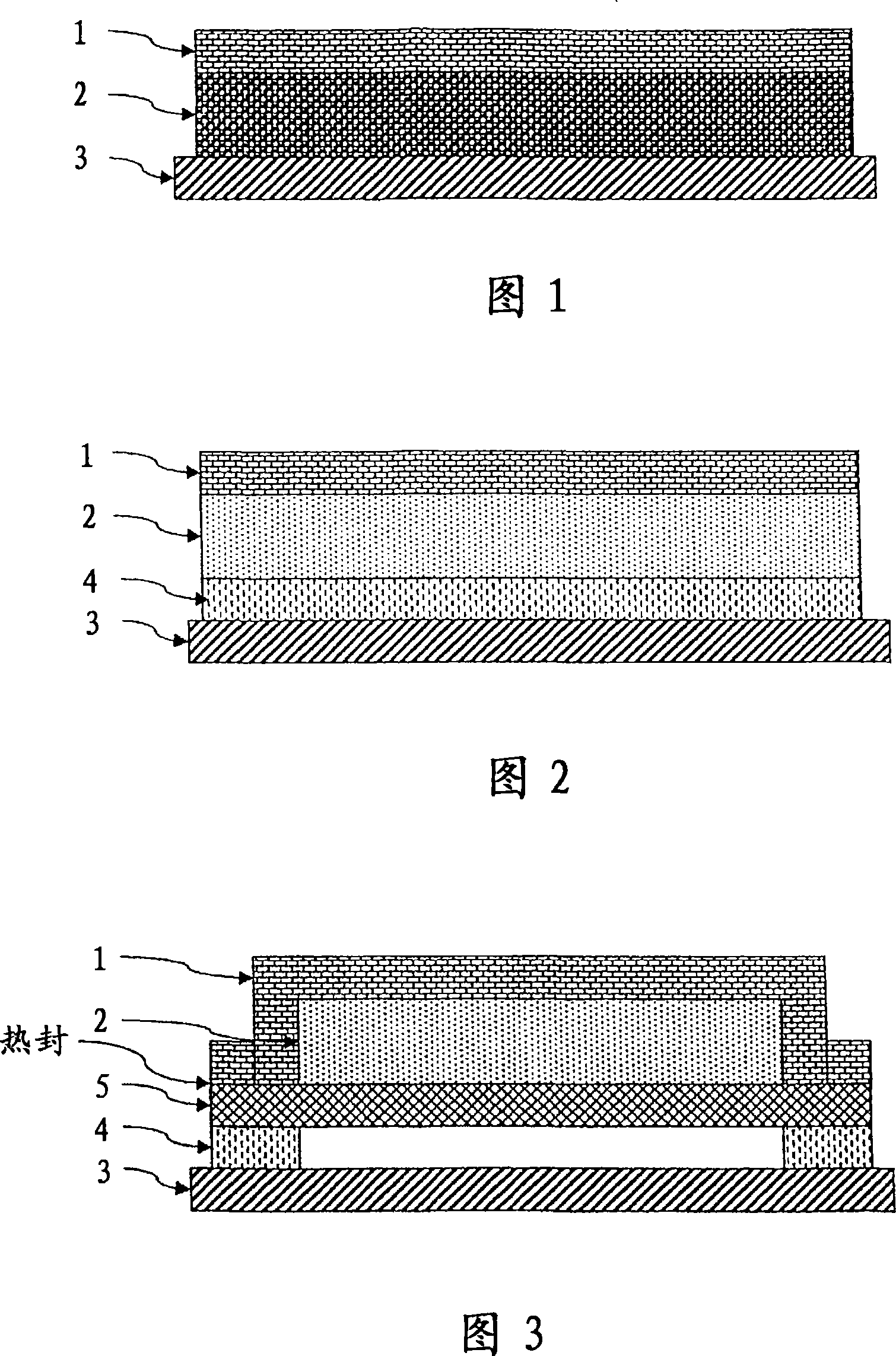

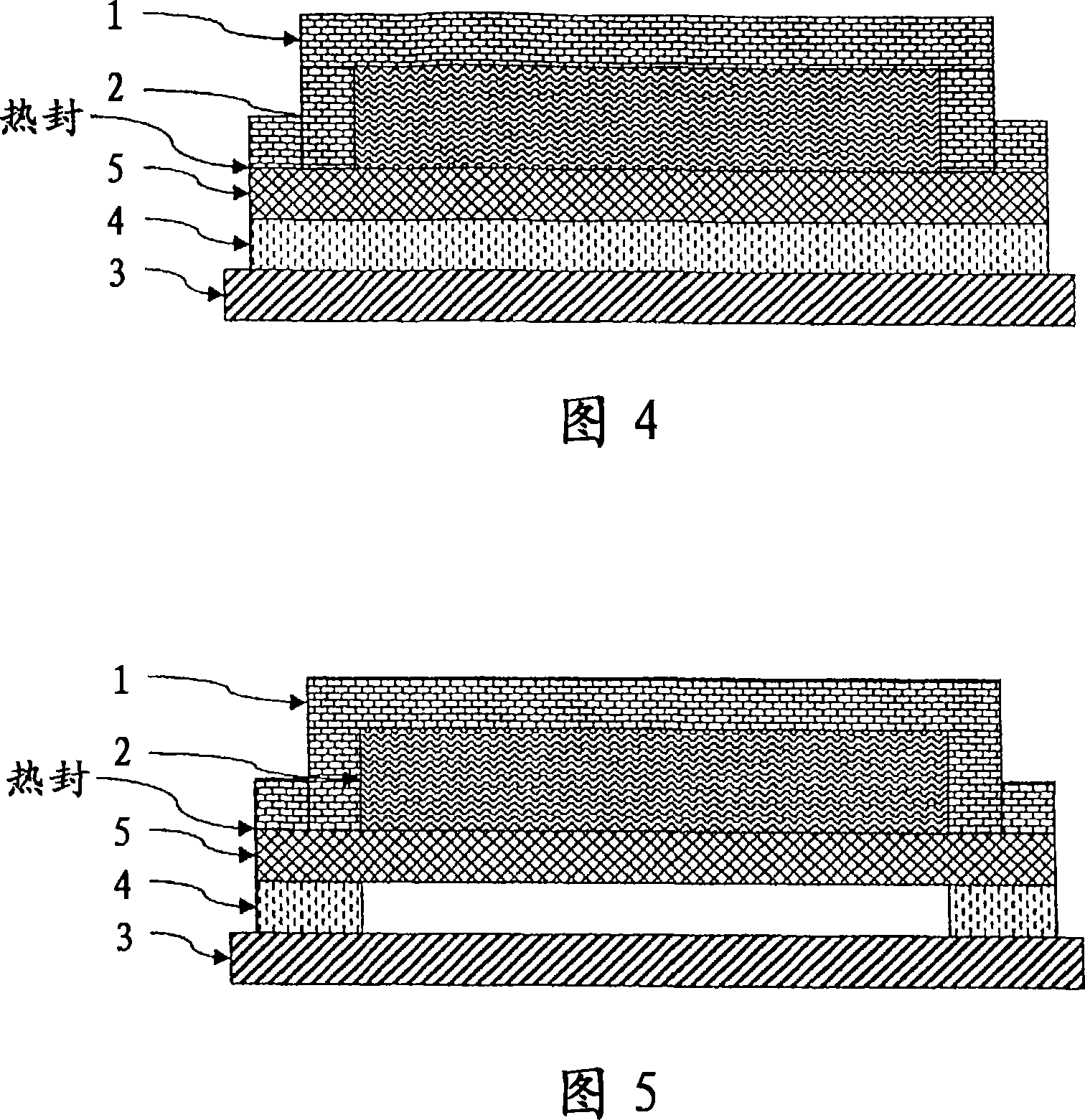

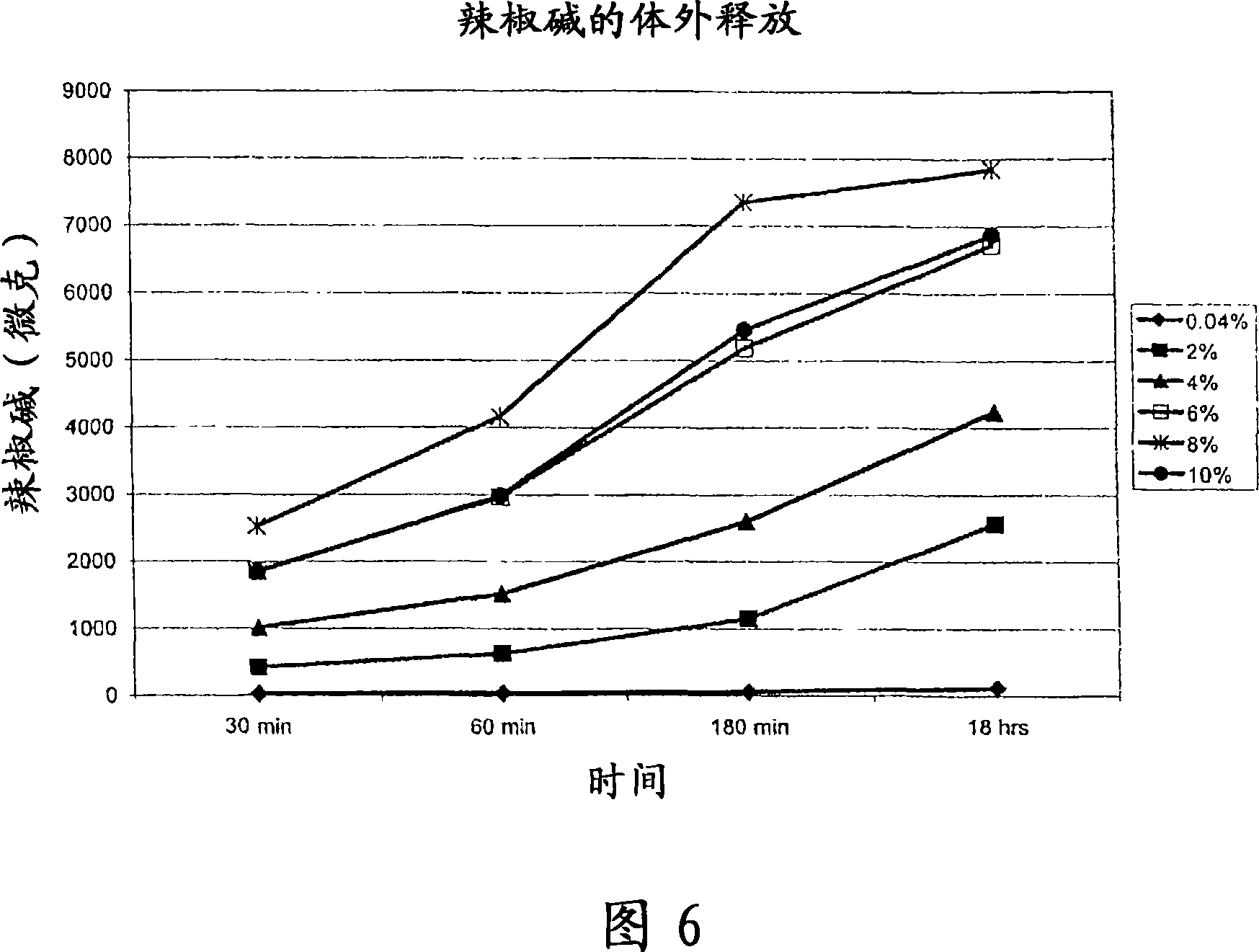

[0096] Example 1: Preparation of a Microreservoir-Type Device Containing 0.04% by Weight Capsaicin in the Drug Depot

[0097] 16.0 g of oleyl alcohol was added to 80 mg of capsaicin and the ingredients were mixed. Next, 200 mg of ethylcellulose was added and mixed well, then left for 2 hours. Add 36.74 g Bio-PSA 4201 and 146.98 grams of Bio-PSA 4301. Vigorously mix the mass until the gelled mixture of oleyl alcohol, capsaicin, and ethyl cellulose is uniformly dispersed in the adhesive as microspheres. The resulting adhesive matrix was then coated on a release liner 3M™ Scotchpak TM On 1022, dry the solvent n-heptane by hot air at a temperature of 35-40°C. Coat weight after removal of n-heptane is about 273.6 g / m 2 . Then use 3M TM Scotchpak TM A 9733 polyester liner was laminated to the dried film, and the finished drug delivery device (5 cm x 5 cm) was punched out. The flushed drug delivery device is then enclosed in sachets of a primary packaging stack.

Embodiment 2

[0098] Example 2: Preparation of a Microreservoir-Type Device Containing 2.0% by Weight Capsaicin in the Drug Depot

[0099] 20.0 g oleyl alcohol was added to 4 g capsaicin and the ingredients were mixed. Next, 200 mg of ethylcellulose was added and mixed well, then left for 2 hours. Add 175.80 g Bio-PSA 4301. Vigorously mix the mass until the gelled mixture of oleyl alcohol, capsaicin, and ethyl cellulose is uniformly dispersed in the adhesive as microspheres. The resulting adhesive matrix was then coated on a release liner 3M TM Scotchpak TM On 1022, dry the solvent n-heptane by hot air at a temperature of 35-40°C. Coat weight after removal of n-heptane is about 277.9 g / m 2 . Then use 3M TM Scotchpak TM A 9733 polyester liner was laminated to the dried film, and the finished drug delivery device (5 cm x 5 cm) was punched out. The flushed drug delivery device is then enclosed in sachets of a primary packaging stack.

Embodiment 3

[0100] Example 3: Preparation of a microreservoir-type device containing 4 wt% capsaicin in the drug reservoir

[0101] Add 36.0 g oleyl alcohol to 8.0 g capsaicin and mix these ingredients. Next, 2.0 g of ethylcellulose was added and mixed well, then left for 2 hours. Add 154.0 g Bio-PSA 4301. Vigorously mix the mass until the gelled mixture of oleyl alcohol, capsaicin, and ethyl cellulose is uniformly dispersed in the adhesive as microspheres. The resulting adhesive matrix was then coated on a release liner 3M TM Scotchpak TM On 1022, dry the solvent n-heptane by hot air at a temperature of 35-40°C. Coat weight after removal of n-heptane is about 218.4 g / m 2 . Then use 3M TM Scotchpak TM A 9733 polyester liner was laminated to the dried film, and the finished drug delivery device (5 cm x 5 cm) was punched out. The flushed drug delivery device is then enclosed in sachets of a primary packaging stack.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com