Mirror polished hard alloy cutting tool and its manufacturing method

A technology of cemented carbide blades and cemented carbides, which is applied in the direction of manufacturing tools, cutting tools for lathes, accessories of tool holders, etc., can solve the problem of increasing the production cost of enterprises and affecting the service life of cutting tools. Tool dimensional stability and consistency In order to improve production efficiency, processing accuracy, high surface finish and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

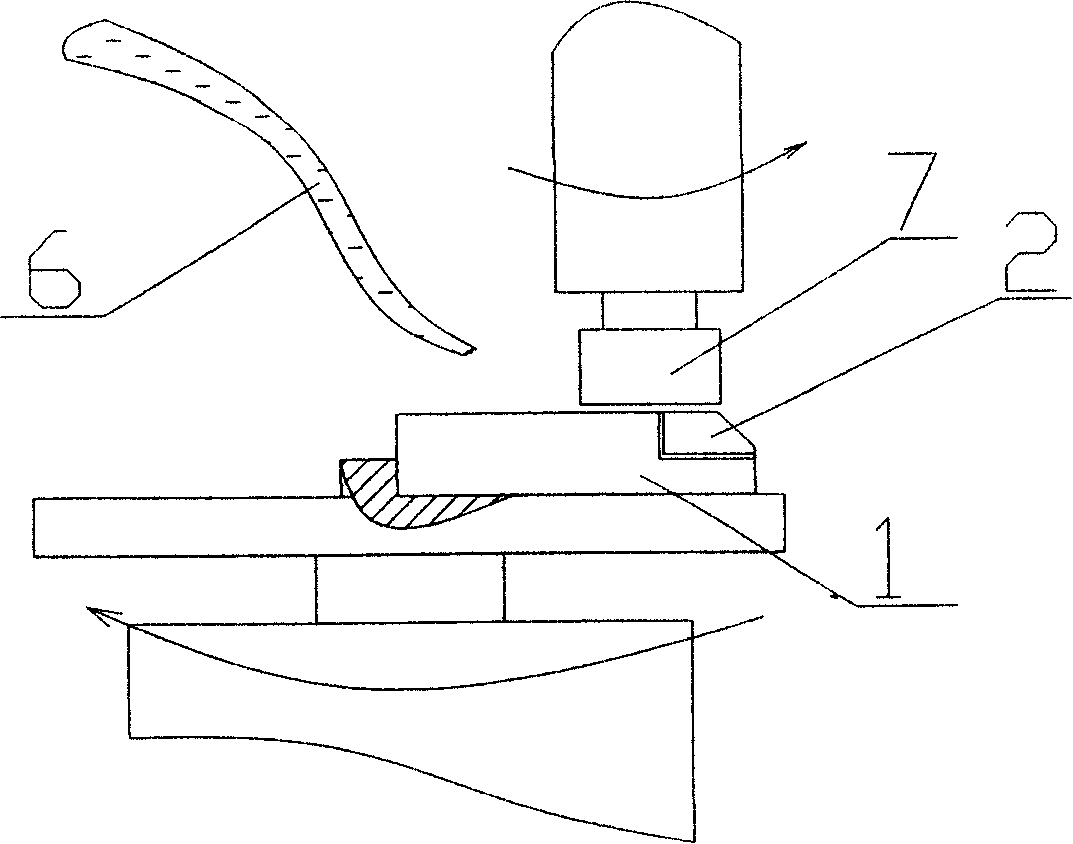

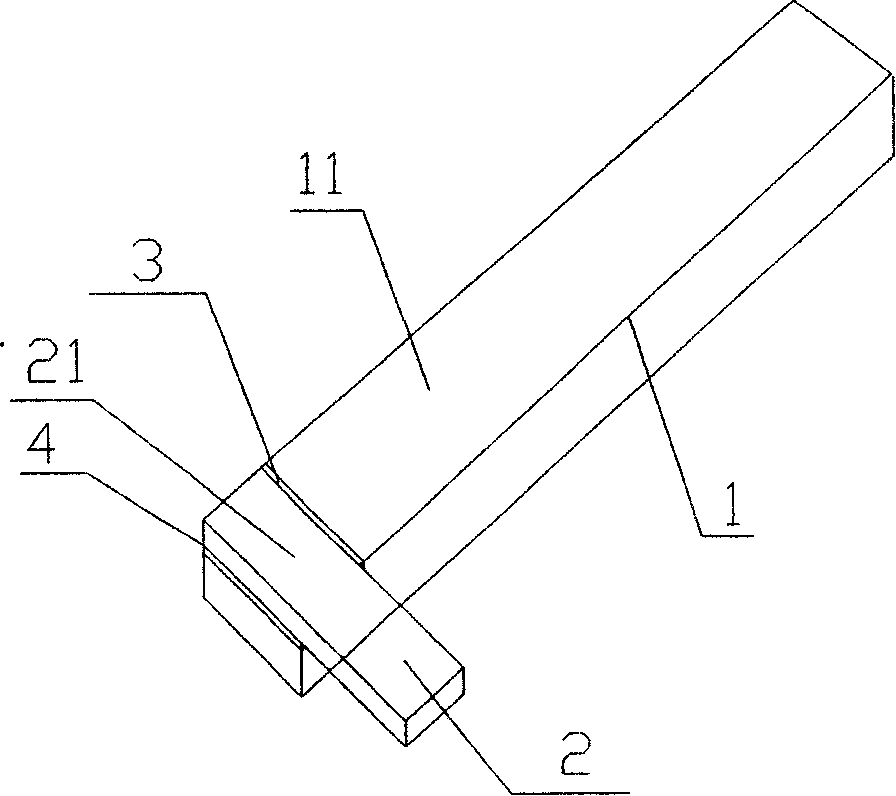

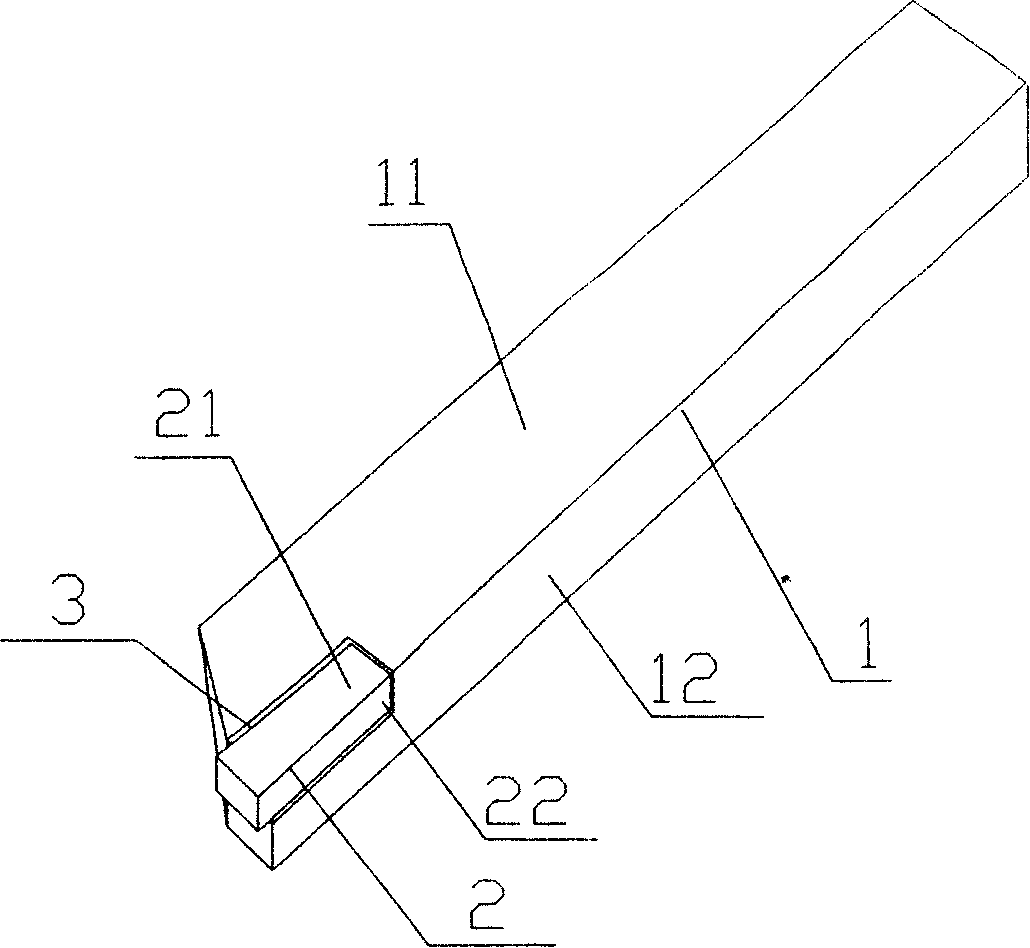

[0031] As shown in the figure, the mirror-polished cemented carbide cutter involved in the present invention is composed of a cutter bar 1 and a cemented carbide blade 2, and cemented carbide is used as a raw material to manufacture the cemented carbide blade 2 in manufacture, and steel is used to manufacture The tool bar 1 of the cutter is welded on the tool bar 1 with a cemented carbide blade 2, and a welding metal layer 3 is formed between the tool bar 1 and the cemented carbide blade 2, and the hard alloy blade 2 and the above-mentioned tool bar 1 After grinding, at least one surface of the cemented carbide blade is on the same surface as the corresponding surface of the tool holder, and the surface roughness of the cemented carbide blade 2 is between 0.012um and 0.4um.

[0032] Firstly, the cemented carbide and steel are initially processed to produce various shapes of cemented carbide tool holder 1 and blade 2, and the mounting part is cut out at one end of the tool rod 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com