Table saw machine

A table saw machine and table body technology, which is applied to sawing equipment, sawing machine devices, sawing components, etc., can solve problems such as time-consuming, affecting the accuracy of a foot switch 70, and losing the requirement for emergency stop.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

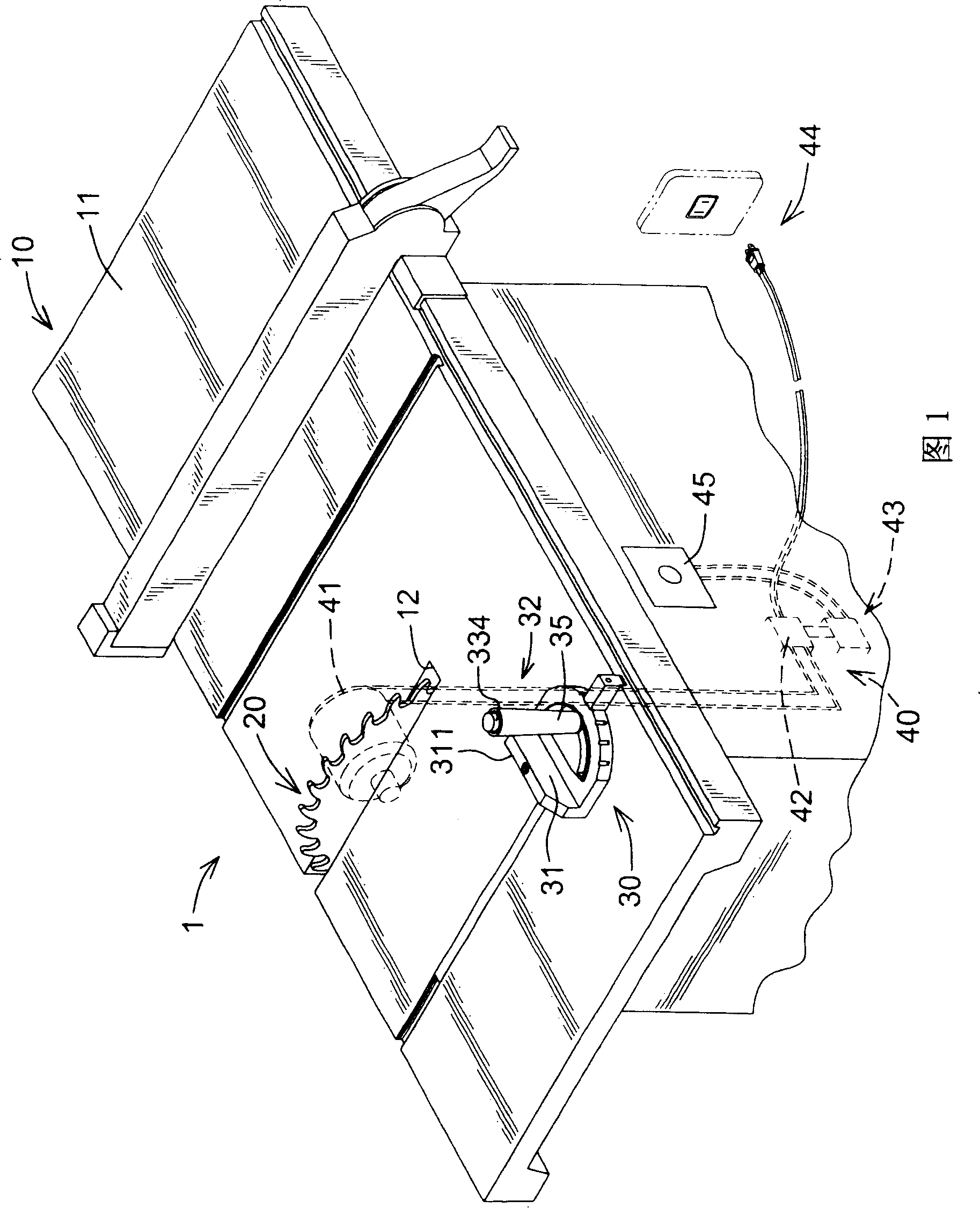

[0044] Referring to FIG. 1 , the present invention provides a table saw 1 with an emergency stop function. The table saw 1 includes a table body 10 , a cutter 20 , a guiding device 30 and a driving device 40 . The table body 10 is provided with an opening 12 and has a table top 11 on which a workpiece (not shown) can be supported; the cutter 20 is combined with the driving device 40 and penetrates the hole 12 for sawing on the table top 11 workpiece.

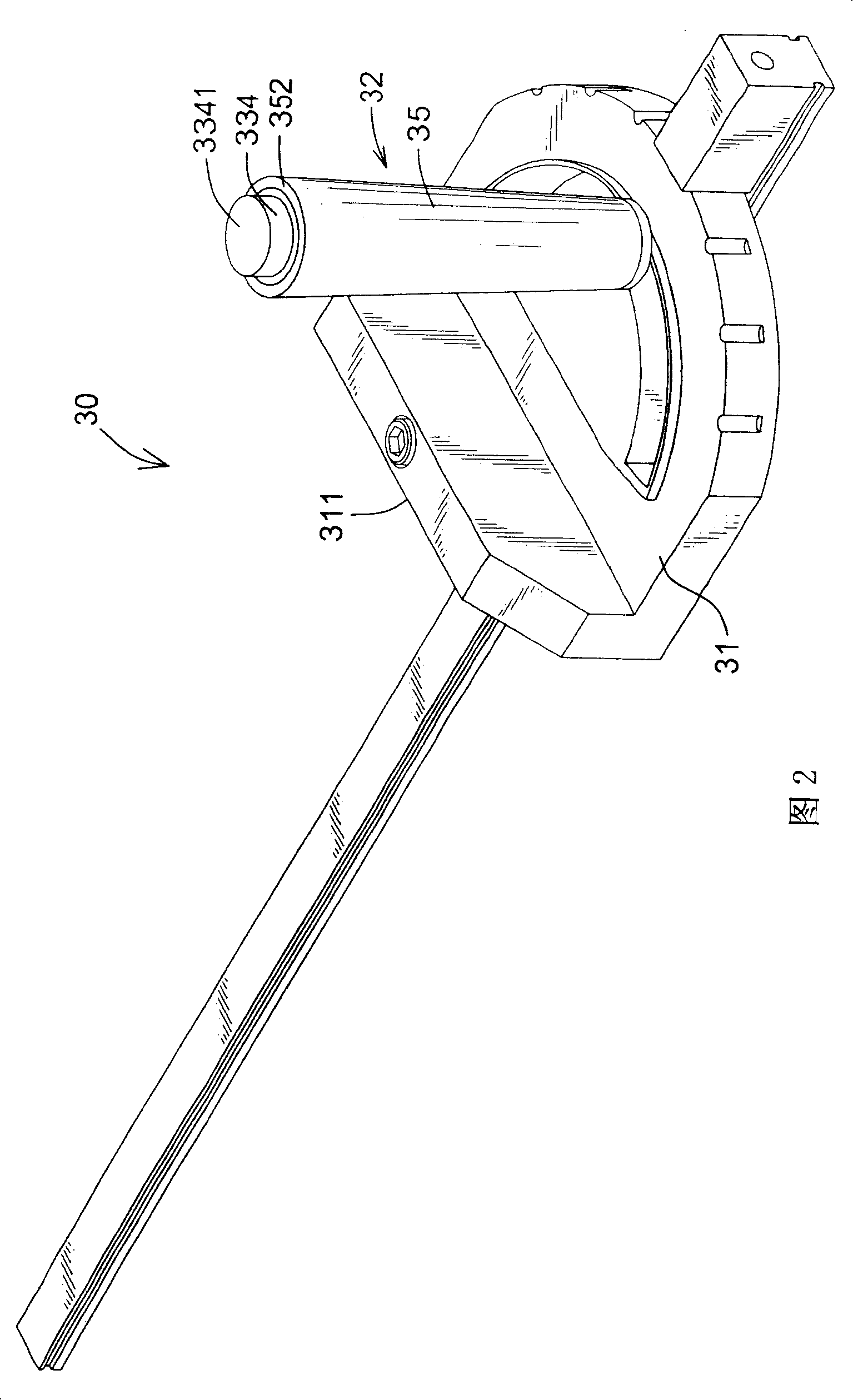

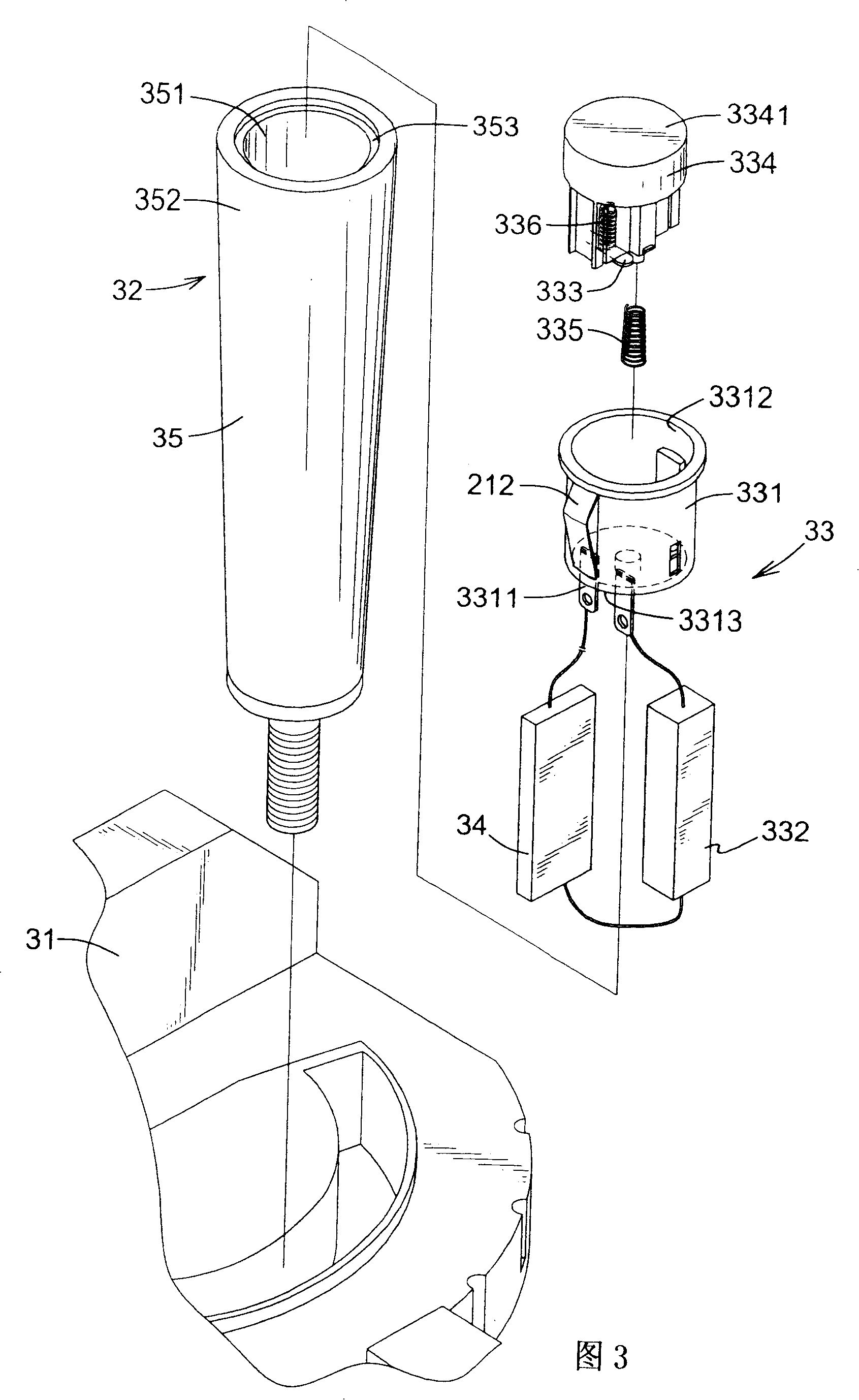

[0045] Please refer to FIG. 1 and FIG. 2 , the guiding device 30 is a miter gauge in this embodiment, which is combined with the table body 10 and can slide back and forth on the table top 11 , and has a pushing member 31 and a holding member 32 . The pusher 31 is used to push the workpiece to move in a sawing direction (front-rear direction), so that the workpiece is cut by the cutter 20. It has a contact surface 311 for pushing the workpiece, and the angle between the contact surface 311 and the sawing direction can be adjust...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com