Pressure adjusting valve

A technology for pressure regulation and pressure adjustment, applied in the direction of internal combustion piston engines, engine components, liquid fuel feeders, etc., can solve problems such as difficulty in maintaining durability, unstable valve opening posture, and inability to use steel balls, etc., to achieve durability High, to avoid the increase of sliding resistance, the effect of low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

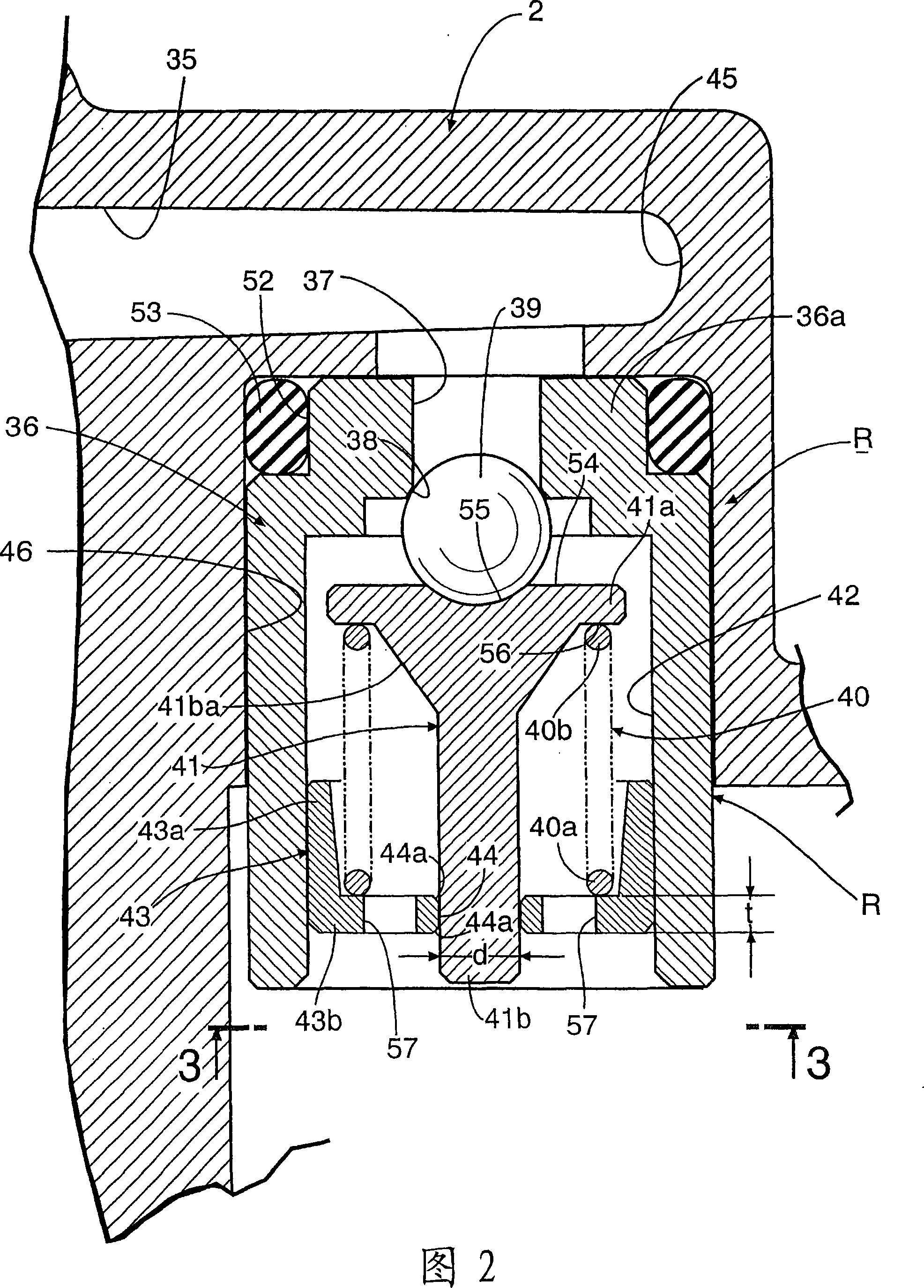

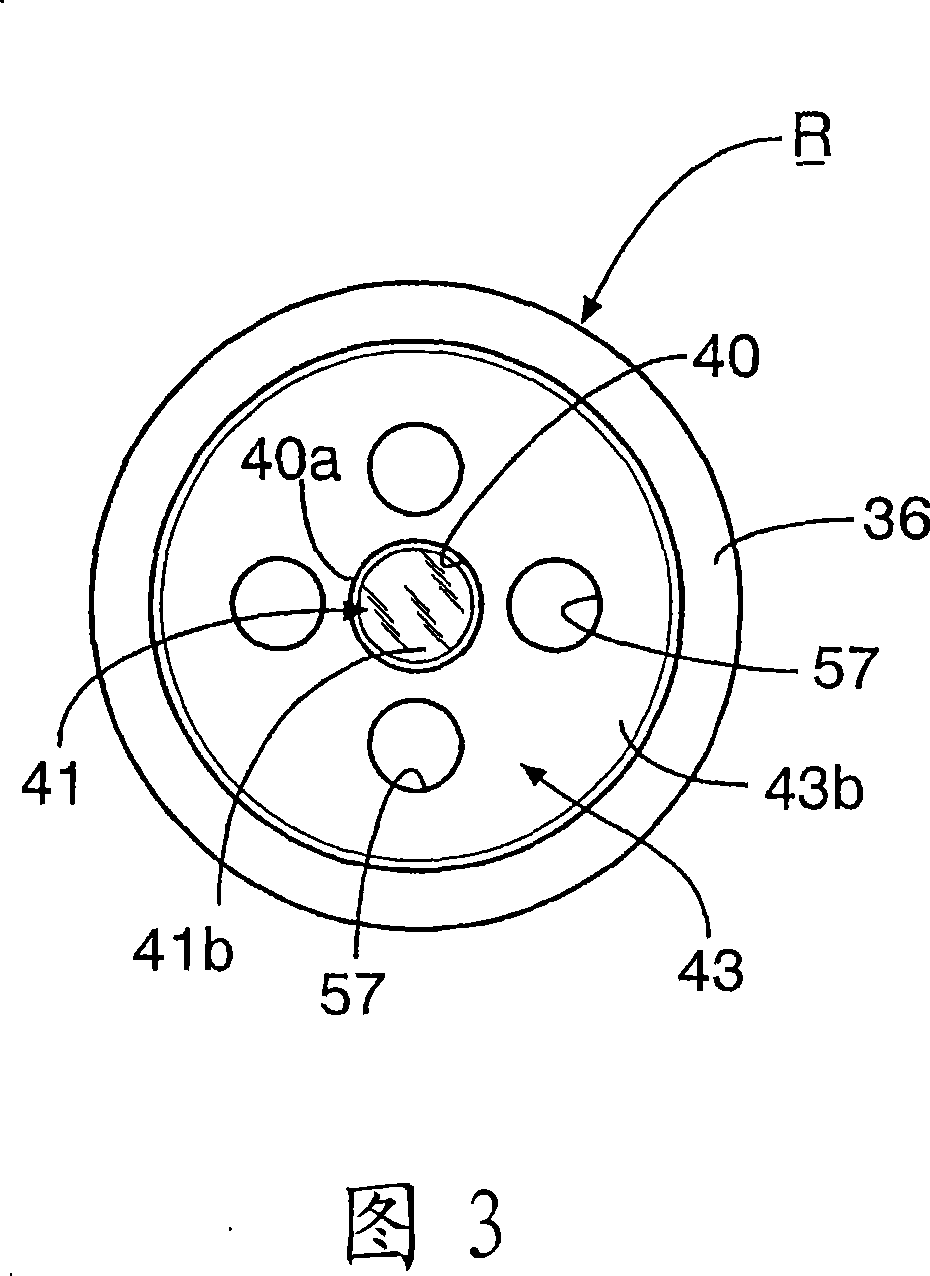

[0034] Next, preferred embodiments of the present invention will be described with reference to the accompanying drawings.

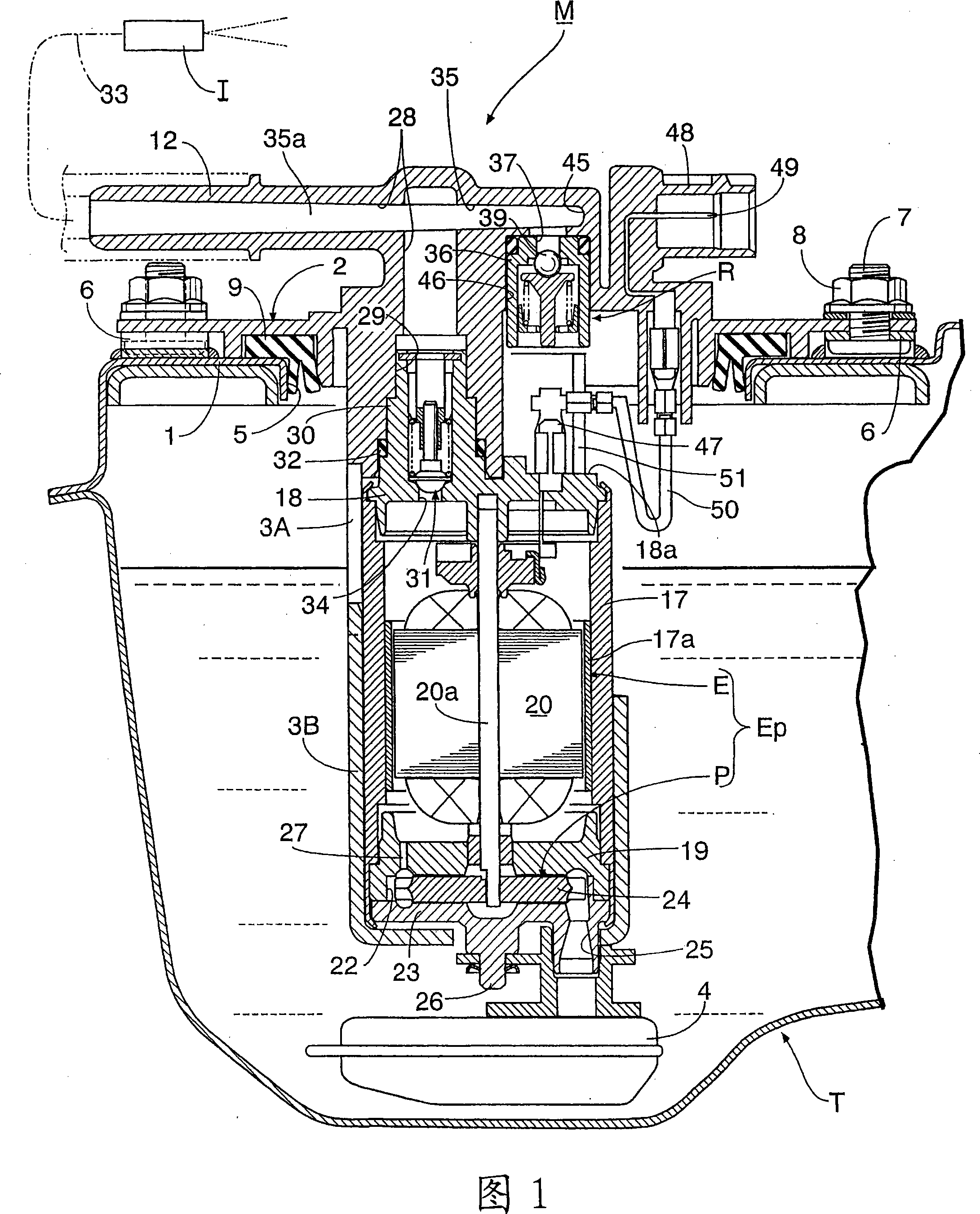

[0035] First, the first embodiment of the present invention will be described. In FIG. 1, a fuel supply module M for supplying fuel in a fuel tank T to a fuel injection valve I of an engine is mounted on a top wall 1 of a fuel tank T mounted on a motorcycle. This fuel supply module M has: an installation base member 2 ; an electric pump Ep arranged vertically in the axial direction directly below the installation base member 2 ; and an upper pump holder 3A integrally formed on the installation base member 2 . the lower pump support 3B, which is detachably engaged with the upper pump support 3A, and accommodates and holds the electric pump Ep in cooperation with the installation base member 2; and the fuel filter installed at the lower end of the electric pump Ep 4.

[0036] An opening 5 for inserting the electric pump Ep into the top wall 1 of the fuel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com