Self-coupling self-locking device for high-lift submersible pump

A technology of self-locking device and submersible pump, which is applied to pump devices, components of pumping devices for elastic fluids, pumps, etc., which can solve problems such as water loss and water can not be discharged, so as to increase discharge volume and improve drainage efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

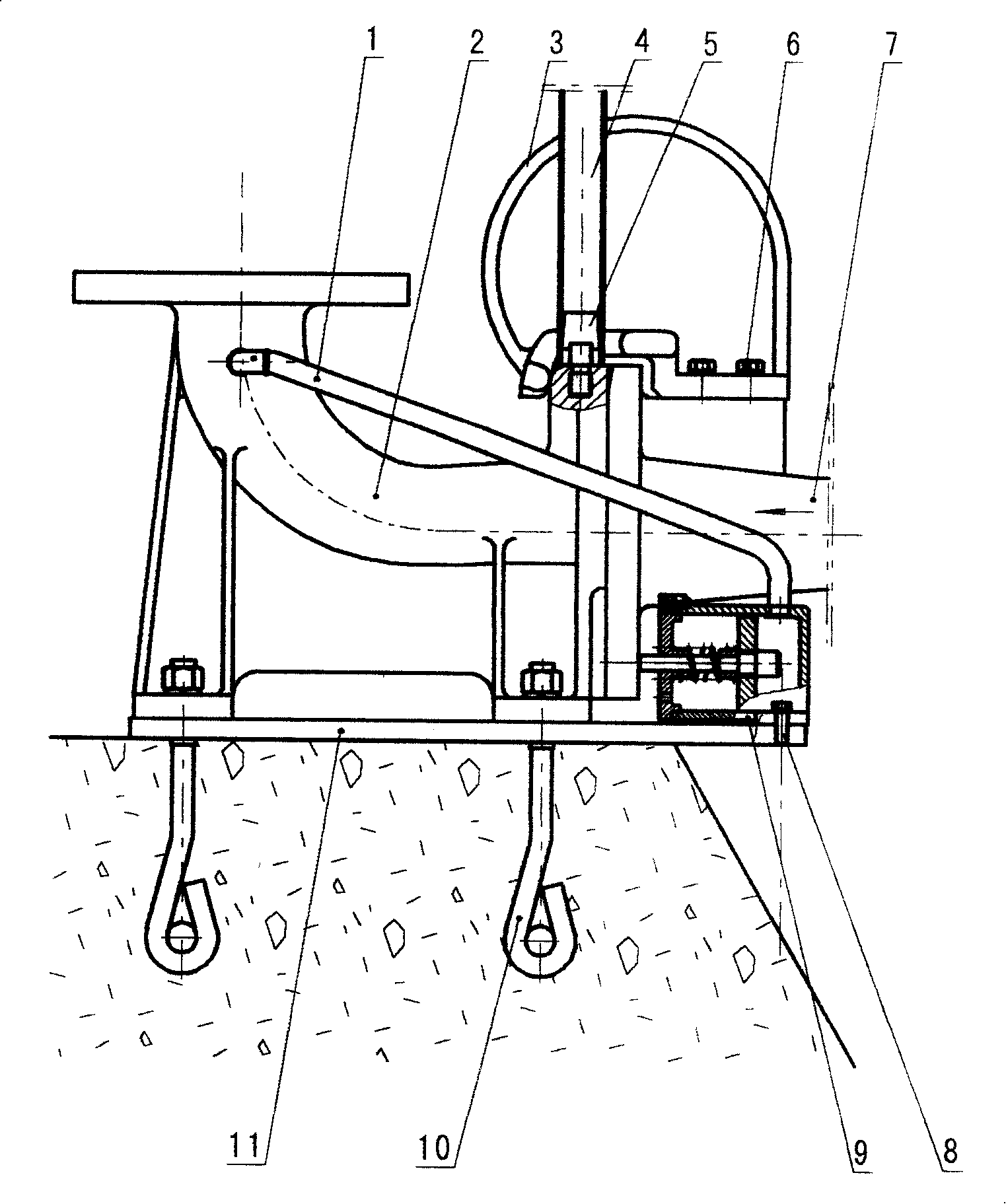

[0031] see figure 1 , in the figure: (1) is the high-pressure infusion tube, (2) is the coupling base, (3) is the pump splint, (4) is the guide rail, (5) is the positioning pin of the guide rail, (6) is the connecting screw, (7) Be a submersible pump, (8) is a connecting screw, (9) is a hydraulic cylinder, (10) is an anchor screw, and (11) is an installation floor.

[0032] Such as figure 1 As shown, the specific structure of the self-coupling and self-locking device of the high-lift submersible pump of the present invention is described as follows:

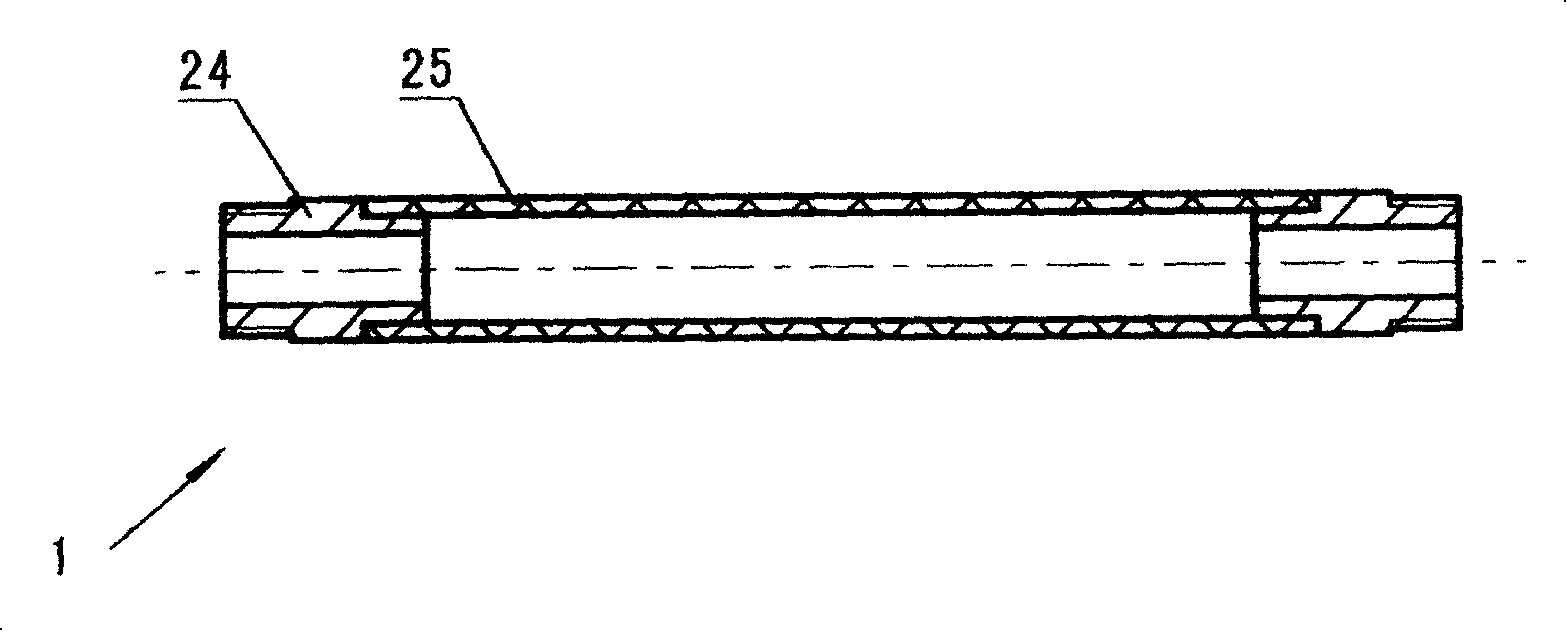

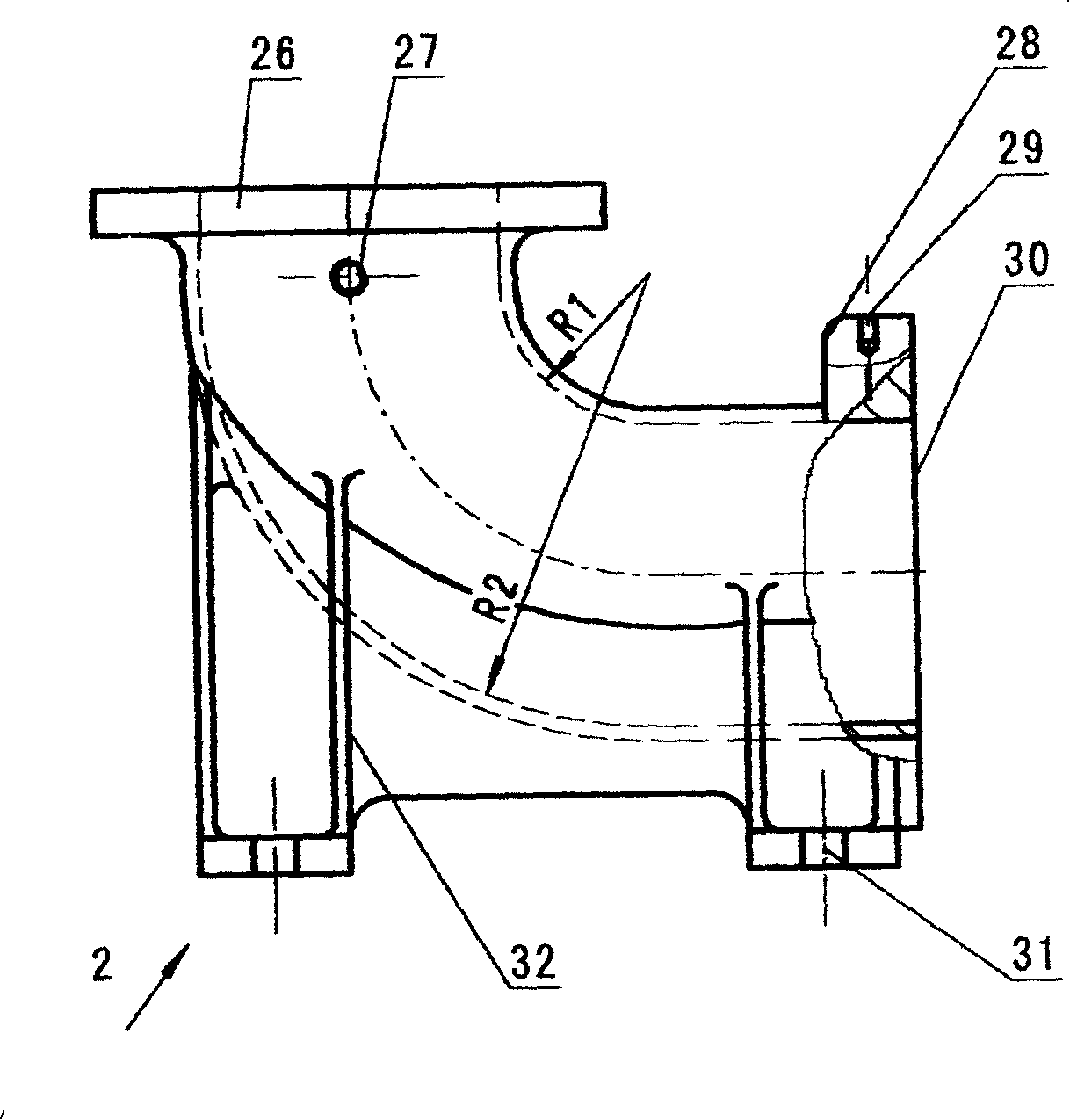

[0033] 1. One end of the high-pressure infusion tube (1) is connected to the high-pressure water intake hole (27) of the coupling base (2), and the other end is connected to the water inlet hole (18) of the hydraulic cylinder (9), such as figure 2 As shown, the high-pressure infusion tube (1) is made up of a joint (24) and a high-pressure hose (25), and the two-end joints (24) are connected to the two ends of the hose (25). T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com