Garbage can capable of unloading at bottom

A technology of bottom unloading and garbage cans, which is applied in the field of garbage cans, which can solve problems such as easy dust and garbage spillage, insufficient inclination angle of garbage cans, dirty dumping of garbage in the bucket, etc., to achieve smooth and thorough dumping, and lock lever movement Smooth, lower center of gravity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The content of the present application will be described below in conjunction with specific embodiments.

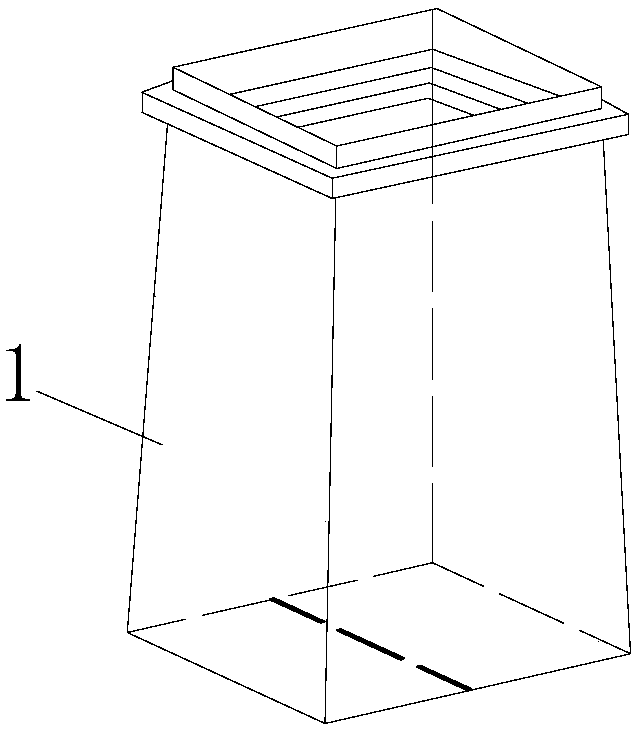

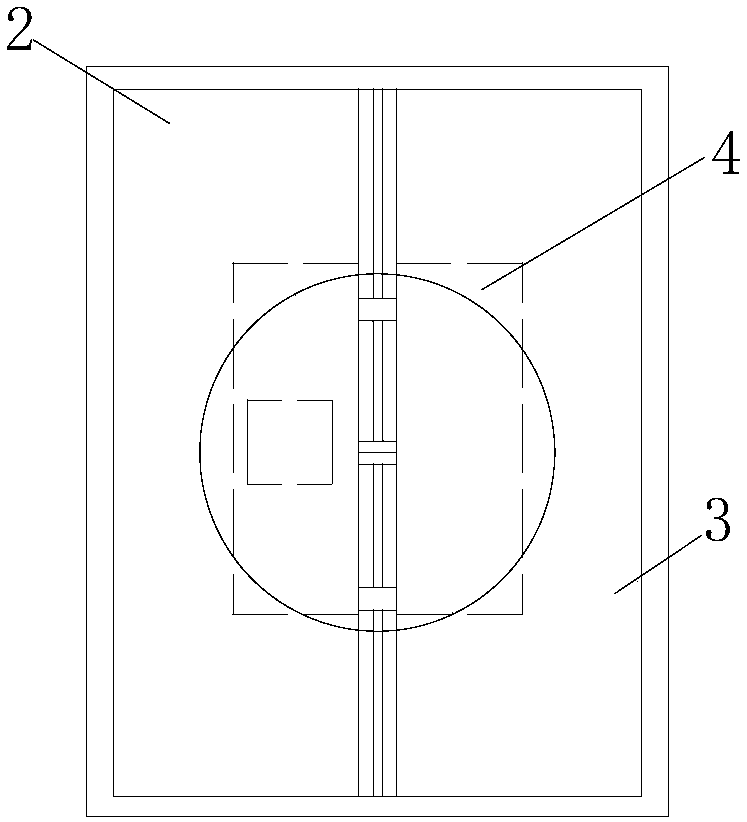

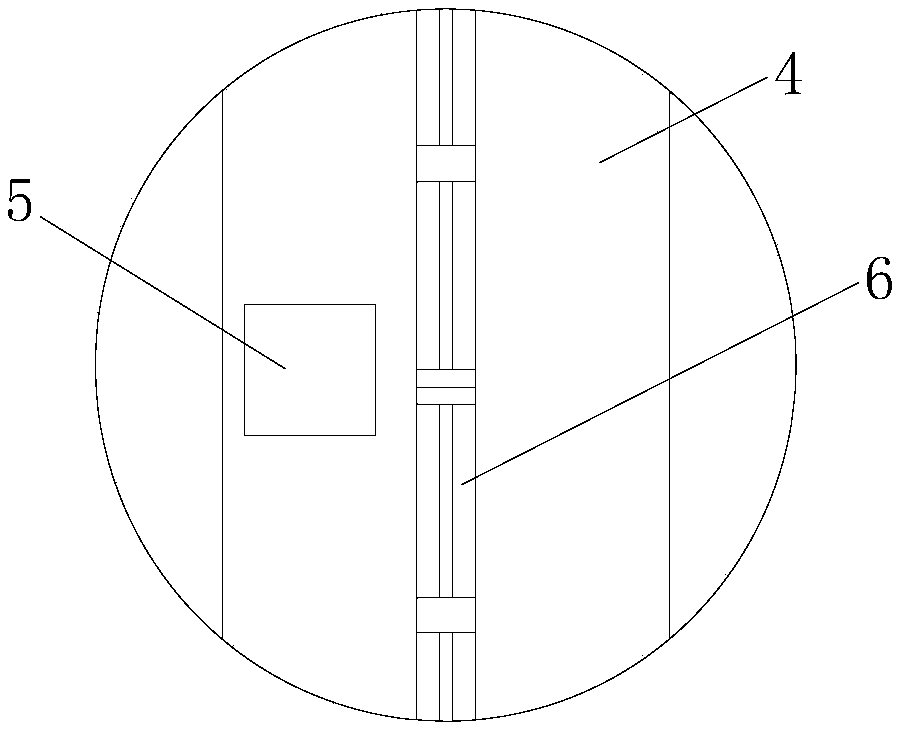

[0028] refer to figure 1 and figure 2 , a bottom discharge trash can proposed by the present application, comprising a bucket body 1, the two ends of the bucket body 1 are open, and the bottom opening of the bucket body 1 is hinged with a left sealing plate 2 and a right sealing plate 3, so The bottom opening of the barrel body 1 is sealed by the cooperation of the left sealing plate 2 and the right sealing plate 3; the left sealing plate 2 is connected with a pressure switch 5 and a pushing mechanism, and the pressure switch 5 and the pushing mechanism Electrically connected, the pushing mechanism is driven and connected with a lock bar 12, and can drive the lock bar 12 to move horizontally; the right sealing plate 3 is provided with a slide 81 that cooperates with the lock bar 12, and the slide The track 81 is on the movement stroke of the lock bar 12 ; in a n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com