Wall-through casing pipe flexible waterproof sealing structure and construction method

A wall-piercing sleeve, flexible waterproof technology, applied in the direction of pipes, pipes/pipe joints/pipe fittings, mechanical equipment, etc., can solve the problems of unbalanced force on support points, increased maintenance costs, and difficult processing, etc., to achieve accelerated The effect of large assembly clearance space, prolonging service life and improving connection strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

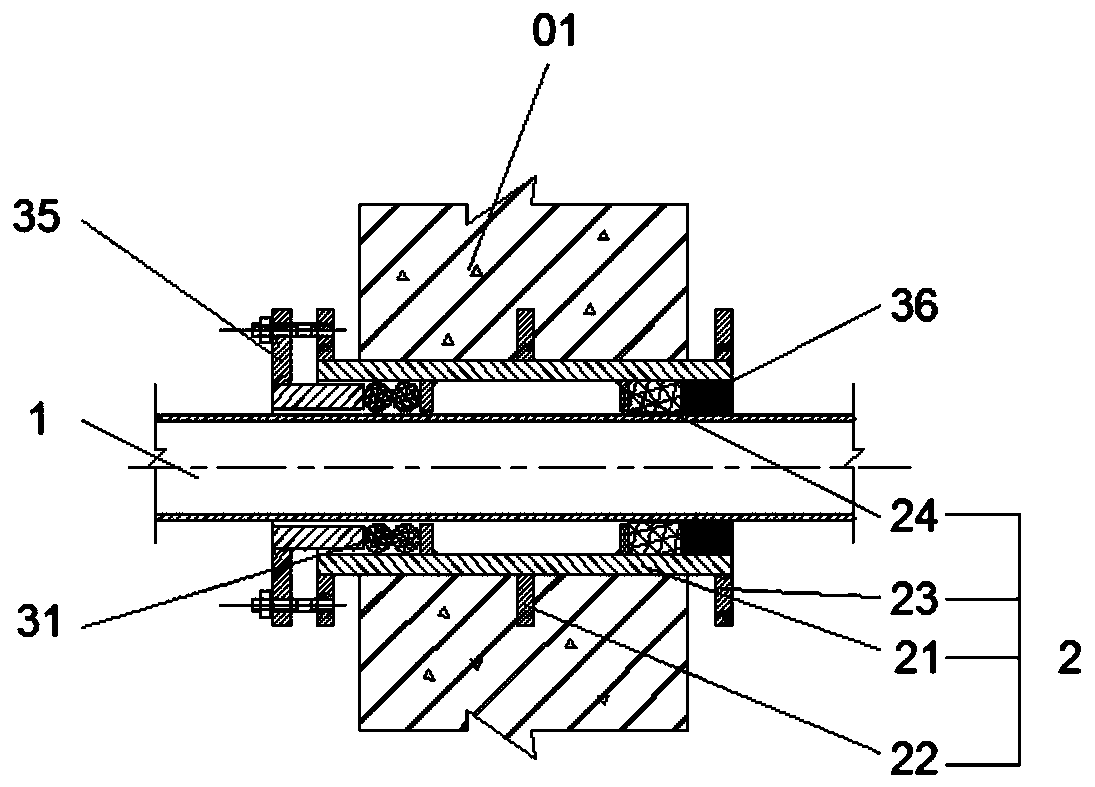

[0054] Figure 2A In the first embodiment shown, the flexible waterproof sealing structure of the wall-piercing sleeve is used to seal the medium pipeline 1 set in the wall 01, including the wall-piercing sleeve 2 and the sealing assembly 3, and the medium pipeline 1 is sheathed in the In the wall bushing 2, the sealing assembly 3 is arranged between the wall bushing 2 and the medium pipeline 1, wherein:

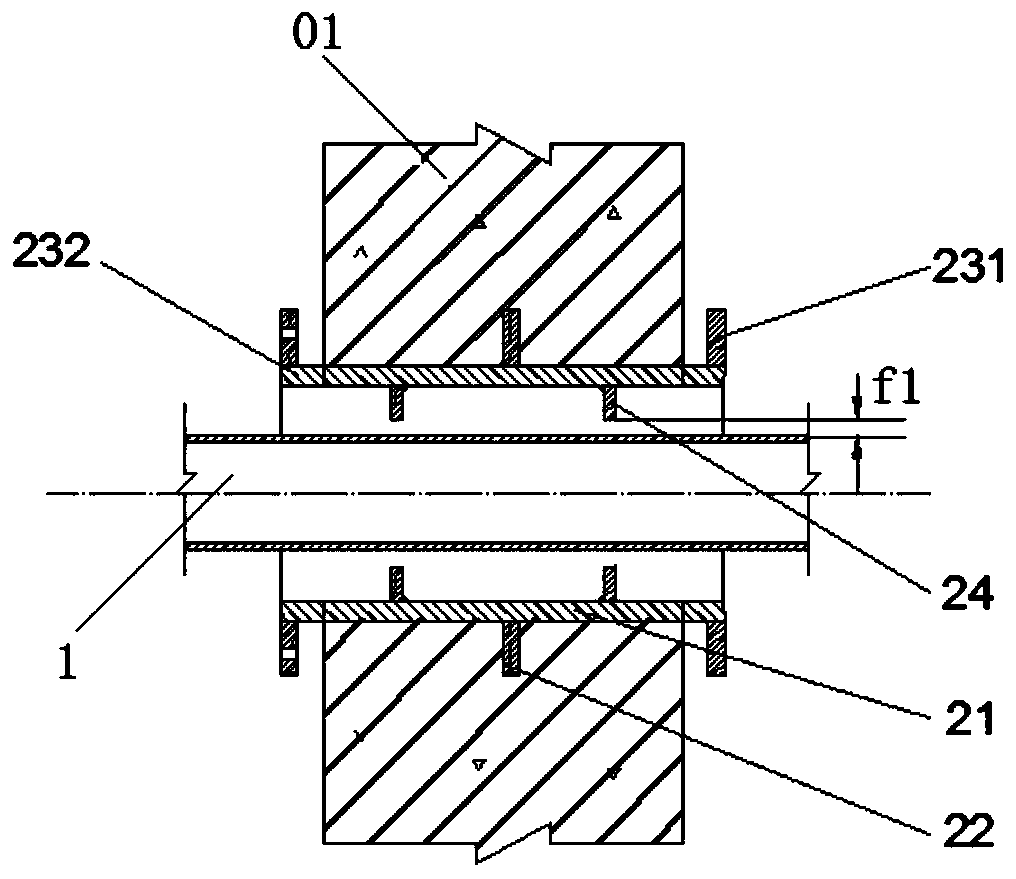

[0055] Existing wall bushing structures such as Figure 1B As shown, there are two inner retaining rings 24 welded inside the pipe body of the wall bushing. The manufacturing process of the structure of this part is complicated. When the pipe diameter of the wall bushing is small, the inner side of the inner retaining ring cannot be welded. Processing, in this structure, the installation gap of the medium pipeline 1 is f1, and the construction and assembly are more difficult. refer to Figure 2B , in this embodiment, the inner retaining ring of the wall bushing 2 is chang...

Embodiment 2

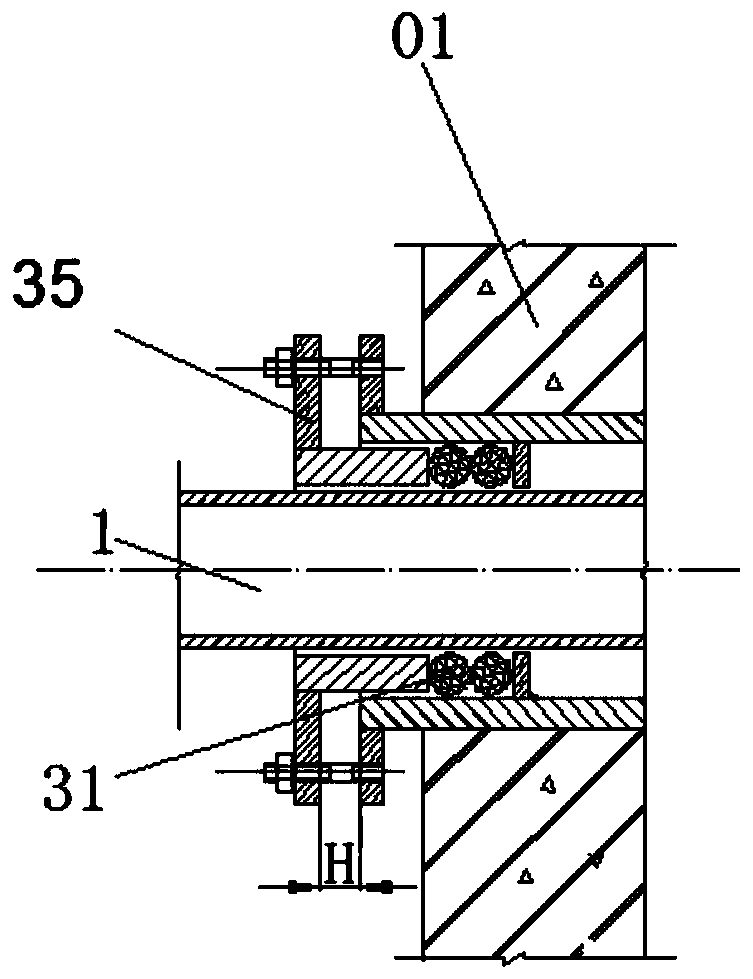

[0075] In this embodiment, the second embodiment of the flexible waterproof sealing structure of the wall casing is as follows: image 3 As shown, the structure is the same as the basic structure of Embodiment 1, and is a reinforced type of Embodiment 1. The difference is that the sealing assembly 3 at least includes flexible sealing assemblies at both ends that are balancedly arranged (the first sealing assembly and the second sealing assembly). sealing assembly) and the flexible sealing assembly (the third sealing assembly) in the middle. Specifically, the sealing assembly 3 is composed of three precompression retaining rings 32 (namely, the axial precompression retaining ring 331 on the upstream surface, the axial precompression retaining ring 332 on the neutral plane and the axial precompression retaining ring 333 on the backwater surface), Three sets of sealing rings 31 separated by three pre-compression retaining rings 32 (namely, the sealing ring 311 on the upstream sur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com