Steam forming method and device for domestic appliances

A technology for household appliances and steam, which is applied in steam generating methods, components of steam boilers, washing devices, etc., which can solve the problems of easy mixing of a large number of water drops, and achieve the effects of simple structure, convenient manufacture, and reduced water drop content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

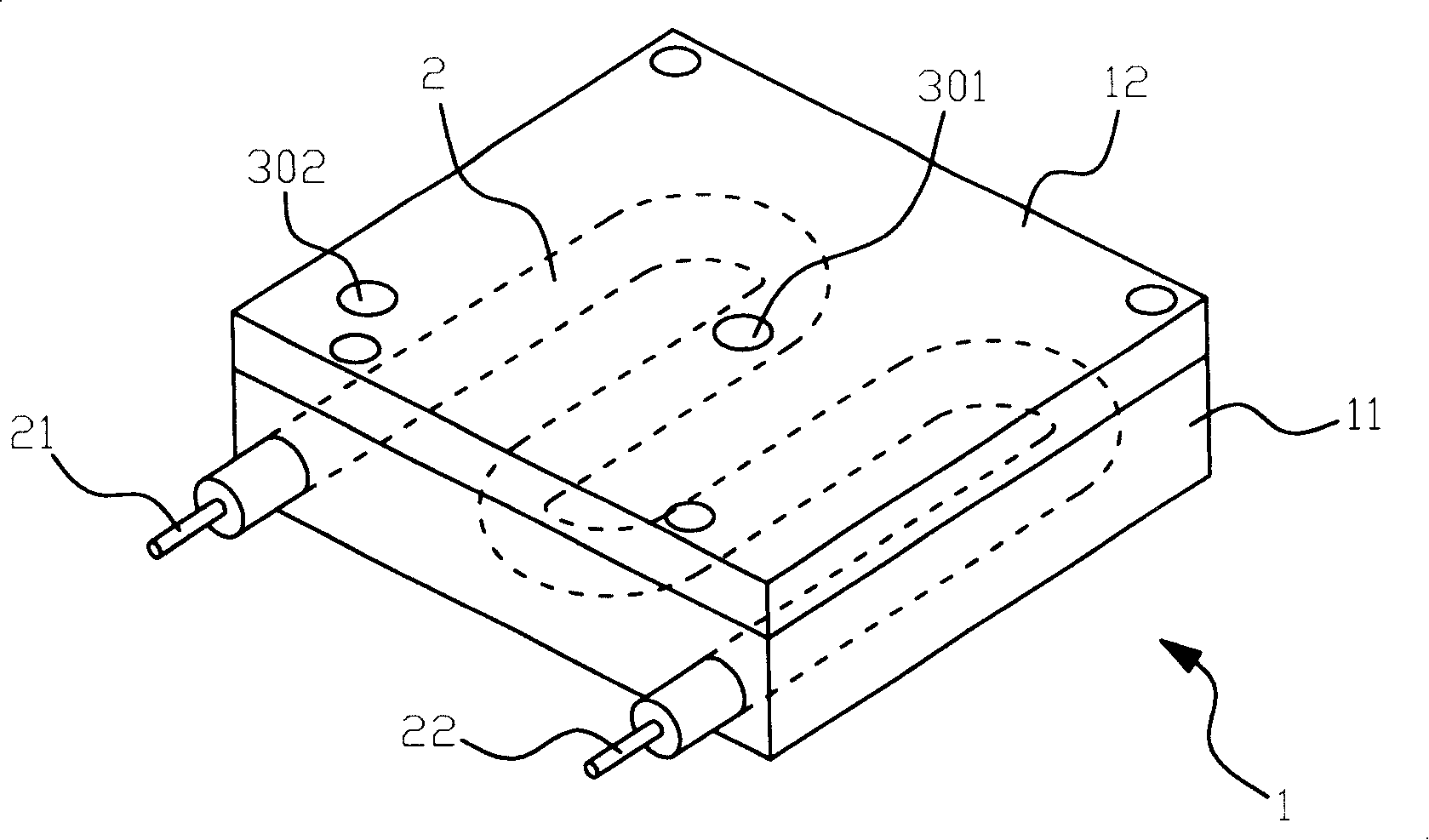

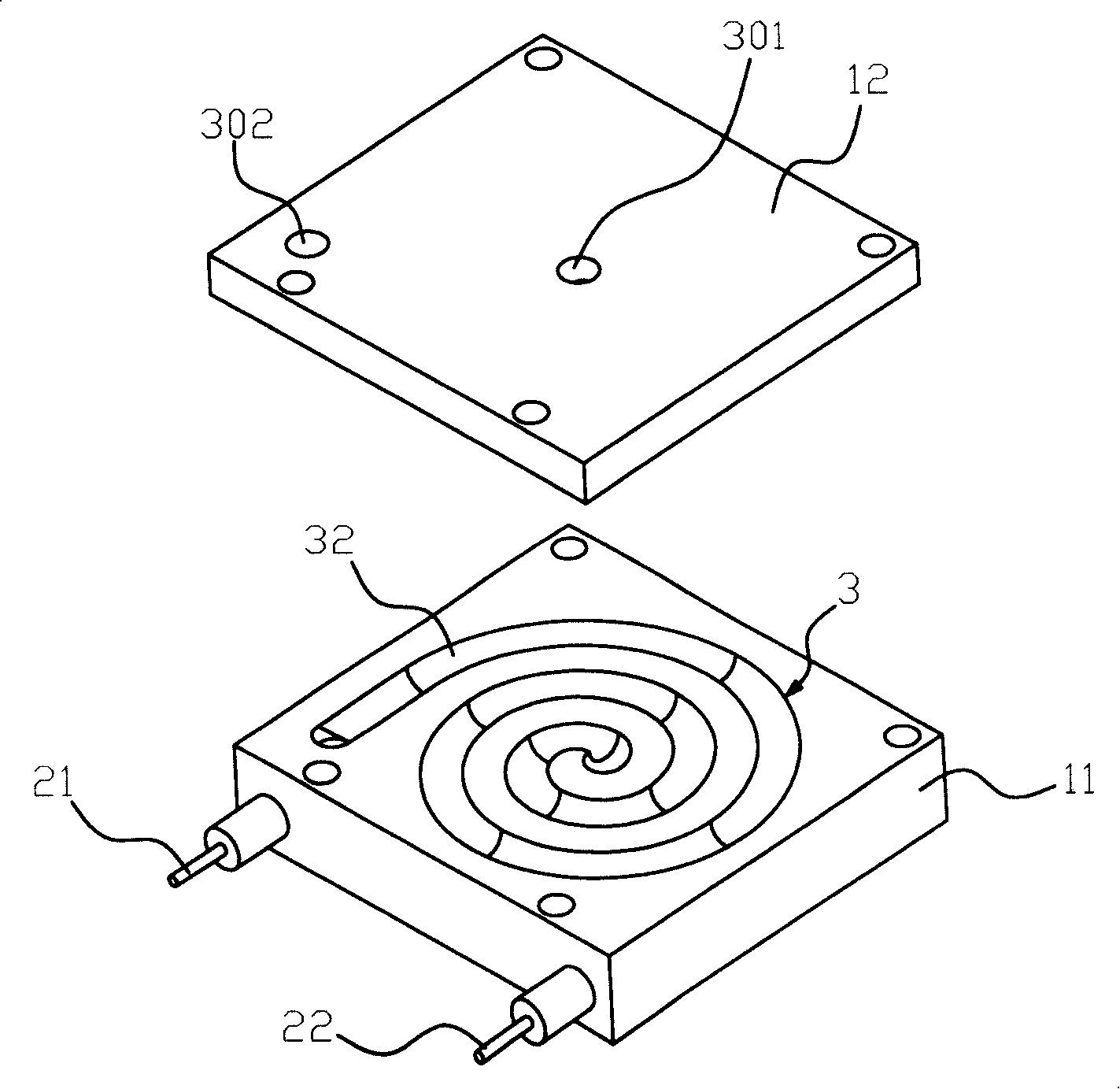

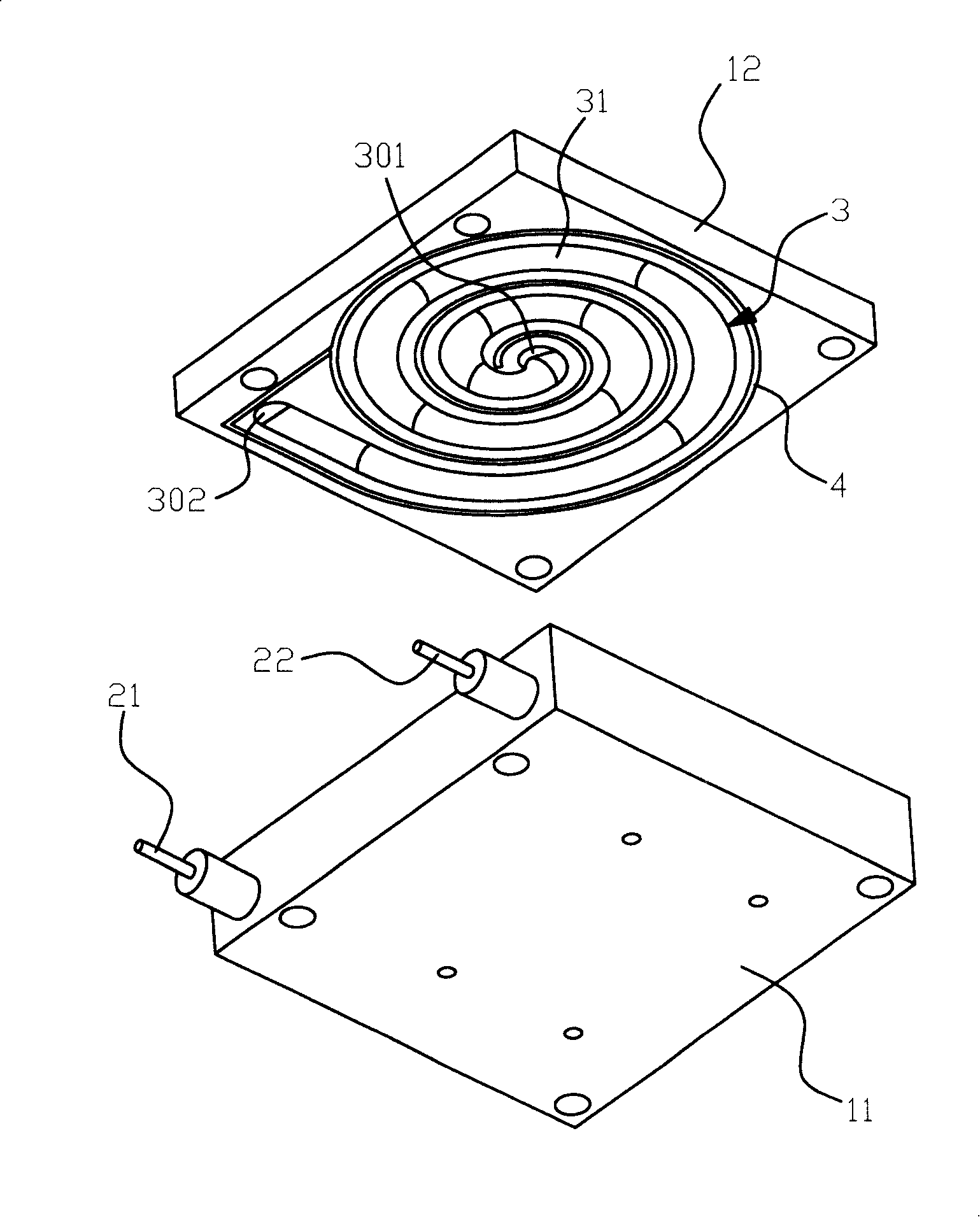

[0028] Specific embodiment one of the present invention, refer to figure 1 The steam forming device includes a heating element 1 which includes a heating main body 11 and a cover plate 12 arranged above the heating main body 11, and the heating main body 11 and the cover plate 12 are fixedly connected by screws. An electric heating tube 2 is embedded in the heating body 11. The electric heating tube 2 is provided with power connectors 21 and 22 exposed outside the heating body 11. The electric heating tube 2 constitutes a heating device for heating the heating body 1.

[0029] Also refer to figure 2 , image 3 The opposite surfaces of the heating body 11 and the cover plate 12 are respectively provided with spiral grooves 31 and 32. When the cover plate 12 is covered above the heating body 11, the spiral grooves 31 and 32 together form a spiral tube cavity 3. . A water inlet 301 is provided on the top surface of the cover plate 12 at a position corresponding to the inner end of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com