Method for quickly designing mould using computer

A computer and general-purpose mold technology, applied in the direction of calculation, special data processing applications, instruments, etc., can solve the problems of low mold design reusability, difficulty for mold companies to respond quickly, low product repetition rate, etc., to shorten the design cycle , reduce design errors, use simple effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

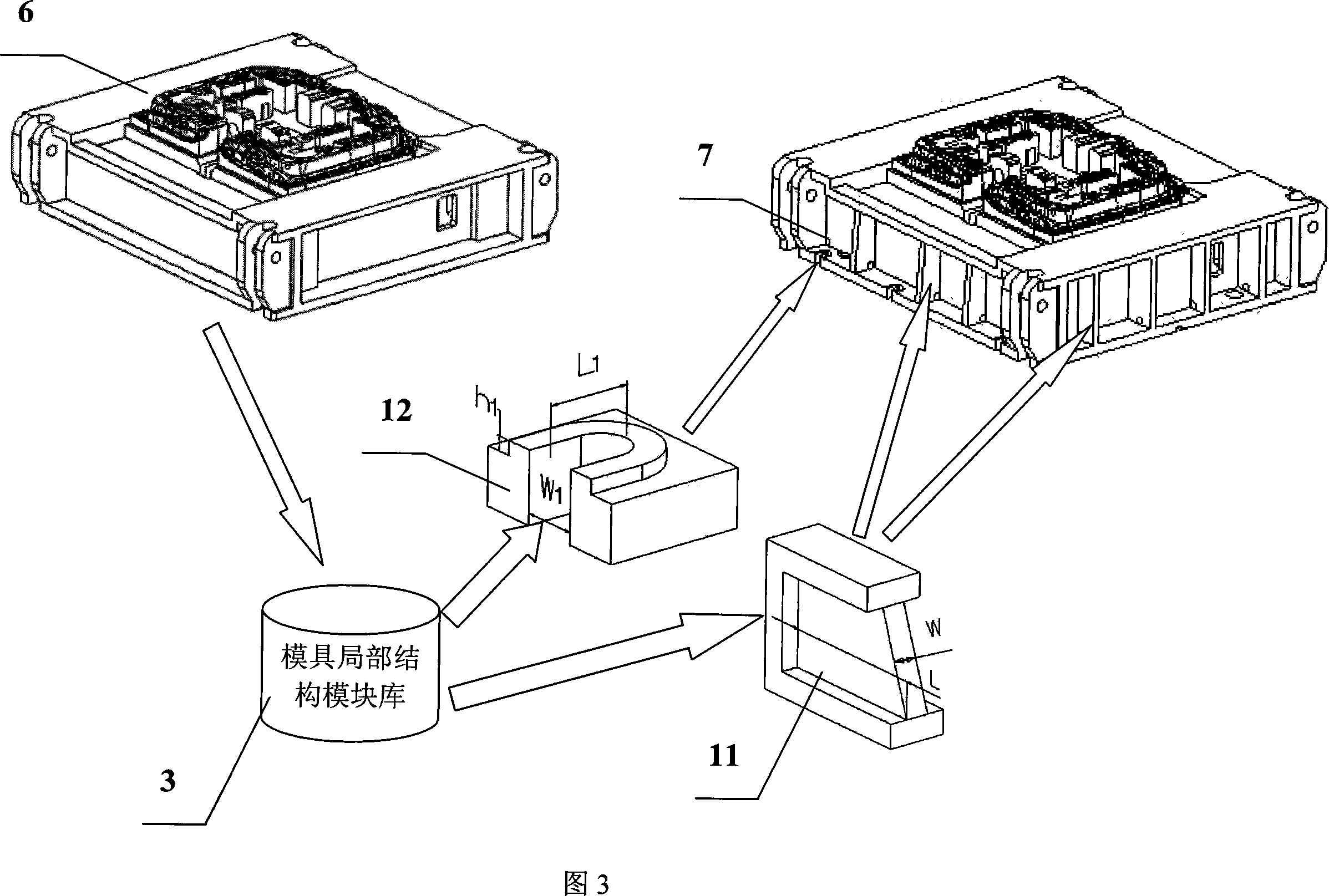

[0022] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

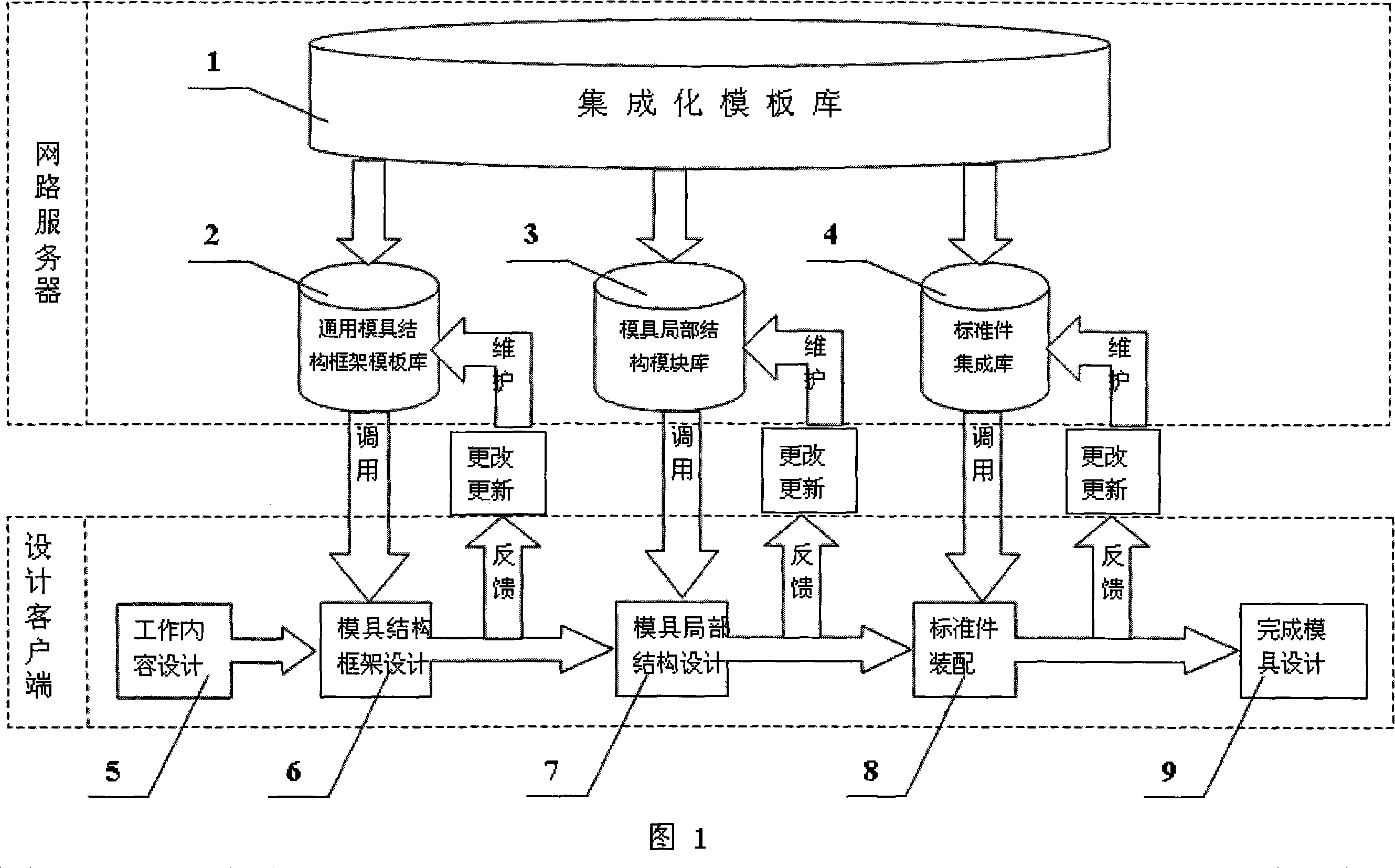

[0023] As shown in Figure 1, the present invention provides a kind of method utilizing computer rapid design mold, comprises the following steps:

[0024] 1). Through the data collection and data processing required by customers, template files are formed, and an integrated template library is established. The integrated template library includes: a general mold structure frame template library, a mold local structure module library, and a standard parts integration library ; Encapsulate the integrated template library on the network server;

[0025] 2). Complete the design of the work content structure according to the process content;

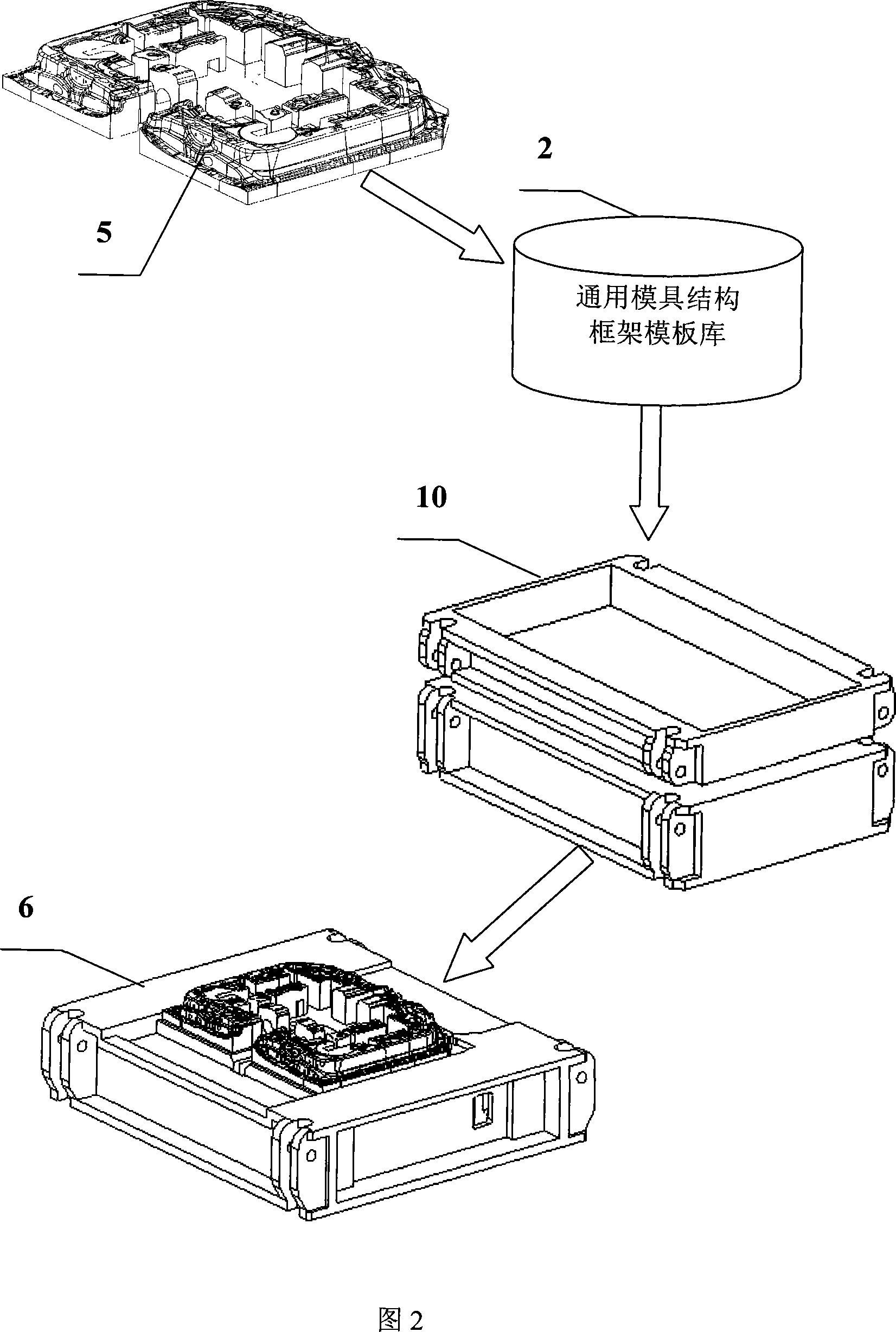

[0026] 3). Determine the adjustment parameters of the mold structure frame according to the size of the work content, and call the same or similar template files in the general mold structure frame template library to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com