Perpendicular magnetic recording medium and magnetic recording/reproducing apparatus

A technology of perpendicular magnetic recording and medium, which is applied in magnetic recording, data recording, recording information storage, etc., and can solve the problems of poor recording/reproducing characteristics, reduced writeability of recording head, and increased recording magnetic field.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0111] The present invention will be explained in more detail below with reference to examples.

example 1

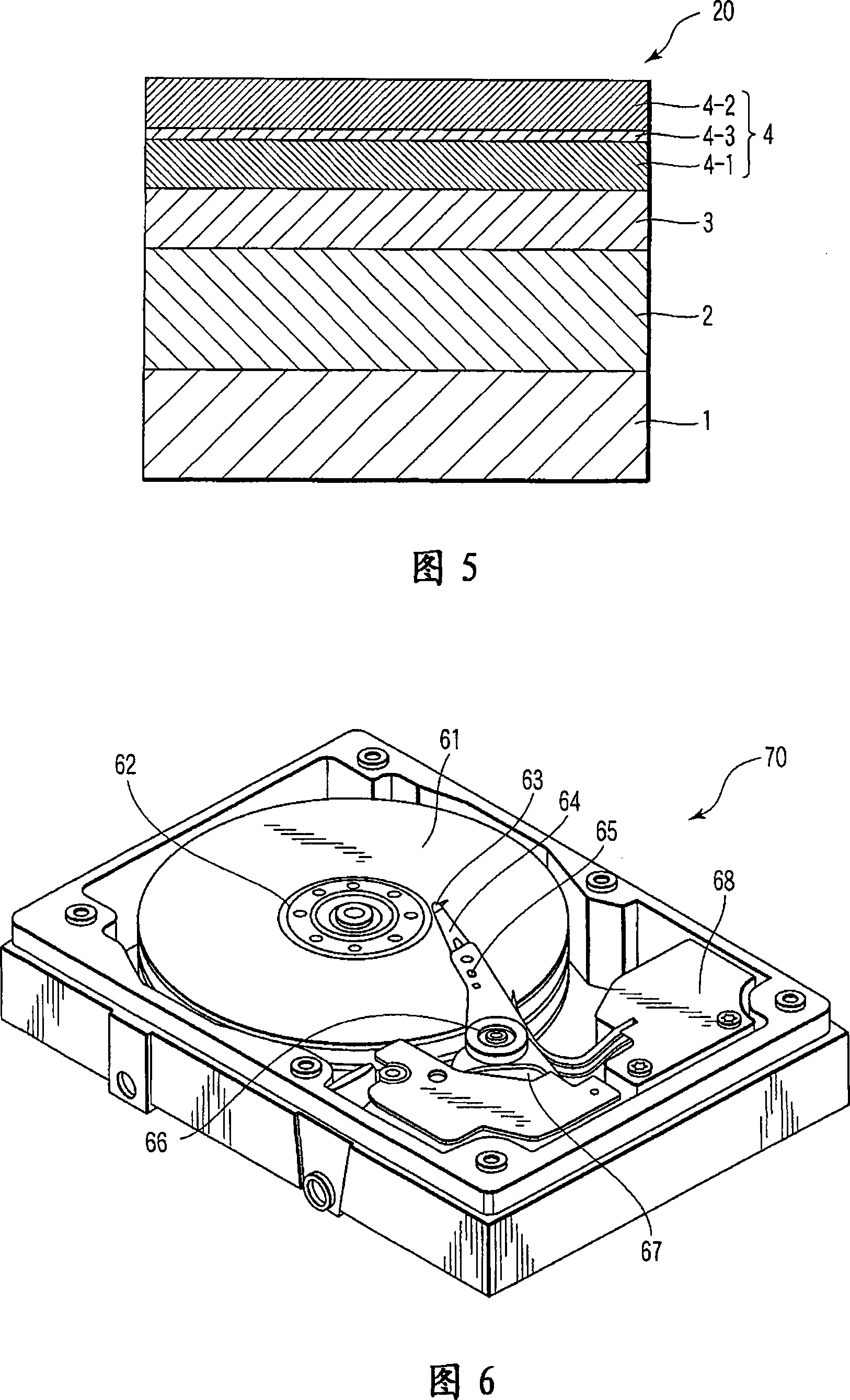

[0113] A 2.5-inch hard disk type non-magnetic glass substrate (TS-10SX manufactured by OHARA) was placed in a vacuum chamber of a C-3010 sputtering apparatus manufactured by ANELVA.

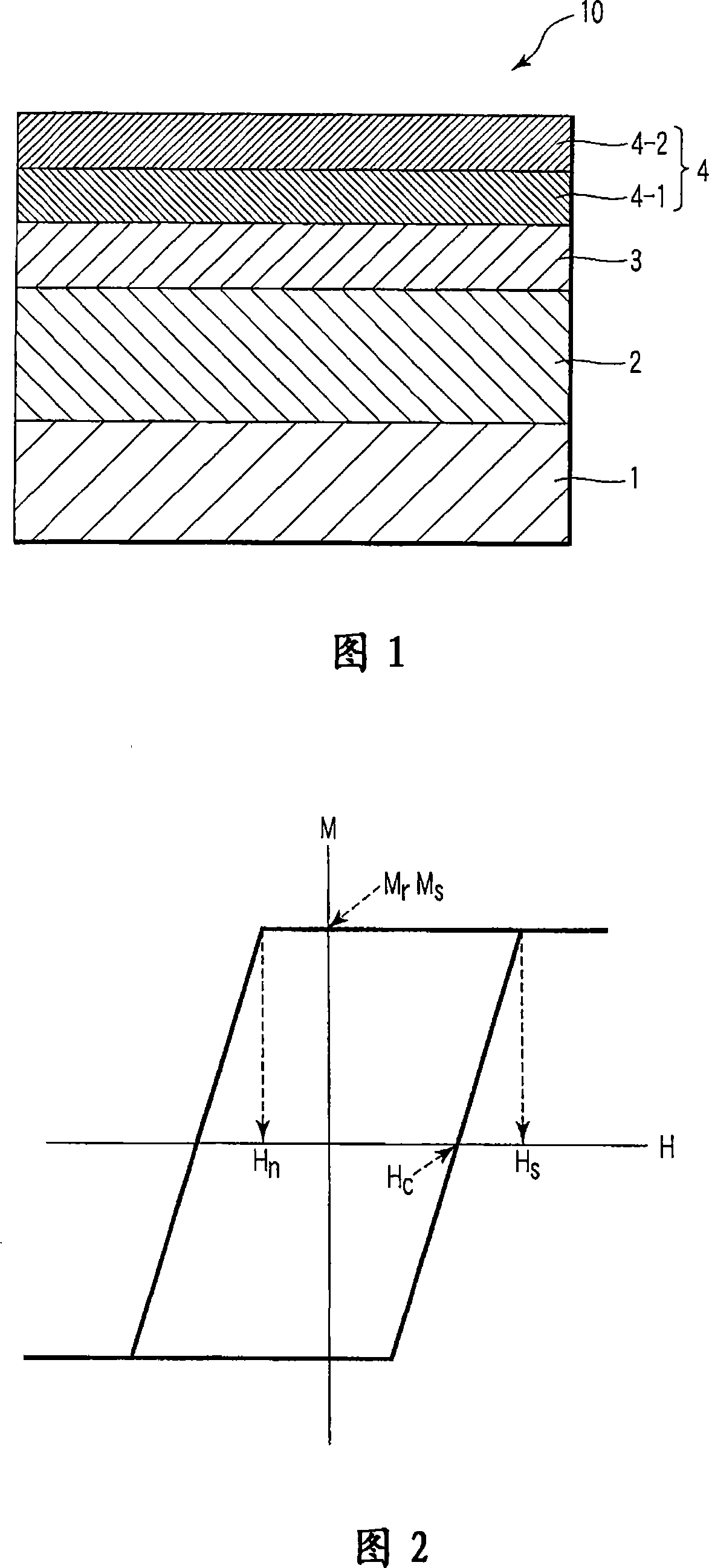

[0114] The vacuum chamber of the sputtering equipment is evacuated to 1×10 -5 After Pa or less, 100-nm-thick Co 90 Zr 5 Nb 5 thin film as a soft magnetic underlayer, a 20-nm thick Ru thin film as a nonmagnetic underlayer, and a 20-nm thick (Co 76 -Cr 6 -Pt 18 )-8mol%SiO 2 thin film as a hard magnetic recording layer, Co 35 Ni 65 -8mol% SiO 2 thin film as a soft magnetic recording layer, and a 5-nm thick C thin film as a protective layer. The film thickness of the soft magnetic recording layer can be varied within the range of 1 to 20 nm. After the thin film was formed, the surface of the protective layer was coated with a 13-angstrom-thick perfluoropolyether (PFPE) lubricant by a dipping method, thereby obtaining a perpendicular magnetic recording medium.

[0115] FIG. 7 is a schematic...

example 2

[0157] In addition to replacing the 20-nm thick (Co 76 -Cr 6 -Pt 18 )-8mol%SiO 2 thin film using Fe-Ni-8mol%SiO 2 , Co-Ni-8mol% SiO 2 , and Fe-Co-8mol% SiO 2 The perpendicular magnetic recording medium was produced in the same procedure as in Example 1 except that any one of them was used as the soft magnetic recording layer, and the composition ratios of these Fe-Ni, Co-Ni and Fe-Co alloys were varied. The film thickness of the soft magnetic recording layer was fixed at 4 nm.

[0158] Each alloy composition is changed by adjusting the target alloy composition.

[0159] The XRD evaluation results show that the magnetic grains in the hard magnetic recording layer of any perpendicular magnetic recording medium have a hcp structure and are oriented in the (0001) plane.

[0160] The results of two-dimensional TEM observation show that the hard magnetic recording layer of any perpendicular magnetic recording medium has a granular structure, in which the grain boundary region...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com