Macaroni product line and production technology thereof

A macaroni and production line technology, applied in the fields of application, food preparation, food science, etc., can solve the problems of difficult loading and unloading, many manual operations, difficult continuous production, etc., and achieve the effects of good product quality, less manual operation, and simple equipment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

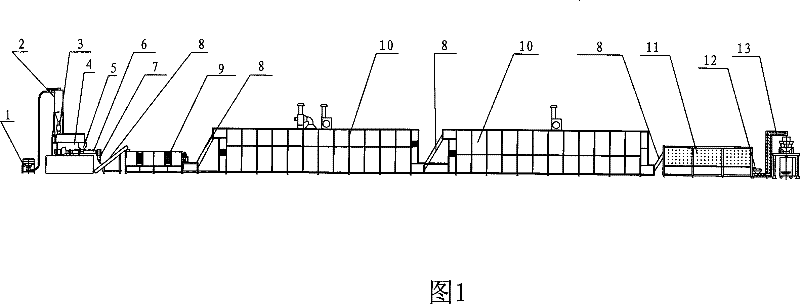

[0029] Such as figure 1 As shown, the macaroni production line of the present invention includes a vibrating screen 1, an air delivery system 2, a vacuum noodle mixing machine 3, a vacuum ripening mixer 4, a feeder 5, an extruder 6, and a cutting machine 7 arranged in sequence according to the material conveying direction. , Hoist 8, vibration pre-drying machine 9, hoist 8, dryer 10, hoist 8, air cooler 11, vibration discharge machine 12, packaging conveyor 1 3.

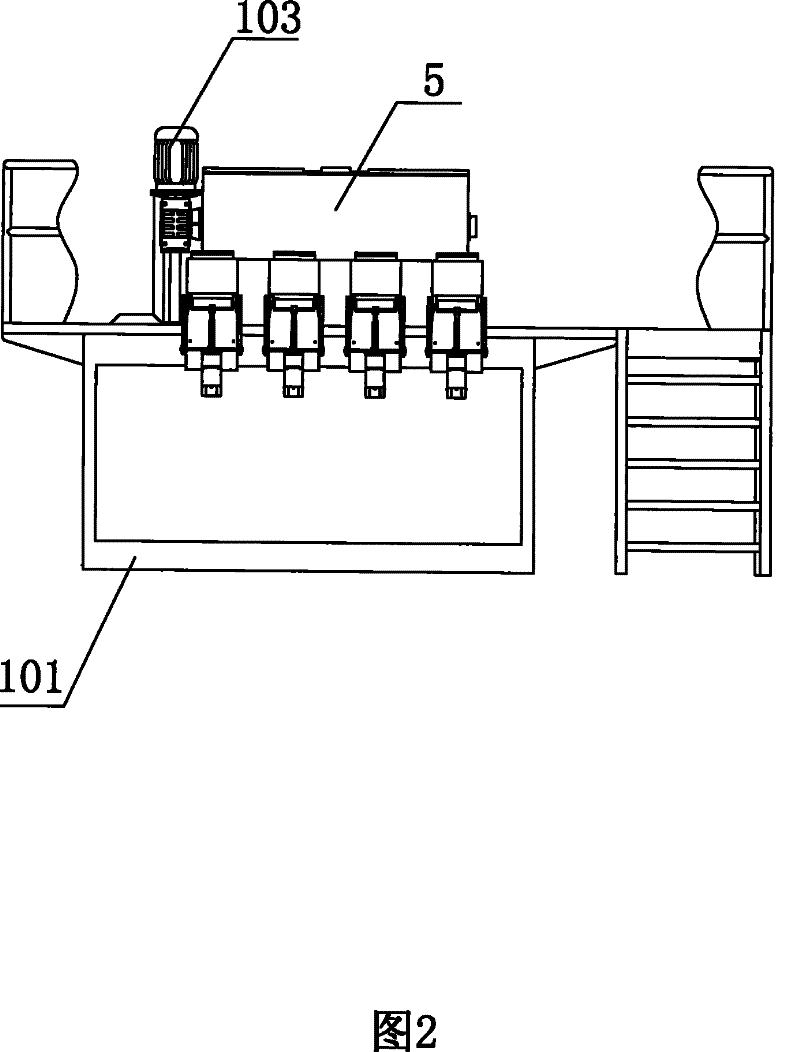

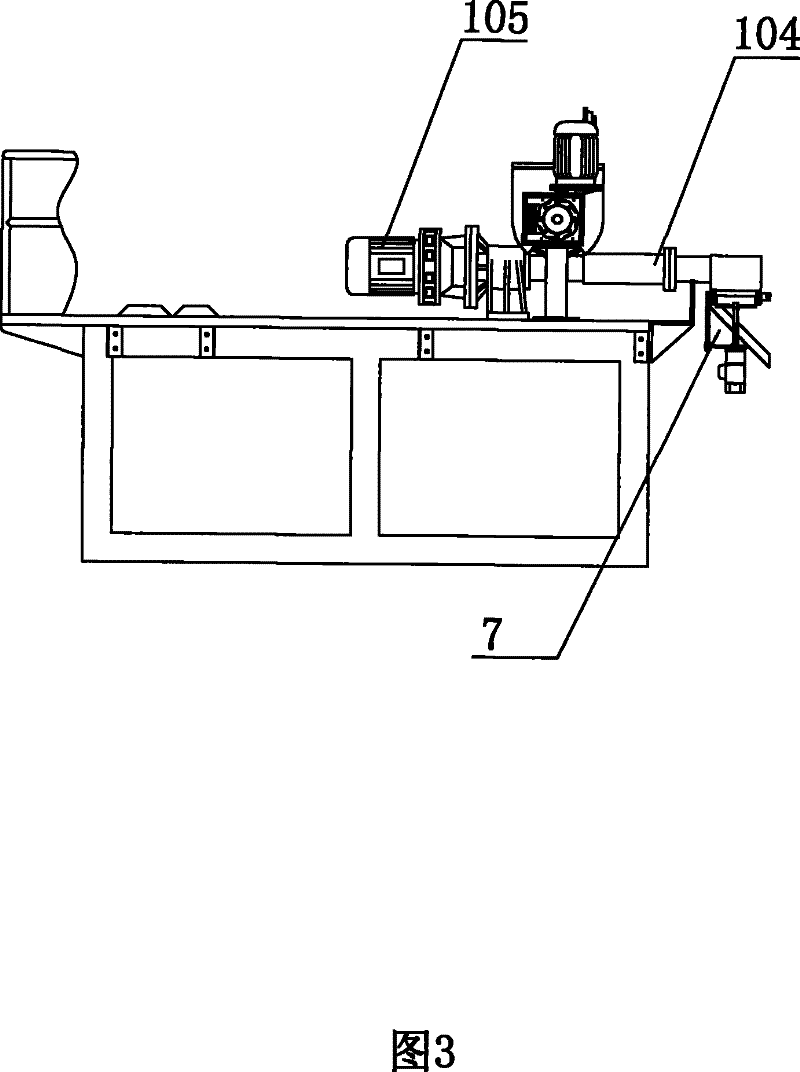

[0030] Please refer to Figure 3 to Figure 7 As shown, the distributing machine 5 includes a housing 109, a distributing rod 107 and a second motor 103 for driving the distributing rod. The distribution rod 107 is symmetrically distributed to both ends with the center point of the distribution rod 107 as the symmetrical point, so as to ensure that the material can be evenly distributed for each screw extrusion device. The material outlet (not shown in the figure) corresponding to the material opening 111 is also pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com