Patents

Literature

49results about How to "The product quality is good and stable" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for preparing high boiling silicone oil by using organic silicon high boiling substances

The invention relates to a method for preparing high boiling silicone oil by using organic silicon high boiling substances, comprising hydrolyzation of alcohol and neutralization, wherein the organic silicon high boiling substances are hydrolyzed in the mixed liquid of alcohol and water and refluxed for 1-4 hours; nitrogen purging is carried out on the reactant, and then the reactant is added with hydrogen chloride dissolved in urea, zinc oxide and ammonium bicarbonate and in the system thereof. The invention integrally uses the organic silicon high boiling substances and lowers the chlorine content in silicon oil products, ensures the molecular weight and viscosity to be controllable and mass to be more stable; the usage of the neutralizing agent and latent solvent is reduced greatly, thus reducing the production cost; the process is simple and the industrial production is easy.

Owner:SHANDONG DONGYUE ORGANIC SILICON MATERIAL

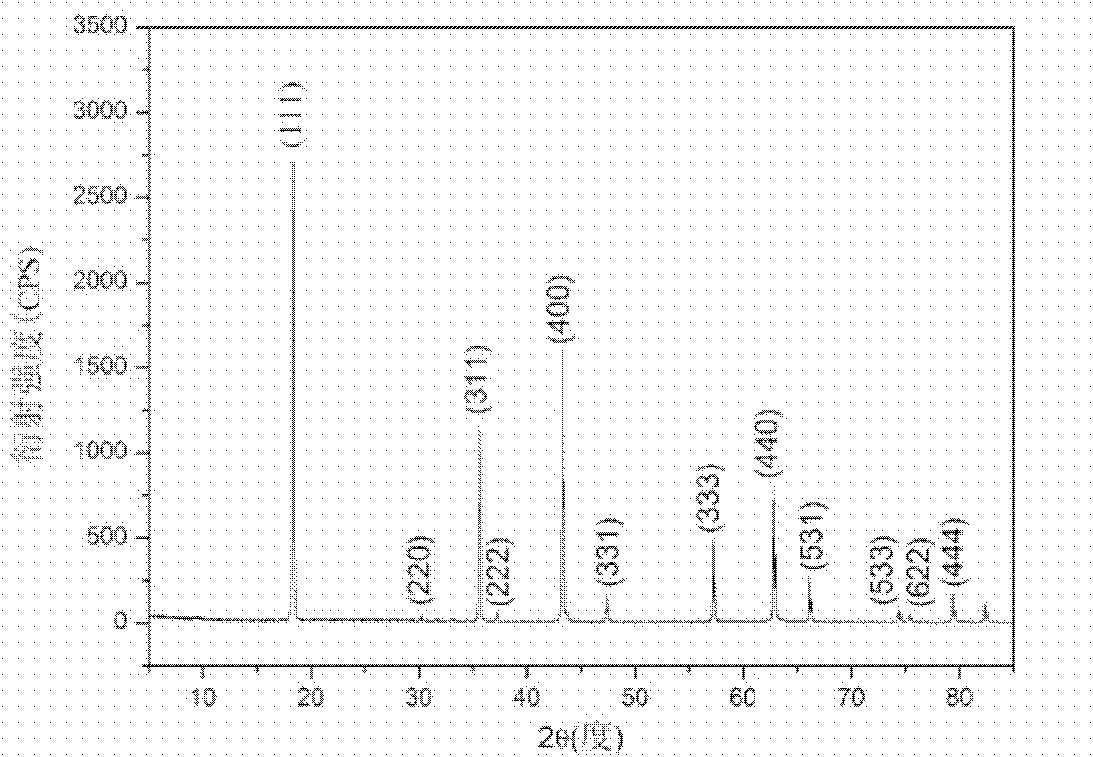

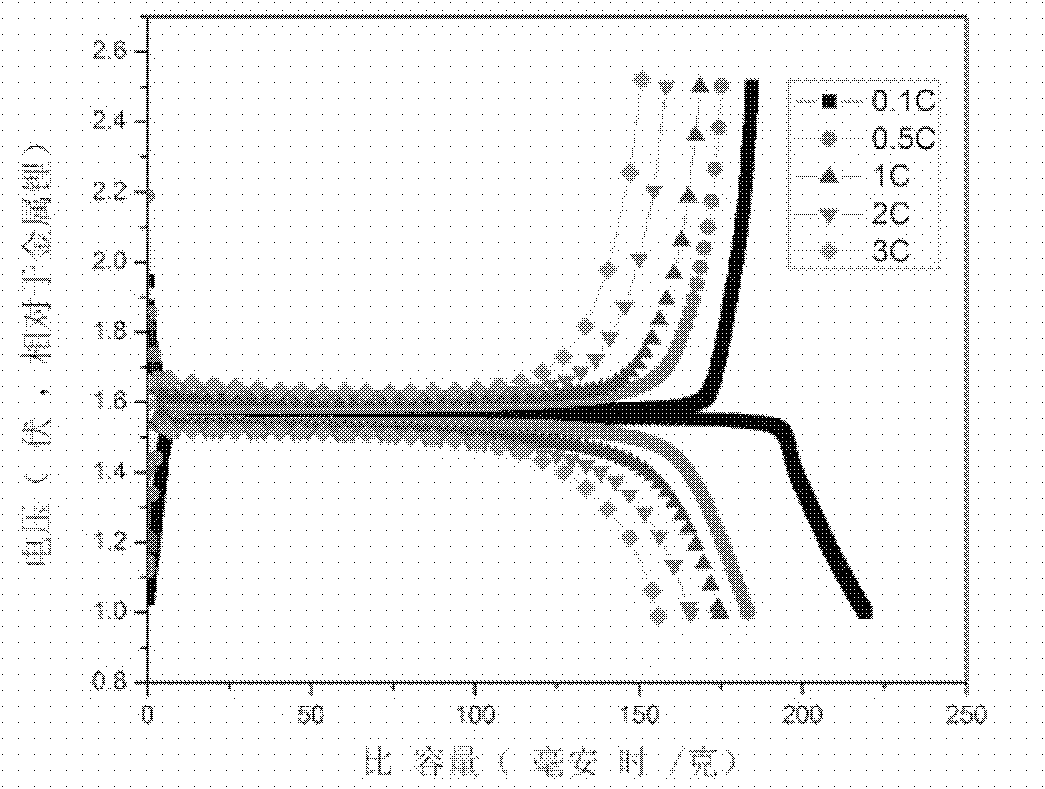

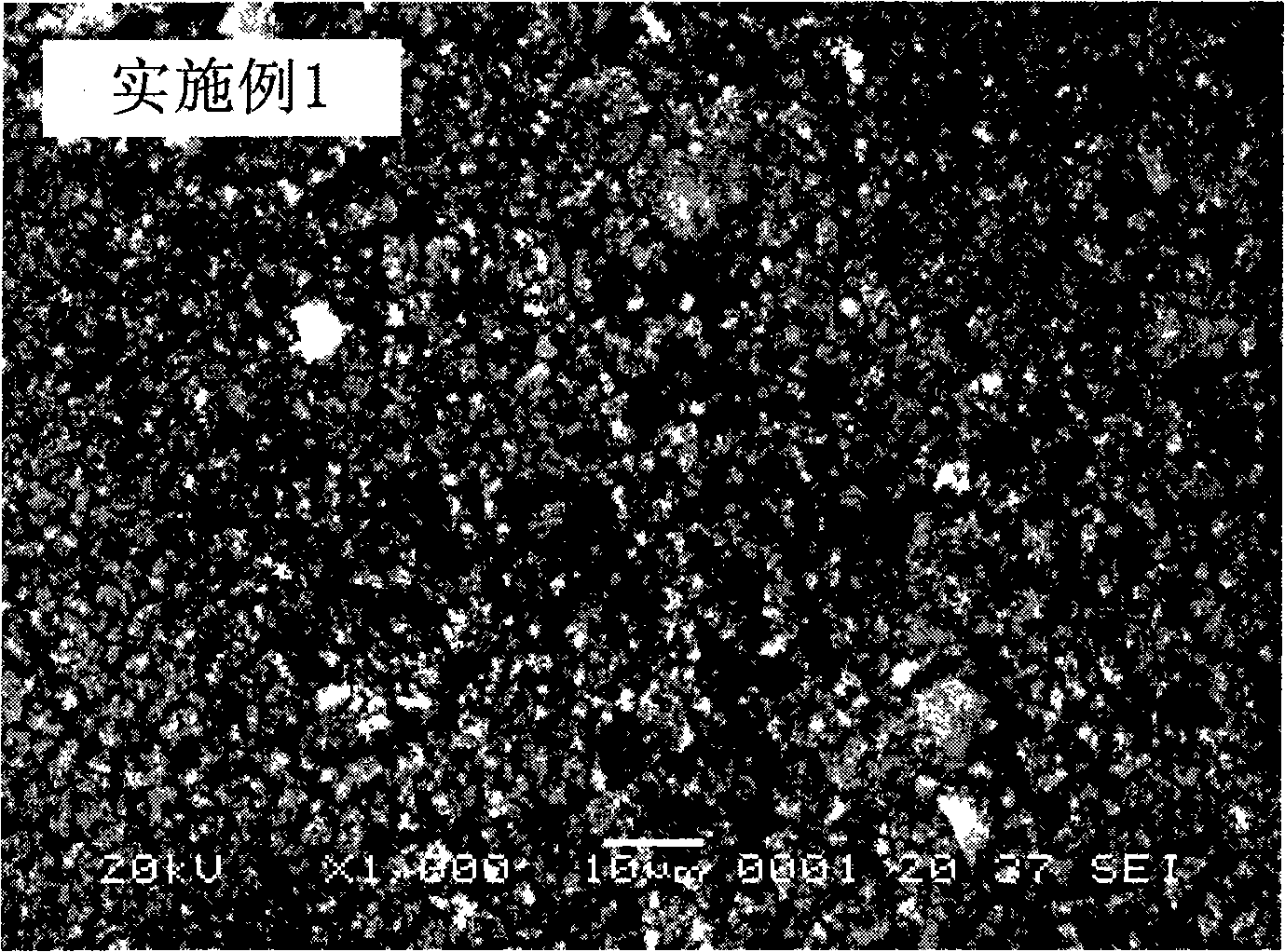

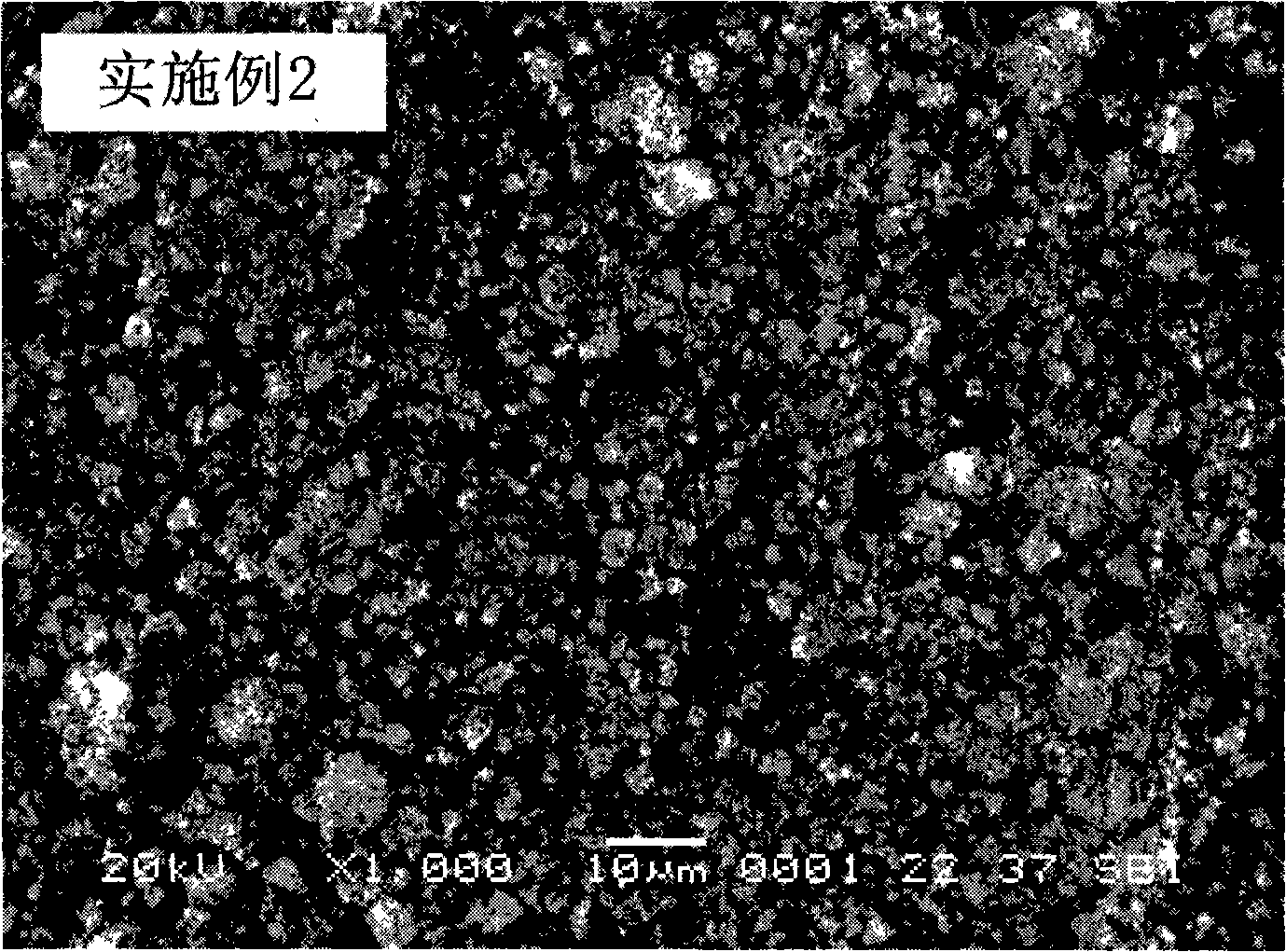

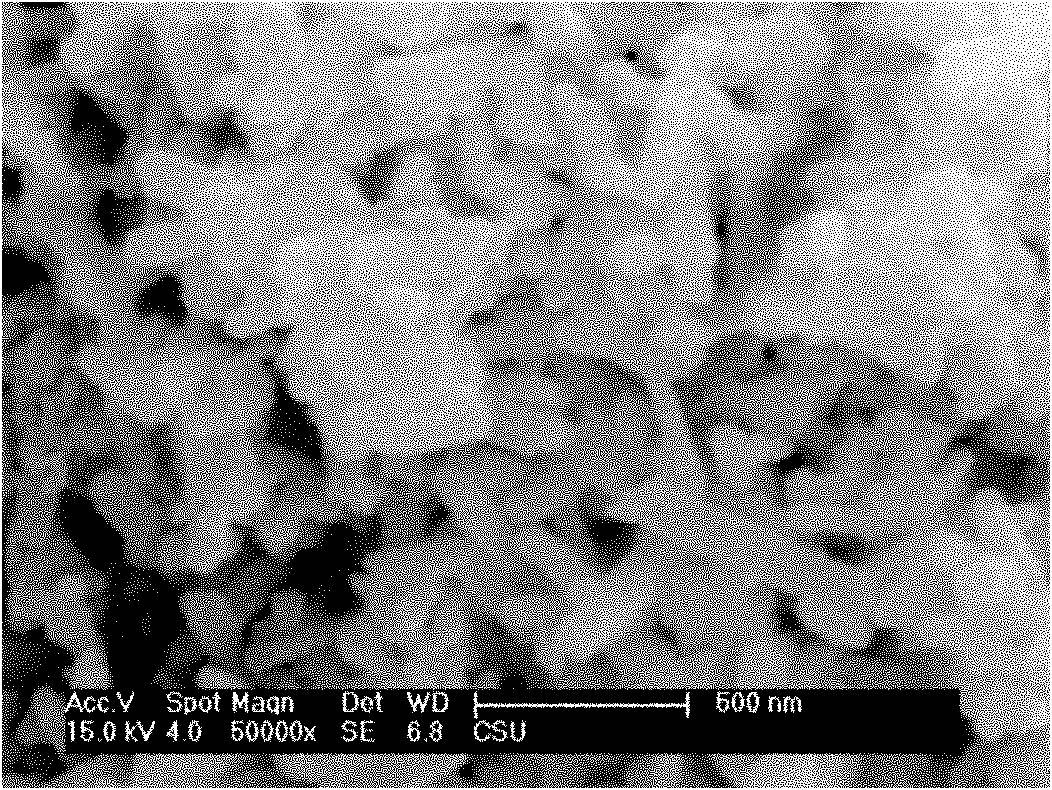

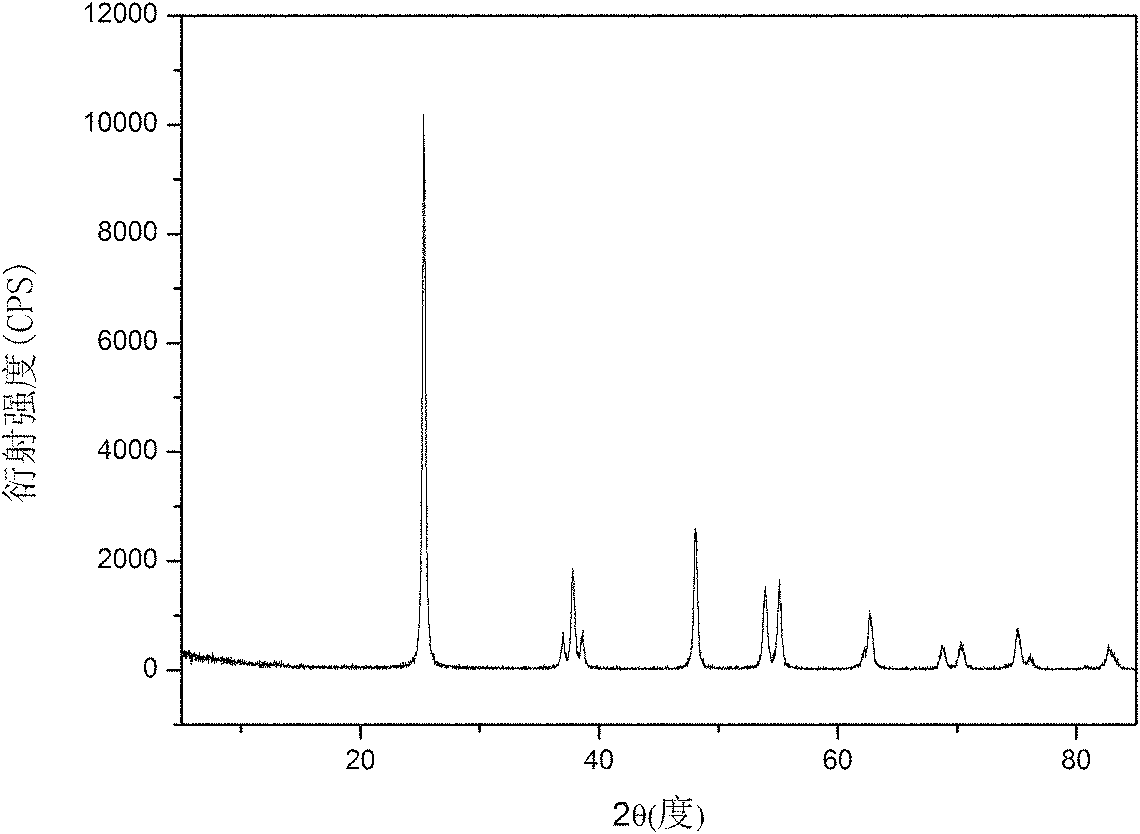

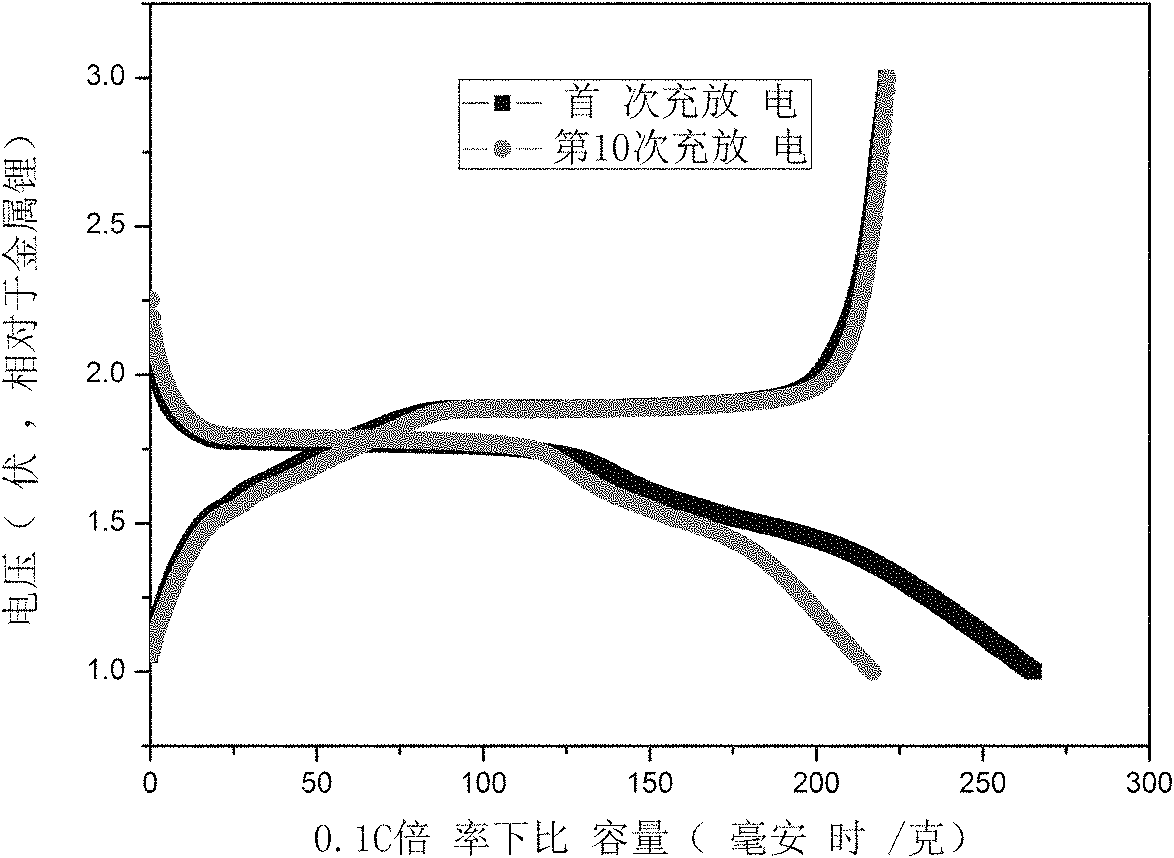

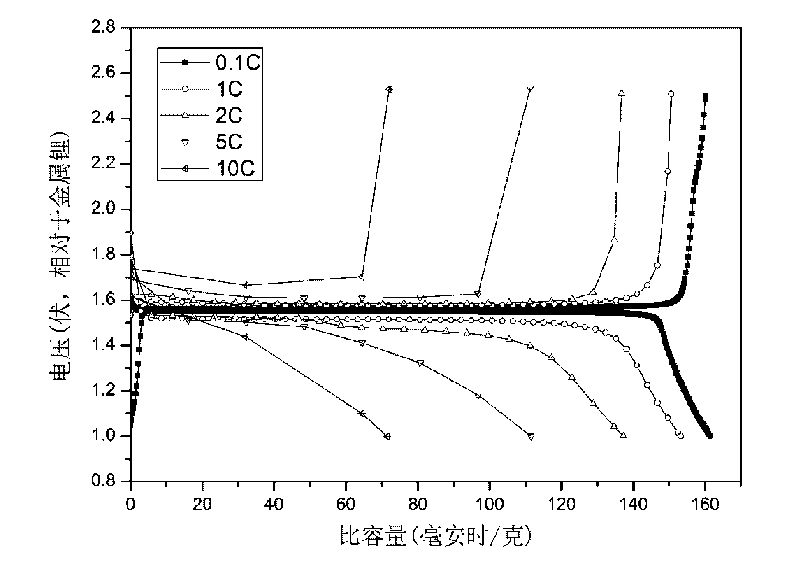

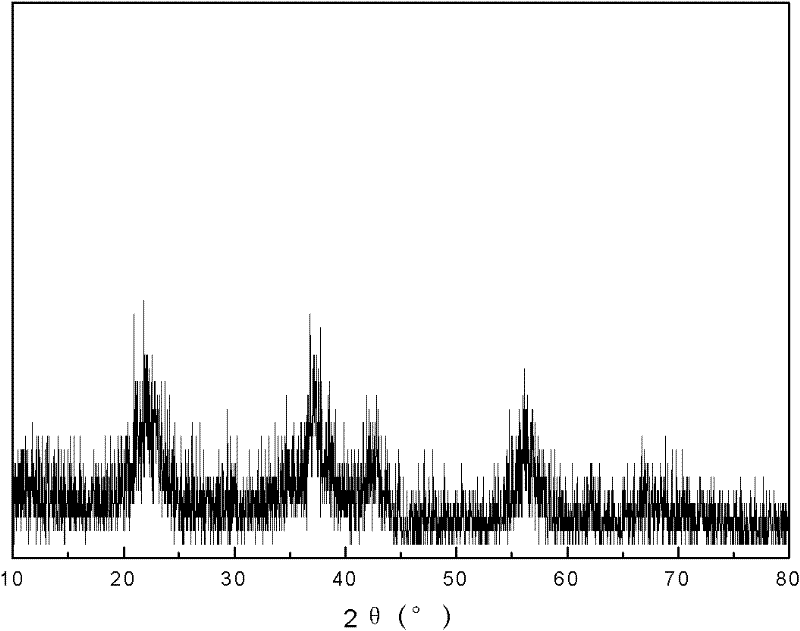

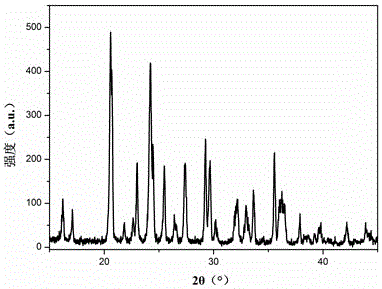

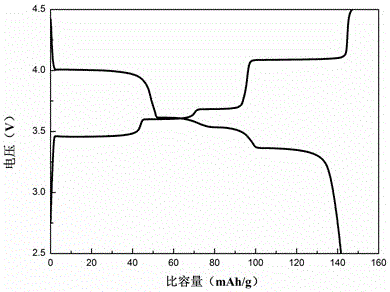

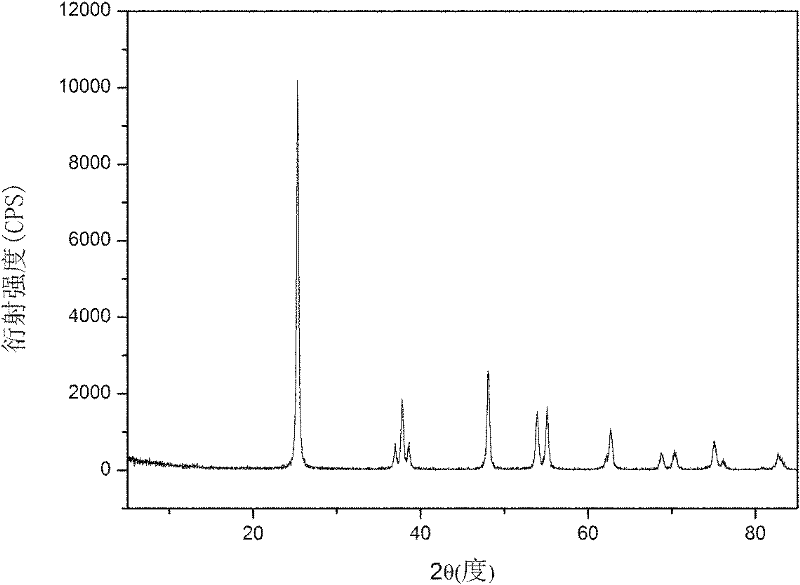

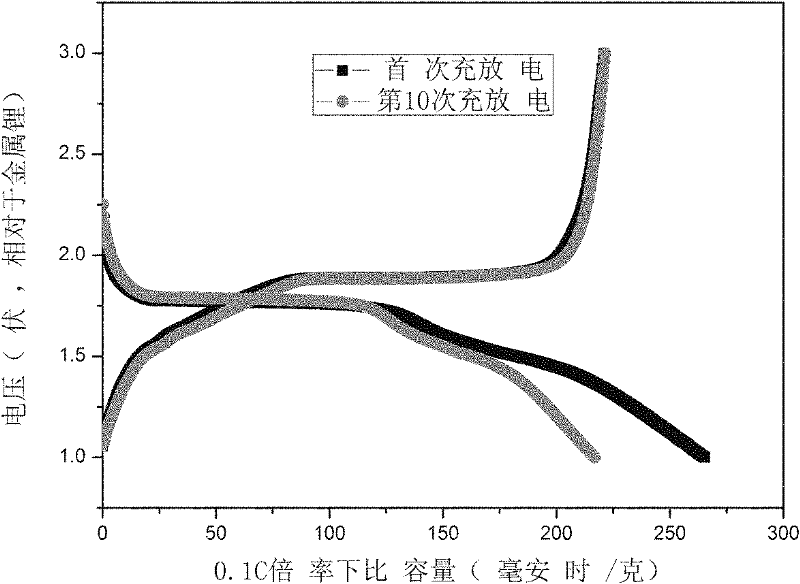

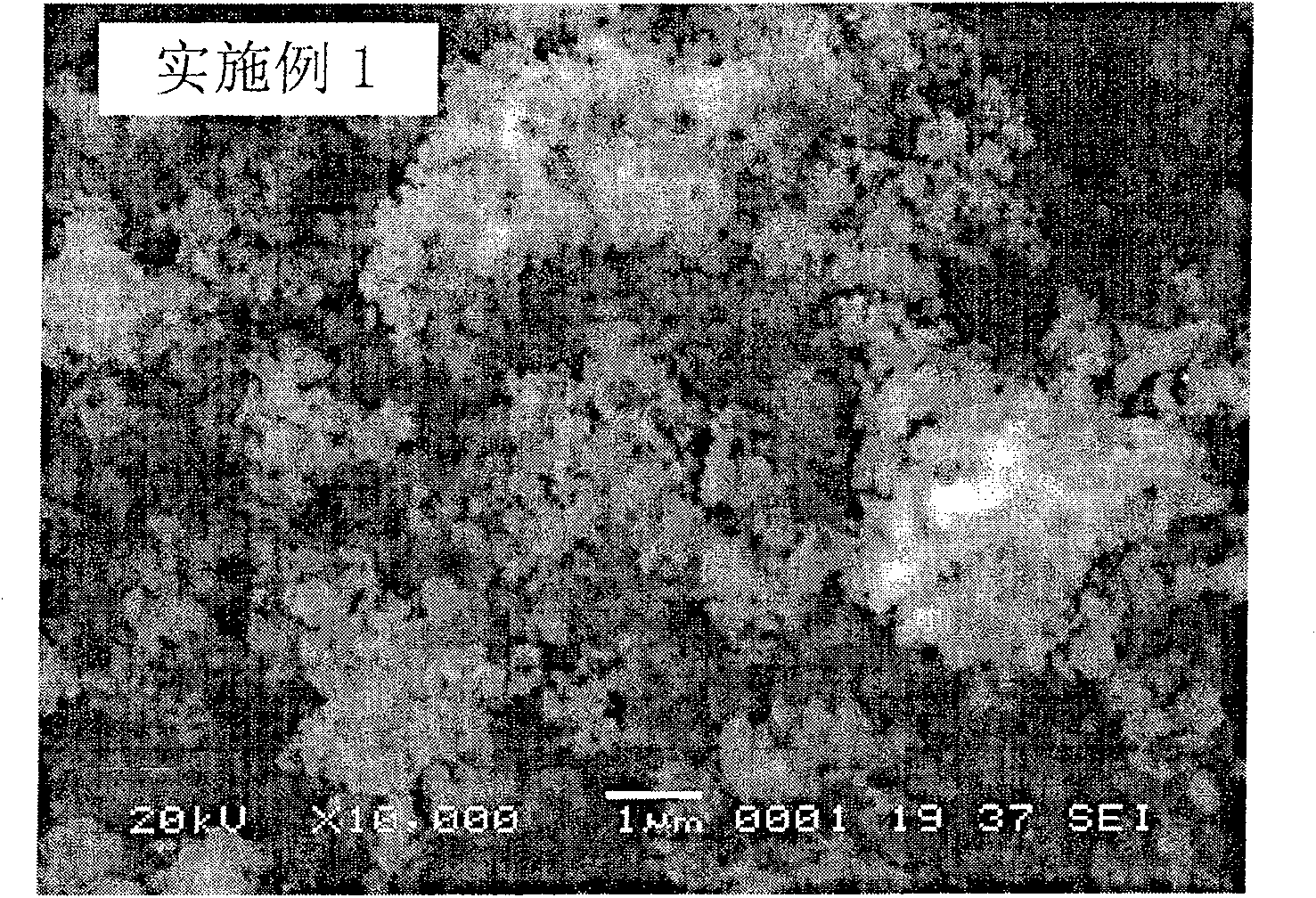

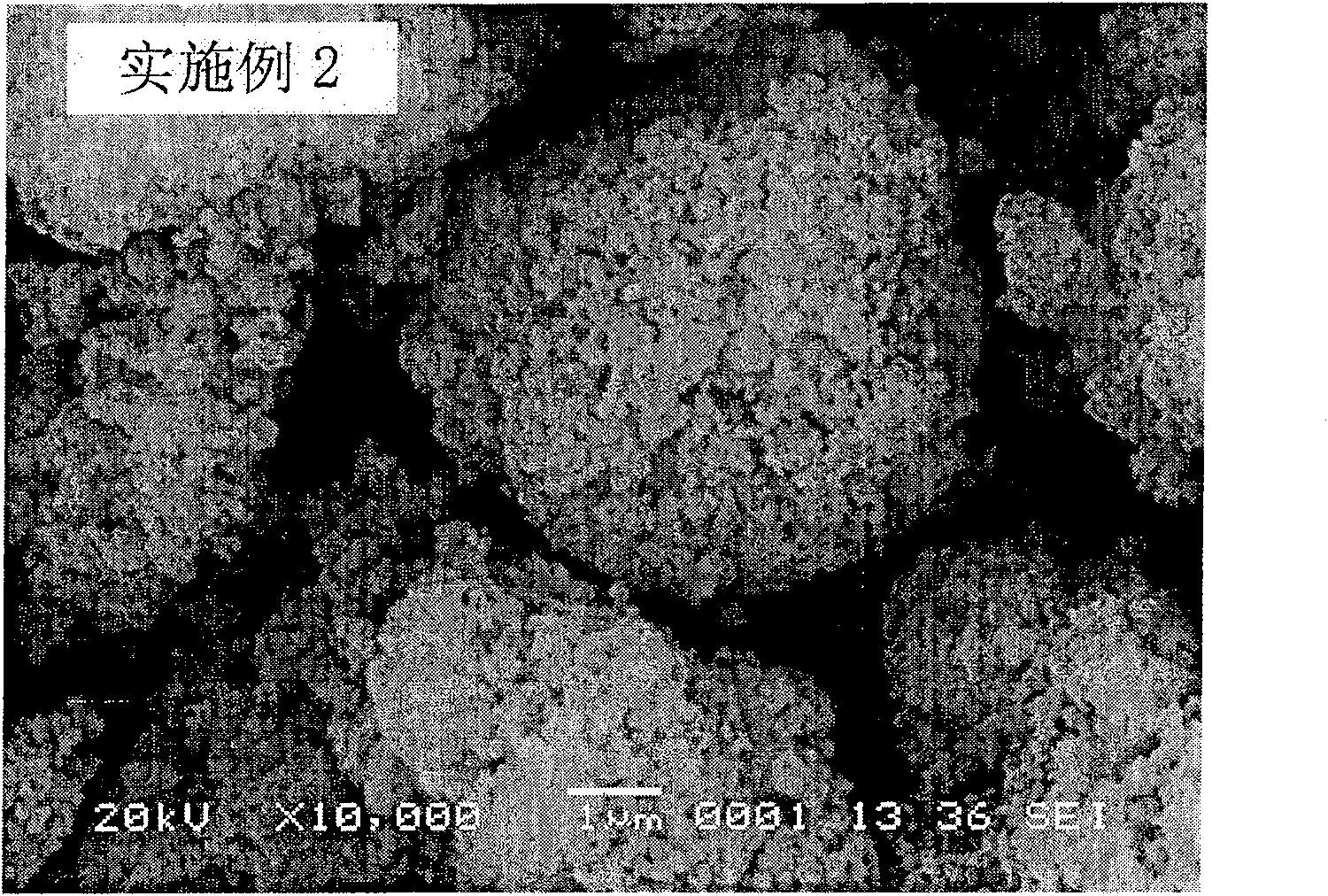

Method for preparing spherical lithium titanate from inorganic titanium sources

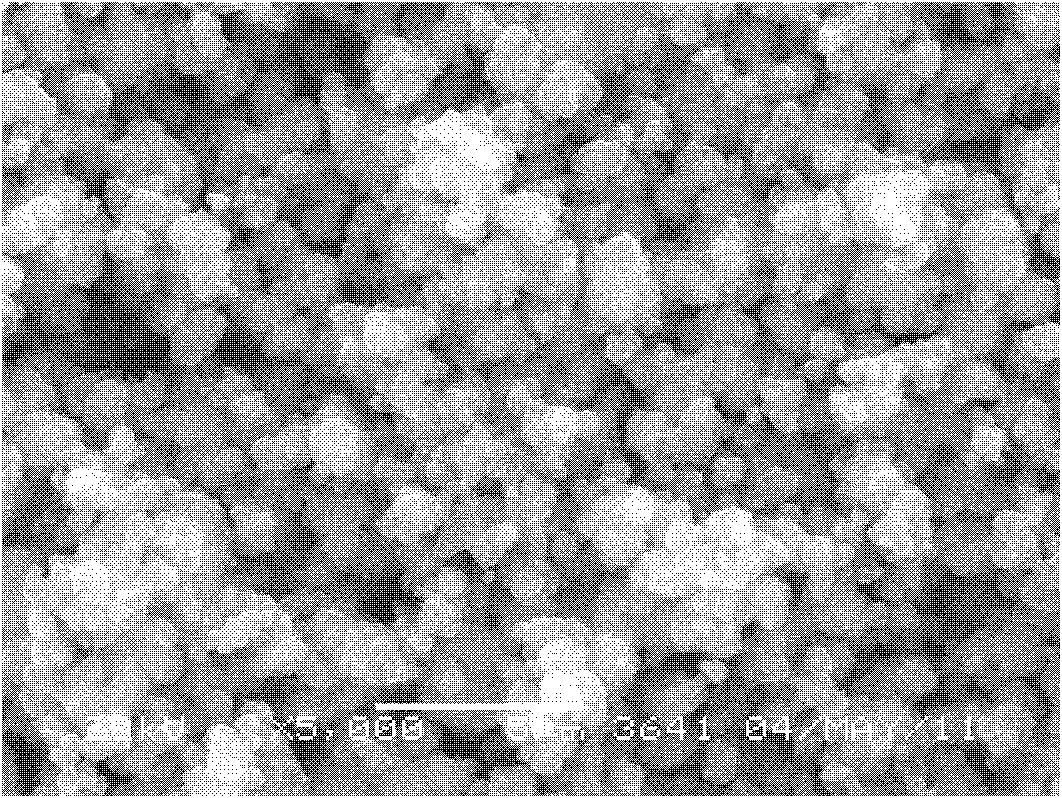

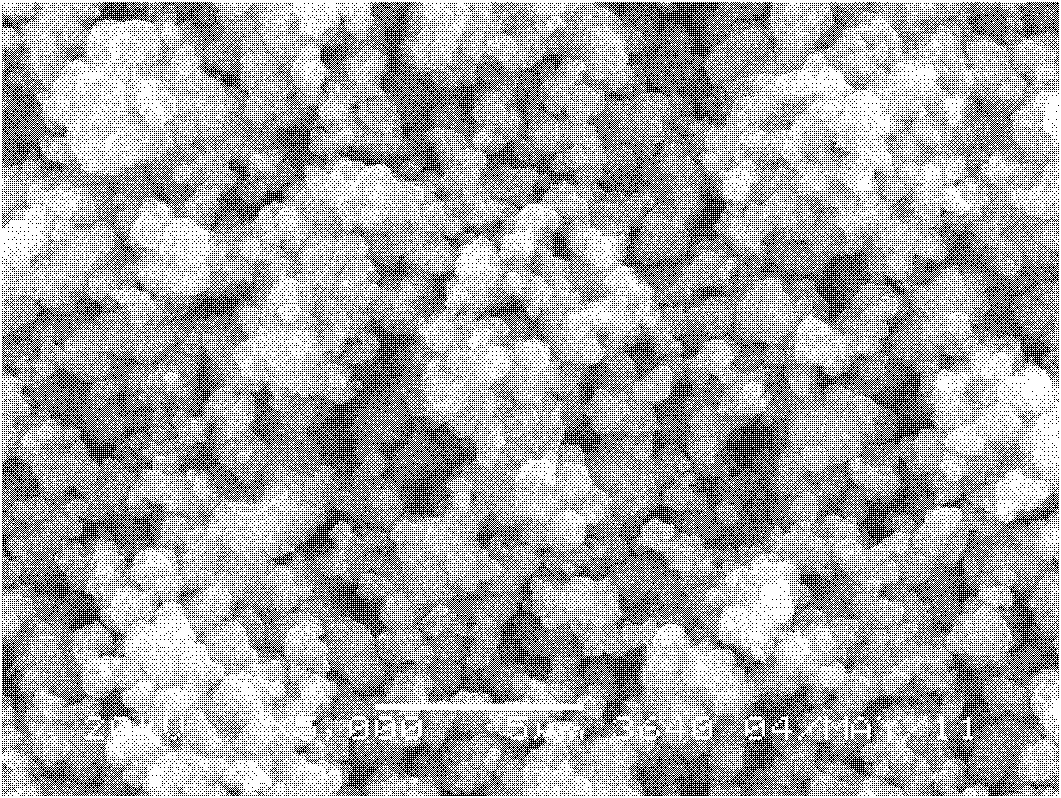

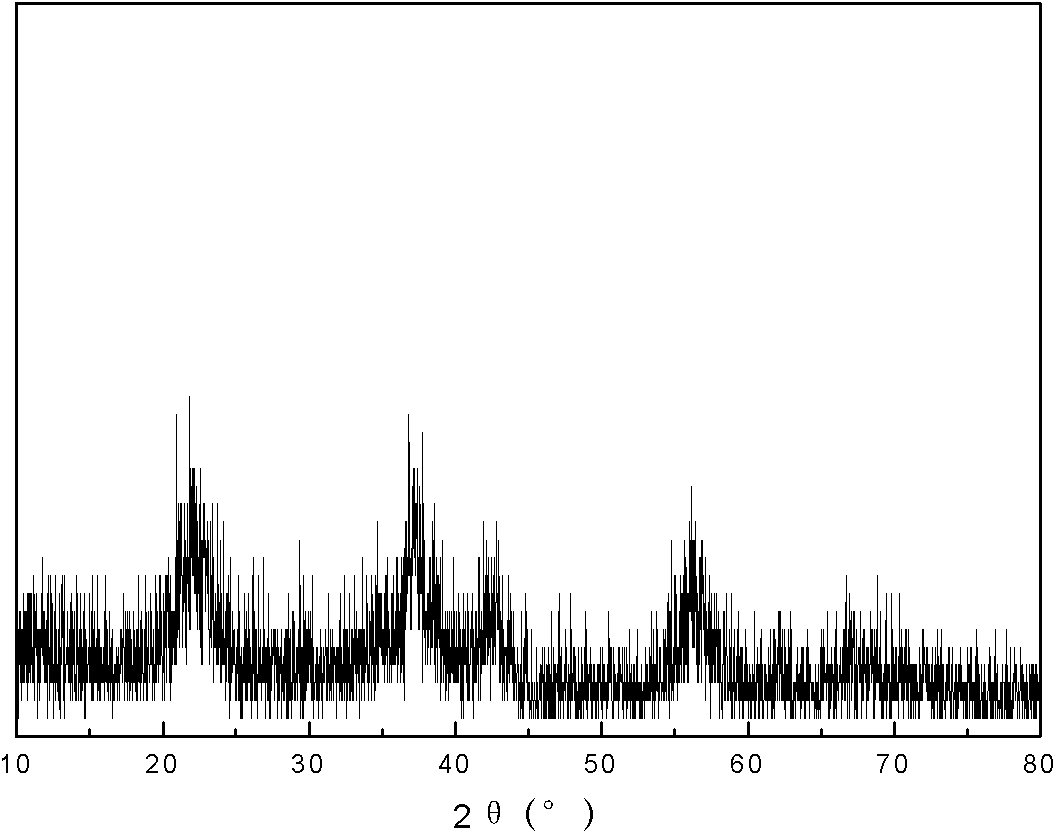

The invention discloses a method for preparing spherical lithium titanate from inorganic titanium sources. The method comprises the following steps: pulping the titanium precipitate prepared from titanic acid or ilmenite and industrial titanic solution with water, adding a coordinating agent to the pulp according to the molar ratio of the coordinating agent to titanium being (1.0:1)-(20:1), adjusting the pH value to be 7-14 with alkali, then carrying out reaction in a stirred reactor at the temperature of 10-80 DEG C for 5-720min and filtering the reactant to obtain titanium solution; adding lithium sources to the solution according to the molar ratio of lithium to titanium being 4:5; and then carrying out spray drying on the mixed solution to obtain a lithium titanate precursor and calcining the precursor in the inert atmosphere at the temperature of 550-900 DEG C for 1-72 hours to obtain lithium titanate, the cathode material of lithium ion batteries. The method has the characteristics of wide raw material range, simple process flows, low energy consumption, low cost, good product particle size and morphology, high purity and excellent electrochemical property.

Owner:CENT SOUTH UNIV

Method for preparing ferric lithium phosphate precursor by comprehensive utilization of ilmenite

InactiveCN101264876ALow costWide variety of sourcesCell electrodesPhosphorus compoundsLithium-ion batteryImpurity

The invention discloses a preparation method for lithium iron phosphate precursor by comprehensively utilizing ilmenite, comprising a plurality of steps: leach the ilmenite in acid and filtrate is obtained by filtering; dissolve a certain amount of other iron sources in the filtrate to make the Fe concentration in the mixed solution as 0.01-3mol / L and the molar ratio of Ti and Fe as 0.0005-0.5; add appropriate amount of oxidant to the mixed solution; use alkali aqueous solution to regulate the system pH as 4.0-14.0; react for 10min to 24h at 10-90 DEG Cin a stir reactor; filter, wash and dry the sedimentation at 50-159 DEG C; after drying, calcine the sedimentation in air at 300-800 DEG C for 1-24h; lithium iron phosphate precursor for the lithium-ion battery cathode material, which is also the ferric oxide of doped-metal elements, can be obtained. The preparation method has the advantages of wide material source, simple technological process, good and stable product quality and low cost.

Owner:CENT SOUTH UNIV

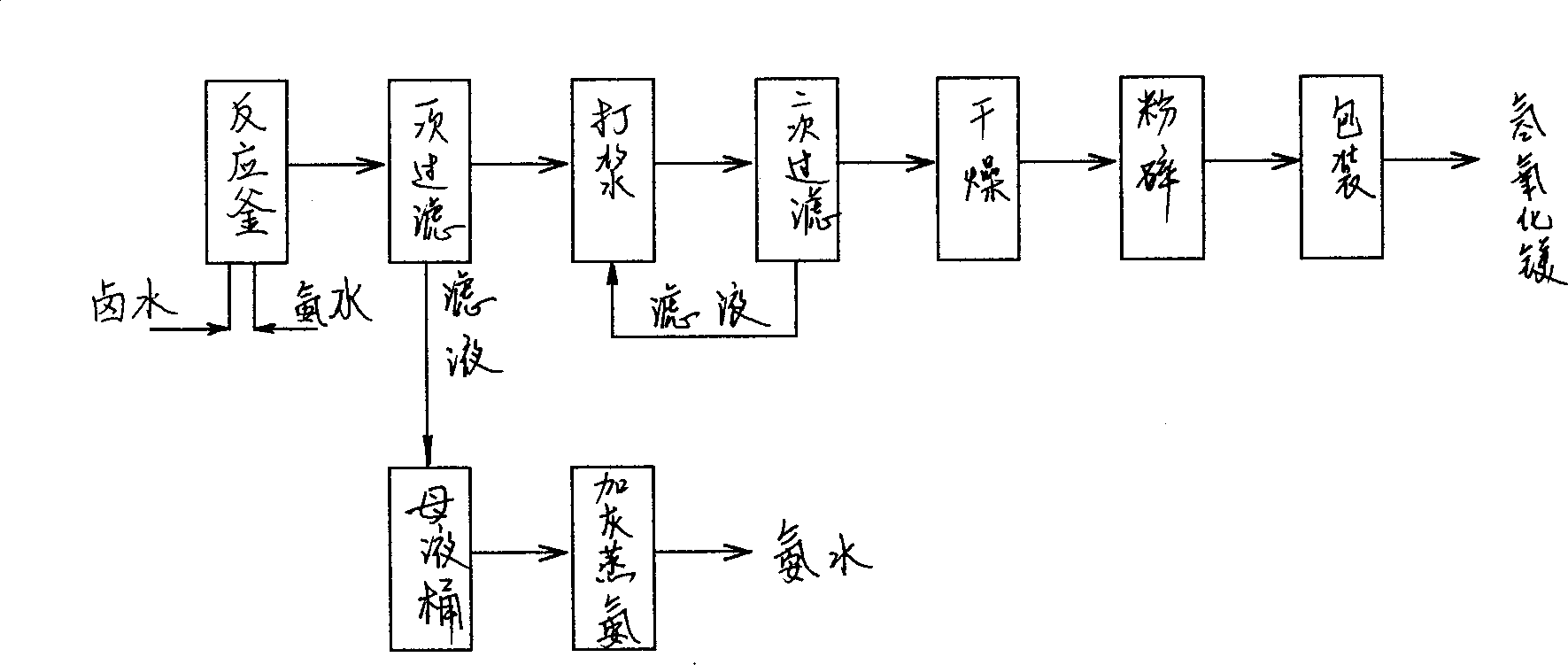

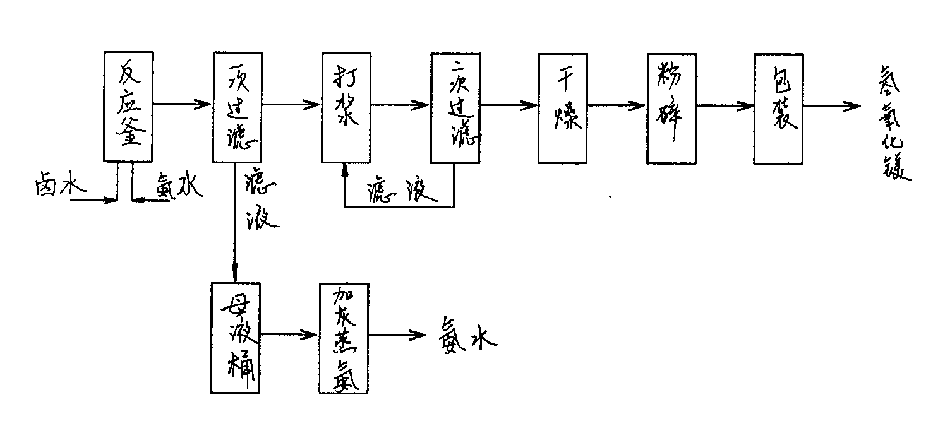

One-step process of producing magnesium hydroxide

InactiveCN1332117ASolve pipeline scarringConstant operating conditionsMagnesium hydroxideChemistryMagnesium

Bittern containing magnesium chloride and ammonia water in the magnesium chloride-to-free ammonia mol. ratio of 1 to 1.3-2.0 are mixed and reacted at 45-90 deg.c for 5-30 min, and the reacted liquid is filtered, washed, dried and crushed to obtain solid magnesium hydroxide. The one-step process is a continuous one with constant operation condition, no scaling in pipeline and high product quality.The process can utilize the afterheat of ammonia water preparation to save power and fresh water. The product may be used as high quality fire retardant.

Owner:SHANDONG HAIHUA GRP CO LTD

Method for producing battery-grade ferrous oxalate by using ferrous sulfate as titanium pigment byproduct

InactiveCN101580464ASufficient raw materialsSimple processCarboxylic acid salt preparationLithium-ion batteryLithium electrode

The invention discloses a method for producing battery-grade ferrous oxalate by using ferrous sulfate as a titanium pigment byproduct. The waste and byproduct ferrous sulfate is dissolved in deionized water; the mixture is filtered; a complexing agent, a surfactant and a precipitation agent are added according to a certain order into the filtrate when violent stirring is carried out; then, aqueous solution of alkaline or acid is used for controlling the pH of the system to be 0.1-5.0, the stirring is not stopped until reaction is carried out at temperature of 20-80 DEG C for 5 min-4 h, aging is carried out for 0-24 h; the obtained sediment is filtered, washed and dried so as to obtain the battery-grade ferrous oxalate, wherein the iron recovery rate can be as high as 99.9 percent. By adjusting the addition order and the addition amount of the additives as well as the pH value of the system, the method causes the types and the amount of metallic elements in the ferrous oxalate to be controllable. The method has the advantages of adequate raw materials, simple process flow, good and stable product quality, low cost and the like, is particularly suitable for providing high-quality iron sources for large production of lithium iron phosphate which is used as the cathode material for a lithium ion battery, and simultaneously also provides a new way for recycling waste residue of ferrous sulfate.

Owner:CENT SOUTH UNIV

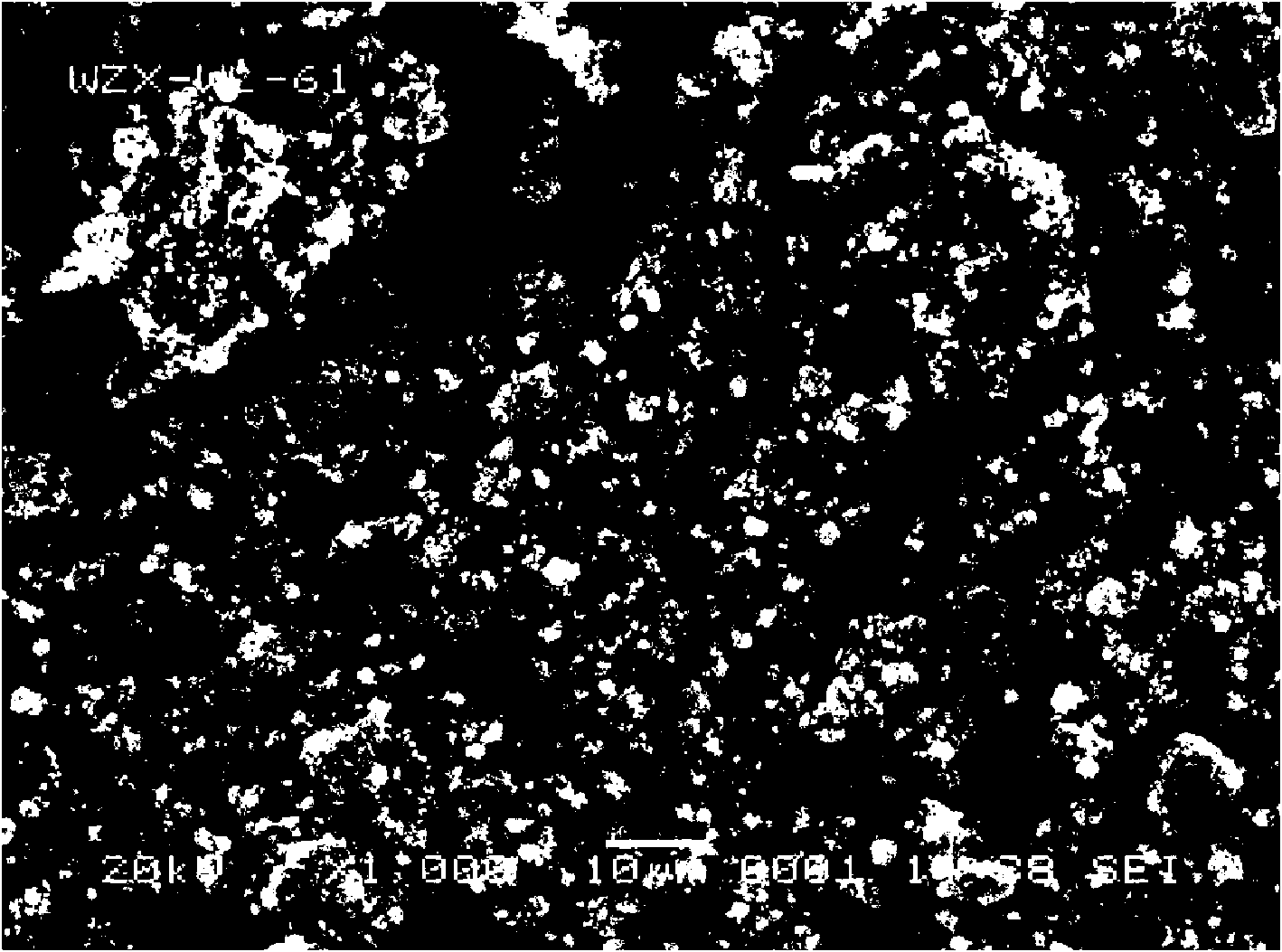

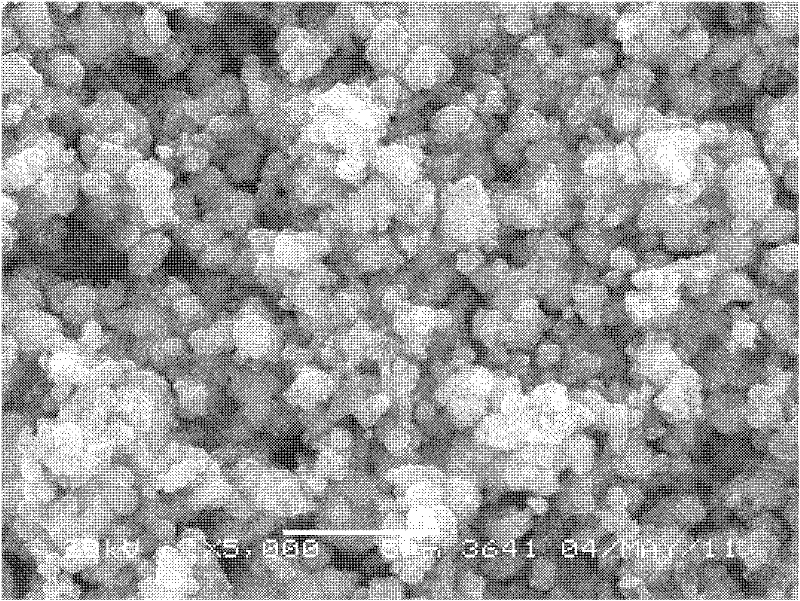

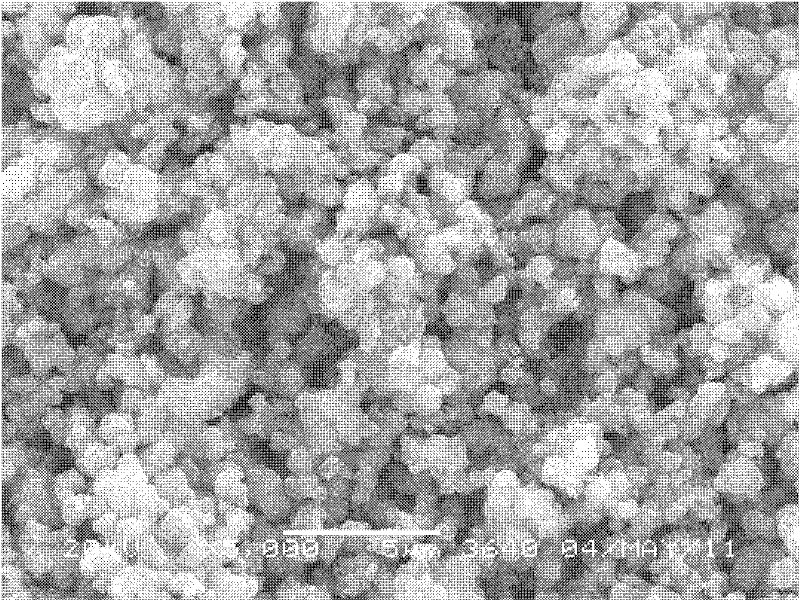

Method for preparing nano-TiO2 serving as cathode material of lithium ion battery

The invention discloses a method for preparing nano-TiO2 serving as a cathode material of a lithium ion battery. The method comprises the following steps of: beating precipitates of titanium prepared from metatitanic acid or various titanium sources by using water, adding a coordinating agent into thick liquid according to a molar ratio of the coordinating agent to the titanium of 1.0:1-10:1, regulating the pH value to be between 7 and 14 by using alkali, reacting in a stirring reactor at the temperature of between 20 and 80 DEG C for 10 to 720 minutes, and filtering to obtain solution of the titanium; and adding the alkali into the solution according to a molar ratio of the alkali to the titanium of 1.0:1-50:1, heating the solution to between 80 and 200 DEG C for 10 to 600 minutes, filtering and washing to obtain a precursor of nano-TiO2, and calcining the precursor at the temperature of 120 and 850 DEG C for 0.5 to 20 hours to obtain the nano-TiO2 serving as the cathode material of the lithium ion battery. The method has the characteristics of wide range of raw materials, simple process flow, low energy consumption, low cost, good appearance of product granularity and excellent electrochemical properties.

Owner:CENT SOUTH UNIV

Method for preparing lithium iron phosphate precursor for positive pole material of lithium-ion battery

InactiveCN103022491AWide variety of sourcesImprove conductivityCell electrodesPhosphorus compoundsMagnesiumLithium electrode

The invention discloses a method for preparing a lithium iron phosphate precursor for a positive pole material of a lithium-ion battery. According to the method, firstly siderite is subjected to leaching, the concentration of liquid is adjusted, then an oxidant and a precipitant are directly added without impurity removal, magnesium and manganese which are beneficial to the electrochemical properties of lithium iron phosphate in the siderite are enabled to be selectively subjected to precipitation through controlling synthesis conditions, and the lithium iron phosphate precursor is obtained after drying. As doped metal elements including magnesium and manganese are uniformly distributed in precursor particles in a phosphate form, re-doping is not required during the synthesis of the lithium iron phosphate, and the conductivity of the lithium iron phosphate can be greatly improved by the doped elements, so that the electrochemical properties of the lithium iron phosphate are greatly improved. According to the method, the source of raw materials is wide, the process flow is simple, the product quality is good and stable, and the cost is low, so that the method is particularly suitable for providing a high-quality iron source for the production of the lithium iron phosphate for the positive pole material of the lithium-ion battery; and meanwhile, siderite resources are comprehensively utilized, and huge economic and ecological benefits are inevitably brought to the society if scale production can be realized.

Owner:广西地博矿业集团股份有限公司

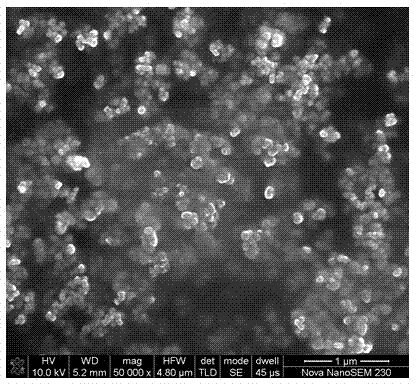

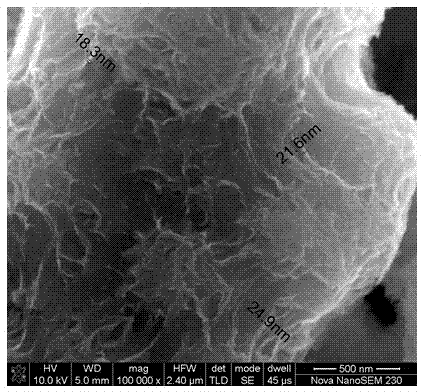

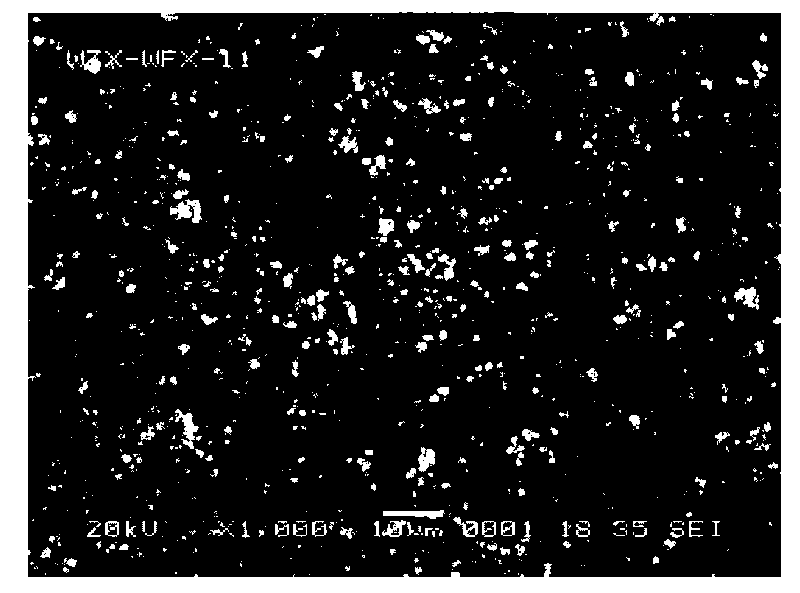

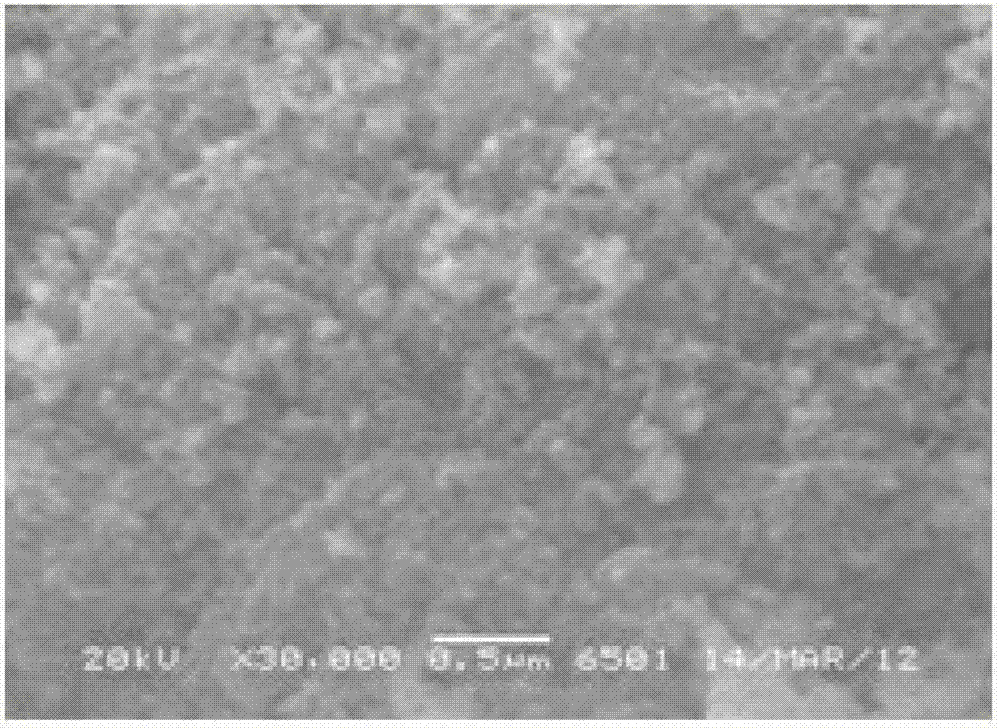

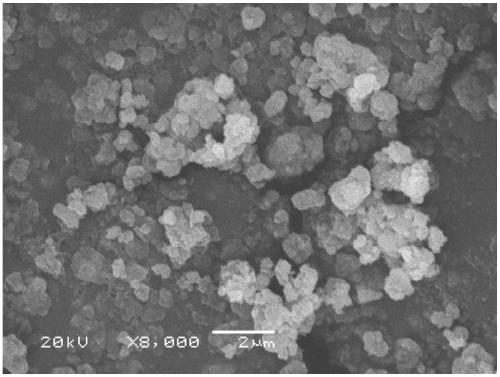

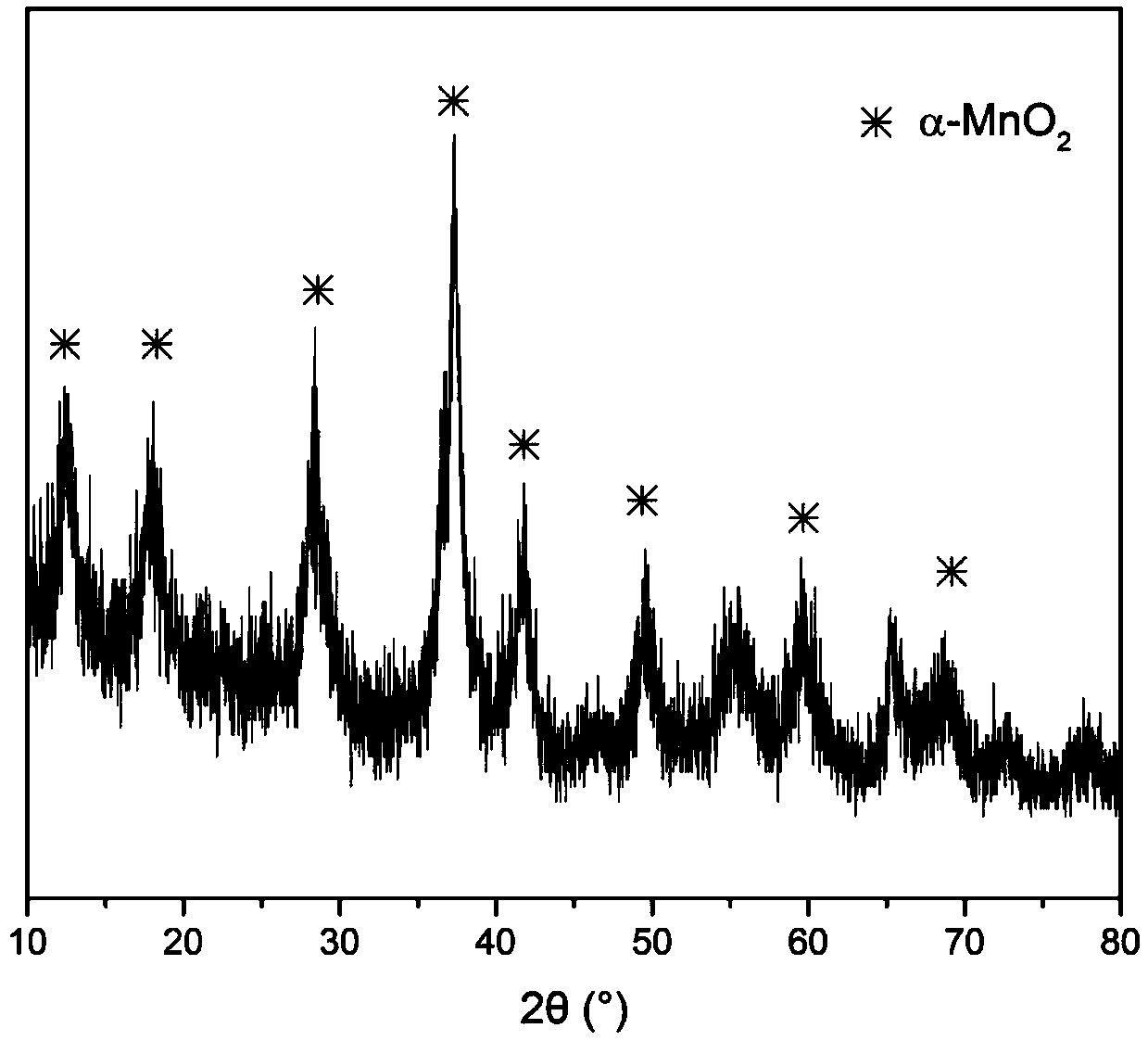

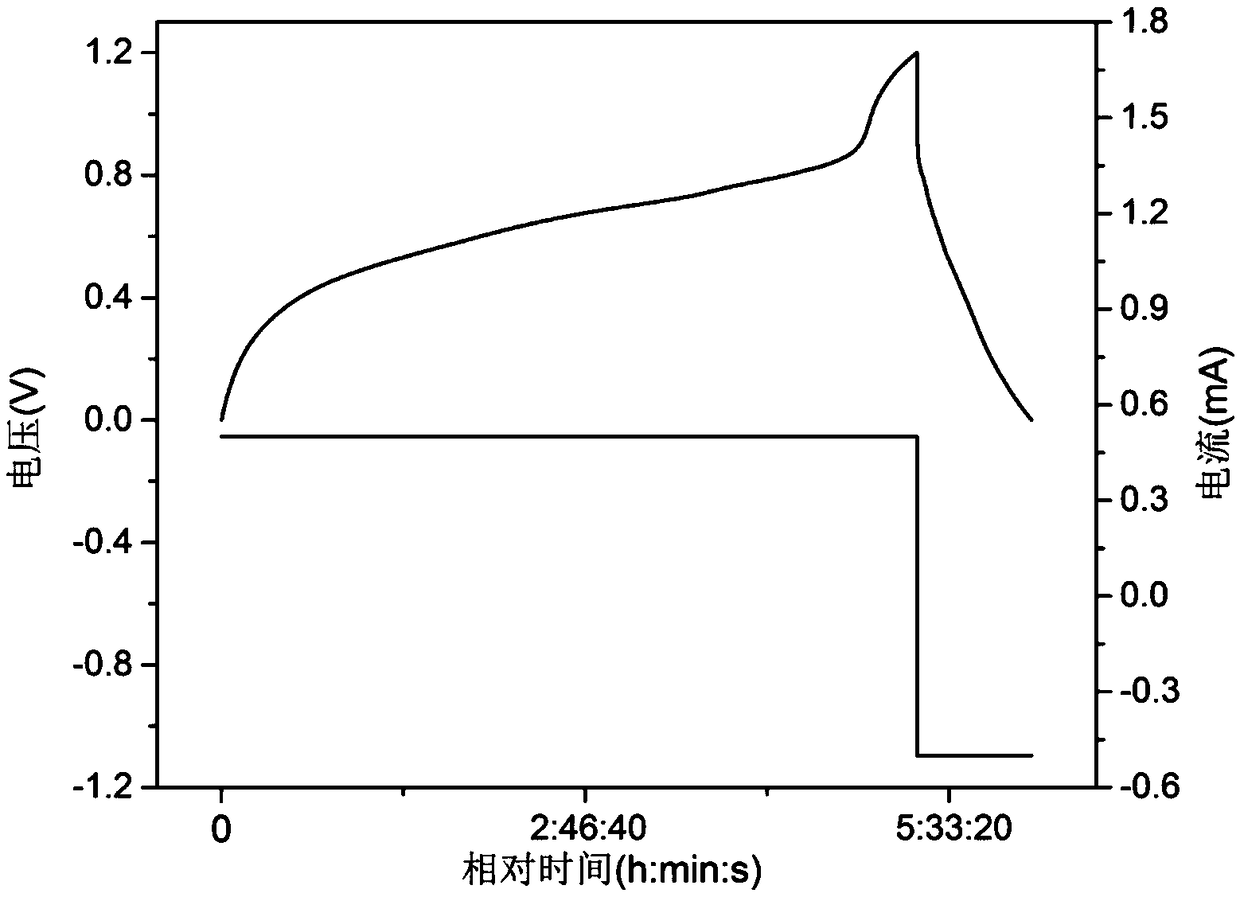

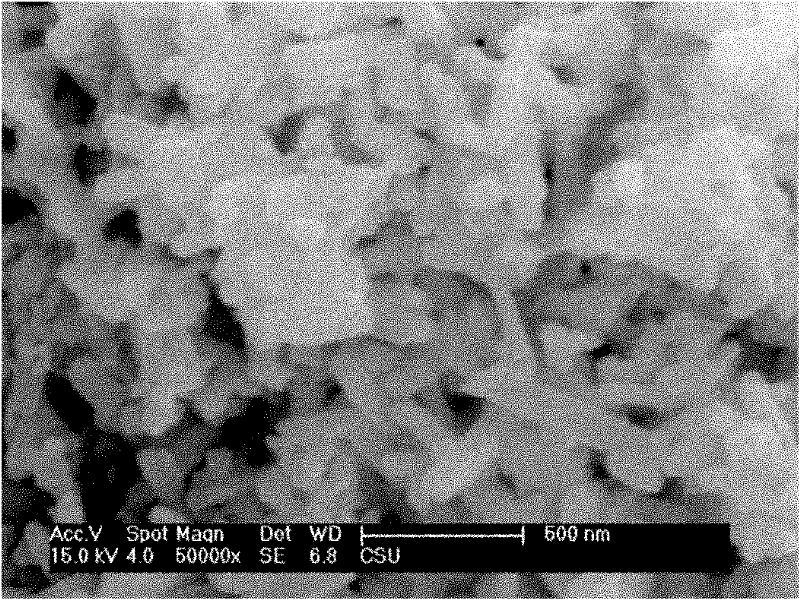

Preparation method and applications of nano-manganese oxide

ActiveCN104773760AUniform particlesReduce incorporationMaterial nanotechnologyManganese oxides/hydroxidesNanowireFluid phase

The invention provides a preparation method of nano-manganese oxide which is of a nanowire net structure. The preparation method comprises the following steps: dropwise adding an oxidant containing aqueous solution or feeding oxidizing gas into an active agent containing manganese salt aqueous solution, and uniformly dispersing; carrying out a liquid-phase co-precipitation reaction, so that nano-sized manganese dioxide is suspended in the solution; filtering the solution; and washing and drying the obtained precipitate subjected to filtering, so that the nano-manganese oxide is obtained. The nano-manganese oxide prepared by using the preparation method disclosed by the invention can be applied to the field of super capacitors and wastewater treatment. According to the invention, through elaborate design, the industrial process is maximally simplified, the quality of products is improved, and the production cycle is shortened, therefore, the method disclosed by the invention is a nano-manganese oxide preparation method which is simple in technological process, small in energy consumption, short in reaction period, good and stable in product quality and low in cost.

Owner:HUNAN RES INST FOR NONFERROUS METALS

Method for preparing precursors of lithium titanate and lithium iron phosphate by comprehensively using ilmenite

InactiveCN101709374AImprove electrochemical performanceLow costCell electrodesTitanium dioxideChemistryTitanium

The invention discloses a method for preparing precursors of lithium titanate and lithium iron phosphate by comprehensively using ilmenite, which comprises the following steps of: 1) separating the ilmenite, namely crushing the ilmenite, leaching the ilmenite with hydrochloric acid, filtering the ilmenite to obtain a residue and a filtrate; 2) preparing the precursor of the lithium titanate, namely washing the residue prepared by step 1) with the hydrochloric acid, adding the washed residue in aqueous alkali, cooking the mixture, filtering the mixture after cooling, and then adding the obtained filter residue in the hydrochloric acid, cooking the mixture, and filtering, washing, drying and calcining the mixture after cooling to obtain the precursor of the lithium titanate; and 3) preparing the precursor of the lithium iron phosphate, namely taking the filtrate prepared by step 1) as a raw material, adding iron powder to reduce ferric iron, diluting the reduced filtrate, adding a complexing agent and a precipitant into the diluted mixture, controlling the pH value of the system, reacting the mixture at 30 to 80 DEG C, aging the reacted mixture, and filtering, washing and drying the obtained precipitate to obtain the precursor of the lithium iron phosphate. The method is wide in raw material source, simple in process flow, good and stable in product quality, low in cost and comprehensive and full in use of the ilmenite.

Owner:CENT SOUTH UNIV

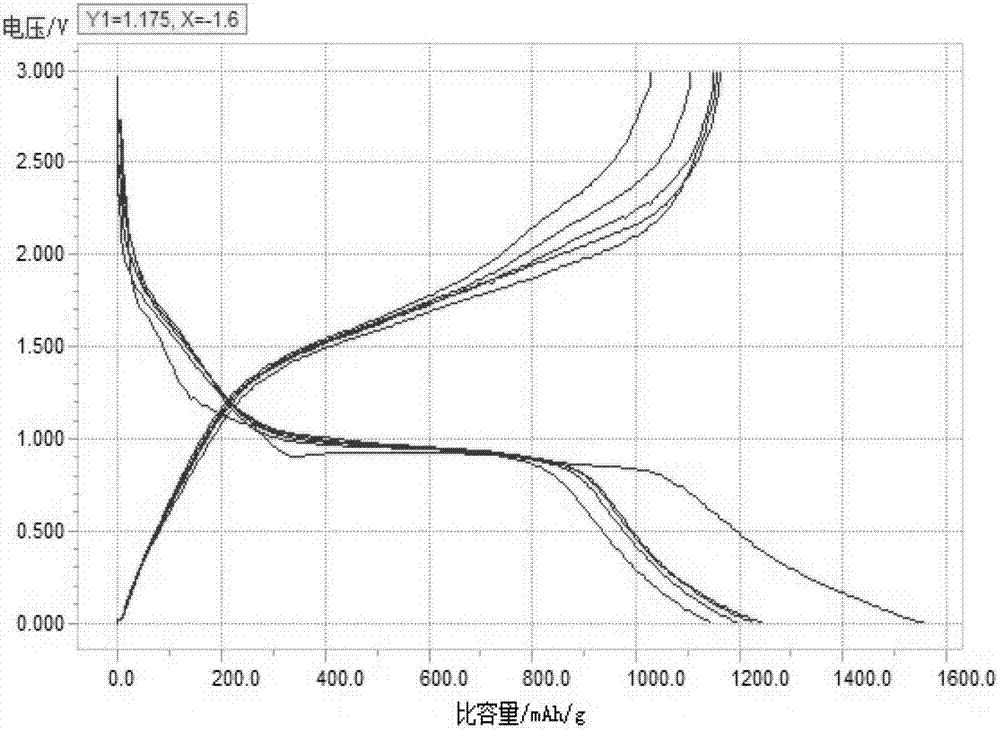

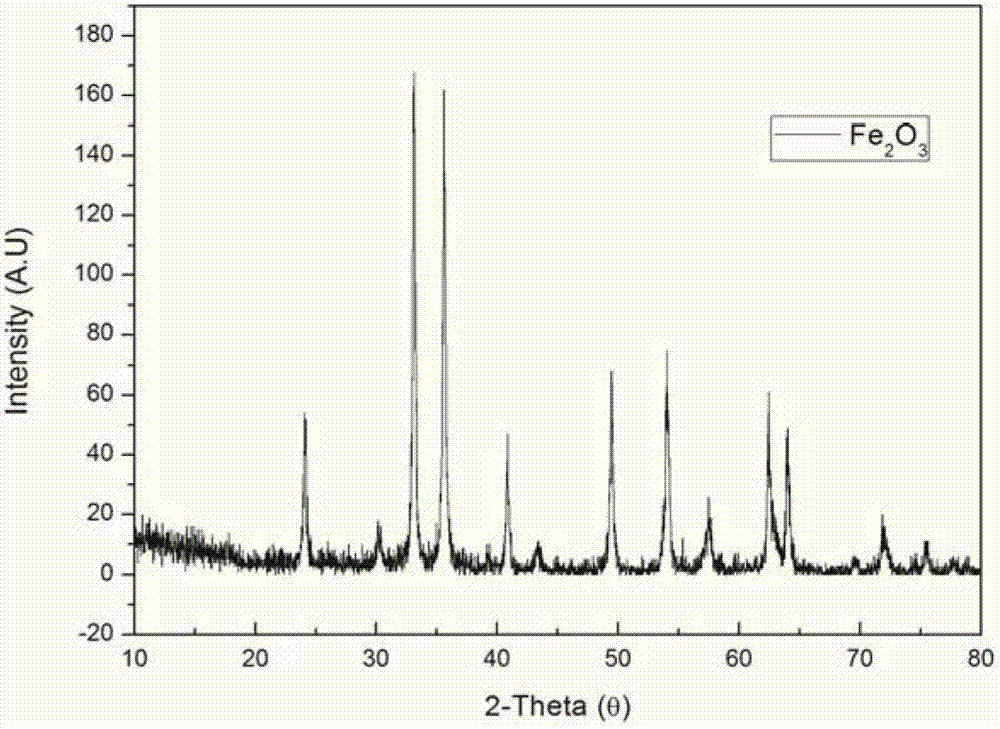

Application of polyacrylic acid in preparation of lithium ion battery anode material nano-sized iron oxide/carbon composite material

InactiveCN102820465AGood particle size and shapeImprove electrochemical performanceCell electrodesNanotechnologyCarbon compositesElectrochemistry

The invention discloses an application of polyacrylic acid in the preparation of a lithium ion battery anode material, namely a nano-sized iron oxide / carbon composite material, comprising the following steps of: adding an iron source into a mixed solution of deionized water and polyacrylic acid for stirred reaction so as to obtain a clear iron-containing solution; evaporating the iron-containing solution until it is gel-like, and carrying out precalcination at the temperature of 200-400 DEG C to obtain a precursor; and calcining the obtained precursor at the temperature of 400-800 DEG C to obtain the nano-sized iron oxide / carbon composite material. The preparation method of the nano-sized iron oxide / carbon composite material provided by the invention has characteristics of wide raw material range, simple process flow, little energy consumption and low cost. The obtained product has good particle morphology and excellent electrochemical performance.

Owner:CENT SOUTH UNIV

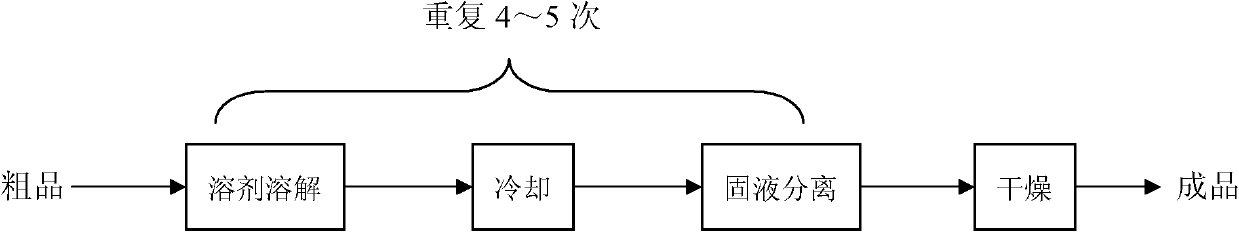

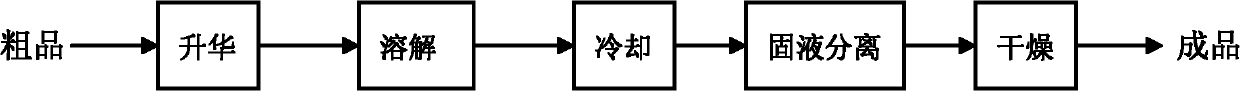

Method for purifying ethyl maltol

The invention discloses a method for purifying ethyl maltol, which is characterized by comprising the following steps of: (1) sublimating a crude ethyl maltol product; (2) dissolving; (3) cooling; (4) carrying out solid-liquid separation; and (5) drying to obtain the finished product. Compared with a method for purifying by adopting solvent decoloration, the method of the invention is simple and convenient to operate and has the advantages of low labor intensity, low solvent and product consumption, high yield, low cost, large production capacity, fast speed, high production efficiency as well as good and stable product quality and is suitable for large-scale industrial production.

Owner:广东省肇庆香料厂有限公司

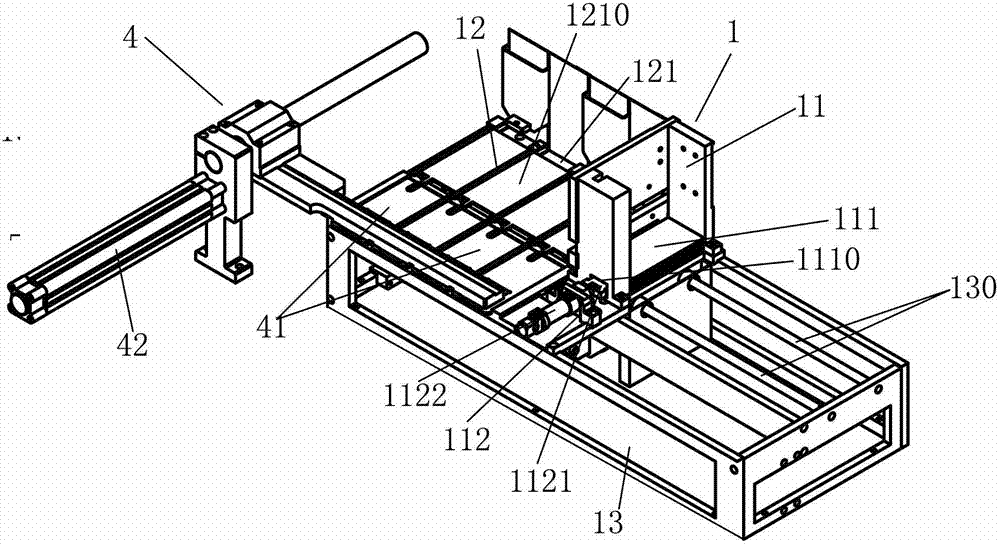

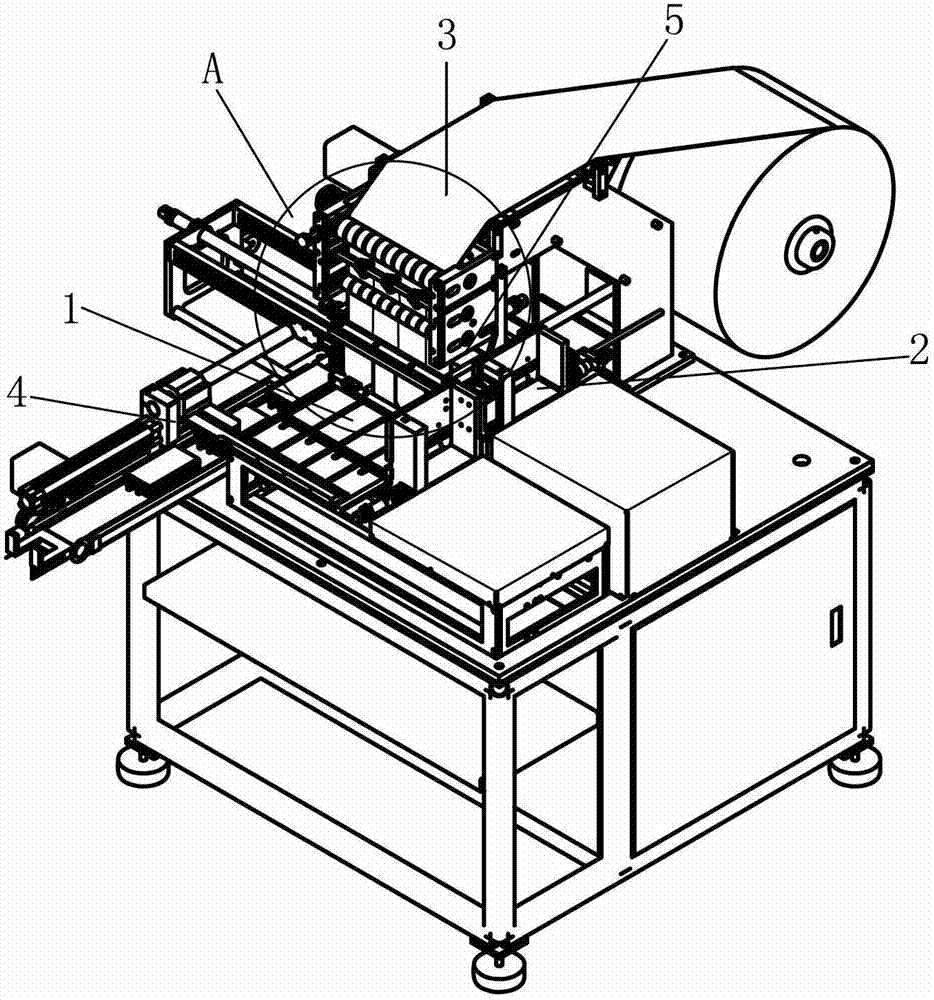

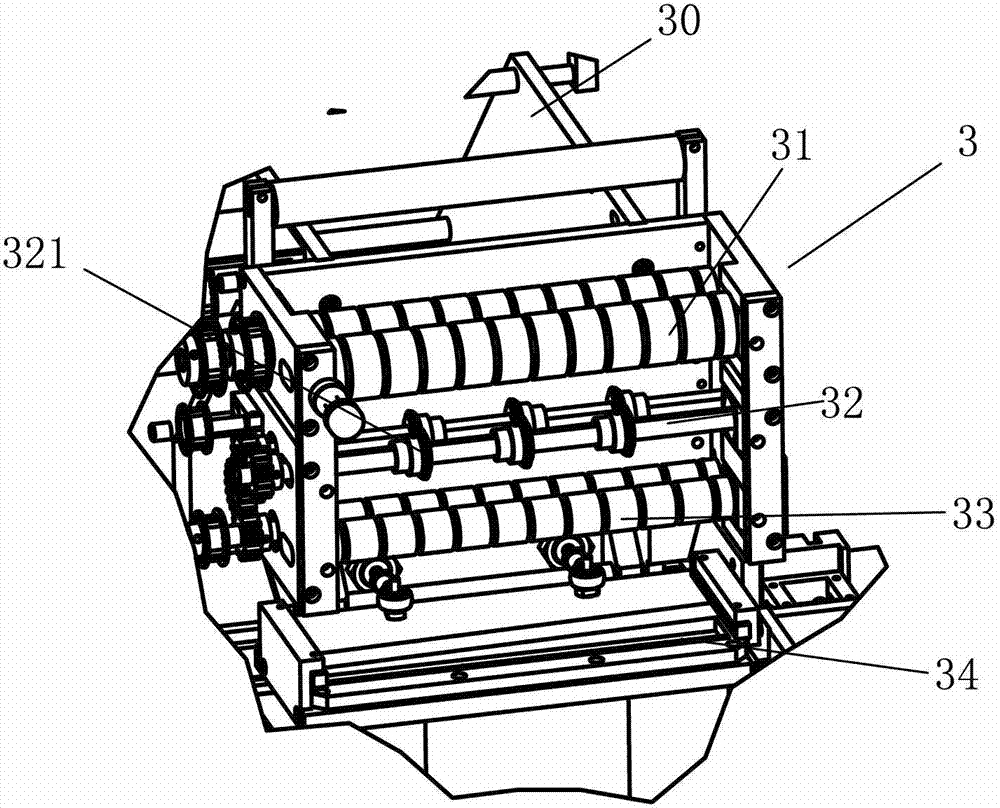

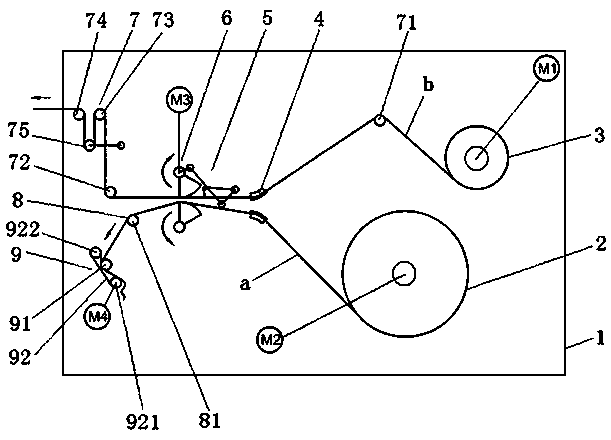

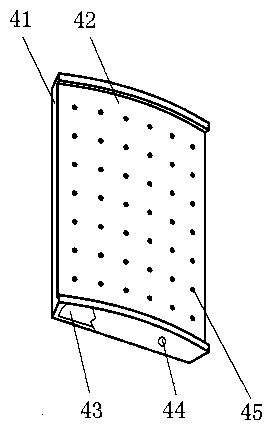

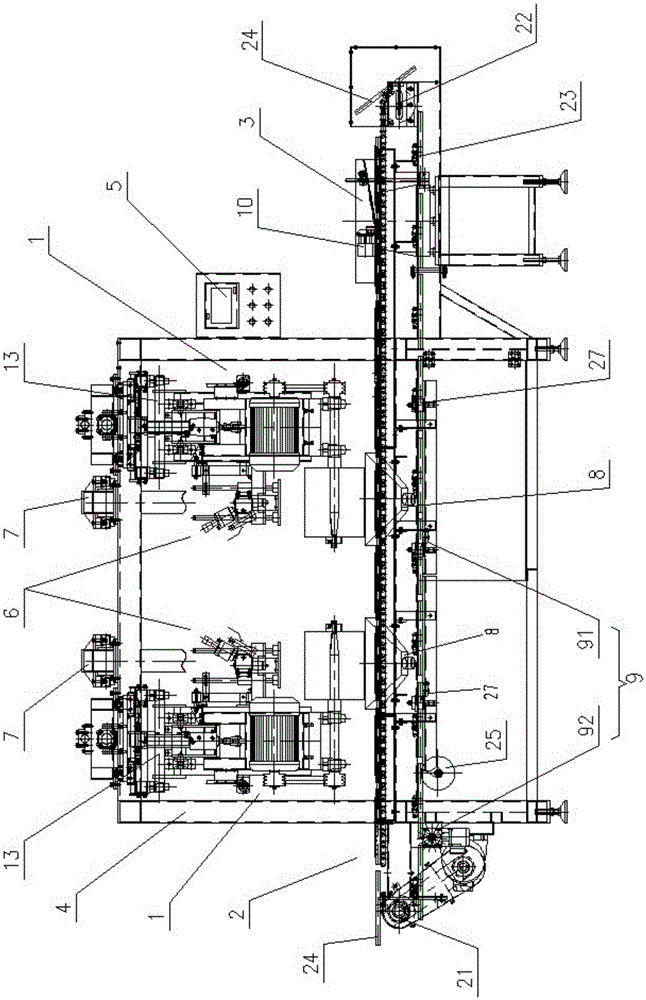

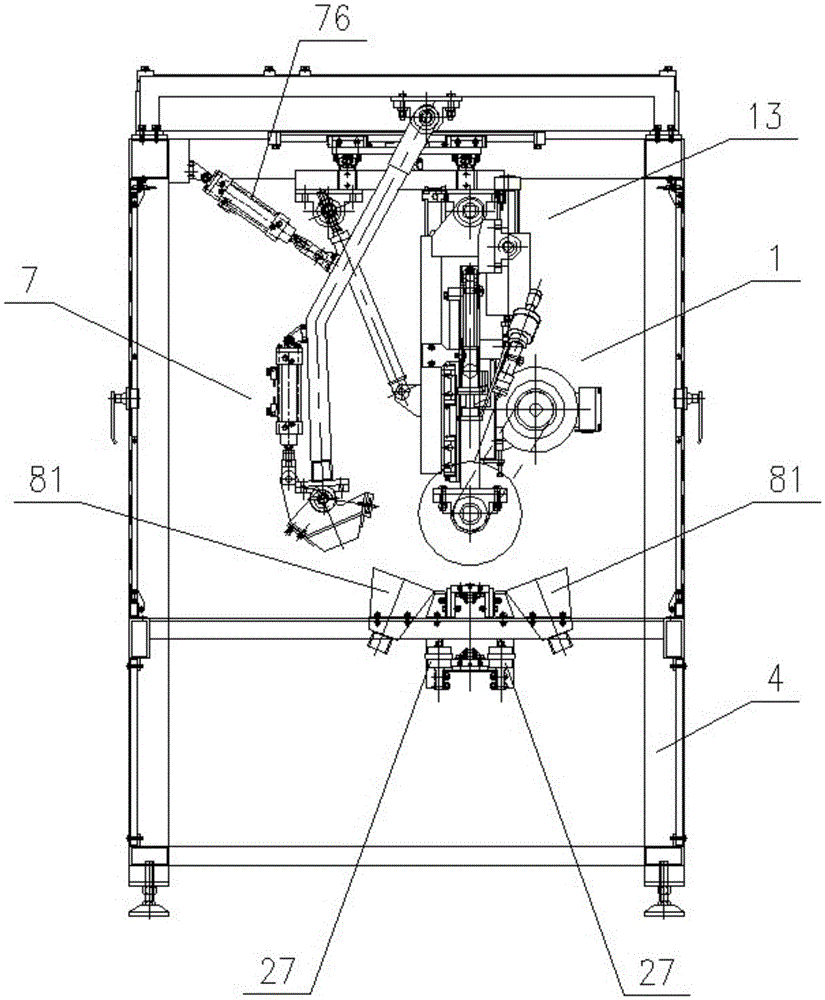

Polar plate dividing mechanism and automatic plate-wrapping assembly device for polar plate

InactiveCN102810696ASimple structureReduce labor intensityFinal product manufactureLead-acid accumulators constructionEngineeringMechanical engineering

The invention discloses a polar plate dividing mechanism and an automatic plate-wrapping assembly device for a polar plate. The polar plate dividing mechanism comprises a polar plate stacking part and a dividing part. The automatic plate-wrapping assembly device for the polar plate comprises a positive electrode pole plate dividing mechanism, a negative electrode pole plate dividing mechanism, a polar plate partition paper conveying, cutting and cladding mechanism, a pushing mechanism, an overlapping assembly mechanism and a control unit. The polar plate dividing mechanism has a simple structure, the labor intensity of workers is reduced, and the production efficiency is improved; and the automatic plate-wrapping assembly device for the polar plate is integrally designed, is high in production capacity and is high and stable in product quality.

Owner:厦门迈通科技有限公司

Method for preparing powdery electrolytic manganese dioxide (EMD)

ActiveCN102242373ALow raw material requirementLow costElectrolysis componentsUltrasound - actionActive agent

The invention discloses a method for preparing powdery electrolytic manganese dioxide (EMD). In the method, the powdery EMD is directly obtained from solution by improving the electrolytic process and controlling the electrolytic condition; and during electrolysis, a diaphragm electrolytic cell is adopted, a lead silver alloy plate or a titanium manganese alloy plate subjected to acid treatment is taken as an anode, and a graphite plate or a stainless steel plate is taken as a cathode. The method comprises the following steps of: preparing electrolyte with 0.1 to 10.0mol / L sulfuric acid and 0.4 to 1.2mol / L manganese sulfate, adding an active agent into the electrolyte, electrolyzing at the temperature of between 20 and 100 DEG C under the action of ultrasonic waves, and filtering to obtain the powdery EMD; and washing the powdery EMD for multiple times, adding a dispersing agent into solution when the powdery EMD is washed for the last time, and drying to obtain the powdery EMD. The method has the characteristics that: the process flow is simple, energy consumption and cost are low, product particles are uniform and have good appearance, and the like.

Owner:CENT SOUTH UNIV

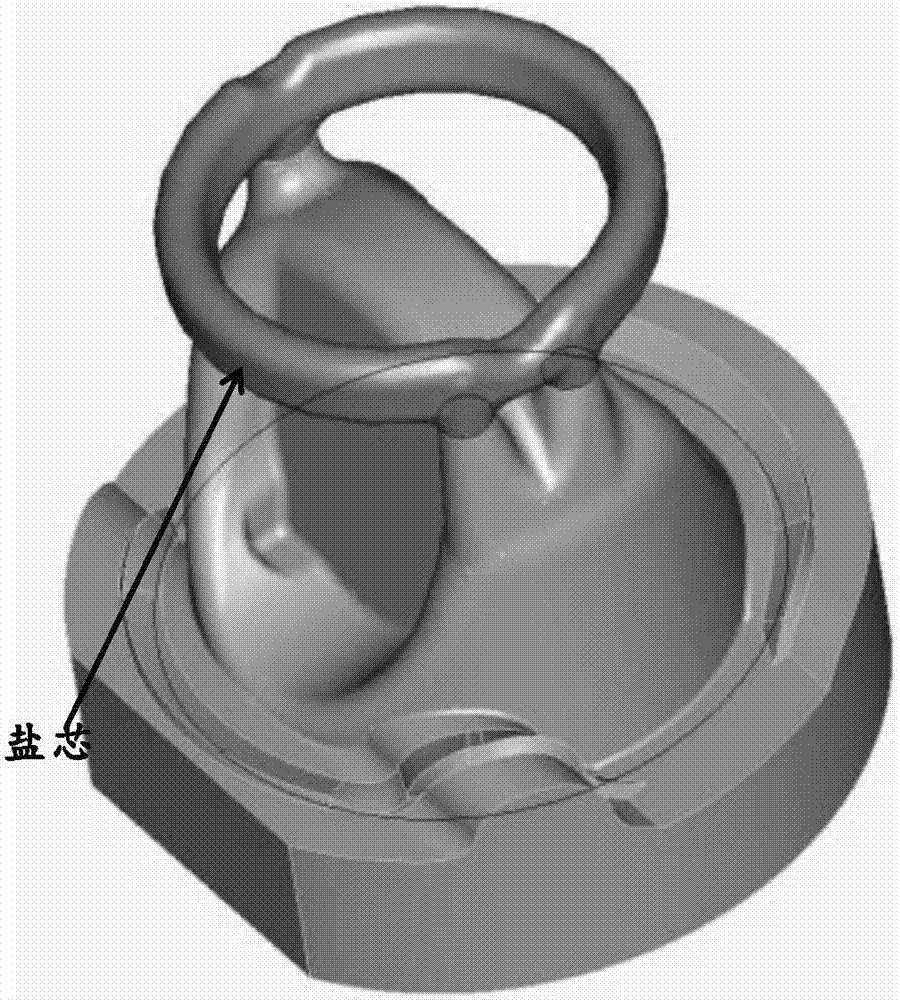

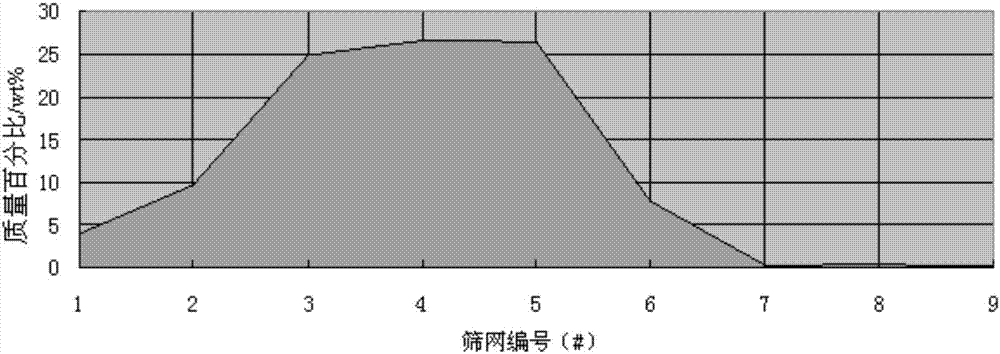

Water-soluble salt core and preparation method thereof

InactiveCN107214304AImprove particle size distributionHigh purityFoundry mouldsFoundry coresWater solubleParticle-size distribution

The invention provides a water-soluble salt core and a preparation method thereof. The preparation method of the water-soluble salt core comprises the following steps: a) performing ball milling, screening and baking on salt powder in sequence to obtain a salt core material; b) The salt core material obtained in step a) is sequentially pressed and sintered to obtain a water-soluble salt core. Compared with the prior art, the present invention can improve the particle size distribution of the salt powder by ball milling, sieving and roasting the salt powder, so that the salt core material is dense and uniform, with high degree of purification, good fluidity, good filling performance, and The pressing and sintering process under specific parameters, the product quality is good and stable, and meets the strength requirements; at the same time, the water-soluble salt core provided by the invention does not contain any additives, is easy to dissolve, and has no residue in the internal cooling oil passage; the product surface is smooth, High dimensional accuracy, capable of forming smooth, dimensionally accurate internal cooling oil passages.

Owner:湖南江滨机器(集团)有限责任公司

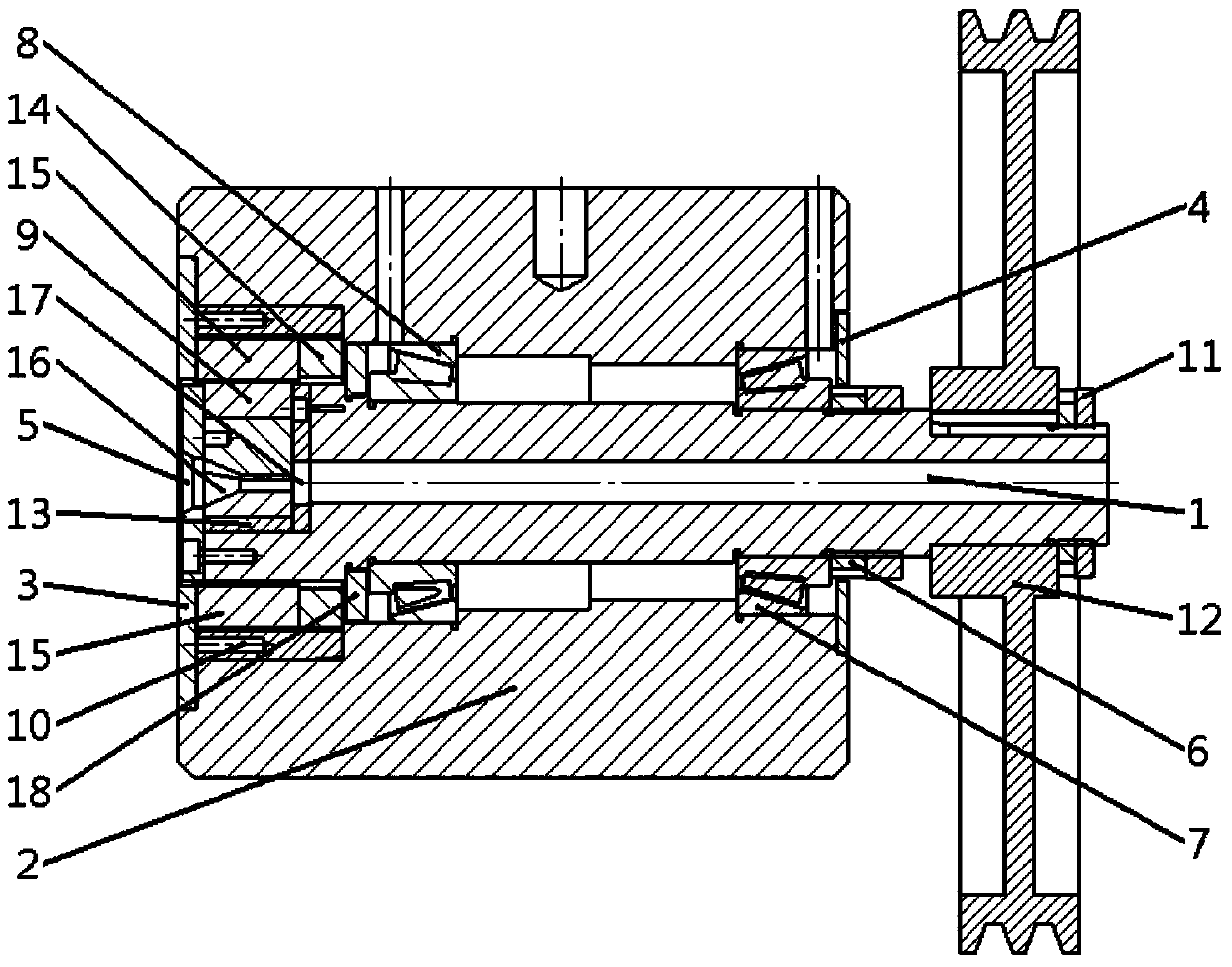

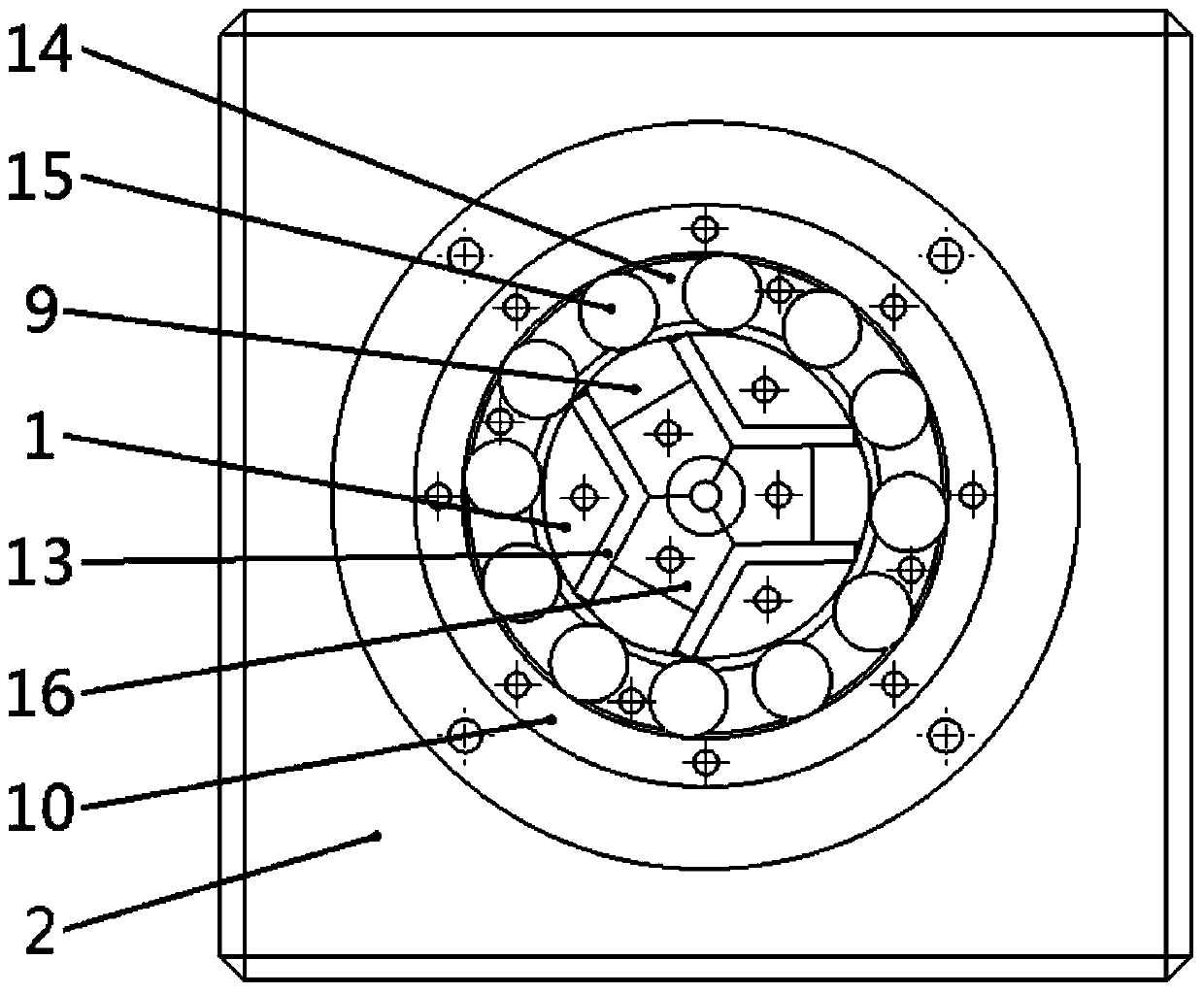

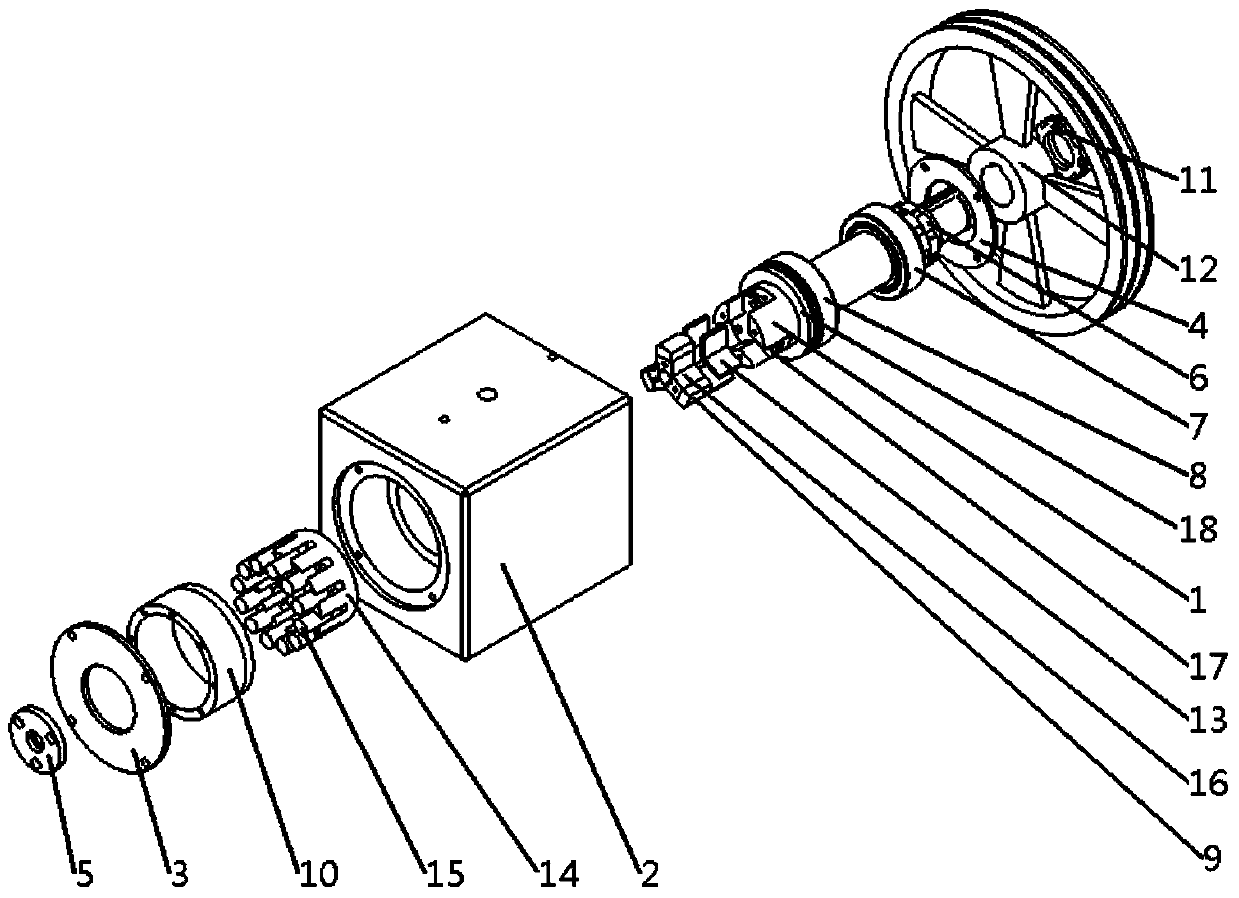

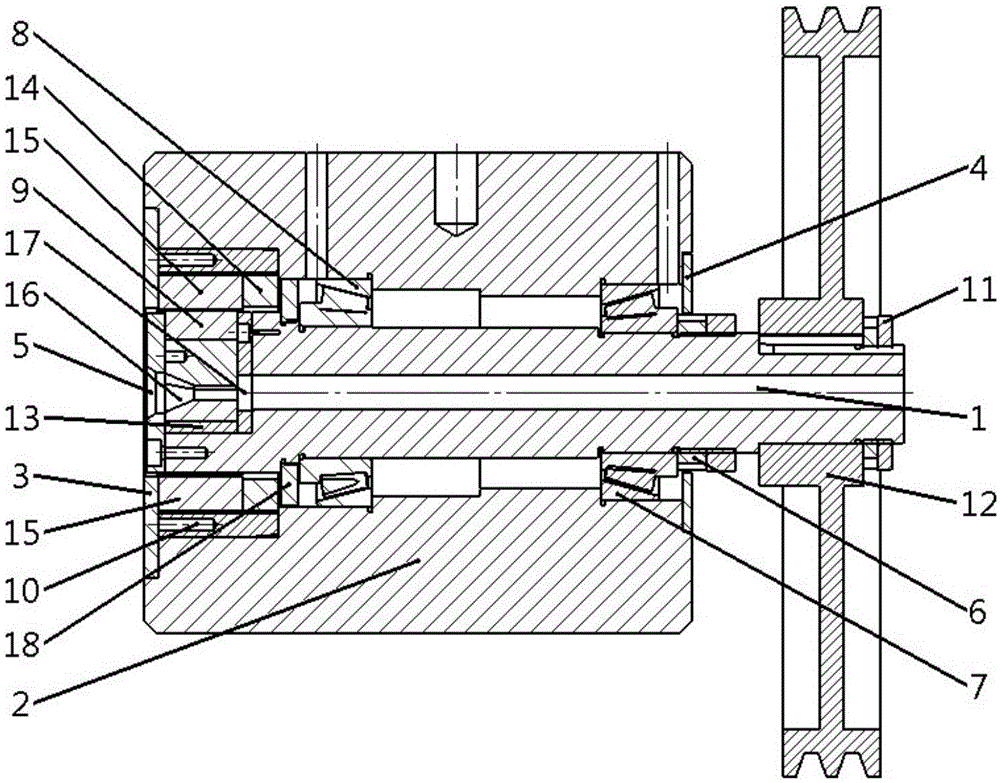

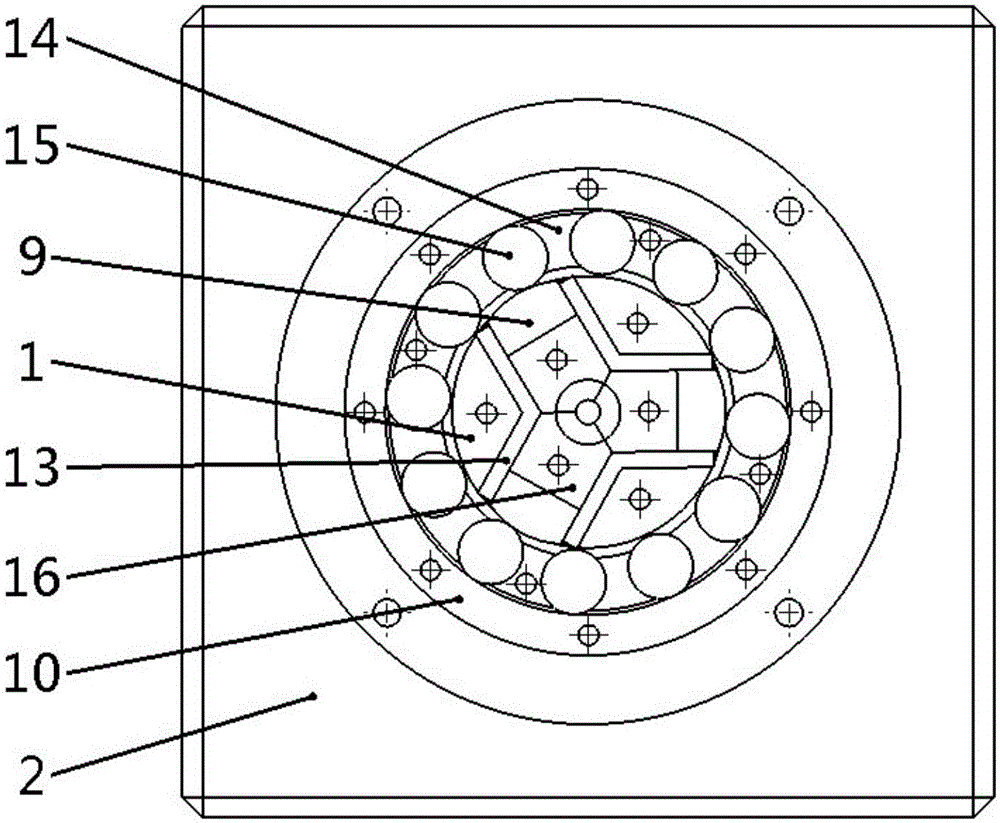

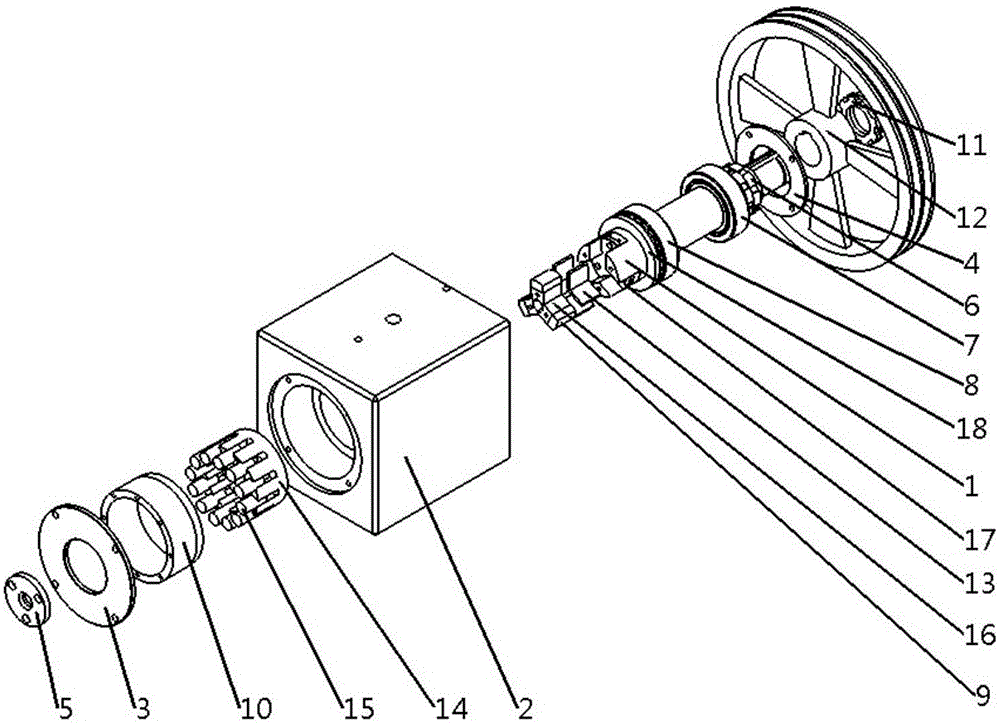

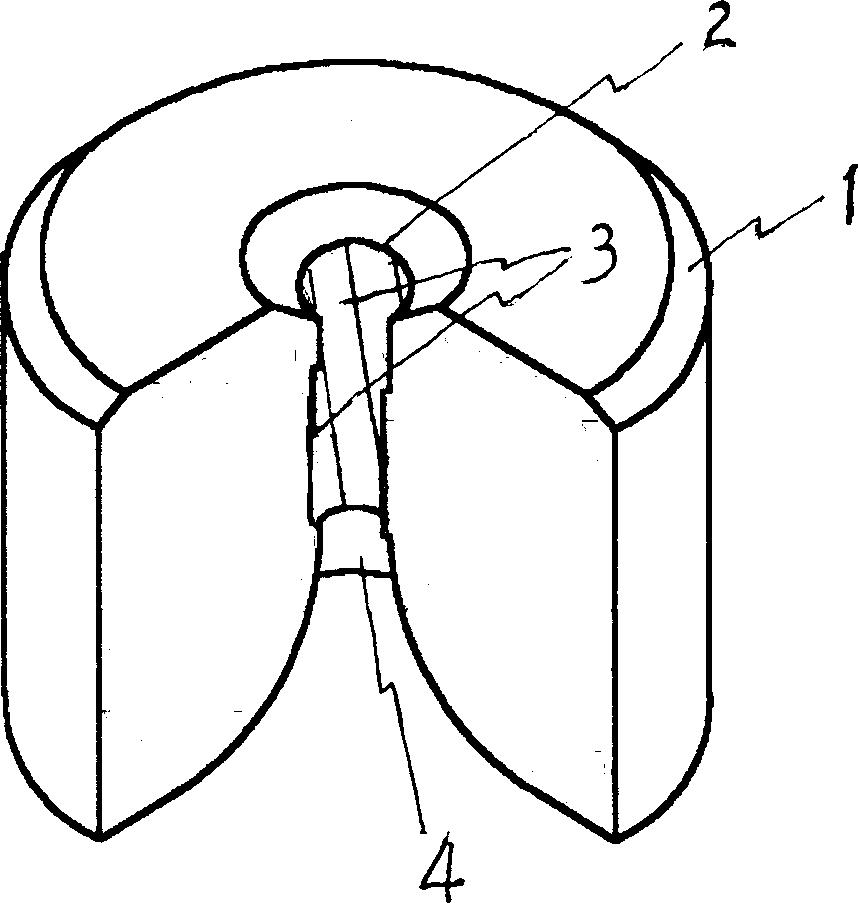

Rotary forging heat pipe reducing die head

The invention discloses a rotary forging heat pipe reducing die head. A spindle is of a hollow cylindrical structure; one end of the spindle is connected with a belt wheel; the other end of the spindle is arranged in a shell; the front end of the spindle is provided with an end face slot provided with three or four openings at the front end of the spindle along the circumference; dies are mounted in the end face slot at the front face of the spindle; each opening of the end face slot is provided one die; the centers of the multiple dies form a cylindrical hollow cavity; a hammer head is mounted at the outer side of the dies and is a lump-like extending part; the outer side of the hammer head is an arc face; a sleeve is arranged at the periphery of the front end of the spindle; a rolling post keeping frame is arranged in the annular space between the sleeve and the outer diameter of the spindle and is provided with multiple blind holes along the peripheral direction; rolling posts are a cylinder-like part and are embedded in the blind holes in the rolling post keeping frame. The rotary forging heat pipe reducing die head solves the problems of large die head consumption, large noise and difficult maintaining in the heat pipe reducing process, and can meet the process demands of large diameter and large hole shrinkage.

Owner:SOUTH CHINA UNIV OF TECH +1

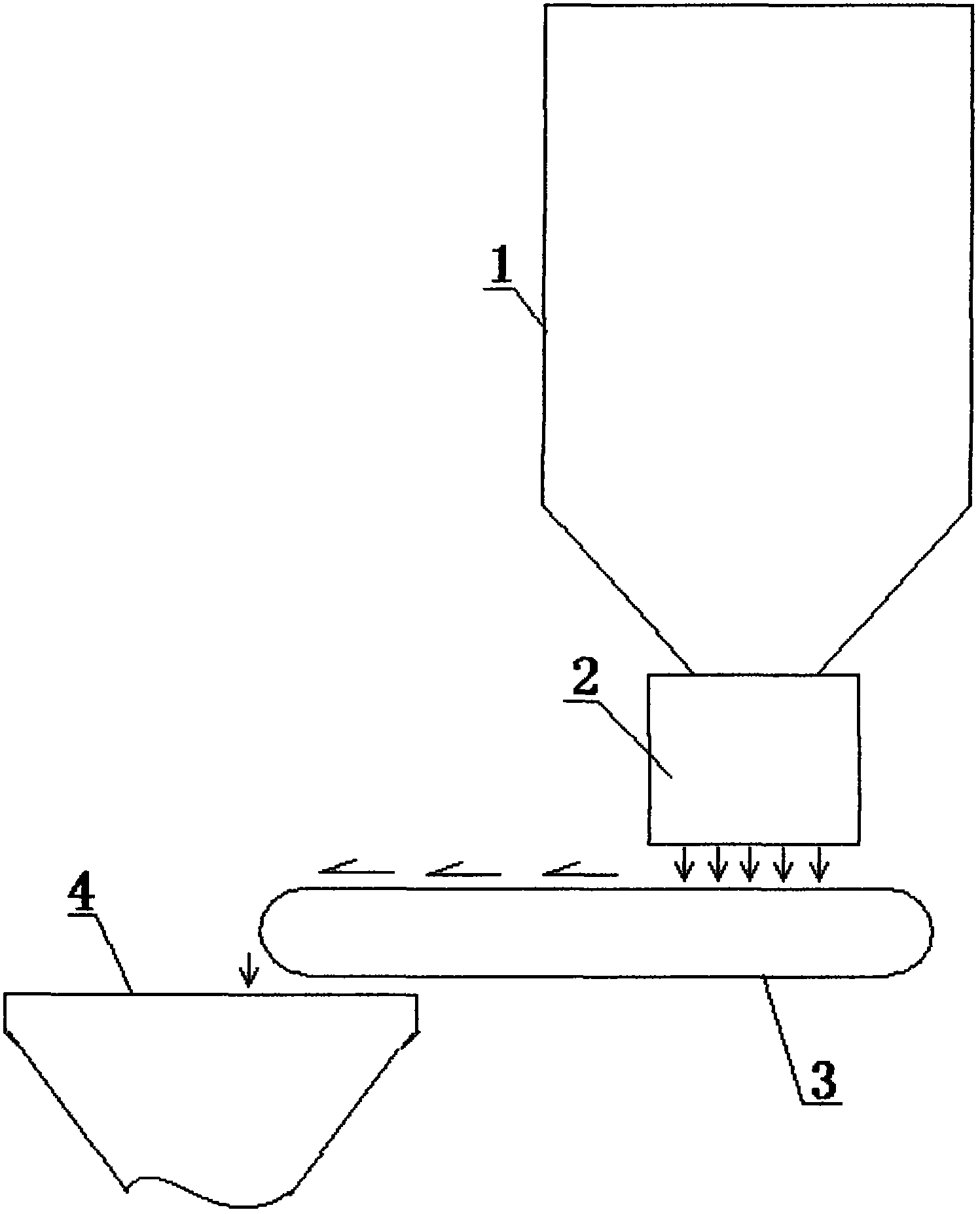

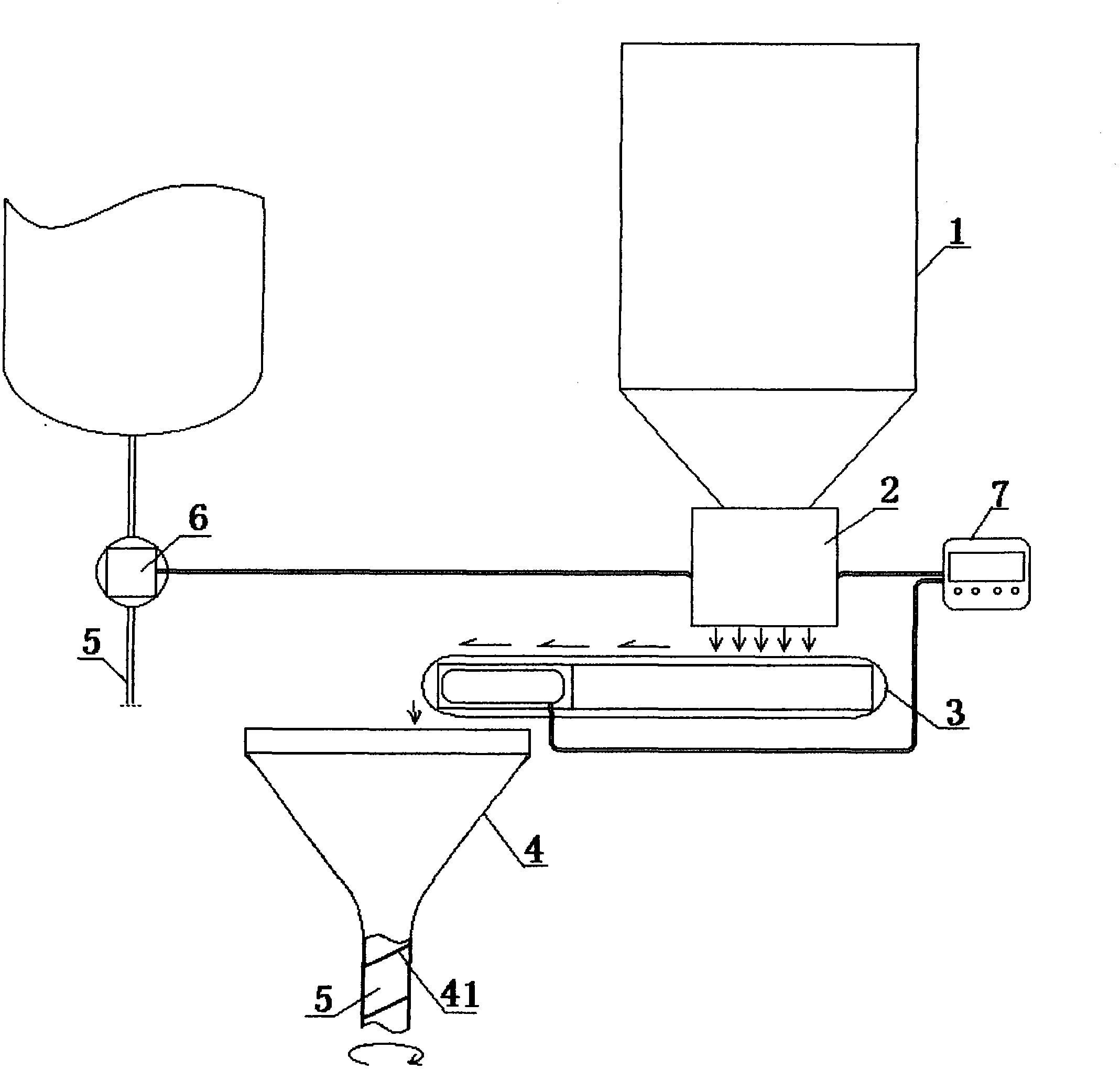

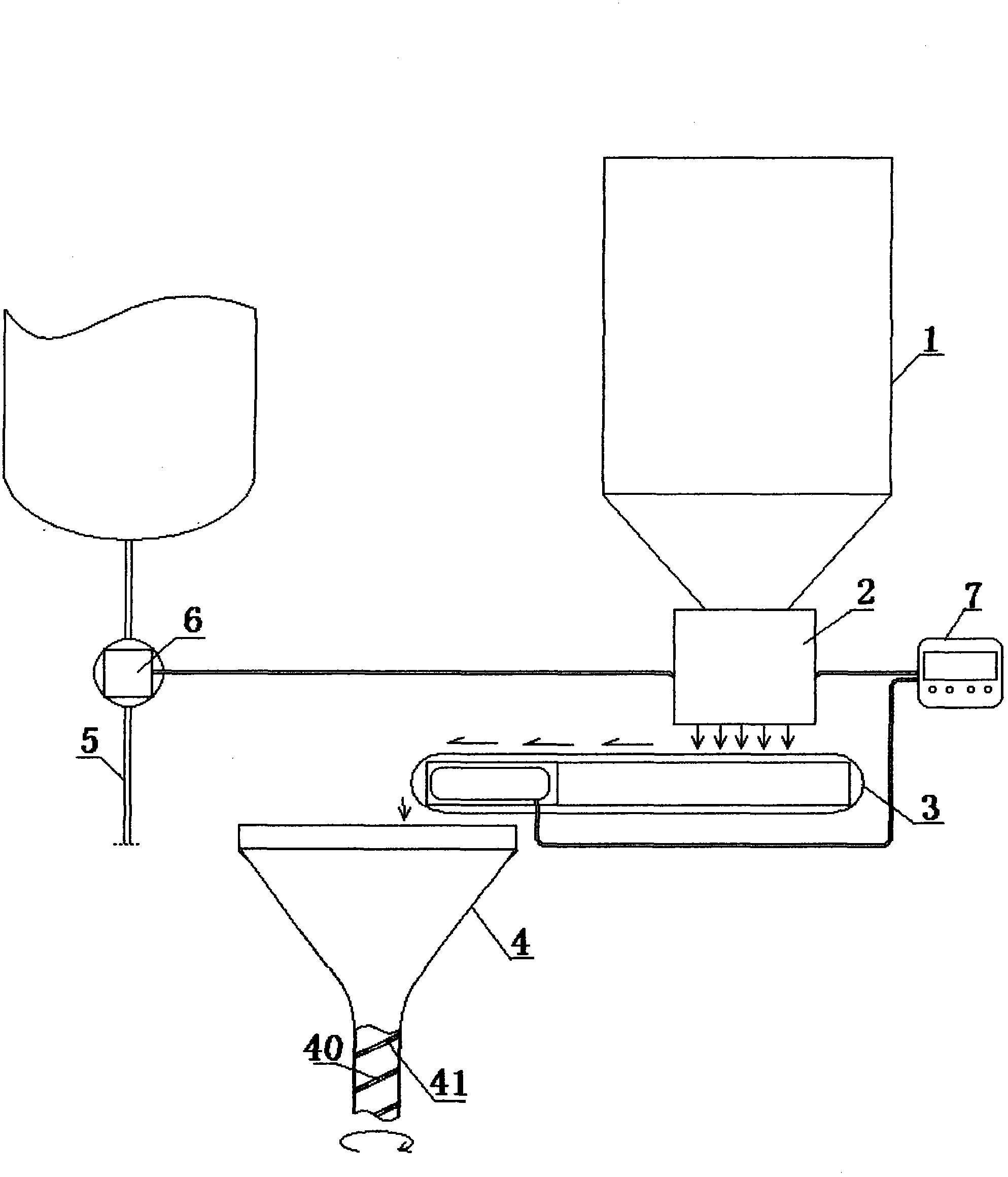

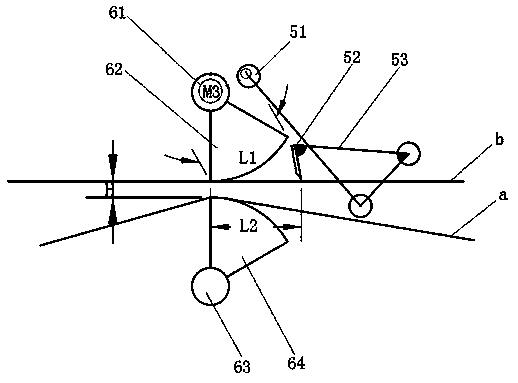

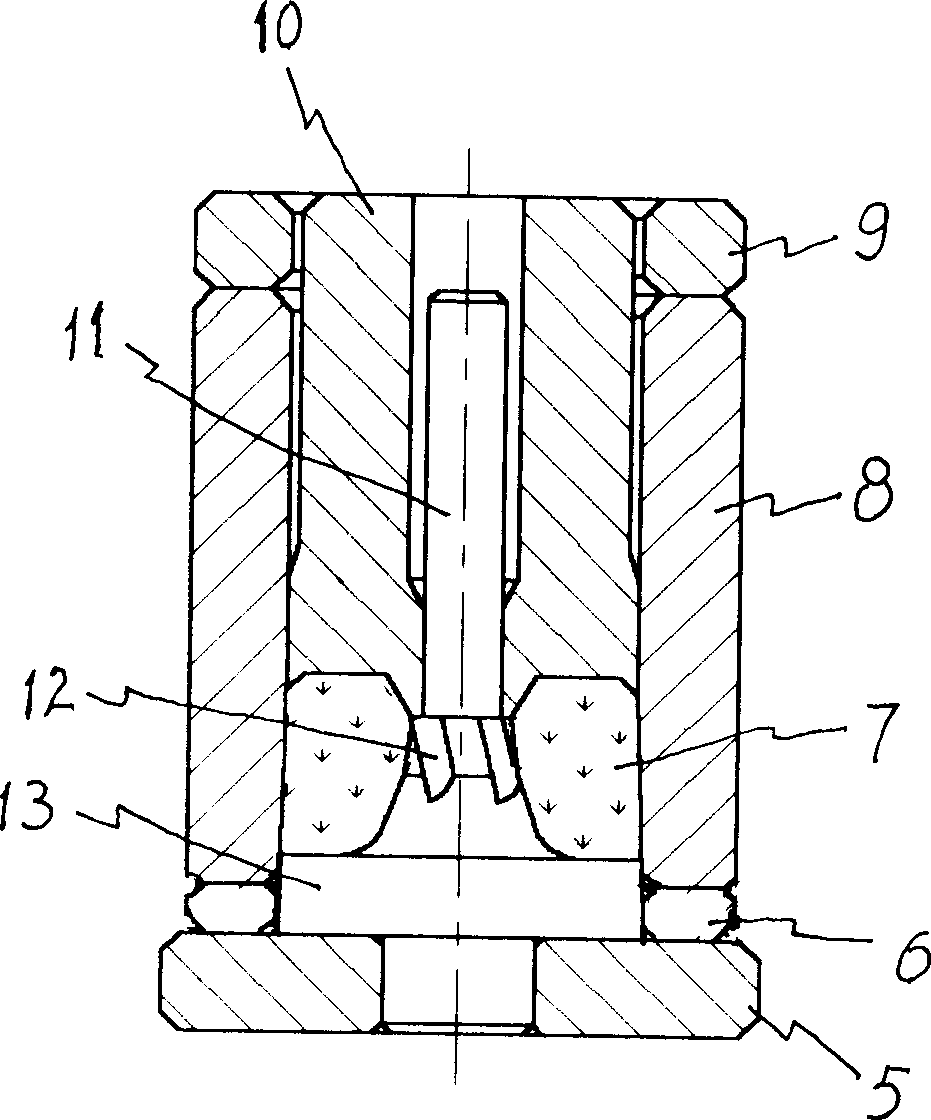

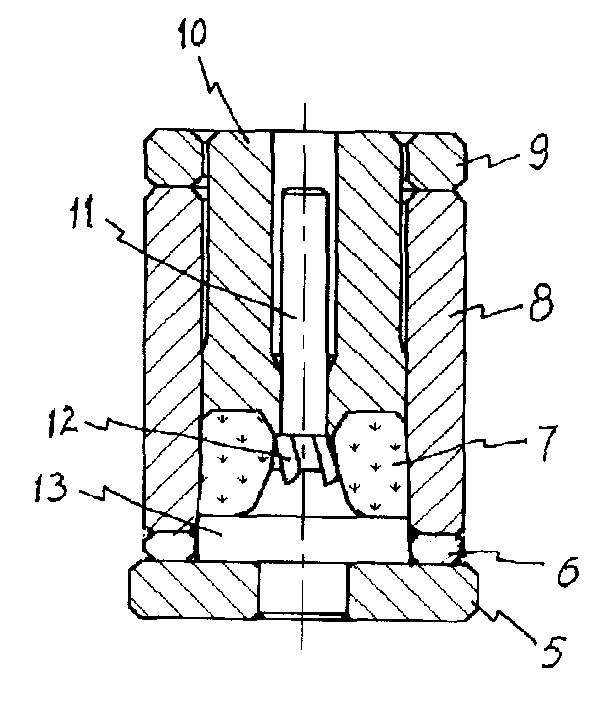

Method and device for accurately feeding mannheim reaction furnace

InactiveCN102674404AGuaranteed feeding ratioThe product quality is good and stableChemical industrySulfate/bisulfate preparationAgricultural engineeringProcess engineering

The invention relates to a method and a device for accurately feeding a mannheim reaction furnace, aiming to solve the problem that the feeding proportion of the conventional mannheim reaction furnace cannot be ensured. The feeding is ensured by arranging a feeder at a material outlet of a potassium chloride feed bin; a electronic belt scale is arranged between the feeder and a potassium chloride feed port of a mannheim furnace to accurately measure the potassium chloride feeding amount or the potassium chloride feeding speed in real time; a sulfuric acid feed pipe of the mannheim furnace is provided with an electric control metering valve to accurately control the sulfuric acid feeding amount or the sulfuric acid feeding speed in real time; and an automatic controller is used for extracting the potassium chloride feeding amount or the potassium chloride feeding speed measured by the belt scale in real time, controlling the electric control metering valve in real time according to the potassium chloride feeding amount or the potassium chloride feeding speed and controlling the potassium chloride feeding amount and the sulfuric acid feeding amount within a specified percentage range all the time. The device has the advantages of ensuring the feeding proportion; ensuring the product quality; improving the product yield and the production efficiency; and making the product quality stable and constant.

Owner:陕西景盛肥业集团有限公司

Novel processing method for sealing strip with characteristics of fire resistance, smoke resistance and sound isolation

The present invention relates to a novel processing method for a sealing strip with characteristics of fire resistance, smoke resistance and sound isolation. The method comprises: preparing raw material particles used for two parts, and forming a mixing material I and a mixing material II, wherein the two parts are a hard bottom plate and a soft wing; cooling by using conical twin screw granulation equipment, and processing into particles respectively at a temperature of 150 DEG C and under 20 Mpa; and preparing two single screw extrusion equipment, respectively adding the particles of the two parts, connecting the mold, and preparing the finished product through the mold. The method of the present invention has the following beneficial effects that: the firm adhesion of the bottom and the soft wing can be ensured, the efficiency is high, the product quality is good, the structure of the produced product is stable, and the new shape structure which can not be produced by the traditional process method can be produced.

Owner:上海加尔福防火密封材料有限公司

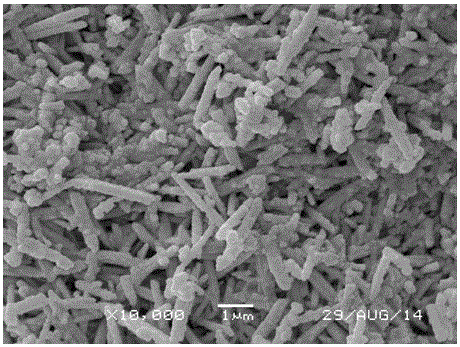

Preparing method for lithium iron phosphate and lithium vanadium phosphate composite anode material precursor

ActiveCN105870428AImproved magnification performanceIncrease profitCell electrodesSecondary cellsLithium iron phosphatePhysical chemistry

A preparing method for a lithium iron phosphate and lithium vanadium phosphate composite anode material precursor comprises the following steps that firstly, ray materials including ferrous gluconate and sodium metavanadate at the mole ratio of 1:2 are dissolved into deionized water respectively, a ferrous gluconate solution and a sodium metavanadate solution are obtained, the concentration of ferrous ions in the ferrous gluconate solution is controlled to be 0.01-0.1 mol / L, then the ferrous gluconate solution and the sodium metavanadate solution are mixed for a reaction, a reaction solution is obtained, PVP is added and stirred, and the pH is regulated to be 4-8 with ammonium hydroxide; secondly, ultrasonic stirring is carried out in a water bath pot at 60-90 DEG C, a uniform solution is obtained and then put into a reaction kettle with a liner, and a reaction is carried out at 180-250 DEG C; thirdly, filtering, washing and drying are carried out, and the lithium iron phosphate and lithium vanadium phosphate composite anode material precursor is obtained. Ferrous metavanadic acid of the lithium iron phosphate and lithium vanadium phosphate composite anode material precursor is in rodlike morphology, and a synthesized lithium iron phosphate and lithium vanadium phosphate composite anode material is excellent in electrochemical performance.

Owner:CENT SOUTH UNIV

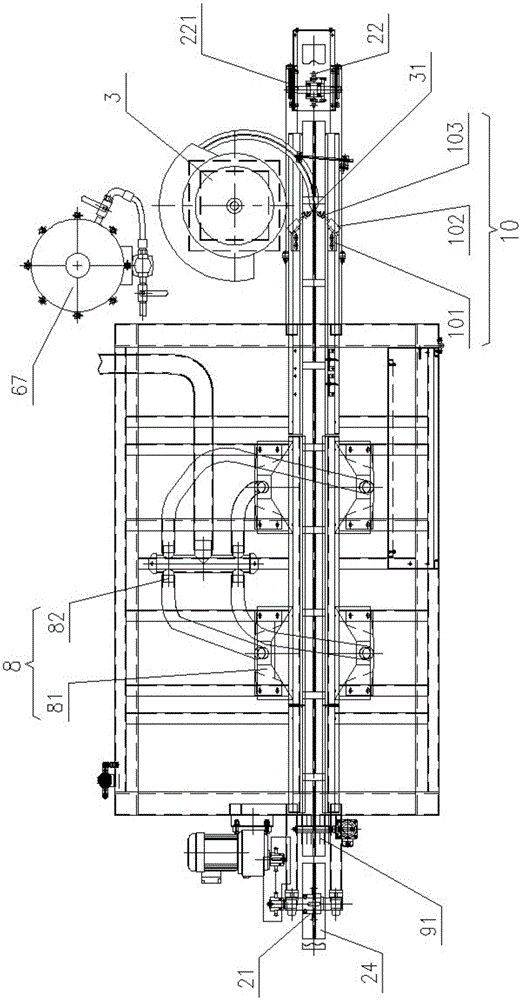

Supply machine for automatic disk change and splicing of tobacco sheets

PendingCN109043651ASolve insufficient fillingSolve quality problemsCigarette manufactureWebs handlingEngineeringDislocation

The invention provides a supply machine for automatic disk change and splicing of tobacco sheets. The supply machine comprises a rack; tobacco sheet disk clamping mechanisms which are respectively used for fixing and transmitting new and old tobacco sheets, a splicing mechanism which is used for splicing the new and old tobacco sheets, support wheel groups which are respectively used for supporting the new and old tobacco sheets and cutting mechanisms which are respectively used for cutting the head ends of the new tobacco sheets and the tail ends of the old tobacco sheets are arranged on therack. The supply machine is characterized in that guiding limiting mechanisms which are respectively used for limiting positions of the new and old tobacco sheets are arranged on the rack and in frontof the splicing mechanism; each guiding limiting mechanism comprises a seat body, on which a longitudinal through groove is formed; and the new and old tobacco sheets respectively pass through the longitudinal through grooves. The supply machine is capable of solving the problems that the tobacco filling amount is insufficient and the product quality is reduced as dislocation is caused during thesplicing in the prior art, and is proper in splicing thickness, high in strength, timely in tobacco sheet end separation, simple in structure, reliable in work and high in automation degree.

Owner:KUNMING DINGCHENG TECH

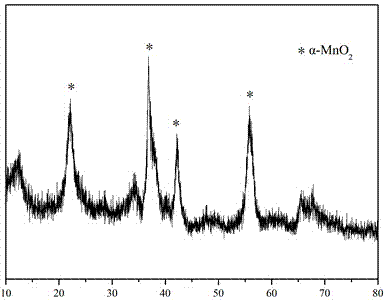

Method for purifying zinc electrodeposition anode mud to prepare manganese sulfate and cell grade manganese dioxide

InactiveCN109502651ASimple and efficient operationUniform particlesHybrid capacitor electrodesNanotechnologyIonLead smelting

The invention discloses a method for purifying zinc electrodeposition anode mud to prepare manganese sulfate and cell grade manganese dioxide. The method comprises the following steps: performing ballmilling on zinc electrodeposition anode mud, performing secondary countercurrent zinc washing, performing reduction leaching on manganese, and removing impurities, thereby obtaining the manganese sulfate solution, wherein the process of performing reduction leaching on manganese comprises the following steps: adding zinc washing slag obtained by zinc washing into deionized water, and introducingreduction gas to perform reduction leaching on manganese, thereby obtaining the leaching liquor. According to the method disclosed by the invention, the operation of each process is very simple and convenient, the requirement on equipment is not harsh, and application to large-scale production is facilitated. According to the method disclosed by the invention, various valuable metal resources in the zinc electrodeposition anode mud can be recycled, lead and silver enter the slag to be fed into a lead smelting furnace so as to recover the lead and silver, and the manganese serves as a supercapacitor electrode material with high additional value in the form of nano-scale alpha-MnO2, so as to be recycled.

Owner:HUNAN RES INST FOR NONFERROUS METALS

Method for preparing nano-TiO2 serving as cathode material of lithium ion battery

InactiveCN101967010BLow costWide variety of sourcesCell electrodesTitanium dioxideGranularityPhysical chemistry

Owner:CENT SOUTH UNIV

A rotary forging heat pipe shrinking die head

The invention discloses a rotary forging heat pipe reducing die head. A spindle is of a hollow cylindrical structure; one end of the spindle is connected with a belt wheel; the other end of the spindle is arranged in a shell; the front end of the spindle is provided with an end face slot provided with three or four openings at the front end of the spindle along the circumference; dies are mounted in the end face slot at the front face of the spindle; each opening of the end face slot is provided one die; the centers of the multiple dies form a cylindrical hollow cavity; a hammer head is mounted at the outer side of the dies and is a lump-like extending part; the outer side of the hammer head is an arc face; a sleeve is arranged at the periphery of the front end of the spindle; a rolling post keeping frame is arranged in the annular space between the sleeve and the outer diameter of the spindle and is provided with multiple blind holes along the peripheral direction; rolling posts are a cylinder-like part and are embedded in the blind holes in the rolling post keeping frame. The rotary forging heat pipe reducing die head solves the problems of large die head consumption, large noise and difficult maintaining in the heat pipe reducing process, and can meet the process demands of large diameter and large hole shrinkage.

Owner:SOUTH CHINA UNIV OF TECH +1

Production and mould for machining spiral mould for ribbed steel bars

A helical die for making ribbed reinforcing steel bars is composed of bottom pad, sleeve barrel, limiter, core rod with helical slot on its cylindrical surface and punch head. It is prepared through proportioning powdered raw materials, die pressing, baking, sintering and polishing. Its advantages are high productivity and quality and low cost.

Owner:ZIGONG CEMENTED CARBIDE CORP

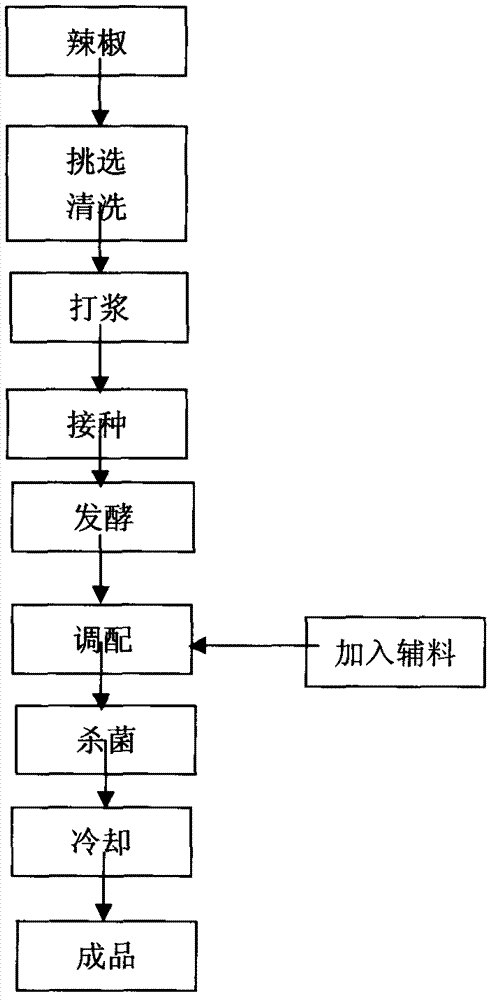

Chili sauce produced by fermentation of pure lactic acid bacteria and production method for chili sauce

ActiveCN102652558BAppropriate sour tasteMild sourFood preparationLeuconostoc mesenteroidesFood flavor

The invention discloses chili sauce produced by fermentation of pure lactic acid bacteria and a production method for chili sauce. The method comprises the following steps of: picking, cleaning and pulping a chili raw material, and inoculating pure lactic acid bacteria for fermentation, wherein the pure lactic acid bacteria consist of lactobacillus planetarium and leuconostoc mesenteroides in a ratio of 2:1; and blending, sterilizing, cooling and storing the fermented chili sauce, and thus obtaining pure lactic acid bacteria fermented chili sauce. Chili is used as the raw material, and a pure strain fermentation technology is adopted, so that the fermentation process is stable and easy to accurately control, and quick production can be realized; and the prepared fermented chili sauce has moderate sourness, proper flavor, good and stable quality, complete nutritional components and soft piquancy, is rich in fermented aroma, and is suitable for industrialized large-scale production.

Owner:新疆新康农业发展有限公司

Method for preparing powdery electrolytic manganese dioxide (EMD)

ActiveCN102242373BLow raw material requirementLow costElectrolysis componentsUltrasound - actionActive agent

The invention discloses a method for preparing powdery electrolytic manganese dioxide (EMD). In the method, the powdery EMD is directly obtained from solution by improving the electrolytic process and controlling the electrolytic condition; and during electrolysis, a diaphragm electrolytic cell is adopted, a lead silver alloy plate or a titanium manganese alloy plate subjected to acid treatment is taken as an anode, and a graphite plate or a stainless steel plate is taken as a cathode. The method comprises the following steps of: preparing electrolyte with 0.1 to 10.0mol / L sulfuric acid and 0.4 to 1.2mol / L manganese sulfate, adding an active agent into the electrolyte, electrolyzing at the temperature of between 20 and 100 DEG C under the action of ultrasonic waves, and filtering to obtain the powdery EMD; and washing the powdery EMD for multiple times, adding a dispersing agent into solution when the powdery EMD is washed for the last time, and drying to obtain the powdery EMD. The method has the characteristics that: the process flow is simple, energy consumption and cost are low, product particles are uniform and have good appearance, and the like.

Owner:CENT SOUTH UNIV

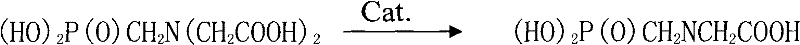

Method for preparing glyphosate by PMIDA catalytic oxidation

ActiveCN101698671BEfficient degradationRaw greenPhysical/chemical process catalystsGroup 5/15 element organic compoundsReaction rateCatalytic oxidation

The invention discloses a method for preparing glyphosate by PMIDA catalytic oxidation, comprising the following steps: 100-110 parts of PMIDA, 5-12 parts of activated carbon and 0.25-1.80 parts of pro-oxidants are added in 300 parts of water by mass part, the mixture is stirred, and then oxygen-containing gas with 70-100 percent of oxygen mass fraction is vented to the mixture to carry out catalytic oxidation reaction, the reaction temperature is 50-100 DEG C, the reaction pressure is 0.5-2.0MPa and the reaction time is 1-2h; after the reaction is finished, the solution is cooled and filtered to obtain filtrated mother liquid and a filter cake 1, the filtrated mother liquid is utilized in a circulating way, the filter cake 1 is hot-melted after water is added and then is filtered to obtain hot filtrate and a filter cake 2, the hot filtrate is cooled and crystallized to obtain solid glyphosate, and the filter cake 2 is recycled and used repeatedly. The method has stable product quality, can greatly improve utilization rate of oxygen and speed up the reaction rate; the production cost is low, formaldehyde can be effectively degraded, thereby meeting the industrial production requirements.

Owner:SHANDONG WEIFANG RAINBOW CHEM +1

head of a polishing machine

InactiveCN103878674BHigh degree of mechanizationImprove efficiencyPolishing machinesGrinding drivesEngineeringMechanical engineering

The invention provides a machine head of a polishing machine. The machine head of the polishing machine comprises a polishing wheel, a rotary driving device rotationally driving the polishing wheel and a spatial motion mechanism carrying the polishing wheel and the rotary driving device and arranged on a machine frame. The rotary driving device and the spatial motion mechanism are connected with a controller in a controlled mode. Thus, the machine head of the polishing machine can serve as a polishing mechanism of the polishing machine. Under the control of the controller, a feeding mechanism is controlled to be started and stopped by a feeding switching device, material bearing templates of a material conveying mechanism are intermittently fed one by one, the material bearing templates are driven to move forwards through a conveying chain, so that a material to be polished is conveyed to the polishing mechanism, and under the spatial position adjustment of the spatial motion mechanism and rotary driving of the rotary driving device, the material to be polished of the corresponding material bearing template is polished by the polishing wheel. Thus, organic continuous polishing operation can be conducted by the polishing machine, the mechanical degree of the whole device is high, the polishing operation is conducted more smoothly, efficiency is high, and practicality is high.

Owner:HUA LIAN GARMENT COMPONENT ENTERPRISE

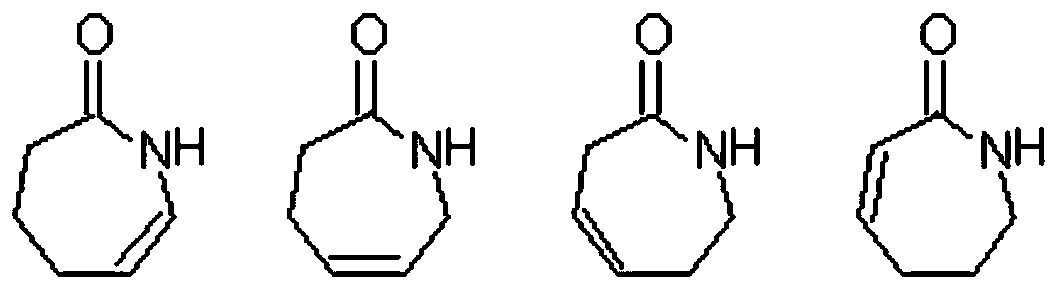

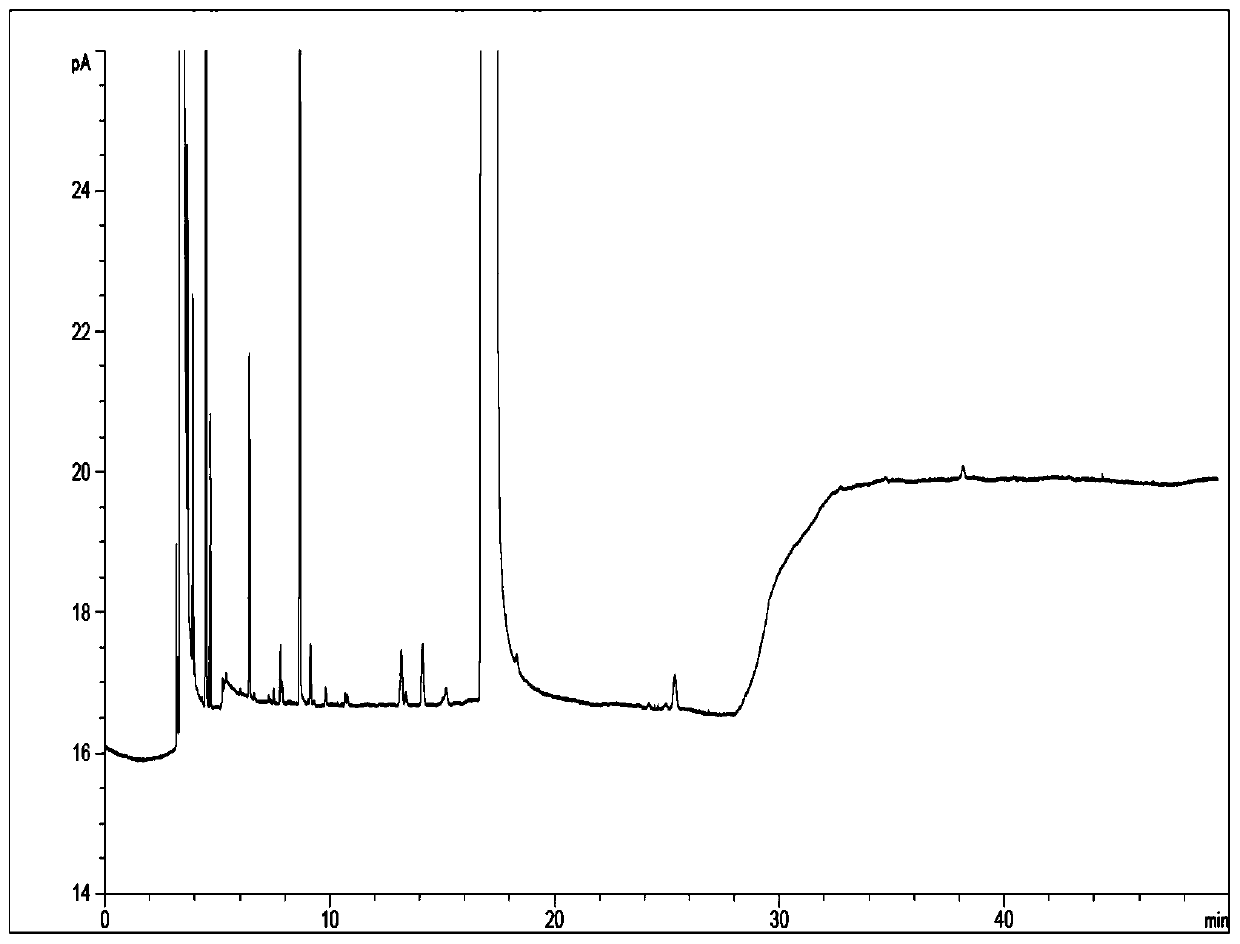

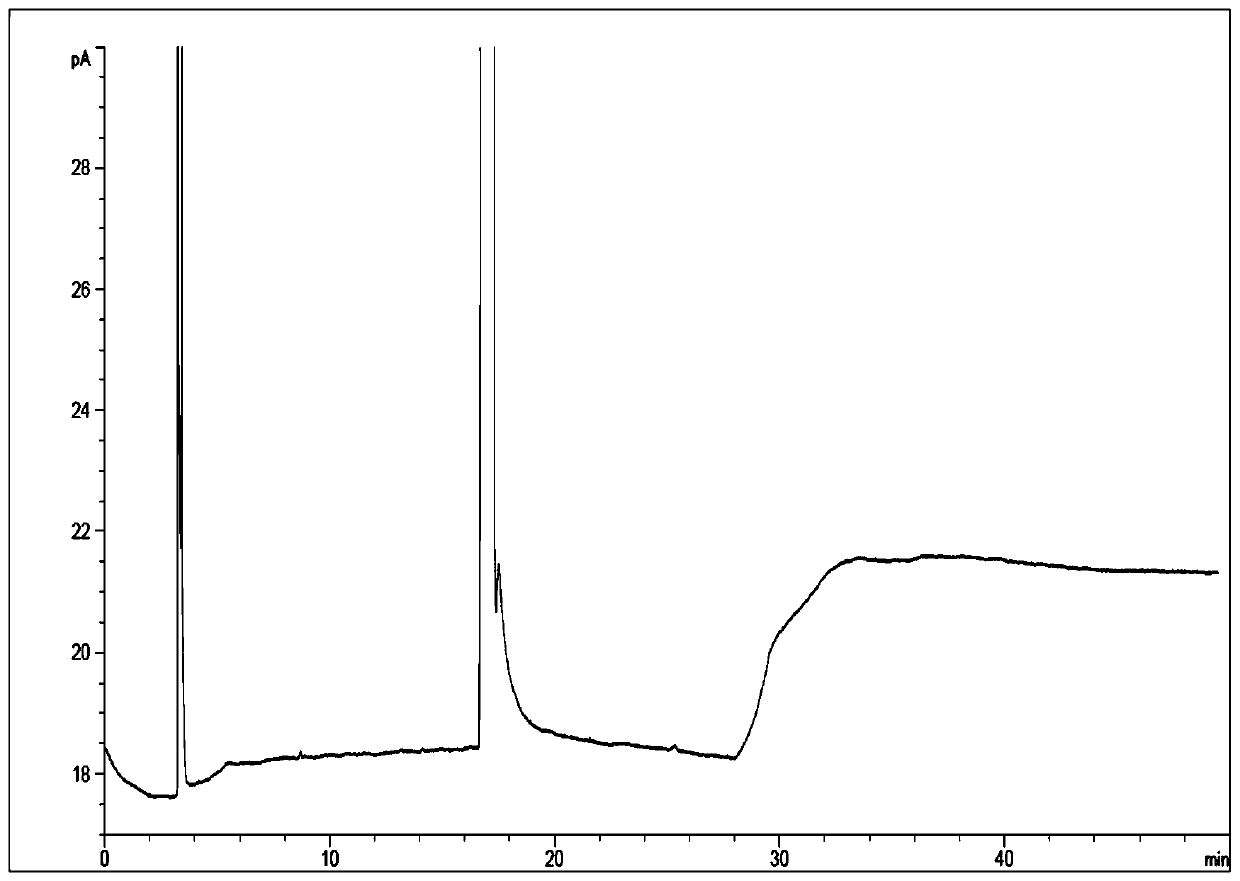

Method for improving quality of caprolactam product subjected to liquid-phase Beckmann rearrangement

The invention discloses a method for improving the quality of a caprolactam product subjected to liquid-phase Beckmann rearrangement. The method is characterized by comprising the following steps: evaporating benzene from a benzene-crude caprolactam solution obtained in a liquid-phase Beckmann rearrangement reaction process to obtain a benzene-crude caprolactam solution of which the caprolactam weight content is greater than or equal to 55%; adding alkane with the carbon atom number of 6-12 into the benzene-crude caprolactam solution with the caprolactam weight content of more than or equal to55% to obtain a benzene-alkane-crude caprolactam solution; crystallizing at a temperature of 10-65 DEG C; washing the crystal and carrying out solid-liquid separation to obtain a crystal product; andcarrying out hydrogenation reaction on the obtained crystallization product in the presence of a catalyst, wherein in the benzene-alkane-crude caprolactam solution, the weight ratio of the mixed solvent of benzene and alkane to crude caprolactam is (0.6-4.0): 1, and the weight ratio of benzene to alkane is 1: (1-50).

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for preparing ferric lithium phosphate precursor by comprehensive utilization of ilmenite

InactiveCN100567144CWide variety of sourcesSimple processCell electrodesPhosphorus compoundsLithium iron phosphatePhosphate

The invention discloses a method for comprehensively utilizing titanic iron ore to prepare a precursor of the lithium iron phosphate, which is characterized in that titanium iron ore is immerged into an acid, filtering, a quantitative other ore resource is dissolved in the filtered solution, making the Fe concentration in the mixed solution to be from 0.01 to 3 mol / L and the molar ration of Ti to Fe to be from 0.0005 to 0.3; an oxidant and a sedimentation agent are put into the solution, wherein the concentration of the oxidant and the sedimentation agent is from 0.01 to 3 mol / L, using an alkaline solution from 0.01 to 6 mol / L to control pH value of the system between 1.5 and 6.0, reacting for from 5 minutes to 24 hours in an agitating reactor at a temperature of between 20 and 90 degree centigrade, the attained sedimentation is rinsed and filtered, the precursor of the lithium iron phosphate for the anode material of a lithium-ion battery is got after the attained sedimentation continues to be dried at a temperature of between 50 and 200 degree centigrade, and the precursor is a mixture of ferric phosphate and doped phosphate. The method for comprehensively utilizing titanic iron ore to prepare the precursor of the lithium iron phosphate has the advantages of wide raw material resource, simple process procedure, good and stable product quality, and low cost, which is particularly applicable to provide the high quality iron resource for the volume production of the lithium iron phosphate for the anode material of the lithium-ion battery and comprehensively utilize the titanic iron ore resource as well.

Owner:CENT SOUTH UNIV

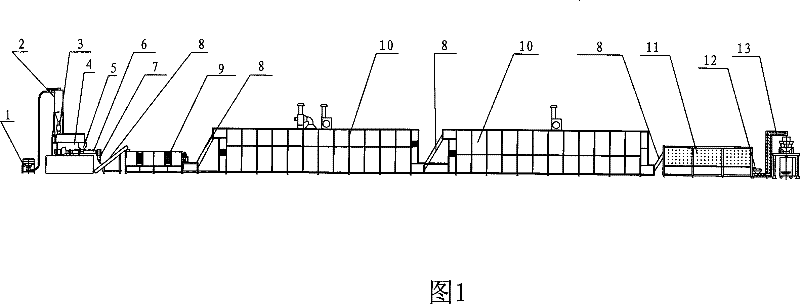

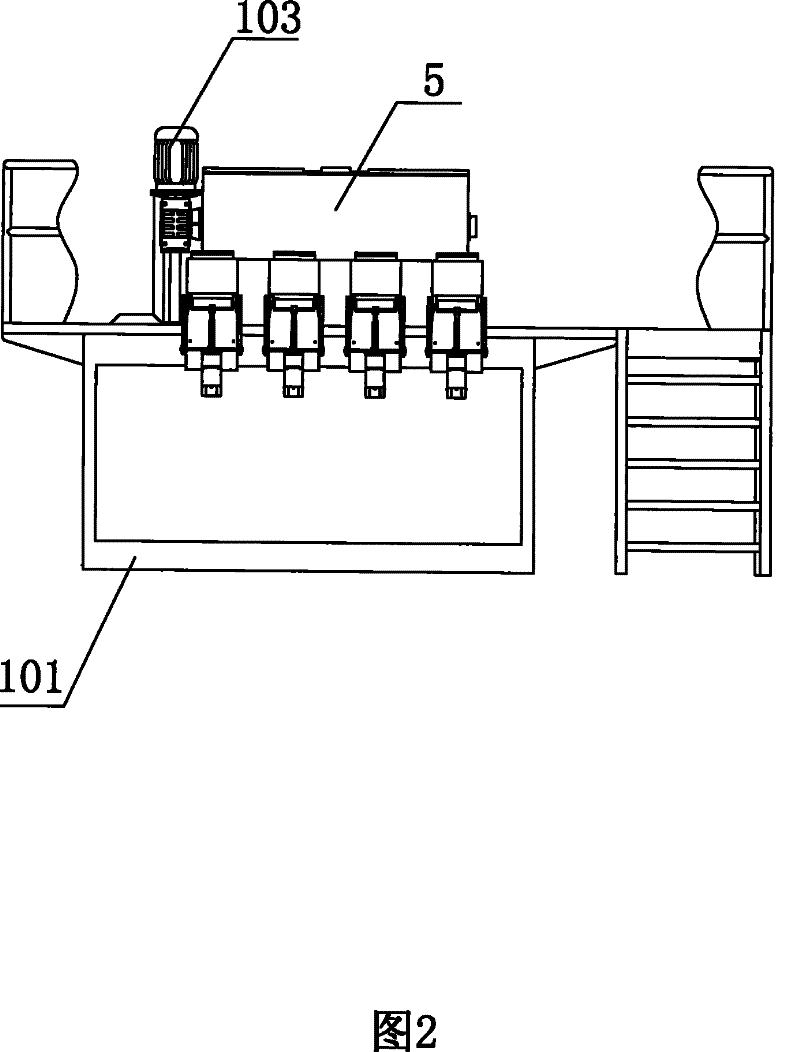

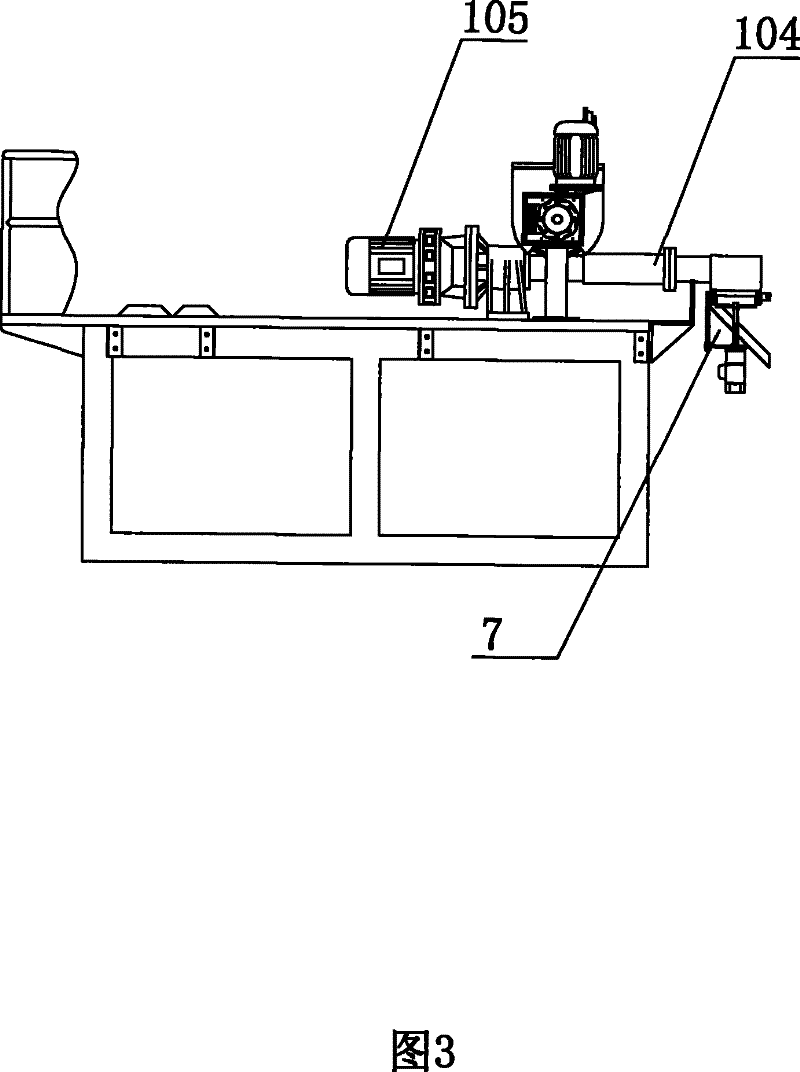

Macaroni product line and production technology thereof

The invention relates to a production line of macaroni, which comprises a shaking screen, an air charging system, a vacuum dough kneading machine, a vacuum aging mixer, a depiler, an extruder, a dinking machine, a hoist, a vibration predrier, a drying hoist, a dryer, an air-cooled hoist, an air-cooled machine, a vibration discharging machine and a package conveyer which are orderly arranged on the material-transferring direction. The production line has the advantages of less artificial operation, safety and health, and large output.

Owner:BUHLER GUANGZHOU FOOD MACHINERY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com