Application of polyacrylic acid in preparation of lithium ion battery anode material nano-sized iron oxide/carbon composite material

A nano-iron oxide, lithium-ion battery technology, applied in battery electrodes, nanotechnology, circuits, etc., can solve problems such as difficult industrial production, and achieve the effects of short reaction cycle, low energy consumption, and good appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

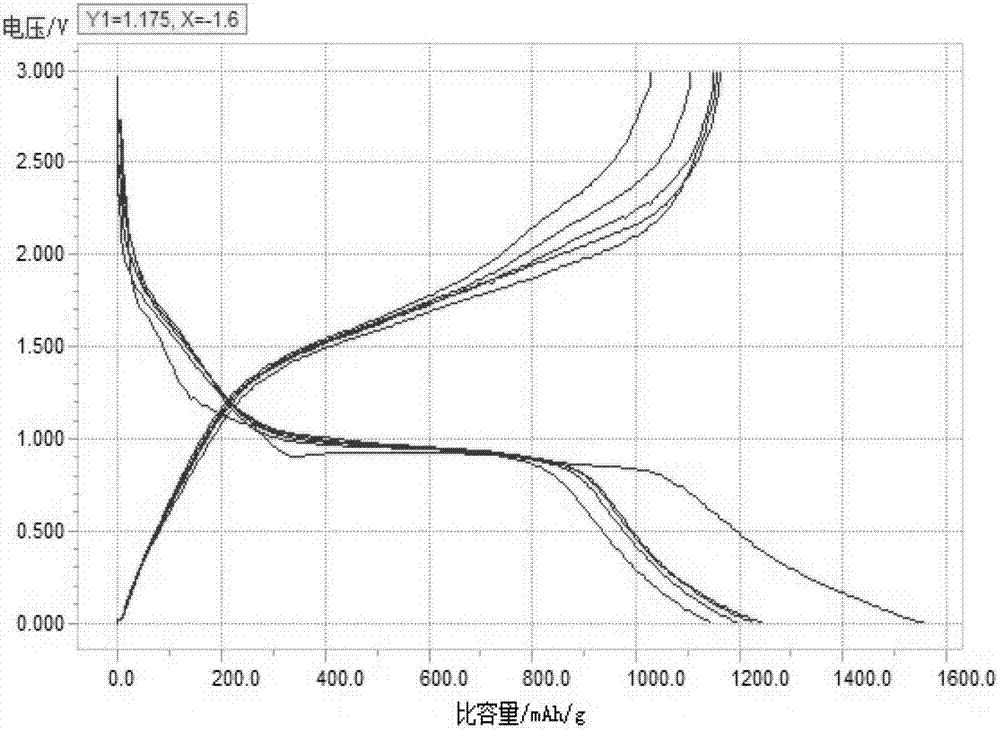

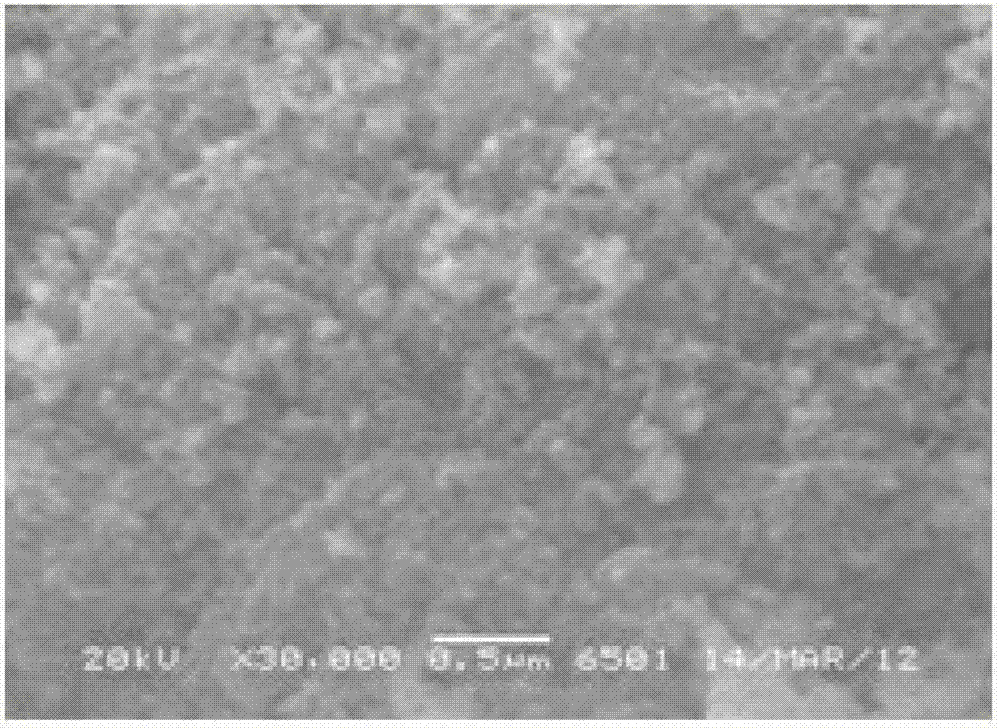

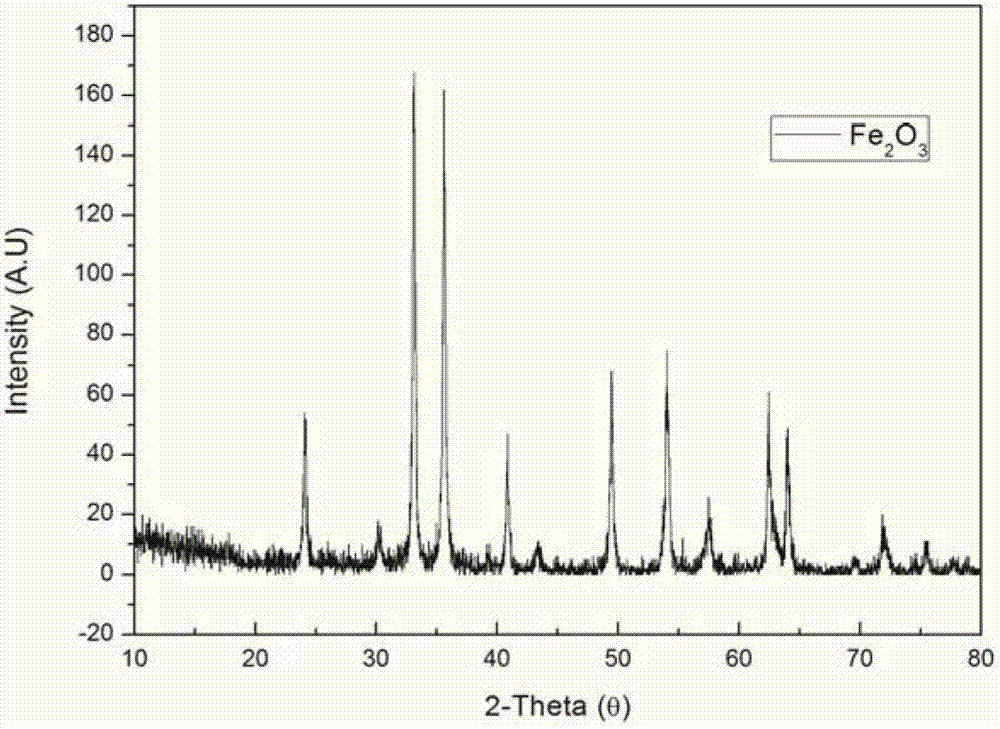

Embodiment 1

[0032] The iron source is 5 grams of chemically pure iron powder, which is dissolved in a mixed solution of deionized water and polyacrylic acid (the content of polyacrylic acid is 10% by mass, the same as in the following examples), and the mass ratio of iron to polyacrylic acid is 1:8 , stir in a water bath at 60°C for 2 hours to dissolve the iron-containing solution, place the iron-containing solution in a constant temperature oscillator to evaporate, the temperature of the water bath is 80°C, and obtain a gel after evaporation for 6 hours; put the gel in a muffle Pre-calcine in the furnace at 300°C for 3 hours, take it out and grind it, and then calcinate it in the air atmosphere of the muffle furnace at 450°C for 5 hours to obtain nano-Fe as the negative electrode material for lithium-ion batteries. 2 o 3 / C Composite.

Embodiment 2

[0034] The iron source is 10 grams of chemically pure ferric nitrate, which is dissolved in a mixed solution of deionized water and polyacrylic acid (the content of polyacrylic acid is 5%), and the mass ratio of iron to polyacrylic acid is 1:2. Stir for 20 minutes to dissolve the iron-containing solution, place the iron-containing solution in a constant temperature oscillator to evaporate, the temperature of the water bath is 90°C, and evaporate for 5 hours to obtain a gel; pre-calcine the gel with a muffle furnace at 400°C for 3 hours , taken out and ground, and then calcined at 500 ° C for 6 hours in a tube furnace oxygen atmosphere to obtain nano-Fe as the negative electrode material for lithium-ion batteries 2 o 3 / C Composite.

Embodiment 3

[0036] The iron source is 5 grams of chemically pure iron powder, which is dissolved in a mixed solution of deionized water and polyacrylic acid (the content of polyacrylic acid is 10%), and the mass ratio of iron to polyacrylic acid is 1:7. Stirring for 3 hours to dissolve the iron-containing solution, place the iron-containing solution in a constant temperature oscillator to evaporate, the temperature of the water bath is 90°C, and obtain a gel after evaporating for 4 hours; pre-calcine the gel with a muffle furnace at 400°C for 3 hour, take it out and grind it, and then calcinate it at 500°C for 5 hours under the argon atmosphere of the tube furnace to obtain nano-Fe 3 o 4 / C Composite.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com