Processing method of high-quality machine-made sand

A processing method and machine-made sand technology, which is applied in the direction of grain processing, etc., can solve the problems that high-quality machine-made sand cannot be produced according to demand, the machine-made sand has poor sphericity, and does not conform to green production, so as to achieve low infrastructure and equipment investment and high particle size. The effect of good shape and easy maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

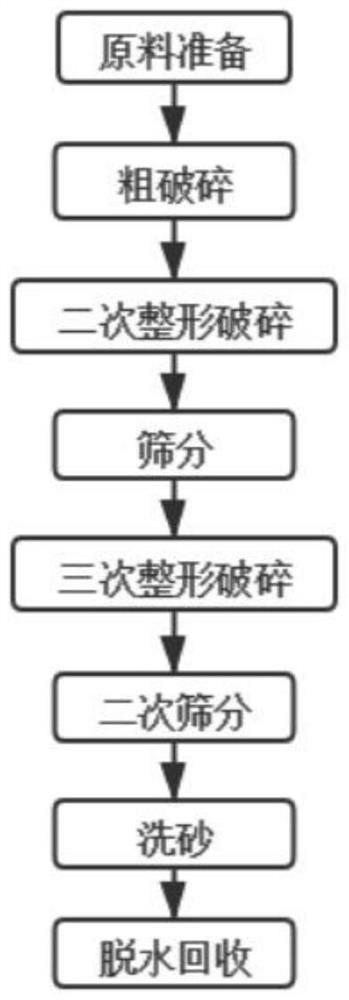

[0039] Such as figure 1 As shown, this embodiment proposes a processing method for high-quality machine-made sand, which specifically includes the following steps:

[0040] Step 1. Preparation of raw materials: Preliminary screening of raw materials. In this embodiment, limestone is selected as raw material, impurities and debris in limestone are removed, and then stored in a raw material warehouse for subsequent use;

[0041] Step 2. Coarse crushing: use an automatic feeder to transport the limestone raw material from the raw material warehouse to the jaw crusher for coarse crushing to obtain crushed stones;

[0042] Step 3, secondary shaping and crushing: transport the roughly crushed crushed stones to the cone crushing and shaping sand making machine for secondary shaping and crushing to obtain sand and gravel with a smaller diameter;

[0043] Step 4. Screening: use the No. 1 vibrating screen to screen the sand and gravel obtained after the secondary shaping and crushing, ...

Embodiment 2

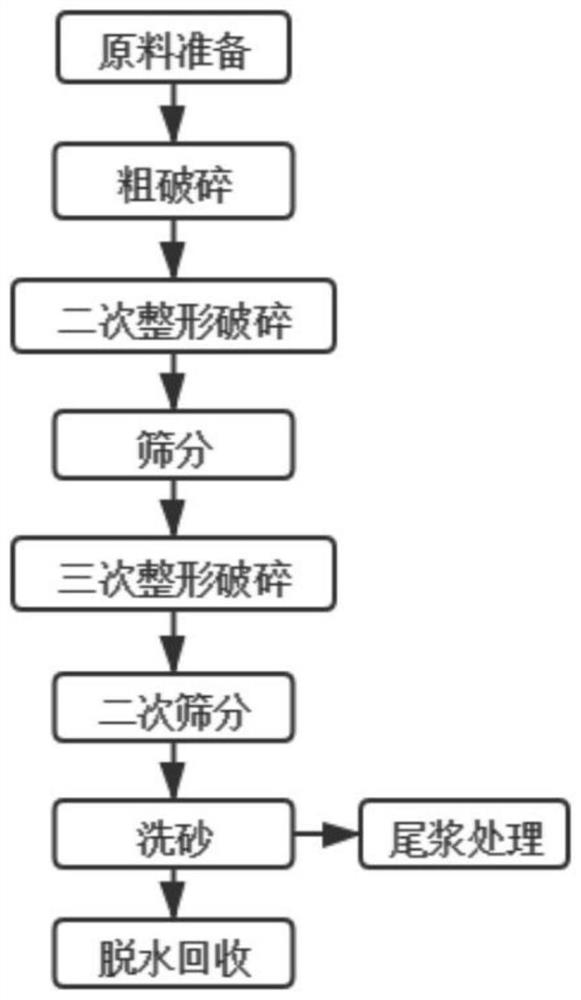

[0050] Such as figure 2 As shown, this embodiment proposes a processing method for high-quality machine-made sand, which specifically includes the following steps:

[0051]Step 1. Preparation of raw materials: Preliminary screening of raw materials. In this embodiment, limestone is selected as raw material, impurities and debris in limestone are removed, and then stored in a raw material warehouse for subsequent use;

[0052] Step 2. Coarse crushing: use an automatic feeder to transport the limestone raw material from the raw material warehouse to the jaw crusher for coarse crushing to obtain crushed stones;

[0053] Step 3, secondary shaping and crushing: transport the roughly crushed crushed stones to the cone crushing and shaping sand making machine for secondary shaping and crushing to obtain sand and gravel with a smaller diameter;

[0054] Step 4. Screening: use the No. 1 vibrating screen to screen the sand and gravel obtained after the secondary shaping and crushing, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com