Method for improving quality of caprolactam product subjected to liquid-phase Beckmann rearrangement

A technology of Beckmann rearrangement and caprolactam, which is applied to the preparation of lactam, chemical instruments and methods, organic chemistry, etc., can solve the problems of high product alkalinity, high environmental protection treatment costs, and large water consumption for ion exchange. Shortening the refining process, stable product quality, and good product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] This example illustrates the method of the invention.

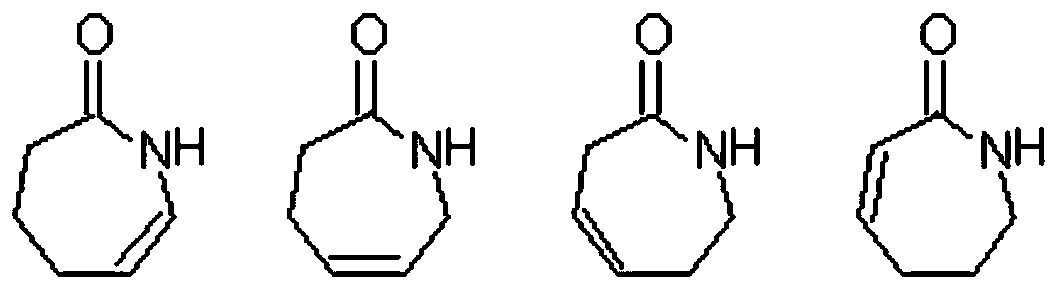

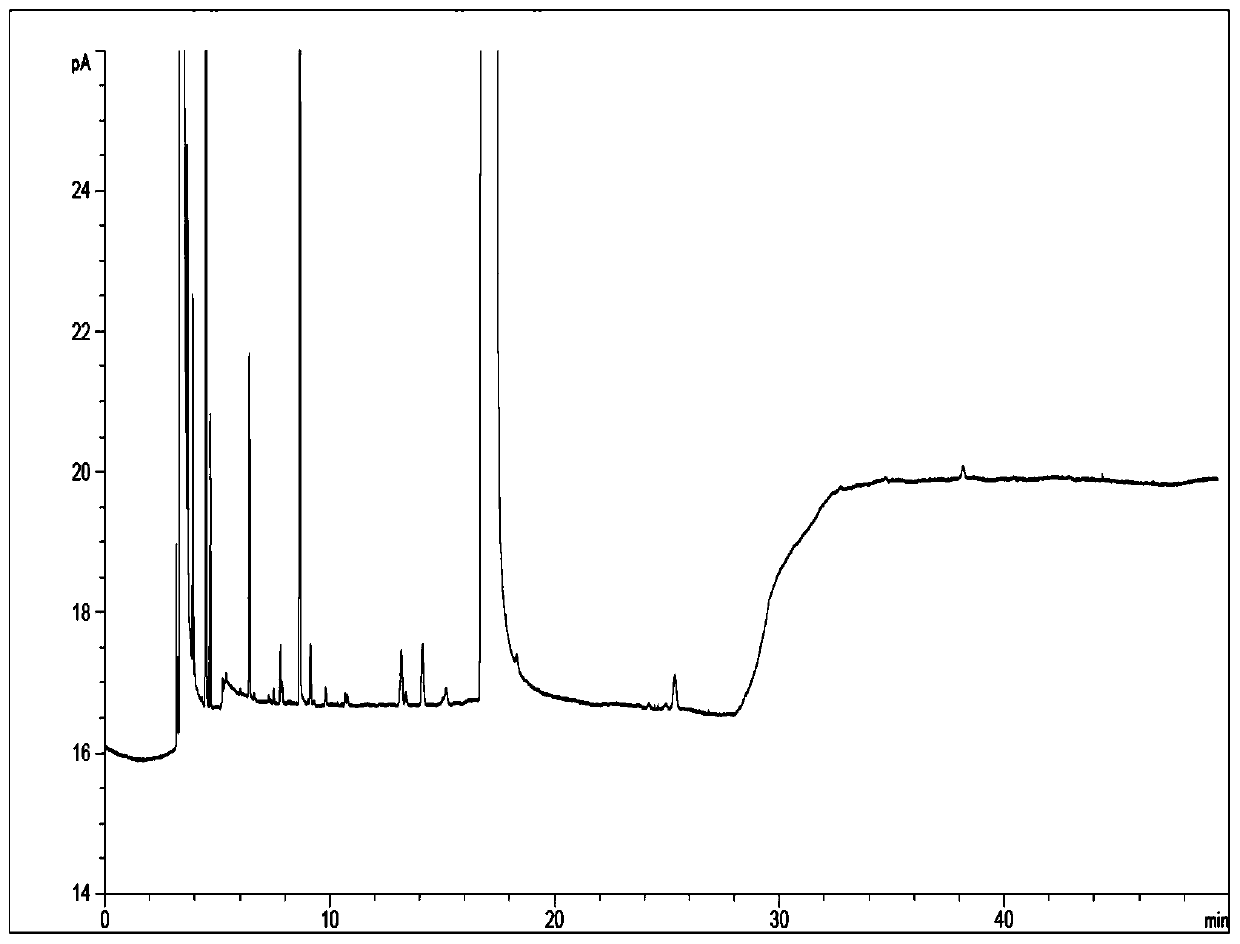

[0055] Raw materials: cyclohexanone oxime liquid-phase Beckmann rearrangement reaction, liquid ammonia neutralization, ammonium extraction and stripping, benzene extraction to obtain a solution of crude caprolactam and benzene, wherein the crude caprolactam content is 17.5% by weight, and the crude caprolactam The main components are: 99.8460 wt% caprolactam, 454ppm cyclohexanone, 53ppm cyanocyclopentane, 21ppm cyclohexenone, 8ppm 3-methylaniline, 13ppm aniline, 218ppm cyclohexanone oxime , 15ppm of n-pentanamide, 25ppm of octahydrophenazine, 52ppm of 1,3,4,5-tetrahydro-2H-azepin-2-one and its isomers, and other unidentified impurities (Chromatogram see figure 2 ).

[0056] The solution of the crude caprolactam product and benzene was evaporated under normal pressure to remove part of the benzene to obtain a mixture of the crude caprolactam product and benzene with a caprolactam content of 80.5% by weight. Take...

Embodiment 2

[0084] This example illustrates the method of the invention.

[0085] Raw material is with embodiment 1.

[0086] The solution of the crude caprolactam product and benzene was evaporated under normal pressure to remove part of the benzene to obtain a mixture of the crude caprolactam product and benzene with a caprolactam content of 75.5% by weight. Take 300g of the above-mentioned mixture of caprolactam crude product and benzene with a caprolactam content of 75.5% by weight, add it to a 1L three-necked flask, and add 266g of n-octane to it (solvent: CPL=1.5:1, benzene:n-octane=21.6:78.4) , heated to 65-70°C, and stirred (at a rate of 150r / min) for 30 minutes to completely dissolve the crude caprolactam product in the mixed solvent. Continue cooling while stirring (at a rate of 100 r / min), the temperature drops to 30° C., and the caprolactam crystals are fully separated out. The obtained slurry was centrifuged to obtain 192.5 g of 99.9955% by weight caprolactam crystals and a...

Embodiment 3

[0091] This example illustrates the method of the invention.

[0092] Raw material is with embodiment 1.

[0093] The solution of the crude caprolactam product and benzene was evaporated under normal pressure to remove part of the benzene to obtain a mixture of the crude caprolactam product and benzene with a caprolactam content of 79.8% by weight. Take 300 g of the above-mentioned mixture of caprolactam crude product and benzene with a caprolactam content of 79.8% by weight, put it into a 1L three-necked flask, and add 300 g of isooctane (solvent: CPL=1.5:1, benzene:isooctane=16.8:83.2) , heated to 65-70°C, and stirred (at a rate of 150r / min) for 30 minutes to completely dissolve the crude caprolactam product in the mixed solvent. Continue cooling while stirring (at a rate of 100 r / min), the temperature drops to 30° C., and the caprolactam crystals are fully separated out. The obtained slurry was centrifuged to obtain 208.3 g of 99.9937% by weight caprolactam crystals and a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| color price | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com