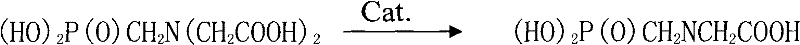

Method for preparing glyphosate by PMIDA catalytic oxidation

A technology of catalytic oxidation and glyphosate, applied in chemical instruments and methods, physical/chemical process catalysts, organic chemistry, etc., can solve the problems of inconvenient production operation, difficult post-processing, difficult preparation, etc., to improve the utilization rate of oxygen , Product quality is stable, and the effect of accelerating the reaction rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] The preparation method of 5A molecular sieve loaded with nanometer nickel oxide:

[0023] Grind 200g of 5A molecular sieve with a mortar and sieve, take 40g of 20-100 mesh molecular sieve, add it to the mixed solution of 70g NiSO4 6H2O and 50g 30% NaOH and reflux for 2h, at a stirring speed of 300r / min at 30℃ Evaporate to dryness, wash with deionized water until neutral, dry and age in an oven at 100 °C for 15 hours, then put the sample in a muffle furnace at 450 °C for 3 hours, press into tablets and pulverize, take 40-70 mesh The sample acts as a co-oxidant.

Embodiment 2

[0025] The preparation method of 5A molecular sieve loaded with nanometer nickel oxide doped with manganese dioxide:

[0026] The 5A molecular sieve of 200g is ground and sieved with a mortar, take 40g of molecular sieve of 20-100 mesh, add 81gMn (NO 3 ) 2 , 119g NiSO4 6H2O and 80g 30% NaOH mixture were refluxed for 4h, evaporated to dryness at 60°C at a stirring speed of 300r / min, washed with deionized water until neutral, dried and aged in an oven at 110°C for 18h, and then The samples were placed in a muffle furnace and calcined at 500 °C for 5 hours. After tableting, they were pulverized. A 40-70 mesh sample was taken as a co-oxidant.

Embodiment 3

[0028] Preparation method of 5A molecular sieve loaded with nanometer nickel oxide:

[0029] Grind 200g of 5A molecular sieve with a mortar and sieve, take 40g of molecular sieve of 20-100 mesh, add it to the mixed solution of 50g NiSO4 6H2O and 120g 30% NaOH and reflux for 3h, at a stirring speed of 300r / min at 50℃ Evaporate to dryness, wash with deionized water until neutral, dry and age in an oven at 115 °C for 19 hours, then put the sample in a muffle furnace at 450 °C for 4 hours, press into tablets and pulverize, take 40-70 mesh The sample acts as a co-oxidant.

PUM

| Property | Measurement | Unit |

|---|---|---|

| micropore | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com