Method for purifying ethyl maltol

A technology of ethyl maltol and a purification method, which is applied in the field of ethyl maltol purification, can solve the problems of high labor intensity, long process time, and low production efficiency, and achieve low labor intensity, high yield, and high production efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

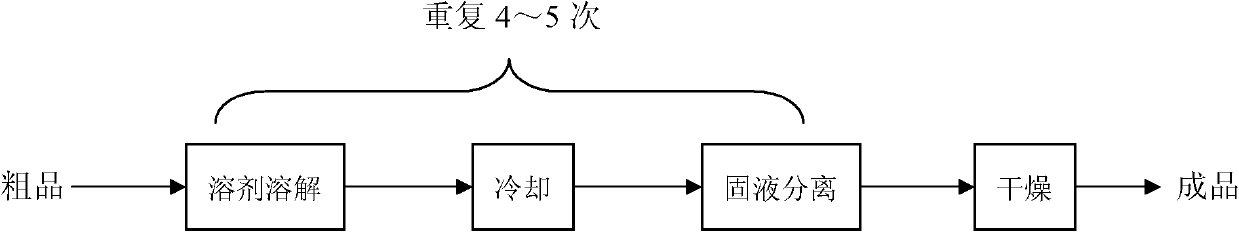

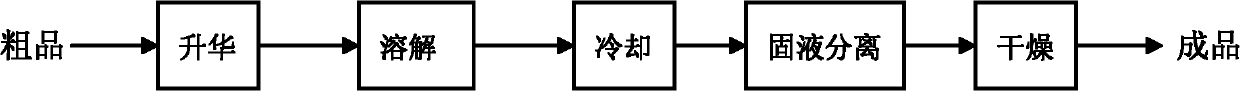

Method used

Image

Examples

Embodiment 1

[0020] The crude product of ethyl maltol is sublimated, and the sublimation temperature is controlled at 210°C. Then the sublimated ethyl maltol is dissolved in a 1:1.3 ethanol-water mixed solution, stirred until completely dissolved, and the vacuum degree is between -0.095 ~ -0.09MPa. Then cool to 5°C until ethyl maltol is fully separated. Then carry out solid-liquid separation. The solid obtained after separation is dried at 60° C. and vacuum degree of -0.095 to -0.09 MPa to obtain a finished product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com