Secondary assembling and locating method, and set bolt

A positioning method and technology of positioning holes, which are applied in the direction of valve devices, engine components, machines/engines, etc., to achieve the effects of easy free rotation, small fit clearance, superior assembly time and assembly complexity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

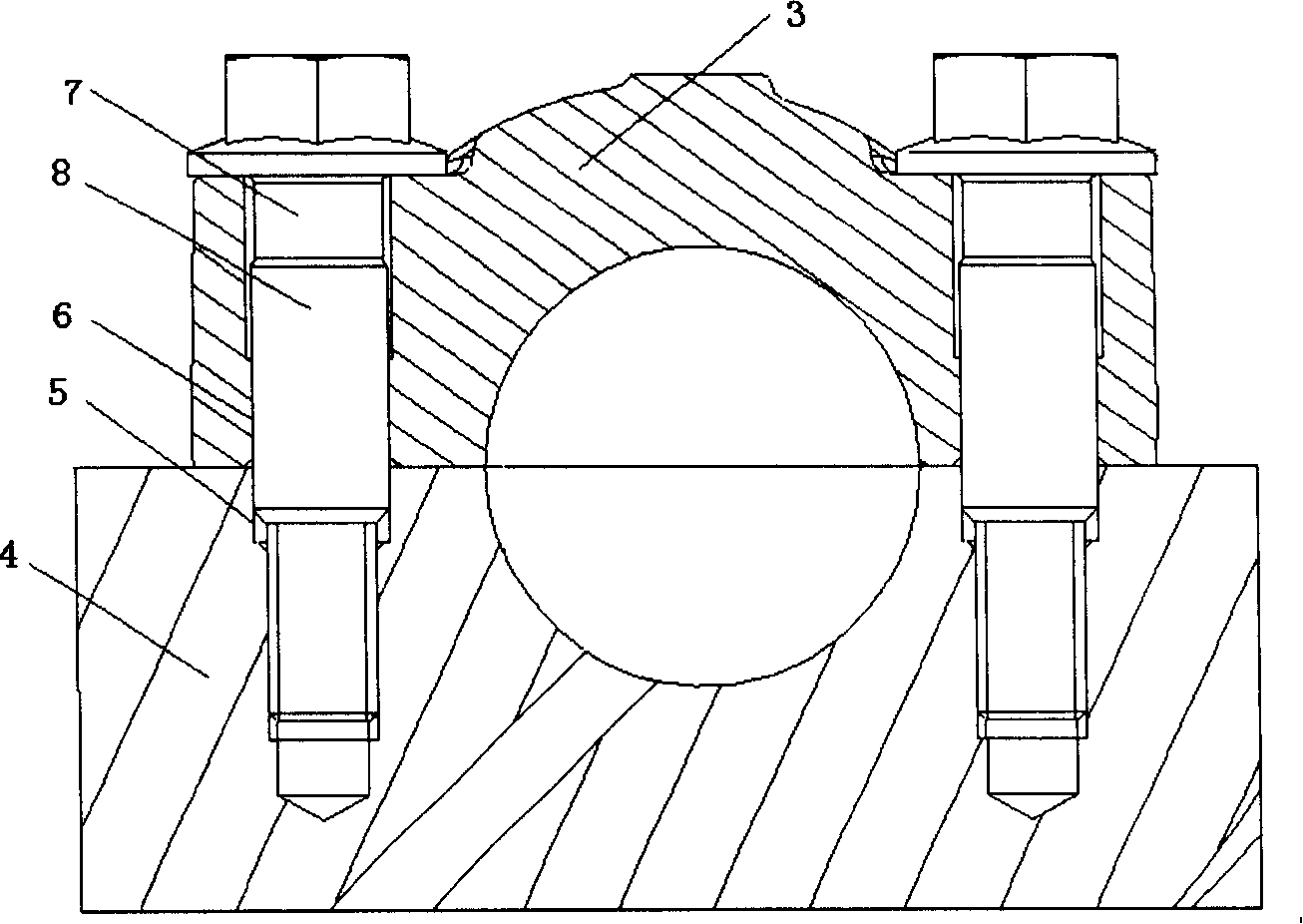

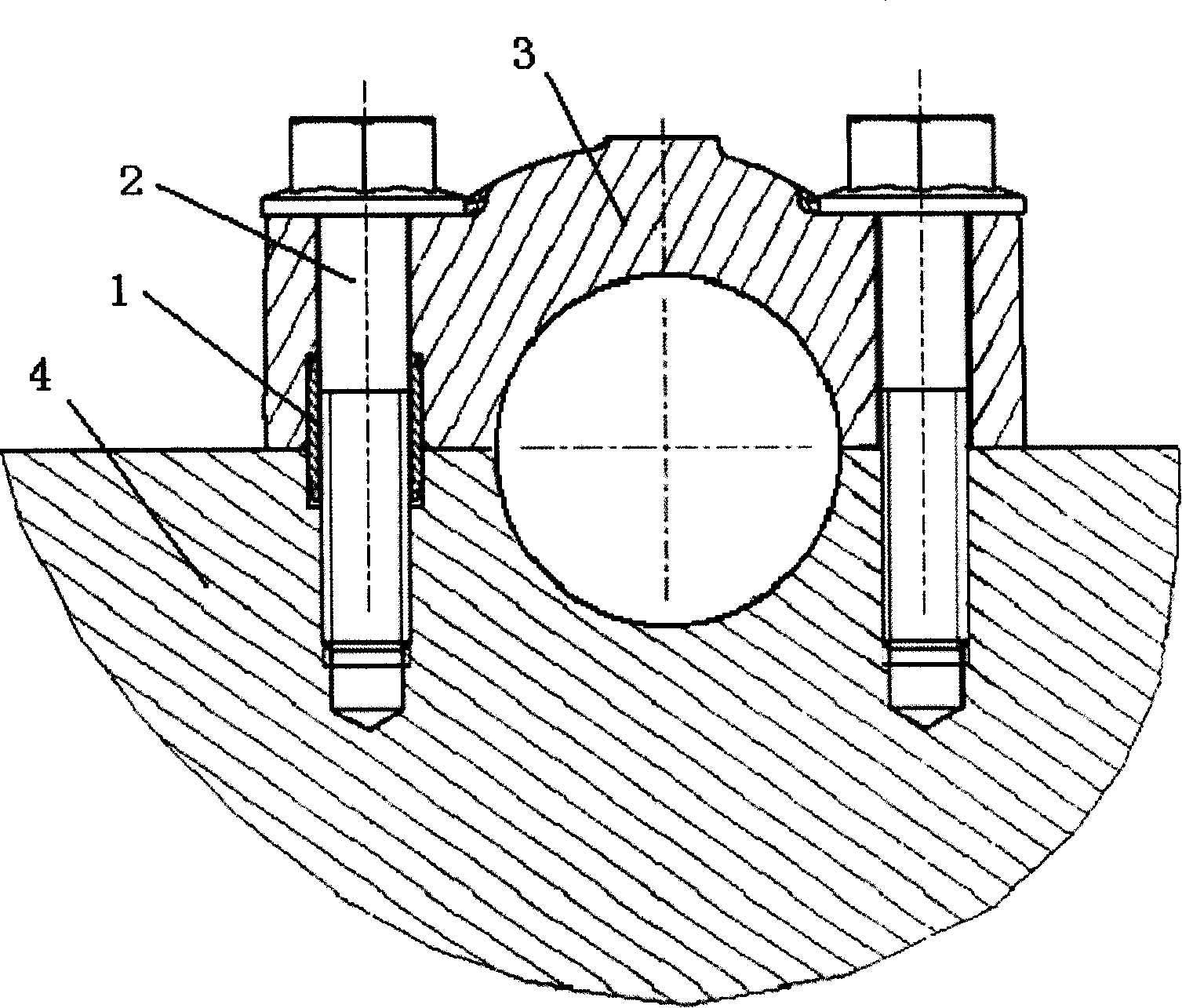

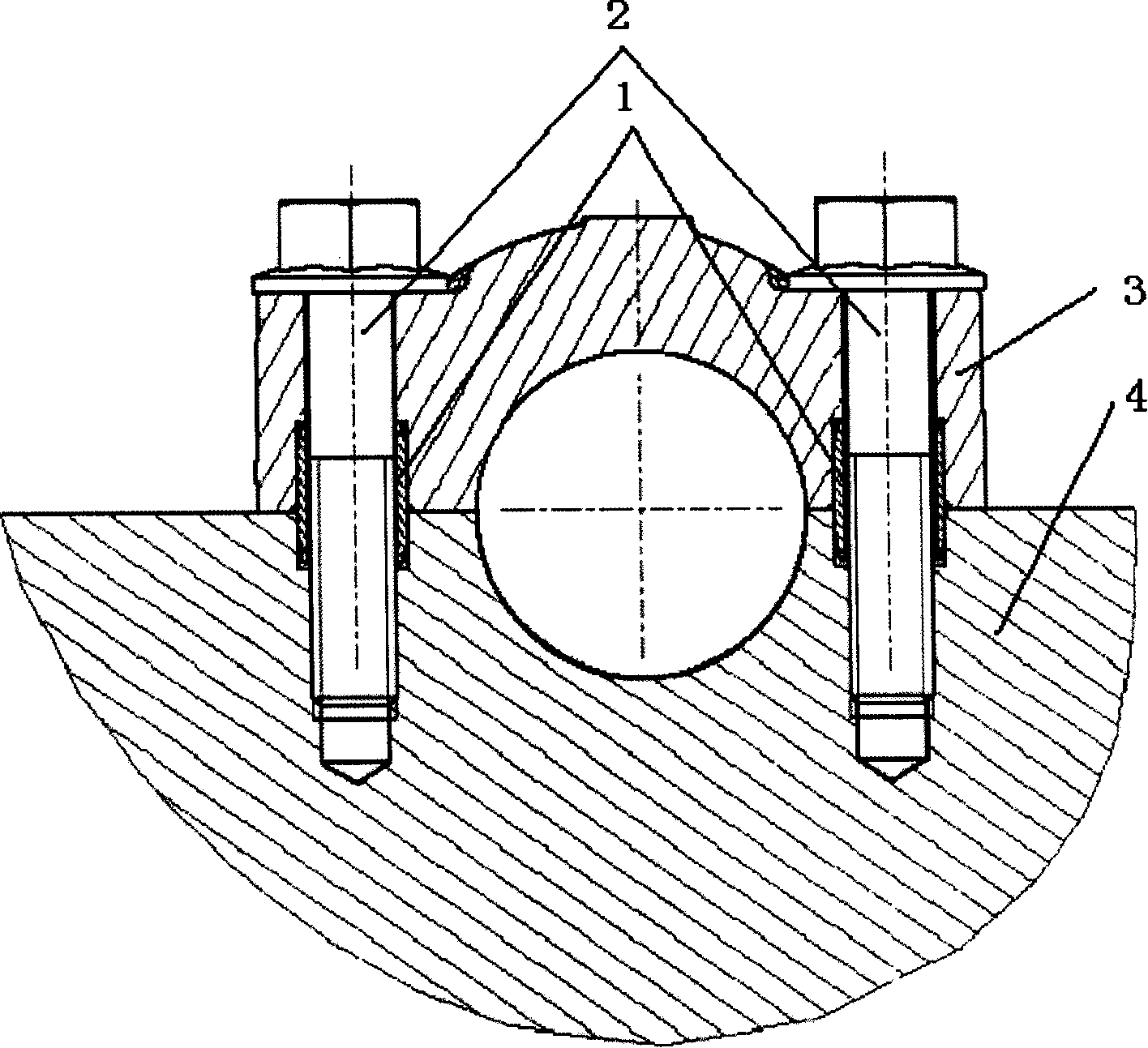

[0024] Embodiment A kind of secondary assembly positioning method, comprises the following main steps:

[0025] 1) Set threaded holes for connection and coaxial positioning holes on the bearing seat cover;

[0026] 2) Set threaded holes for connection and coaxial positioning holes on the bearing seat;

[0027] 3) Insert the positioning connecting bolts into the positioning holes of the bearing seat and bearing cover. The positioning polished rod sections on the positioning connecting bolts are respectively inserted into the positioning holes of the bearing seat and the bearing cover, and the precise clearance fits.

[0028] The method further includes the following steps: setting a pair of threaded holes for connection and coaxial positioning holes on both ends of the bearing seat cover and the bearing seat, so as to accurately limit the degrees of freedom in six directions.

[0029] For the precise clearance fit described in step 3) of the above method, the clearance takes ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com