On-line checkout equipment for contact pressure of motorcycle pantograph

A technology for contact pressure and testing equipment, applied in force/torque/work measuring instruments, measuring devices, instruments, etc., can solve the problems of high cost, low reliability, high price, etc., to reduce the purchase cost, prolong the service life, Easy-to-use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

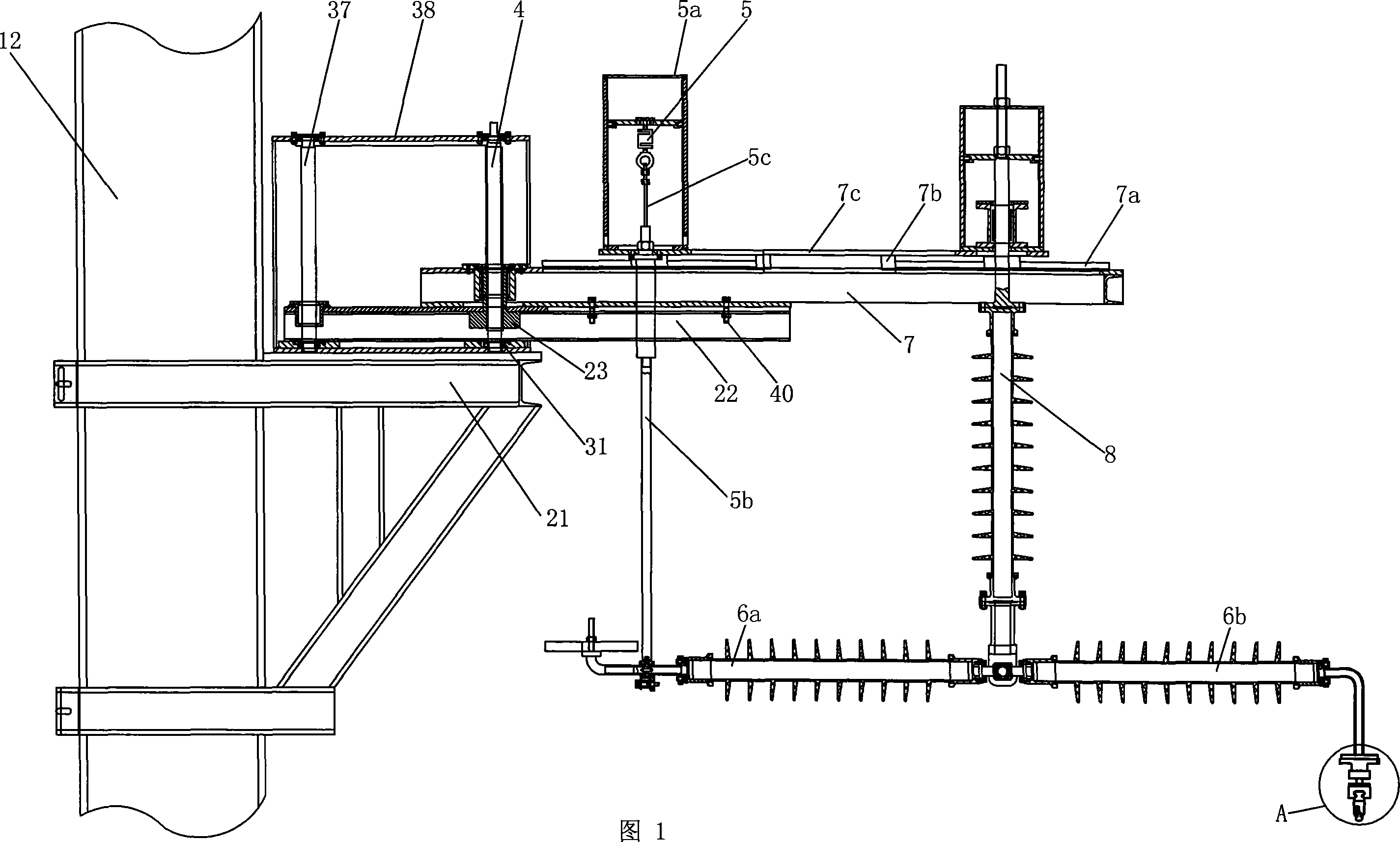

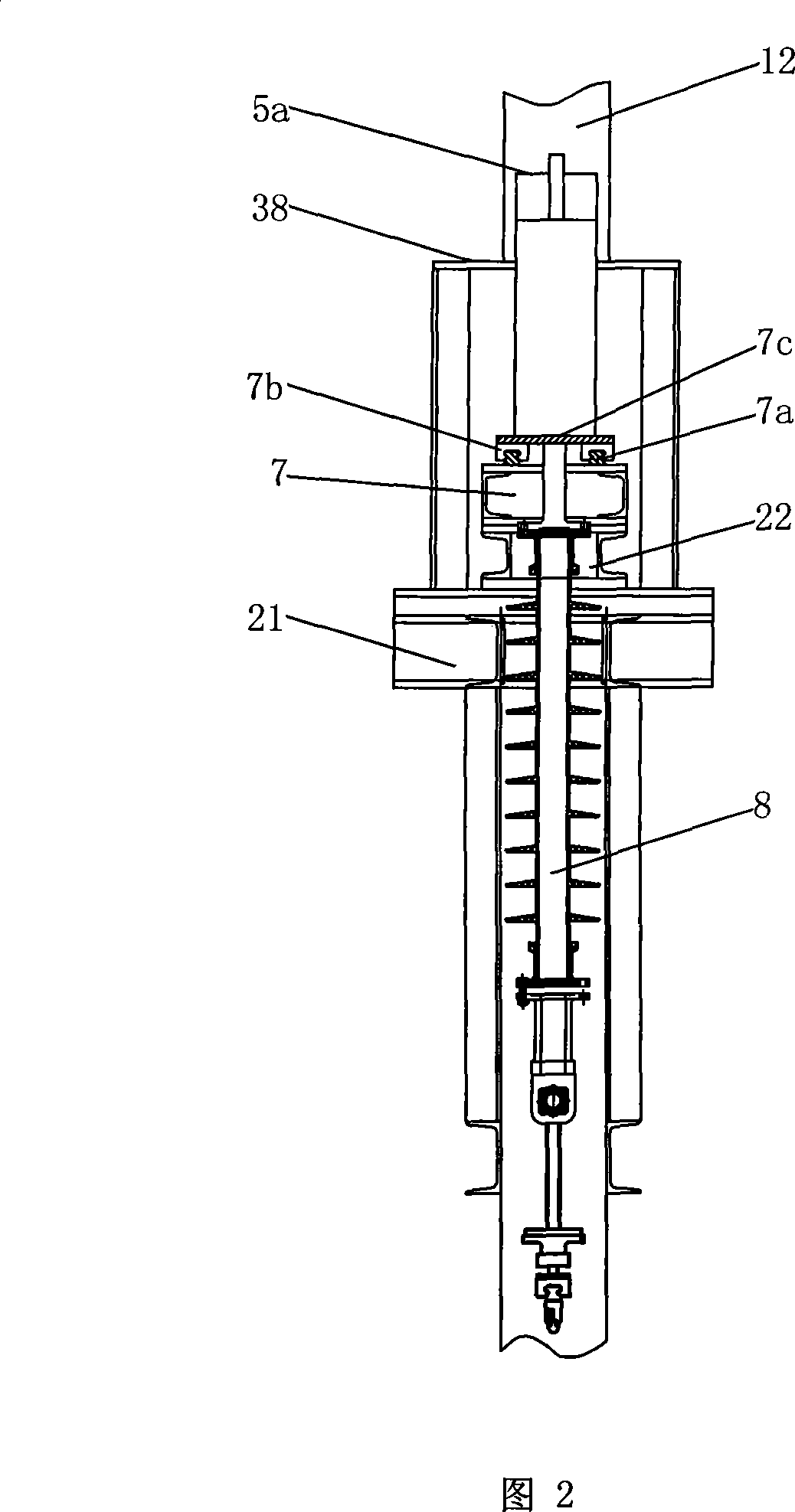

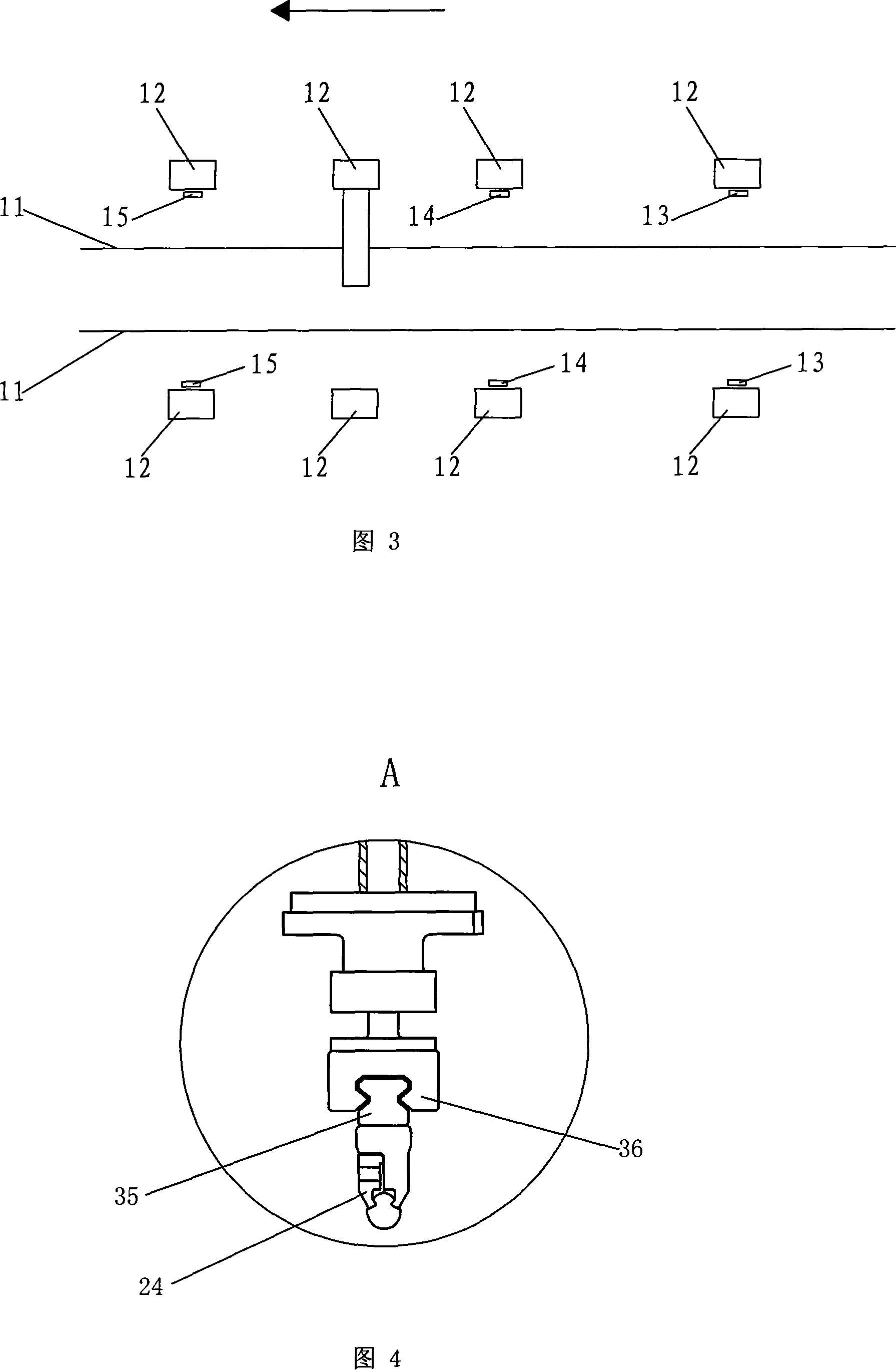

[0032] Figures 1 and 2 show that a specific embodiment of the present invention is: an online detection device for the contact pressure of a locomotive pantograph, which is fixed with a bracket 21 on the rail side of the column 12 on the outside of the rail, and a lifting screw 4 The lower end of the lower end is fixed on the inner ring of the bearing 31 of the support 21, and the lifting screw mandrel 4 passes through the workbench mounting frame 22 and the work platform 7 above the support 21 successively, and cooperates with the lifting nut 23 fixed on the workbench mounting frame 22; The working platform 7 is fixed on the working platform installation frame 22 through the connecting stud 40 .

[0033] Pulling pressure sensor 5 is fixed on the working platform 7 close to column 12 side, and the key line 5c that links to each other with pulling pressure sensor 5 passes working platform 7 and workbench installation frame 22 and links to each other with an end of proximal horizon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com