Method for preparing hydrated icaritin

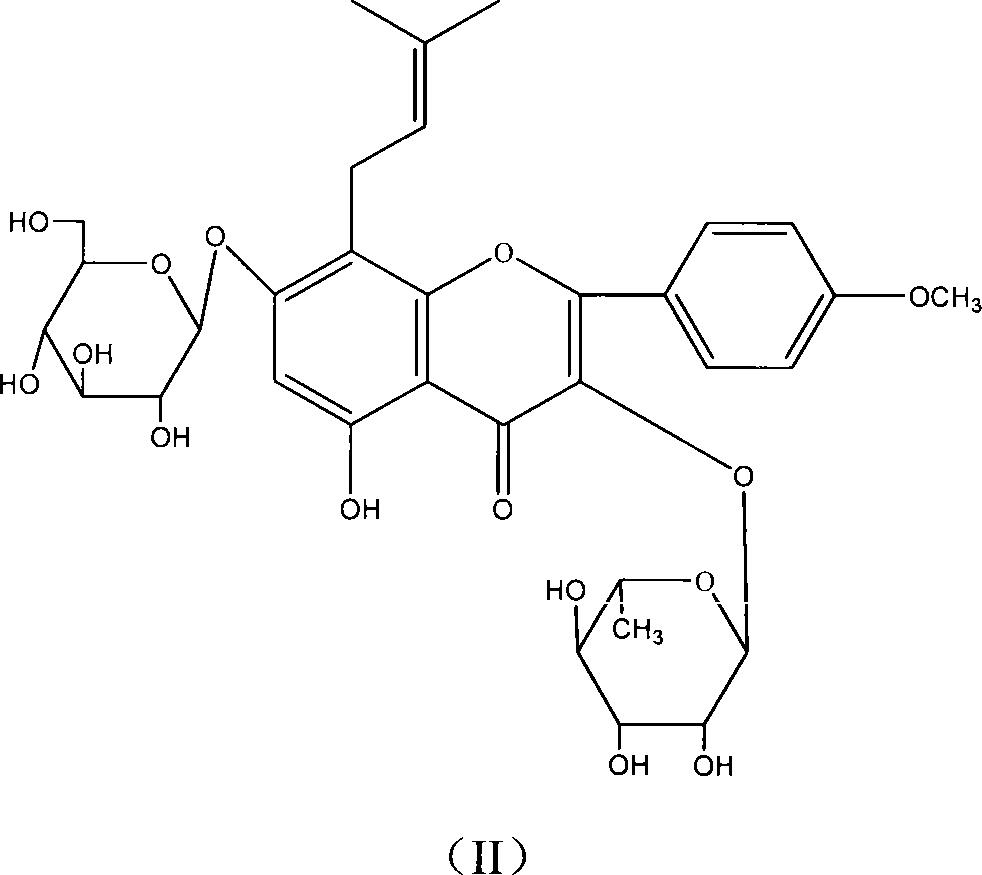

A technology for hydrating icariin and icariin, which is applied in fermentation and other directions, can solve the problems of low content and achieve high yield and convenient processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

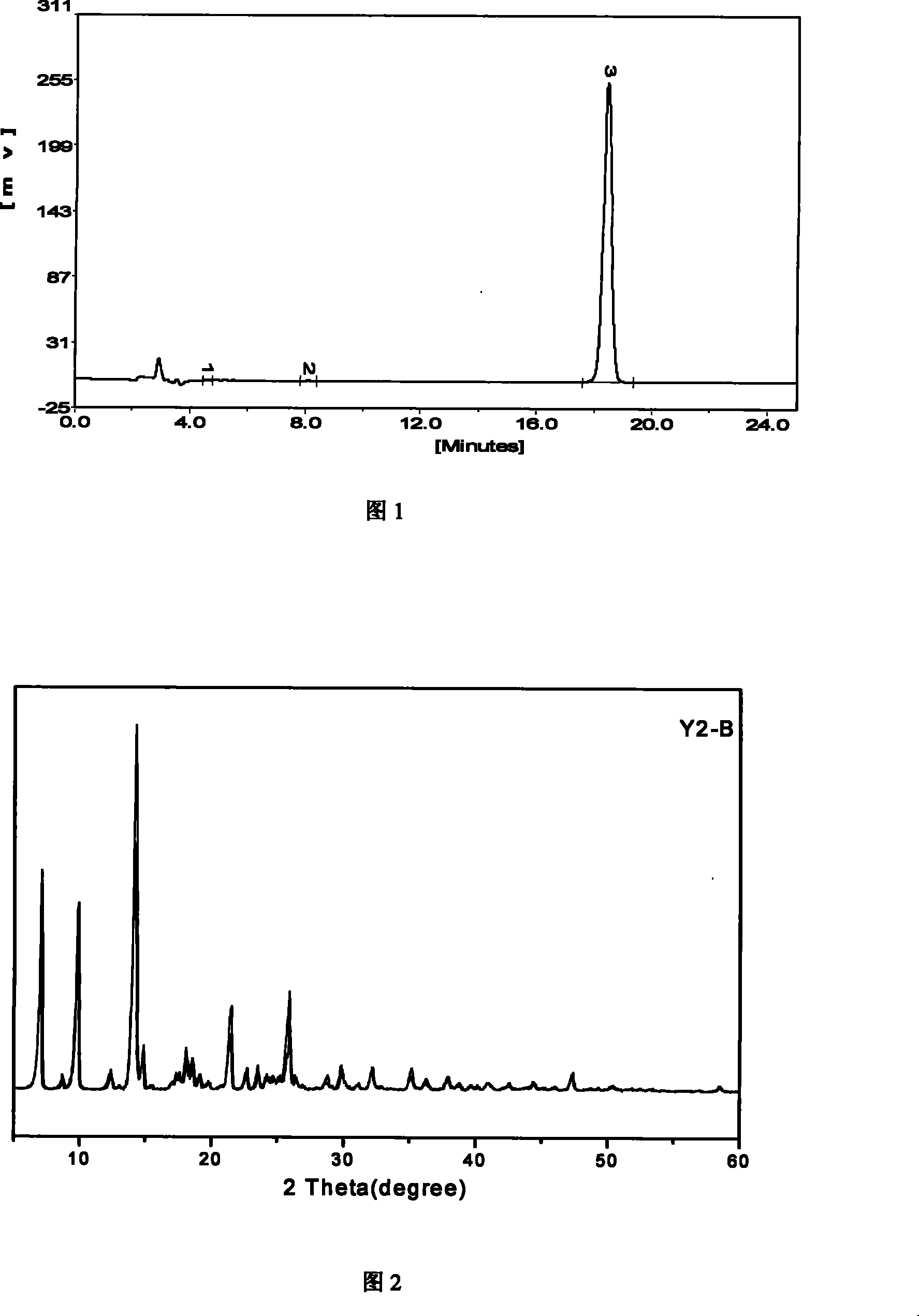

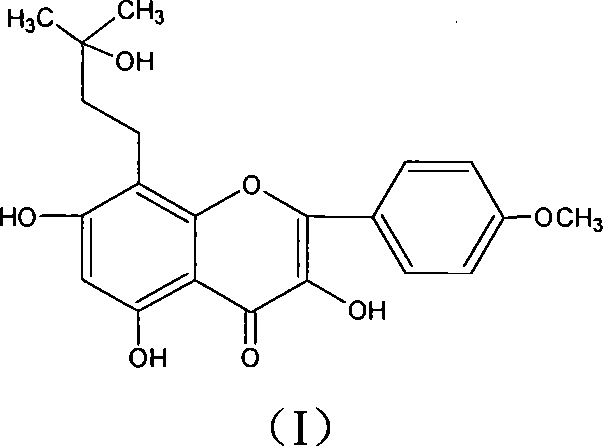

Image

Examples

Embodiment 1

[0027] 1.1 Reaction of icariin with hydrochloric acid solution:

[0028] Take 5 g of icariin (content above 90%), add it to 250 mL of 3N hydrochloric acid solution (concentrated hydrochloric acid and water are prepared at a volume ratio of 3:7), stir, gradually raise the temperature to 80 ° C, and maintain it for 1 hour. After the reaction is over, cool and place to make the precipitation complete. Filter, and wash the precipitate with water several times to neutrality (if it cannot be washed to neutrality, a small amount of NaOH solution can be used to neutralize the acidity). The filtrate was discarded or kept for the next reaction.

[0029] 1.2 Reaction of hydrochloric acid reaction product with cellulase

[0030] Add the above hydrochloric acid reaction product to 250mLNaH 2 PO 4 -Na 2 HPO 4 (pH 5.0, 50 uM) buffer solution, then add about 5 mL of cellulase (comprehensive enzyme activity ≥ 18,000 u / mL), and stir at 40°C for 36 hours. After the reaction, cool down, ad...

Embodiment 2

[0048] 2.1 The reaction between icariin and cellulase

[0049] Take icariin 5g (content above 90%), add to 250mLNaH 2 PO 4 -Na 2 HPO 4 (pH 4.8, 50 uM) buffer solution, then add about 5 mL of cellulase (comprehensive enzyme activity ≥ 18,000 u / mL), and stir at 50°C for 24 hours. After the reaction is over, cool and place to make the precipitation complete. Filter and wash the precipitate with water several times.

[0050] 2.2 Reaction of enzymatic hydrolysis product with hydrochloric acid solution:

[0051] The above enzymatic hydrolysis product was added to 500 mL of 1N hydrochloric acid solution (concentrated hydrochloric acid and water were prepared at a volume ratio of 1:10), stirred, and the temperature was gradually raised to 60° C. and maintained for 8 hours. After the reaction is over, cool and place to make the precipitation complete and filter. The precipitate was washed with water until neutral.

[0052] 2.3 Aftertreatment of the reaction solution: (same as E...

Embodiment 3

[0055] 3.1 Reaction of icariin with hydrochloric acid solution:

[0056] Take 5 g of icariin (content above 90%), add it to 500 mL of 1N hydrochloric acid solution (concentrated hydrochloric acid and water are prepared at a volume ratio of 1:10), stir, gradually raise the temperature to 80 ° C, and maintain it for 8 hours. After the reaction is over, cool and place to make the precipitation complete. Filter, and wash the precipitate with water several times to neutrality (if it cannot be washed to neutrality, a small amount of NaOH solution can be used to neutralize the acidity). The filtrate was discarded or kept for the next reaction.

[0057] 3.2 Reaction of hydrochloric acid reaction product with cellulase

[0058] Add the above hydrochloric acid reaction product to 250mLNaH 2 PO 4 -Na 2 HPO 4 (pH5.5, 50uM) buffer solution, then add about 5mL of cellulase (comprehensive enzyme activity ≥ 18,000u / mL), and stir at 40°C for 32 hours. After the reaction, cool down, add ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com