A kind of uv resin cleaning agent and its preparation process and application method

A cleaning agent and resin technology, applied in the field of cleaning agents, can solve the problems of isopropanol being highly flammable, difficult to breathe, residues on cleaning objects, etc., and achieve the effects of non-flammable flash point, high safety, and wide application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

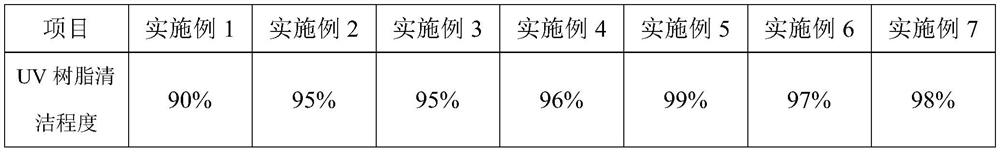

Examples

Embodiment 1

[0046] Embodiment 1: The specific content of each ingredient added in the premixing process of the ingredients is as follows

[0047] Mixed fatty ethers include diethylene glycol ethyl ether and diethylene glycol methyl ether mixed at a volume ratio of 1:1;

[0048] Mixed fatty ether 30%;

[0049] Propylene Glycol 50%;

[0050] Sodium Cetyl Sulfate 20%.

Embodiment 2

[0051] Embodiment 2: The specific content of each ingredient added in the premixing process of the ingredients is as follows

[0052] Mixed fatty ethers include diethylene glycol ethyl ether and diethylene glycol methyl ether mixed at a volume ratio of 1:1;

[0053] Mixed fatty ether 80%;

[0054] Propylene Glycol 10%;

[0055] Sodium Cetyl Sulfate 10%.

Embodiment 3

[0056] Embodiment 3: the specific content of each ingredient added in the premixing process of the ingredients is as follows

[0057] Mixed fatty ethers include diethylene glycol ethyl ether and diethylene glycol methyl ether mixed at a volume ratio of 1:1;

[0058] Mixed fatty ether 65%;

[0059] Propylene Glycol 30%;

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

| flash point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com