Multiple shaft directions warp knitting machine

A multi-axial, warp knitting machine technology, applied in flat warp knitting machines, warp knitting, textiles and papermaking, etc., can solve problems such as increasing the risk of yarn breakage, and achieve the effect of avoiding yarn tension fluctuations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

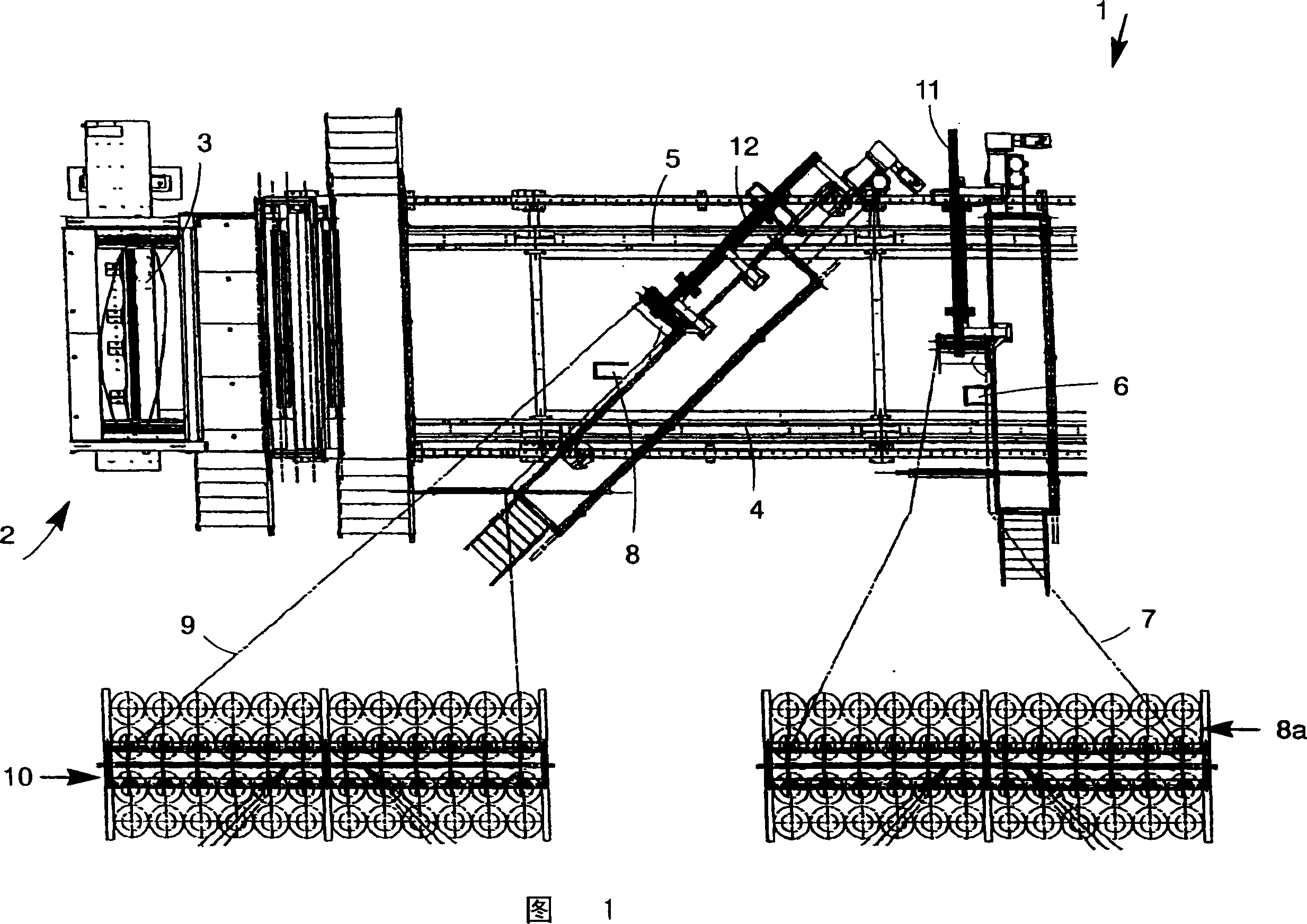

[0021] The multiaxial warp knitting machine 1 has a knitting machine 2 which in turn has a knitting zone 3 which, as will be explained below, serves as a curing device.

[0022] A conveying device consisting of a first longitudinal conveyor 4 and a second longitudinal conveyor 5 is provided for conveying the yarn to the knitting zone 3 . The yarns are placed here in layers on the longitudinal conveyors 4 , 5 .

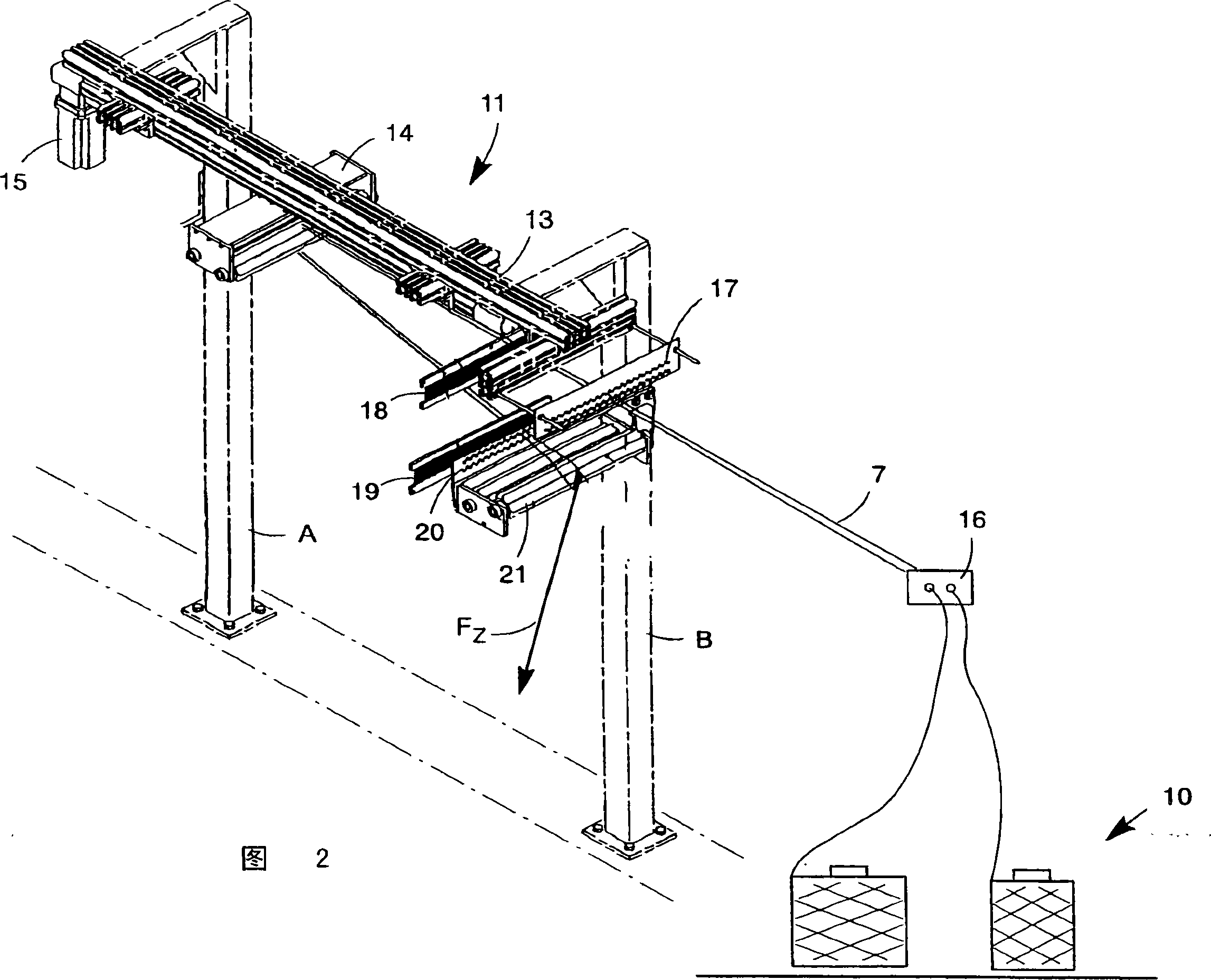

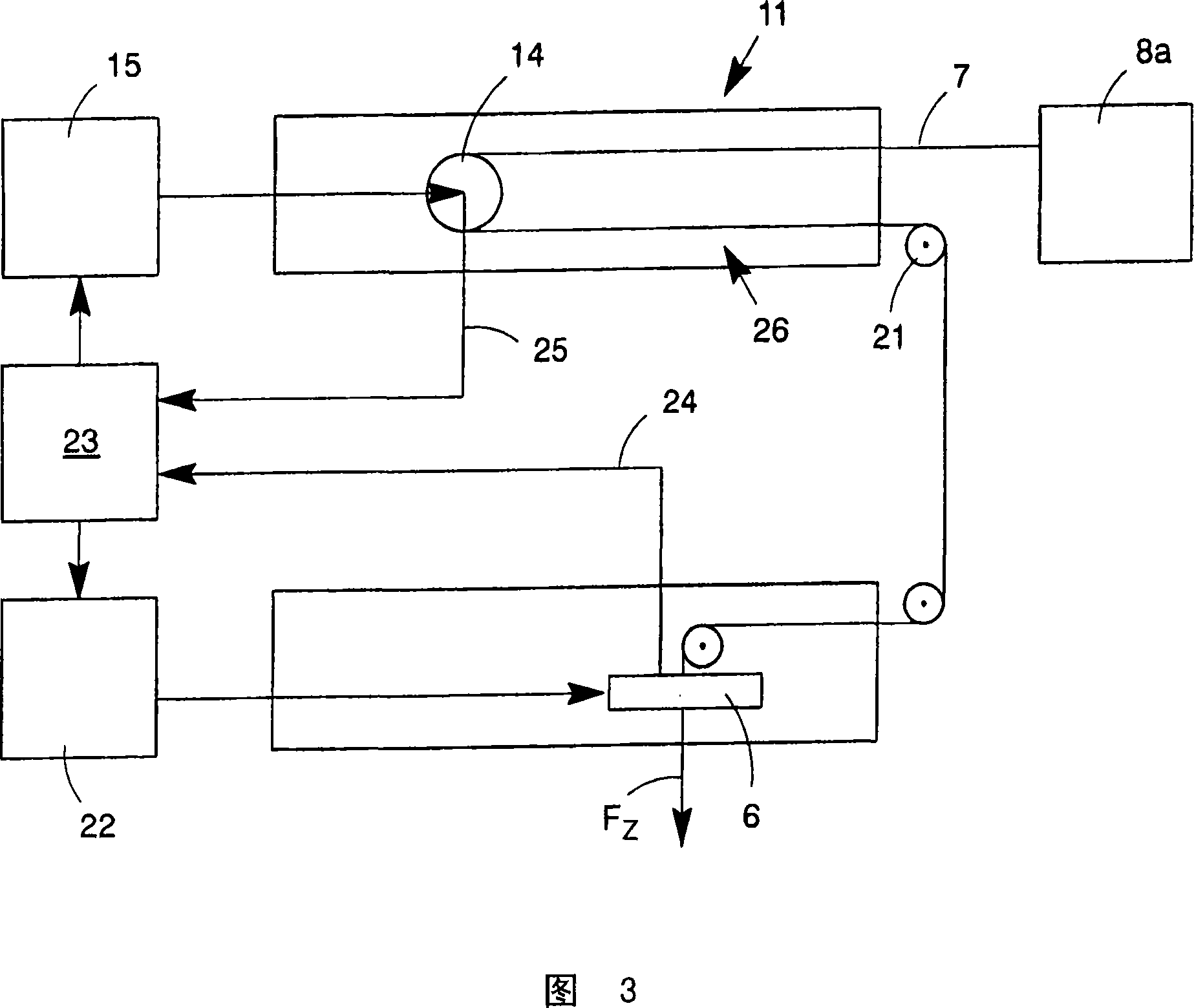

[0023] Furthermore, a first laying device 6 is provided, which withdraws the yarn 7 from the warp creel 8a and places it on the longitudinal conveyors 4, 5 at an angle of 90° with respect to the direction of movement of the longitudinal conveyors 4, 5. 4, 5 above or inside. A second laying device 8 is provided, which draws out the yarns 9 from the warp creel 10 and takes these yarns 9 as yarn layers at an angle of about 45° relative to the direction of movement of the longitudinal conveyors 4, 5. Placed on or in said longitudinal conveyors 4 , 5 .

[0024] In a know...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com